Introduction: Navigating the Global Market for led light strips pc

The global market for LED light strips with printed circuit boards (PCBs) is rapidly evolving, driven by increasing demand for energy-efficient, versatile lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers—especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe—the ability to navigate this complex landscape is critical to securing quality products that meet both performance standards and budget constraints. Understanding the nuances behind materials, manufacturing processes, and quality control protocols can significantly impact procurement success.

This comprehensive guide offers a deep dive into the essential aspects of LED light strips PC, starting from the core components such as high-grade LED chips and PCB fabrication techniques, to rigorous quality assurance and certification requirements. Buyers will gain clarity on the different types of LED strips available—including flexible, rigid, waterproof, and customizable options—enabling them to select products tailored to specific project needs and environmental conditions.

Additionally, the guide explores strategies for sourcing from reliable suppliers, balancing cost-efficiency with product reliability, and leveraging bulk purchasing benefits. It also highlights market trends and addresses frequently asked questions to equip buyers with actionable insights that reduce risk and streamline procurement.

By consolidating critical knowledge and practical advice, this resource empowers B2B buyers across emerging and established markets—such as Thailand and Mexico—to make informed decisions, optimize supply chains, and capitalize on the latest innovations in LED lighting technology.

Understanding led light strips pc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible LED Strip PCBs | Thin, bendable printed circuit boards allowing curves | Architectural lighting, retail displays, signage | + Easy installation in tight spaces – May have lower heat dissipation |

| Rigid LED Strip PCBs | Solid, inflexible boards providing robust support | Industrial lighting, machinery, fixed fixtures | + Superior heat management – Limited adaptability to shapes |

| Waterproof LED Strip PCBs | Encapsulated with silicone or epoxy for moisture resistance | Outdoor lighting, marine, hospitality | + Durable in harsh environments – Higher cost and weight |

| High-Density LED Strip PCBs | Closely spaced LEDs for high brightness and uniformity | Task lighting, commercial spaces, film sets | + Intense illumination – Increased power consumption |

| RGB and Smart LED Strip PCBs | Integrated RGB LEDs with controllers for color-changing effects | Entertainment venues, smart homes, retail | + Versatile and customizable – More complex installation and higher price |

Flexible LED Strip PCBs

Flexible LED strip PCBs are designed with thin, bendable substrates that allow them to conform to curved or irregular surfaces. This flexibility makes them ideal for architectural accents, retail display lighting, and dynamic signage where installation space is limited or non-linear. B2B buyers should consider the trade-off between flexibility and thermal management, as flexible PCBs typically dissipate heat less efficiently, which can affect lifespan. For projects requiring intricate layouts or easy retrofit installations, flexible strips offer significant advantages.

Rigid LED Strip PCBs

Rigid LED strip PCBs provide a sturdy and durable base for LED chips, supporting better heat dissipation and longer operational lifespans. These are suited for industrial environments or fixed lighting applications where durability and thermal performance are priorities. B2B buyers targeting manufacturing plants, warehouses, or fixed commercial installations benefit from the robustness of rigid PCBs. However, their inflexibility limits use in curved or irregular spaces, so project design must accommodate straight-line installations.

Waterproof LED Strip PCBs

Waterproof LED strip PCBs are coated with protective layers such as silicone or epoxy, ensuring resistance to moisture, dust, and environmental factors. This makes them indispensable for outdoor applications, marine environments, hospitality venues, and any setting exposed to humidity or splashes. Buyers from regions with high humidity or outdoor projects should prioritize waterproof variants despite their higher cost and weight. Ensuring IP ratings and certifications during procurement is critical for compliance and durability.

High-Density LED Strip PCBs

High-density LED strips feature LEDs placed closely together, producing intense and uniform illumination suitable for task lighting, commercial spaces, and film or photography setups. These strips consume more power but deliver superior brightness and color consistency. B2B buyers focusing on environments requiring high light output should assess power supply requirements and heat management solutions. Bulk procurement often includes options for custom brightness levels to match project specifications.

RGB and Smart LED Strip PCBs

RGB and smart LED strip PCBs integrate multi-color LEDs with controllers enabling dynamic color changes and programmable effects. These are popular in entertainment venues, smart home installations, and retail environments seeking engaging lighting experiences. Buyers must consider the complexity of installation, compatibility with control systems, and higher upfront costs. The ability to customize lighting scenes and integrate with IoT devices can offer substantial value-adds for technologically advanced projects.

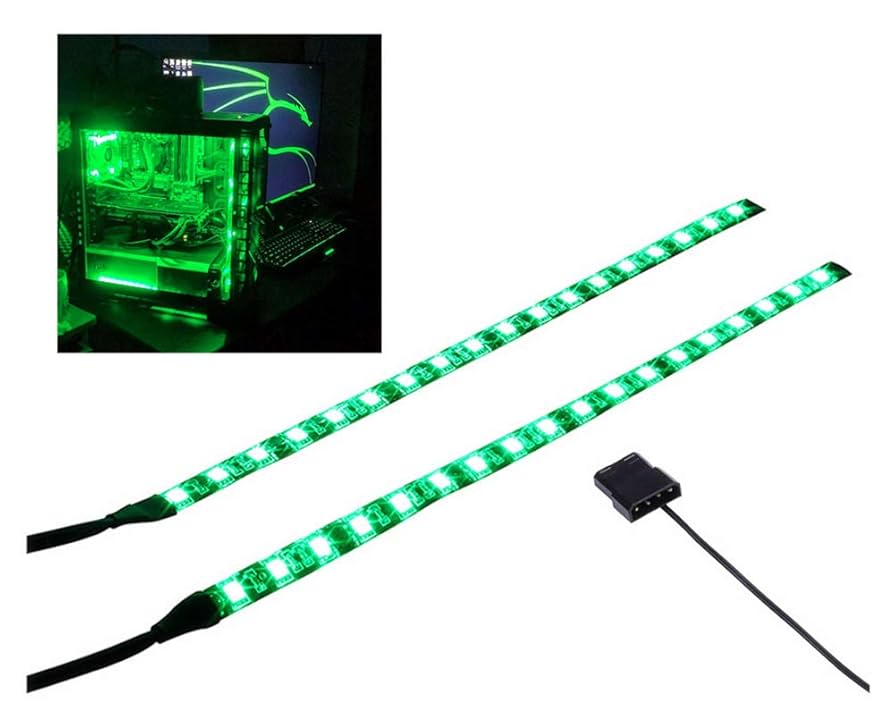

Related Video: The Ultimate Guide to RGB LED Strips!

Key Industrial Applications of led light strips pc

| Industry/Sector | Specific Application of led light strips pc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in retail stores and showrooms | Enhances product visibility, attracts customers, and improves ambiance | High color rendering index (CRI), customizable lengths, durability for high-traffic areas |

| Hospitality & Tourism | Decorative lighting in hotels, restaurants, and event venues | Creates inviting atmospheres, supports brand aesthetics, and offers energy savings | Waterproof or moisture-resistant options, flexible PCBs for varied installation surfaces |

| Automotive Manufacturing | Interior ambient lighting for vehicles | Adds value through aesthetic appeal and functional lighting, supporting brand differentiation | Compliance with automotive standards, heat resistance, and longevity under vibration |

| Industrial & Warehousing | Task and safety lighting in production lines and storage areas | Improves worker safety and productivity with reliable, bright illumination | Robust PCBs with excellent heat dissipation, long lifespan, and easy installation |

| Architecture & Construction | Architectural lighting for façades and interior design | Enables creative lighting designs, energy efficiency, and long-term cost savings | Weatherproofing, UV resistance, and compatibility with smart control systems |

Retail & Commercial Lighting

In retail environments across Africa, South America, the Middle East, and Europe, LED light strips with PCBs are widely used to accentuate products and create visually appealing displays. These strips provide uniform, bright lighting that draws customers’ attention and highlights merchandise effectively. Buyers should prioritize high CRI LED chips to ensure colors appear true and vibrant, which is critical for product presentation. Flexible PCBs allow installation in various display configurations, while durable adhesive backing ensures longevity in busy commercial spaces.

Hospitality & Tourism Applications

Hotels, restaurants, and event venues utilize LED light strips PC for mood and decorative lighting that enhances guest experiences. These strips are often installed in areas with high humidity or exposure to moisture, such as bathrooms and outdoor terraces, requiring moisture-resistant or waterproof designs. For international buyers, especially in tropical or coastal regions, sourcing LED strips with flexible PCBs that withstand environmental conditions without compromising light quality is vital. Customizable color options also enable alignment with brand themes.

Automotive Manufacturing

LED light strips with PCBs are integral to modern vehicle interiors, providing ambient lighting that improves aesthetics and user comfort. Automotive manufacturers in global markets demand LED strips that meet strict industry standards for heat resistance, durability under vibration, and long operational life. Buyers from emerging automotive hubs in regions like Mexico or Thailand should ensure suppliers can certify compliance with local and international automotive regulations, as well as provide products tailored for complex interior geometries using flexible PCBs.

Industrial & Warehousing Lighting

In industrial settings, LED strip lights mounted on PCBs are used for task lighting on assembly lines and safety illumination in warehouses. They offer bright, consistent light that reduces errors and enhances worker safety. For B2B buyers in manufacturing hubs or logistics centers, sourcing LED strips with excellent heat dissipation capabilities and robust PCB materials is crucial to withstand harsh operating conditions. Easy installation and maintenance-friendly designs help minimize downtime and operational costs.

Architecture & Construction

Architectural projects across continents increasingly incorporate LED strip lighting for façades, coves, and interior accents, leveraging the versatility of LED strips on PCBs. These applications demand weatherproof and UV-resistant strips to endure outdoor exposure in diverse climates. Additionally, compatibility with smart lighting controls is becoming essential for energy management and dynamic lighting effects. Buyers should focus on suppliers offering customizable lengths and color temperatures to meet specific design requirements while ensuring compliance with regional safety and environmental standards.

Related Video: LED – Light Emitting Diode | Basics, Characteristics, Working & Applications | LED Vs PN Diode

Strategic Material Selection Guide for led light strips pc

Selecting the appropriate material for the printed circuit board (PCB) in LED light strips is a critical decision that influences product performance, durability, and cost-effectiveness. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding the properties and trade-offs of common PCB materials is essential for sourcing LED strips that meet local standards and application needs.

FR-4 (Flame Retardant 4)

Key Properties:

FR-4 is a glass-reinforced epoxy laminate known for its excellent mechanical strength, electrical insulation, and moderate thermal resistance (typically up to 130°C). It offers good dimensional stability and is widely used in rigid PCB applications.

Pros & Cons:

– Pros: Cost-effective, readily available globally, and compatible with standard manufacturing processes. It provides solid structural support and is flame retardant, meeting many safety regulations.

– Cons: Limited heat dissipation compared to specialized materials, which can affect LED longevity in high-power applications. It is rigid, which restricts flexibility in installation.

Impact on Application:

Ideal for indoor LED strip lighting where rigidity is acceptable and heat generation is moderate. Less suitable for flexible or high-heat environments such as outdoor or industrial settings.

Considerations for International Buyers:

FR-4 PCBs generally comply with global standards like UL94 V-0 for flame retardancy and are accepted under ASTM and IEC norms. Buyers in regions with strict fire safety codes (e.g., Europe’s CE marking requirements) will find FR-4 compliant products readily available. However, in hot climates such as parts of Africa or the Middle East, additional heat management may be necessary.

Polyimide (PI) Flexible PCB

Key Properties:

Polyimide-based PCBs are flexible, with excellent thermal stability (up to 260°C), chemical resistance, and mechanical durability. They maintain performance under bending and twisting, making them ideal for dynamic installations.

Pros & Cons:

– Pros: High heat resistance, excellent flexibility, and superior chemical resistance. Enables innovative LED strip designs for curved or irregular surfaces.

– Cons: Higher cost and more complex manufacturing process than FR-4. Requires specialized handling and quality control.

Impact on Application:

Best suited for flexible LED strips used in automotive lighting, architectural accents, or wearable tech where bending and heat resistance are critical.

Considerations for International Buyers:

Buyers in markets like South America and Europe, where flexible lighting solutions are growing, will benefit from PI PCBs. Compliance with ISO and IPC standards is common, but buyers should verify supplier certifications due to the complexity of manufacturing. In regions with high humidity or chemical exposure (e.g., Middle East industrial zones), PI’s chemical resistance is advantageous.

Aluminum (Metal Core PCB)

Key Properties:

Aluminum PCBs feature a metal core (usually aluminum) that provides superior heat dissipation, mechanical strength, and durability. They typically withstand temperatures up to 130–150°C and offer excellent thermal conductivity.

Pros & Cons:

– Pros: Outstanding heat dissipation extends LED lifespan and performance, especially in high-power or outdoor LED strips. Robust against mechanical stress and corrosion-resistant when properly coated.

– Cons: Higher material and manufacturing costs. Heavier and less flexible than other PCB types, limiting use in flexible LED strips.

Impact on Application:

Preferred for high-brightness LED strips, outdoor lighting, and industrial environments where heat management is critical. Also suitable for markets with harsh environmental conditions.

Considerations for International Buyers:

Aluminum PCBs meet many international standards including RoHS and REACH, important for European buyers. Buyers in Africa and the Middle East should consider corrosion protection coatings due to saline or humid environments. The higher upfront cost is offset by longer product life and reduced maintenance.

CEM-1 (Composite Epoxy Material)

Key Properties:

CEM-1 is a composite PCB material made from woven glass fabric and paper core with epoxy resin. It offers moderate mechanical strength and electrical insulation but has lower thermal resistance (~105°C) compared to FR-4.

Pros & Cons:

– Pros: Very low cost and easy to manufacture. Suitable for low-end, cost-sensitive LED strip applications.

– Cons: Poor heat dissipation and mechanical durability. Not suitable for high-performance or long-lifespan LED strips.

Impact on Application:

Typically used in budget LED strip products where cost is the primary driver and performance requirements are minimal. Not recommended for outdoor or high-temperature environments.

Considerations for International Buyers:

While attractive for price-sensitive markets in Africa and parts of South America, buyers must weigh the trade-off in durability and compliance. CEM-1 may not meet stringent certifications like UL or CE, limiting its use in regulated markets such as Europe.

Summary Table

| Material | Typical Use Case for led light strips pc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | Rigid indoor LED strips with moderate heat generation | Cost-effective, flame retardant | Limited heat dissipation, rigid form | Low |

| Polyimide (PI) | Flexible LED strips requiring high heat and chemical resistance | High flexibility and thermal stability | Higher cost, complex manufacturing | High |

| Aluminum | High-power, outdoor, and industrial LED strips | Excellent heat dissipation and durability | Heavy, less flexible, higher cost | Medium |

| CEM-1 | Budget LED strips with low performance requirements | Very low cost | Poor heat resistance and durability | Low |

This analysis equips international B2B buyers with actionable insights to select PCB materials aligned with their project demands, environmental conditions, and regulatory frameworks. Prioritizing material properties and compliance will ensure procurement of LED strip lights that deliver optimal performance and reliability across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led light strips pc

The manufacturing of LED light strips with printed circuit boards (PCBs) is a complex, multi-stage process that demands precision, quality materials, and rigorous quality assurance to meet the diverse needs of international B2B buyers. Understanding the main manufacturing stages and quality control (QC) practices is crucial for buyers, especially those operating in Africa, South America, the Middle East, and Europe, where compliance and reliability are paramount.

Key Manufacturing Stages for LED Light Strips with PCBs

-

Material Preparation and Sourcing

The foundation of quality LED strips lies in sourcing premium components: high-efficiency LED chips, copper-clad PCBs (flexible or rigid), adhesives, and protective coatings. Reputable manufacturers procure LED chips from top-tier suppliers to ensure luminous efficacy and longevity. The PCB material must offer excellent thermal conductivity to dissipate heat efficiently, preventing premature failure. Adhesives and encapsulants are selected based on the intended application environment (indoor, outdoor, wet conditions). -

PCB Fabrication

PCBs are fabricated to precise specifications, often using flexible substrates such as polyimide or rigid substrates like FR4, depending on product design. This stage involves etching copper traces, layering, and applying solder masks. High-quality PCB fabrication ensures mechanical strength, flexibility where required, and optimal electrical performance, which are critical for long-term reliability. -

Component Mounting and Assembly

LED chips and other components are mounted onto the PCB through surface-mount technology (SMT). Automated pick-and-place machines position the LEDs with micron-level accuracy before soldering, typically via reflow ovens. This stage demands strict control to avoid defects such as cold solder joints or misaligned LEDs, which can affect light uniformity and performance. -

Protective Finishing and Adhesive Application

After assembly, LED strips often receive protective coatings (silicone or epoxy) to guard against moisture, dust, and mechanical damage. The adhesive backing is applied to facilitate installation. The choice of adhesive impacts installation ease and durability, especially in varying climates—an important consideration for buyers in diverse regions. -

Packaging and Logistics Preparation

Finally, LED strips are carefully packaged to prevent damage during transit. Packaging may include anti-static materials and moisture barriers. Custom packaging options can support branding and compliance with import regulations in different countries.

Illustrative Image (Source: Google Search)

Quality Assurance and Control in LED Strip Manufacturing

International Standards and Certifications

-

ISO 9001: A foundational quality management standard ensuring consistent manufacturing processes and continual improvement. Many reputable LED strip manufacturers maintain ISO 9001 certification to demonstrate commitment to quality.

-

CE Marking: Required for products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

-

RoHS Compliance: Restricts hazardous substances, crucial for environmentally conscious markets globally.

-

UL, ETL, and CSA Certifications: Important in North America but increasingly recognized worldwide for electrical safety assurance.

-

API and IEC Standards: Relevant for industrial or specialized lighting applications, ensuring compatibility and safety.

Critical Quality Control Checkpoints

-

Incoming Quality Control (IQC): All raw materials and components, especially LED chips and PCBs, undergo rigorous inspection upon arrival. Parameters such as LED brightness, PCB integrity, and adhesive quality are verified against specifications.

-

In-Process Quality Control (IPQC): During assembly, continuous monitoring ensures soldering quality, component placement accuracy, and adherence to process parameters. Automated optical inspection (AOI) systems often detect defects early.

-

Final Quality Control (FQC): Completed LED strips are subjected to comprehensive testing, including electrical performance, light uniformity, color temperature, and mechanical durability. Visual inspections and functional testing under simulated operating conditions are common.

Common Testing Methods

-

Electrical Testing: Ensures correct voltage, current, and power consumption, verifying efficiency and safety.

-

Luminous Intensity and Color Consistency: Measured using spectrometers to confirm brightness and color temperature uniformity across batches.

-

Thermal Testing: Checks heat dissipation capabilities to prevent overheating during operation.

-

Environmental Stress Testing: Simulates exposure to humidity, temperature fluctuations, and mechanical stress to assess durability, especially important for outdoor or industrial applications.

-

Adhesion and Flexibility Tests: For flexible LED strips, these tests verify that the product can withstand bending and installation without damage.

How B2B Buyers Can Verify Supplier Quality Control

-

Factory Audits: Conduct on-site or third-party audits to evaluate manufacturing processes, QC systems, and compliance with international standards.

-

Review of QC Documentation: Request detailed inspection reports, test certificates, and compliance documentation to validate claims.

-

Third-Party Inspection Services: Engage independent inspection agencies to perform random sampling and testing before shipment, reducing risk.

-

Sample Testing: Order product samples for in-house testing aligned with your specific application requirements, ensuring compatibility and performance.

-

Supplier Certifications: Verify the authenticity and currency of supplier certifications such as ISO 9001, CE, RoHS, and others relevant to your market.

Quality Control Considerations for International Buyers

-

Regional Compliance Nuances:

Buyers in Europe must prioritize CE and RoHS certifications, while Middle Eastern and African markets may require adherence to local electrical safety standards and import regulations. South American buyers should consider certifications recognized by Mercosur or local regulatory bodies. -

Climate and Environmental Adaptability:

Given the diverse climates across Africa, South America, and the Middle East, ensure the LED strips have appropriate IP ratings (e.g., IP65 or above) for dust and water resistance. Adhesives and coatings must withstand heat, humidity, and UV exposure prevalent in these regions. -

Logistics and Packaging:

Robust packaging is critical to prevent damage during long transit routes common in these markets. Confirm that suppliers use moisture-resistant and anti-static materials. -

Communication and Transparency:

Language barriers and time zone differences can impact QC communication. Choose suppliers with transparent reporting and responsive customer service to address quality concerns promptly. -

Customization and Scalability:

For buyers in emerging markets like Thailand or Mexico, the ability to request custom lengths, packaging, or even branding can provide competitive advantages. Ensure suppliers can scale production without compromising quality.

Summary for B2B Buyers

For international B2B buyers evaluating LED light strips with PCBs, understanding the manufacturing and QC processes empowers informed sourcing decisions. Prioritize suppliers who demonstrate:

- Robust material sourcing and precise PCB fabrication.

- Strict assembly controls with advanced automation.

- Comprehensive multi-stage QC aligned with ISO 9001 and relevant certifications.

- Transparent quality verification via audits, reports, and third-party inspections.

- Adaptability to regional compliance requirements and environmental conditions.

By partnering with manufacturers who excel in these areas, businesses across Africa, South America, the Middle East, and Europe can secure reliable, high-performance LED strips that meet both functional and regulatory demands, ensuring long-term success in their lighting projects.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led light strips pc Sourcing

Understanding the cost and pricing dynamics of sourcing LED light strips with PCBs is essential for international B2B buyers aiming to optimize procurement and maximize value. The pricing structure is multifaceted, influenced by material quality, manufacturing complexity, and supply chain logistics, all of which vary depending on buyer location and order specifics.

Key Cost Components in LED Strip Light PCB Sourcing

-

Materials: The largest portion of costs stems from sourcing high-quality LED chips, PCBs (flexible or rigid), adhesives, and protective coatings. Premium LED chips with higher luminous efficacy and PCBs with superior heat dissipation capabilities command higher prices but ensure longer lifespan and performance.

-

Labor and Manufacturing Overhead: Skilled labor is required for precise PCB fabrication, chip mounting, soldering, and assembly. Overhead includes factory utilities, equipment depreciation, and quality control systems. Factories with advanced automation can reduce labor costs, but this varies by region.

-

Tooling and Setup: Initial tooling for PCB production and assembly line setup incurs upfront costs, which are amortized over production volume. Custom designs or special PCB specifications increase tooling expenses.

-

Quality Control (QC): Rigorous testing for functionality, durability, and compliance with international certifications (e.g., CE, RoHS, UL) adds to costs but is critical for ensuring product reliability and reducing returns.

-

Logistics and Shipping: International freight, customs duties, and insurance impact final landed costs. Shipping costs can fluctuate based on volume, shipping method (air vs. sea), and geopolitical factors affecting trade routes.

-

Profit Margin: Suppliers typically include a margin that reflects market demand, competitive positioning, and brand value.

Primary Price Influencers for International Buyers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders reduce per-unit costs due to economies of scale and better amortization of fixed costs. Buyers from regions like Africa or South America should consolidate orders to meet MOQ thresholds and negotiate volume discounts.

-

Specifications and Customization: Customized lengths, colors, packaging, or integrated smart controls increase manufacturing complexity and cost. Buyers must balance customization benefits against price sensitivity.

-

Material Quality and Certifications: Higher-grade LED chips, premium PCBs, and compliance with multiple certifications raise costs but reduce risks related to product failure and regulatory issues in target markets.

-

Supplier Reputation and Location: Established suppliers with proven track records may charge premiums but offer reliability and warranty support. Proximity to manufacturing hubs (e.g., China, Southeast Asia) can reduce shipping times and costs.

-

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears transportation risk and cost. Buyers should clarify terms to avoid unexpected expenses and consider payment terms that optimize cash flow.

Strategic Tips for B2B Buyers in Africa, South America, the Middle East, and Europe

-

Negotiate Beyond Unit Price: Engage suppliers on payment terms, packaging options, warranty periods, and after-sales support to capture hidden value.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but installation ease, energy efficiency, maintenance costs, and product lifespan. Higher upfront costs may translate into savings over time.

-

Request Samples and Third-Party Testing Reports: Validate product quality and certification authenticity before committing to bulk orders, especially when sourcing from new suppliers.

-

Plan for Logistics Complexity: Account for longer lead times and potential customs delays in certain regions. Collaborate with freight forwarders experienced in your market to optimize shipping routes and costs.

-

Leverage Group Buying or Local Partnerships: Pooling demand with other buyers or working with local distributors can improve bargaining power and reduce per-unit costs.

-

Stay Informed on Market Trends: Keep abreast of raw material price fluctuations, technological advances (like smart LED strips), and regulatory changes affecting import/export.

Indicative Pricing Disclaimer

Prices for LED light strips with PCBs vary widely based on order size, customization, and supplier. As a rough benchmark, standard wholesale LED strip lights range from $1 to $5 per meter depending on quality and features. Buyers should treat these figures as indicative and conduct due diligence for accurate quotations.

By comprehensively analyzing these cost factors and leveraging strategic procurement approaches, international B2B buyers can secure high-quality LED strip lights with PCBs that align with their budget and project requirements, ensuring both competitive pricing and product reliability.

Spotlight on Potential led light strips pc Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led light strips pc’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led light strips pc

Key Technical Properties of LED Strip Lights PCBs

Understanding the core technical specifications of the printed circuit boards (PCBs) used in LED strip lights is crucial for making informed purchasing decisions in B2B transactions. These properties directly affect product performance, durability, and installation success across diverse markets such as Africa, South America, the Middle East, and Europe.

1. Material Grade of PCB

The PCB material—commonly FR-4 (fiberglass epoxy) or flexible polyimide—determines mechanical strength and heat resistance. High-grade materials ensure efficient heat dissipation, preventing LED failure and extending lifespan. For buyers, selecting the right material is essential for compatibility with installation environments, especially in hot or humid climates.

2. Copper Thickness and Trace Width

Copper layers on PCBs carry electrical current and affect heat conduction. Typical copper thickness ranges from 1 oz to 3 oz per square foot. Thicker copper improves current capacity and heat dissipation, critical for high-brightness LED strips. Trace width tolerance influences reliability; narrower traces may risk overheating. B2B buyers should specify copper thickness to match power requirements and safety standards.

3. Flexibility vs. Rigidity

PCBs can be rigid, flexible, or rigid-flex. Flexible PCBs allow bending around corners and curved surfaces, ideal for dynamic installations. Rigid PCBs provide stability and durability in fixed applications. Understanding the project’s physical demands will help buyers choose the correct PCB type, impacting installation ease and long-term performance.

4. Tolerance and Dimensional Accuracy

Tolerance refers to the allowable deviation in PCB dimensions and hole placements during fabrication. Tight tolerances (±0.1 mm or better) ensure proper component alignment and soldering quality. For OEM manufacturers or integrators, this precision minimizes assembly errors and reduces waste, improving overall cost efficiency.

5. Surface Finish

Common PCB surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). ENIG is preferred for its corrosion resistance and flatness, enhancing solder joint reliability—especially important for LED chips. Buyers should confirm surface finish to guarantee compatibility with manufacturing processes.

6. Adhesive Backing Quality

Though not part of the PCB itself, the adhesive backing quality is integral to the final LED strip product. High-quality adhesives ensure secure mounting on various surfaces, resisting peeling under heat or moisture. This property is vital for installations in challenging environments common across international markets.

Common Trade Terminology in LED Strip Light Procurement

Navigating the international B2B LED lighting market requires familiarity with key trade terms. Understanding these terms facilitates clearer communication with suppliers and ensures smoother transactions.

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products that are rebranded and sold by other companies. In LED strips, OEM suppliers provide customizable PCBs and lighting solutions. Buyers often collaborate with OEMs for tailored products, controlling branding and specifications.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. MOQs vary widely depending on manufacturer capabilities and product type. Knowing the MOQ helps buyers plan inventory and budgets effectively, especially when testing new products or entering new markets.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for price, lead time, and terms based on specific product requirements. RFQs are essential in comparing offers and negotiating deals. Providing detailed technical specs in an RFQ leads to more accurate and competitive quotes.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Examples include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms helps buyers manage logistics risks and costs.

Lead Time

The period between placing an order and receiving the goods. Lead time impacts project schedules and inventory management. Buyers should clarify lead times upfront to avoid delays, especially for large or custom orders.

Certification Compliance

Refers to adherence to international standards such as CE, RoHS, UL, or ETL. Certifications assure product safety, environmental compliance, and market acceptance. Buyers should require certified products to meet regulatory demands in target regions.

By mastering these technical properties and trade terms, international B2B buyers can confidently source LED strip light PCBs that meet quality standards, optimize costs, and ensure reliable supply chain performance. This knowledge empowers buyers to tailor specifications to diverse application needs and negotiate effectively with global suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led light strips pc Sector

Market Overview & Key Trends

The global market for LED light strips with printed circuit boards (PCBs) is expanding rapidly, driven by growing demand across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing energy efficiency, customization, and smart lighting integration. Countries like Thailand and Mexico, with burgeoning manufacturing and construction industries, are becoming key importers and users of advanced LED strip solutions.

Key market drivers include:

- Energy efficiency and cost savings: LED strips offer significant reductions in electricity consumption compared to traditional lighting, appealing to cost-conscious buyers and governments promoting green energy.

- Customization and flexibility: The availability of flexible PCBs and various chip configurations allows for tailored lighting solutions, critical for markets requiring bespoke designs such as retail, hospitality, and architectural projects.

- Smart and IoT-enabled lighting: Integration with smart controls and app-based management is a growing trend, especially in Europe and the Middle East, where smart city initiatives and automation are gaining momentum.

- Supply chain diversification: Buyers from Africa and South America are increasingly sourcing from multiple regions, including Asia and Europe, to mitigate risks related to geopolitical tensions and shipping disruptions.

Emerging sourcing trends for B2B buyers:

- Preference for suppliers offering end-to-end solutions, including design customization, certification compliance, and after-sales service.

- Demand for rapid turnaround and smaller MOQ (minimum order quantity) to enable market testing before scaling.

- Increasing interest in suppliers providing transparent supply chains with traceable materials and adherence to international standards such as CE, UL, and RoHS.

For buyers in emerging markets, understanding the nuances of PCB quality, LED chip performance, and adhesive durability is essential to avoid costly returns and ensure long-term product reliability.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a strategic imperative in the LED strip light sector. International B2B buyers are under increasing pressure to source products that minimize environmental impact and adhere to ethical supply chain practices.

Environmental Impact Considerations:

- Material selection: Use of lead-free solder, halogen-free PCBs, and low-toxicity adhesives reduces harmful emissions and waste during manufacturing and disposal.

- Energy consumption: High-efficiency LED chips and optimized PCB designs contribute to lower operational carbon footprints.

- Packaging: Sustainable packaging materials and minimalistic designs help reduce plastic waste and shipping emissions.

Ethical Supply Chain Practices:

- Transparent sourcing of raw materials, including conflict-free minerals used in LED chips and PCBs, is vital for corporate social responsibility (CSR) compliance.

- Suppliers with certifications such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) provide assurance of ethical labor practices.

- Buyers should seek partners that conduct regular audits and provide supply chain traceability to mitigate risks related to forced labor or environmental violations.

Green Certifications to Look For:

- RoHS (Restriction of Hazardous Substances): Limits hazardous materials in electrical products.

- CE Marking: Ensures product safety and environmental compliance within the European Economic Area.

- Energy Star: Indicates energy-efficient performance.

- UL Environment: Certification for sustainable product design and manufacturing.

By prioritizing sustainability and ethical sourcing, B2B buyers not only meet regulatory requirements but also enhance brand reputation and appeal to environmentally conscious end customers.

Evolution of LED Light Strips with PCBs

The evolution of LED strip lights from basic rigid boards to sophisticated flexible PCBs has transformed the lighting industry. Initially, LED strips were simple, single-color products with limited applications. Advances in PCB technology enabled the development of flexible, durable substrates that could be cut to custom lengths and installed in diverse environments.

The integration of high-quality LED chips with improved luminous efficacy and longer lifespan has further propelled adoption. Over the last decade, the sector has embraced smart lighting features, including dimming, color-changing capabilities, and wireless control, making LED strips a versatile solution for modern lighting needs.

For international B2B buyers, understanding this evolution helps in selecting products that leverage the latest technology while balancing cost, durability, and functionality tailored to regional market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led light strips pc

-

How can I effectively vet LED strip light PCB suppliers for international B2B purchases?

To vet suppliers, start by verifying their certifications such as ISO, CE, RoHS, and UL to ensure compliance with international standards. Request detailed company profiles, including production capacity, quality control processes, and client references, especially from your region (Africa, South America, Middle East, Europe). Ask for product samples to assess quality firsthand. Additionally, check their track record on timely delivery and after-sales support. Utilize third-party audits or factory visits when possible, and leverage platforms with verified supplier credentials to minimize risks. -

What customization options are typically available for LED strip light PCBs in bulk orders?

Most manufacturers offer customization including PCB length, LED density, chip type, color temperature, adhesive backing, and packaging. Some suppliers also provide custom branding or private labeling, which is valuable for market differentiation. For projects requiring specific functionalities, options like waterproofing (IP rating), dimmable circuits, or smart connectivity can be negotiated. Communicate your exact technical and design requirements early to ensure feasibility and accurate pricing, keeping in mind that more complex customizations may affect minimum order quantities (MOQs) and lead times. -

What are the common minimum order quantities (MOQs) and lead times for international orders of LED strip light PCBs?

MOQs vary widely depending on the supplier and level of customization but typically range from 500 to 5,000 meters per order. Standard, off-the-shelf LED strip PCBs usually have lower MOQs, while custom designs may require larger commitments. Lead times can range from 3 to 8 weeks, factoring in production, quality testing, and shipping. For buyers in Africa, South America, the Middle East, and Europe, additional transit time should be anticipated. Establish clear timelines upfront and consider suppliers who offer partial shipments or stock availability to manage project schedules effectively. -

What payment terms are advisable when sourcing LED strip light PCBs internationally?

Secure payment terms often include a 30% deposit upfront with the balance paid upon shipment or after passing quality inspections. Letters of credit (LC) provide an added layer of security for large orders. For new supplier relationships, consider using escrow services or payment platforms offering buyer protection. Negotiate terms that balance supplier confidence and your risk tolerance, and avoid full prepayment unless the supplier has a proven reputation. Always ensure contracts clearly define payment milestones linked to production and delivery stages. -

How can I ensure the quality and reliability of LED strip light PCBs before and after shipment?

Request product samples for initial testing and verify compliance with relevant certifications like CE, RoHS, and UL. Insist on supplier-provided quality control reports and factory inspection records. Third-party quality inspections before shipment can prevent defects reaching your warehouse. Upon receipt, conduct batch testing for luminous efficacy, adhesion, and electrical safety. Establish clear warranty terms covering defects and malfunction. For ongoing quality assurance, build a strong communication channel with your supplier and consider long-term partnerships to encourage consistent standards. -

Which certifications are essential for LED strip light PCBs to meet international market requirements?

Key certifications include CE (European market safety compliance), RoHS (restriction of hazardous substances), UL or ETL (North American electrical safety), and ISO 9001 (quality management). For environmentally conscious buyers, certifications like REACH and Energy Star are important. These certifications not only ensure compliance with import regulations in Africa, South America, the Middle East, and Europe but also reassure end customers of product safety and sustainability. Always verify that certificates are current and issued by accredited bodies. -

What logistics considerations should international B2B buyers keep in mind when importing LED strip light PCBs?

Consider factors such as shipping mode (air vs. sea), customs clearance procedures, import duties, and local regulations. Sea freight is cost-effective for large orders but slower, while air freight offers speed at higher costs. Use freight forwarders experienced in electronics shipments and ensure proper packaging to protect against moisture and static damage during transit. Confirm that suppliers provide complete shipping documentation, including commercial invoices, packing lists, and certificates of origin, to avoid customs delays. Plan for potential delays due to regional holidays or port congestions. -

How should disputes or quality issues be handled with international LED strip light PCB suppliers?

Establish dispute resolution mechanisms within your contract, such as mediation or arbitration, preferably in neutral jurisdictions. Document all communications and inspections thoroughly. In case of quality issues, promptly report defects with photographic evidence and inspection reports. Request corrective actions such as product replacement, refunds, or discounts. Maintain open communication channels to facilitate amicable solutions. Leveraging trade insurance or third-party inspection services can further protect your interests. Building long-term relationships with trustworthy suppliers reduces the likelihood of disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led light strips pc

Strategic sourcing of LED light strips with high-quality PCBs is essential for businesses aiming to optimize product performance, durability, and cost-efficiency. By prioritizing suppliers who demonstrate stringent quality control, use premium LED chips, and adhere to international certifications such as CE and RoHS, buyers can ensure long-term reliability and customer satisfaction. Additionally, evaluating PCB types—flexible versus rigid—and adhesive quality aligns product specifications with diverse application needs, from commercial installations to innovative design projects.

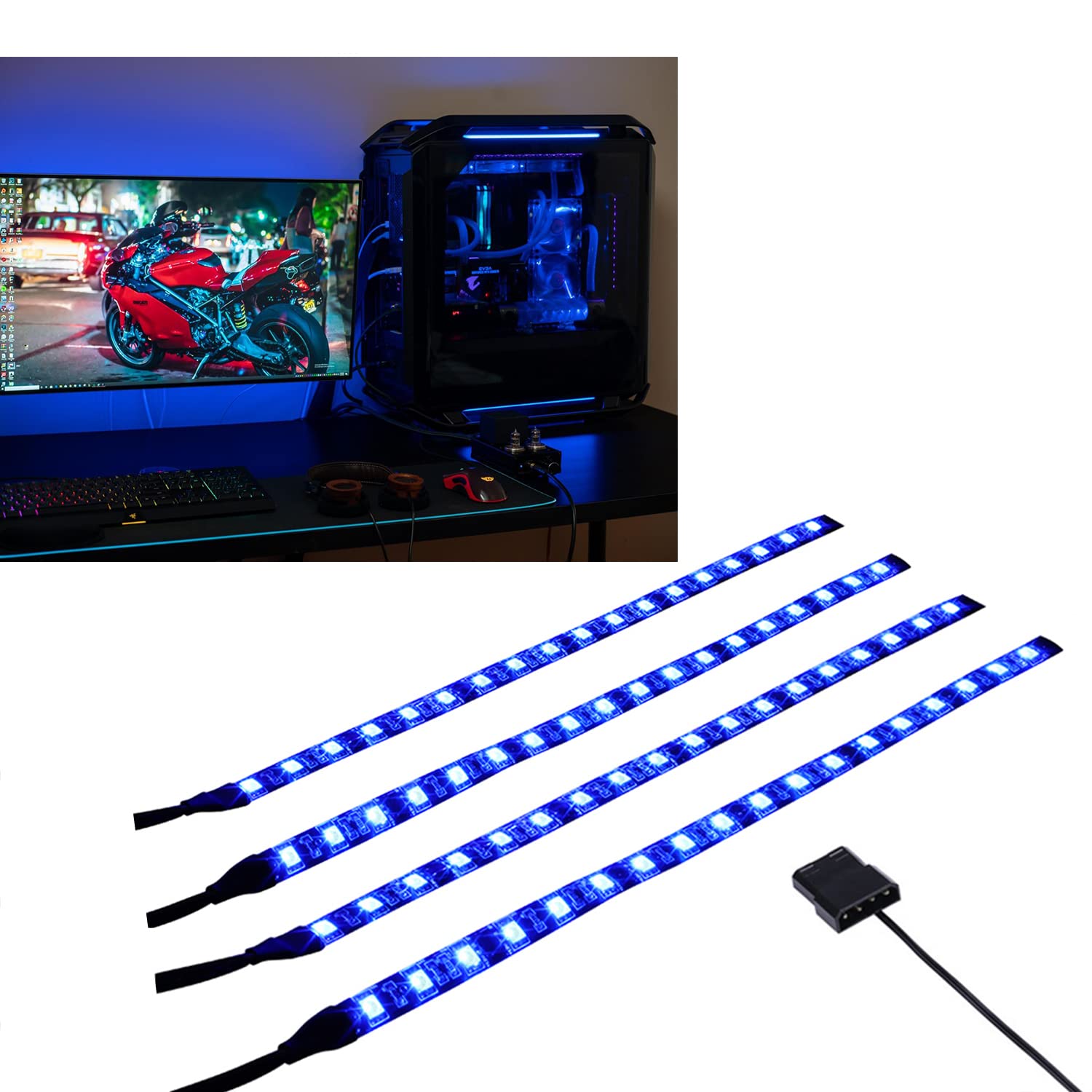

Illustrative Image (Source: Google Search)

For international B2B buyers in Africa, South America, the Middle East, and Europe, leveraging wholesale purchasing offers significant advantages including cost savings, product variety, and access to the latest LED technologies. Strategic partnerships with reputable manufacturers and distributors also streamline logistics and reduce lead times, vital for competitive market positioning. Requesting samples and verifying supplier warranties further mitigates risk and enhances procurement confidence.

Looking ahead, the LED lighting market continues to evolve rapidly with advances in smart and energy-efficient solutions. Buyers who invest in strategic sourcing today will not only benefit from superior product quality but also position themselves to capitalize on emerging trends and expanding applications. Embrace a proactive sourcing strategy to illuminate your projects with innovation, reliability, and value.