Article Contents

Industry Insight: Color Changing Led Light Strips

The commercial and industrial lighting sector is undergoing a transformative shift as energy efficiency, design flexibility, and smart integration become critical drivers in architectural and functional illumination. Among the most impactful innovations in this space are color changing LED light strips, which offer dynamic lighting solutions for a wide range of applications—from retail environments and hospitality venues to manufacturing facilities and transportation hubs. These advanced lighting systems enable precise control over ambiance, branding visibility, and operational efficiency, making them a strategic asset in modern facility design.

A key consideration in the adoption of color changing LED strips for commercial and industrial use is compliance with rigorous safety and performance standards. Products bearing ETL and CE certifications are essential for ensuring electrical safety, electromagnetic compatibility, and adherence to North American and international regulatory requirements. These certifications not only validate product reliability but also provide peace of mind for facility managers, architects, and electrical contractors specifying lighting for demanding environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the LED lighting industry, specializing in high-performance, code-compliant lighting solutions for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC combines innovation with strict quality control to deliver color changing LED light strips that meet ETL and CE standards, ensuring durability, color consistency, and seamless integration into intelligent building systems. As the demand for adaptive, energy-efficient lighting grows, Beauty STC continues to set benchmarks in performance and reliability for professional-grade illumination.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces premium color-changing LED light strips engineered for demanding architectural, retail, and high-end residential applications where accurate color rendering, efficiency, and environmental resilience are paramount. Our strips prioritize performance metrics critical to professional installations, distinguishing us through rigorous material selection and manufacturing processes.

Lumens per Watt efficiency is a core focus, directly impacting operational costs and thermal management. Our standard RGBW (Red, Green, Blue, White) color-changing strips achieve 18-22 lumens per watt when operating in high-CRI white modes (typically 2700K-4000K). This efficiency is maintained through the use of high-efficacy 2835 or 3535 SMD LEDs paired with optimized constant-current drivers. It is important to note that lumen output and efficacy vary significantly across color channels; pure white channels deliver the highest lm/W, while saturated colors like deep red or blue inherently produce fewer lumens per watt due to the physics of narrow-spectrum emission. Beauty STC provides detailed spectral power distribution (SPD) charts and lumen output data per channel for precise project planning, ensuring realistic expectations for mixed-color applications.

Achieving a Color Rendering Index (CRI) greater than 90, particularly Ra9 (saturated red rendering), is exceptionally challenging for tunable white and RGBW systems yet critical for applications where skin tones, textiles, or merchandise must appear natural. Beauty STC accomplishes this through proprietary RGBW+ architecture. We integrate a dedicated high-CRI (95+) 2700K-4000K white LED chip alongside the standard RGB elements, avoiding the common industry practice of mixing only RGB to simulate white. This dedicated white channel, utilizing phosphor-converted diodes with meticulously selected rare-earth elements, ensures Ra values consistently exceed 92 and Ra9 remains above 90 across the entire white tuning range. Independent LM-79 test reports verify these metrics, as many competitors achieve high Ra only at specific CCTs or sacrifice Ra9 significantly. Our strips minimize metamerism and provide stable, accurate color across diverse illumination scenarios.

Environmental protection is non-negotiable for reliable long-term performance. Beauty STC offers color-changing strips in multiple certified IP ratings, clearly defined by IEC 60529 standards and validated through third-party testing. Our standard flexible PCB strips feature IP20 rating for dry indoor use. For damp locations like kitchens or covered patios, we provide IP65-rated strips with a robust, optically clear silicone coating applied via precision dispensing, protecting against dust and low-pressure water jets. For fully submerged applications such as pool lighting, cove lighting exposed to weather, or marine environments, our premium IP68-rated strips utilize a double-layer encapsulation process: the LEDs and PCB are first potted in medical-grade silicone, then housed within a seamless, UV-stabilized silicone jacket extruded directly over the assembly. This method prevents delamination and moisture ingress far more effectively than simple coating, ensuring 50,000-hour rated life even in harsh conditions. Every IP-rated strip undergoes 100% production line submersion testing at 1 meter depth for 24 hours.

Beauty STC’s commitment to quality is embedded in every layer. We source only Toshiba, Samsung, or Epistar LED diodes with tight binning tolerances (SDCM ≤ 3-step MacAdam ellipse for whites), utilize 2oz copper-backed flexible PCBs for superior heat dissipation compared to standard 1oz boards, and implement automated optical inspection (AOI) during SMT assembly. Our silicone materials are UL 94 V-0 rated and free of volatile organic compounds (VOCs) that cause yellowing. This meticulous approach results in color-changing strips with exceptional lumen maintenance (L70 > 50,000 hours), minimal color shift over time, and reliable operation under continuous full-power use – a standard expectation for Beauty STC products specified by leading architects and lighting designers globally. We provide comprehensive photometric data, IES files, and compliance documentation to support professional integration.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China is a modern, fully integrated LED lighting production plant designed to support high-volume manufacturing with strict quality control. Strategically located within the Guangdong province’s industrial corridor, the Jiangmen factory benefits from advanced infrastructure and proximity to key supply chain partners, enabling efficient production and logistics.

The factory is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, featuring high-speed, precision SMT machines from leading global manufacturers. These machines ensure accurate placement of LED components, resistors, capacitors, and ICs onto flexible and rigid PCBs used in LED light strips. The SMT lines are supported by automated optical inspection (AOI) systems that verify component alignment and solder quality in real time, minimizing defects and ensuring consistent product reliability.

For quality assurance, the factory implements comprehensive aging and burn-in testing procedures. Completed LED light strips undergo extended aging tests—typically 24 to 72 hours—under varying temperature and load conditions to simulate long-term operation. This process identifies early-life failures, ensuring only stable and durable products reach customers. Additional tests include waterproof verification (for IP-rated strips), color consistency checks using spectrometers, and performance validation across voltage fluctuations.

Beauty STC has strong OEM/ODM capabilities tailored specifically for color-changing LED light strips. The company supports customized solutions including different densities of RGB, RGBW, or addressable LEDs (such as SK6812 or WS2812B), custom PCB widths and lengths, unique diffuser options, and tailored control protocols. Clients can specify branding, packaging, controller features (such as app, remote, or voice control integration), and even custom color tuning or sequencing. The factory’s engineering team works closely with clients from prototyping through to mass production, offering design for manufacturing (DFM) feedback and full compliance support for international standards including CE, RoHS, and UL.

Overall, the Jiangmen factory combines automated precision, rigorous testing, and flexible customization to serve global partners seeking high-quality, reliable, and innovative color-changing LED lighting solutions.

Application Scenarios

Color-changing LED light strips offer significant flexibility for enhancing ambiance and functionality across commercial environments. In hotels, their primary value lies in creating dynamic guest experiences. Install them discreetly within cove lighting in lobbies to shift from warm welcome tones during check-in to cooler, energetic hues for evening events. Corridors benefit from subtle accent lighting that changes color to indicate directions or special floors, while banquet halls and conference rooms utilize them for instant scene setting—transitioning from professional presentations to vibrant social events without physical reconfiguration. Spa and wellness areas particularly leverage color therapy applications, though direct exposure in guest rooms should be avoided to prevent sleep disruption; instead, use them in vanity mirrors or under furniture for indirect mood lighting. Always ensure controls are intuitive for staff and guests, with presets for common scenarios.

Malls present opportunities for high-impact visual engagement and retail enhancement. Exterior facades and entryways use color-changing strips for dramatic seasonal displays or brand activations, drawing attention from street level. Within retail spaces, integrate them behind product displays or in window vitrines to highlight merchandise—cool whites for electronics, warm ambers for luxury goods—with the ability to refresh looks weekly. Common areas like food courts employ them for thematic energy during lunch rushes shifting to calmer tones in evenings, while event zones in central atriums rely on them for concerts or holiday celebrations. Critical here is selecting high-CRI strips (90+) to maintain true product colors and ensuring robust thermal management due to extended daily operation, especially near skylights where ambient heat accumulates.

Offices require a more restrained approach focused on well-being and zoning. Reserve color-changing capabilities for collaborative spaces like break rooms or creative lounges where dynamic lighting can energize teams during brainstorming sessions, transitioning to serene blues for relaxation. Executive lobbies might use them for subtle brand color accents during client presentations. Crucially, avoid installing them in standard workstations where circadian lighting principles demand stable, tunable-white systems for focus and fatigue reduction. If used in reception areas, ensure colors complement corporate identity without causing visual distraction. Never compromise emergency lighting compliance—color-changing strips must not interfere with exit signage visibility or override mandatory egress illumination paths.

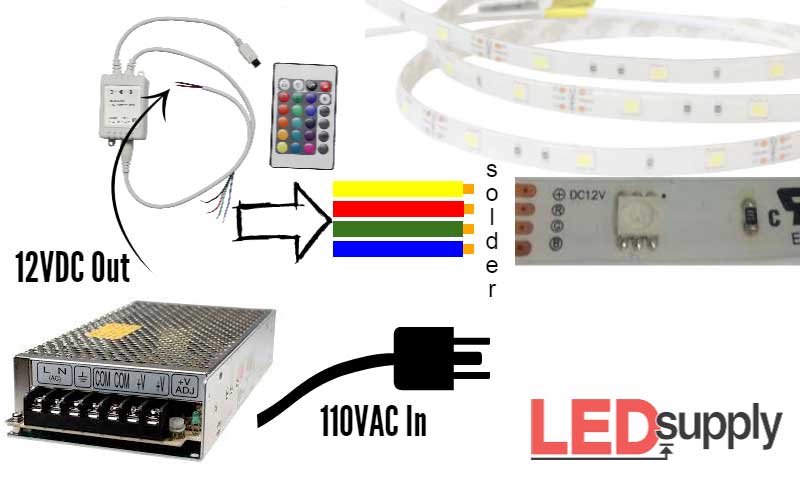

Installation demands meticulous planning to avoid common pitfalls. Always calculate total load per power supply channel and implement power injection every 5 meters for strips exceeding 10 meters to prevent voltage drop and color inconsistency at far ends. Use dedicated aluminum mounting channels not only for clean aesthetics but for essential heat dissipation—thermal runaway remains the top cause of premature failure. Verify driver compatibility: constant-voltage strips require matching voltage drivers, while constant-current types need precise mA regulation. In high-traffic zones like malls or hotel corridors, recess all components fully and seal end caps against dust ingress. For control systems, prioritize DALI or 0-10V in offices for integration with building management, while hotels and malls often benefit from DMX for complex shows—but always test wireless signal penetration through structural elements beforehand. Finally, conduct a full 24-hour burn-in test on a sample run under operational conditions to catch any flicker or color shift issues before final mounting.

Why Choose Beauty STC Lighting

Transform your lighting projects with dynamic color changing LED light strips designed for exceptional performance and versatility. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our high-quality strips offer seamless color transitions, durable construction, and customizable options to meet your specific needs.

Elevate your brand with reliable, energy-efficient lighting products manufactured to the highest standards. For partnership inquiries and product details, contact our sales manager at [email protected]. Let Beauty STC be your preferred lighting solutions partner.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.