Introduction: Navigating the Global Market for best led under cabinet lights

Under cabinet LED lighting has rapidly become a cornerstone solution in both commercial and residential projects worldwide, valued for its ability to enhance functionality, aesthetics, and energy efficiency. For international B2B buyers—especially those operating in dynamic markets such as Africa, South America, the Middle East, and Europe—the demand for best-in-class LED under cabinet lights presents lucrative opportunities to upgrade kitchens, offices, retail displays, and hospitality environments with precision lighting solutions that blend seamlessly into diverse architectural styles.

Understanding the nuances of this product category is critical for sourcing the right fixtures that meet specific performance, durability, and design requirements. This guide delivers a comprehensive framework covering all essential facets: from the various types of LED under cabinet lights—linear fixtures, puck lights, tape systems—to the materials and manufacturing standards that ensure long-lasting quality and safety compliance. It also explores key supplier profiles, quality control benchmarks, cost considerations, and regional market trends that influence pricing and availability.

Equipped with actionable insights and practical evaluation criteria, this guide empowers B2B buyers from Kenya, Turkey, Brazil, UAE, Germany, and beyond to make informed decisions that align with their project specifications and budget constraints. Whether you are upgrading existing installations or developing new commercial ventures, this resource demystifies complexities around installation methods, power options, and emerging smart lighting technologies. By leveraging this knowledge, international buyers can confidently navigate supplier negotiations, optimize procurement strategies, and ultimately deliver superior lighting solutions that drive customer satisfaction and business growth.

Understanding best led under cabinet lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional LED Linear | Long, low-profile bars providing uniform light distribution | Commercial kitchens, offices, retail displays | Pros: High brightness, energy-efficient, easy to link multiple units Cons: Requires professional hardwiring for optimal installation, less portable |

| LED Strip Lights | Flexible, adhesive-backed strips with customizable lengths | Modular displays, hospitality, residential projects | Pros: Flexible installation, customizable lengths, low heat Cons: Adhesive may degrade in humid environments, lower light intensity per unit length |

| LED Puck Lights | Small, round fixtures offering focused, accent lighting | Display cabinets, retail shelving, task lighting | Pros: Compact, easy to install, excellent for accent lighting Cons: Limited area coverage, may require multiple units for uniform lighting |

| Battery-Powered Lights | Wireless, portable units powered by replaceable or rechargeable batteries | Temporary setups, remote locations, retrofit projects | Pros: No wiring needed, easy installation Cons: Battery maintenance, lower continuous runtime, less suitable for permanent installations |

| Smart LED Under Cabinet | Integrated with smart controls (dimming, color tuning, scheduling) | Smart offices, luxury retail, high-end residential | Pros: Advanced control, energy savings, customizable ambiance Cons: Higher initial cost, requires compatible smart infrastructure |

Traditional LED Linear Fixtures

These are the most widely used under cabinet lights in commercial and residential settings. Characterized by their elongated shape and even light output, they suit environments requiring consistent, bright illumination such as kitchens, workstations, and retail counters. For B2B buyers in regions like Europe and the Middle East, hardwired versions are preferred for permanent installations, while plug-in models suit quick retrofit projects. Key considerations include voltage compatibility (line vs. low voltage), installation complexity, and ability to daisy-chain for larger coverage.

LED Strip Lights

LED strips offer remarkable flexibility in installation due to their adhesive backing and cut-to-length design. They excel in applications demanding seamless, linear illumination with minimal fixture visibility, making them ideal for hospitality venues and modular retail displays. Buyers from Africa and South America should assess environmental conditions, as adhesive durability can vary in humid or dusty climates. Additionally, strip lights typically require compatible drivers and controllers, which should be factored into procurement decisions.

LED Puck Lights

Puck lights provide focused pools of light and are favored for accentuating specific areas such as display cases or work surfaces. Their compact size allows for easy mounting inside cabinets or under shelves. For B2B customers, puck lights are advantageous where targeted illumination enhances product visibility, such as in boutique retail or specialized office setups. However, multiple units may be necessary for uniform lighting, impacting total cost and installation time.

Battery-Powered Lights

Offering wireless convenience, battery-powered LED under cabinet lights are well-suited for temporary installations or locations where electrical access is limited. This type appeals to buyers managing retrofit projects or mobile setups in emerging markets. While installation is straightforward, ongoing battery replacement or recharging should be considered in operational cost analyses. These lights often come with adhesive or magnetic mounts, facilitating flexible positioning but limiting long-term durability.

Smart LED Under Cabinet Lights

Smart LED options integrate IoT capabilities, enabling remote control over brightness, color temperature, and scheduling. These systems attract B2B buyers aiming to enhance user experience and energy efficiency in upscale commercial or residential environments. Procurement should include evaluation of compatibility with existing smart building platforms and potential need for professional integration services. Although initial investment is higher, benefits include operational savings and differentiated product offerings.

Related Video: How to install LED linkable under cabinet lights – easy accurate method

Key Industrial Applications of best led under cabinet lights

| Industry/Sector | Specific Application of best led under cabinet lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Kitchens | Task lighting for food preparation and plating stations | Enhances visibility, hygiene, and safety; improves workflow | Durability, moisture resistance, energy efficiency, and ease of installation |

| Retail and Display | Highlighting merchandise in display cabinets and shelves | Attracts customer attention, enhances product visibility | Adjustable color temperature, uniform light distribution, low heat emission |

| Laboratory and Research | Illumination of workbenches and instrument stations | Provides precise, shadow-free lighting for detailed tasks | High CRI (color rendering index), flicker-free operation, long lifespan |

| Manufacturing and Assembly | Focused lighting on assembly lines and quality control stations | Improves accuracy, reduces errors, boosts productivity | Robust build quality, low power consumption, compatibility with industrial controls |

| Hospitality and Interior Design | Ambient and accent lighting under bars, cabinets, and counters | Creates appealing atmospheres; enhances guest experience | Customizable brightness, color tuning, remote control capability |

Commercial Kitchens

In commercial kitchens across Africa, South America, the Middle East, and Europe, best LED under cabinet lights are critical for task lighting at food prep and plating stations. These lights provide bright, shadow-free illumination that enhances food safety and hygiene by allowing staff to clearly see ingredients and surfaces. International buyers must prioritize moisture-resistant and energy-efficient fixtures that withstand humid environments and reduce operational costs. Easy installation options, including plug-in or hardwire, are also vital to accommodate diverse kitchen layouts and electrical standards.

Retail and Display

Retail environments benefit significantly from LED under cabinet lights to spotlight merchandise in display cabinets and shelves. This application draws customer attention and elevates product appeal through consistent, glare-free lighting. Buyers from regions like Turkey and Kenya should focus on sourcing lights with adjustable color temperatures to match various product colors and materials, along with low heat emission to protect delicate goods. Uniform light distribution and discreet fixture design enhance the retail ambiance without overwhelming the space.

Laboratory and Research Facilities

Laboratories and research centers require precision lighting to support detailed analytical work. LED under cabinet lights offer shadow-free, high-CRI illumination that ensures accurate color perception and reduces eye strain during extended tasks. For international B2B buyers, sourcing flicker-free, long-lasting fixtures with stable power requirements is essential to maintain consistent performance. Compliance with local safety and electrical standards is also a key consideration, especially in highly regulated environments.

Manufacturing and Assembly Lines

In manufacturing and assembly sectors, focused under cabinet lighting enhances visibility on production lines and quality control stations, minimizing errors and boosting throughput. Buyers should seek rugged, industrial-grade LED fixtures with low power consumption and compatibility with existing control systems. For markets in South America and the Middle East, durability against dust and vibrations and ease of maintenance are critical factors to ensure continuous operation in demanding industrial settings.

Hospitality and Interior Design

Hotels, restaurants, and luxury interiors use LED under cabinet lights to create ambient and accent lighting under bars, cabinetry, and counters, enriching the guest experience with customizable atmospheres. International buyers must evaluate options offering dimmable brightness, tunable color temperatures, and smart control features to adapt lighting scenes dynamically. Attention to aesthetic integration and energy efficiency is vital for hospitality venues aiming to reduce costs while maintaining high design standards.

Related Video: The 6 Best LED Light Strips For Under Cabinet Lighting

Strategic Material Selection Guide for best led under cabinet lights

When selecting materials for the best LED under cabinet lights, international B2B buyers must evaluate options based on durability, thermal management, corrosion resistance, and compliance with regional standards. The choice of material directly impacts product longevity, installation ease, and overall lighting performance, especially in diverse environments found across Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight with excellent thermal conductivity, which is critical for dissipating heat generated by LEDs. It offers good corrosion resistance, especially when anodized, and can withstand moderate temperature variations typical in indoor lighting applications.

Pros & Cons: Aluminum’s high thermal conductivity enhances LED lifespan by preventing overheating. It is relatively easy to manufacture into various profiles such as linear bars or housings, allowing for sleek, low-profile designs. However, raw aluminum can oxidize if not properly treated, and anodizing adds to production cost. Aluminum fixtures may also require grounding in certain electrical installations, adding complexity.

Impact on Application: Aluminum is ideal for linear LED fixtures and light bars where heat dissipation is crucial. Its corrosion resistance suits humid or coastal environments, common in parts of Africa and South America. For buyers in regions like Turkey or Europe, anodized aluminum complies well with ASTM and DIN standards, ensuring product reliability and market acceptance.

International Considerations: Buyers should verify anodizing quality and thickness to meet local corrosion resistance requirements, especially in coastal or industrial areas. Aluminum products often meet global standards such as ASTM B221 and EN 573, facilitating smoother import/export processes. Its recyclability also aligns with European Union environmental directives, appealing to eco-conscious markets.

Polycarbonate (PC)

Key Properties: Polycarbonate is a durable thermoplastic with high impact resistance and good transparency, making it excellent for diffusers or lens covers. It has moderate heat resistance but lower thermal conductivity compared to metals.

Pros & Cons: Polycarbonate offers excellent shatter resistance and can be molded into complex shapes, supporting innovative design. It is lighter and less expensive than metals but can yellow over time if exposed to UV light without proper additives. Its lower thermal conductivity requires careful integration with heat sinks to avoid LED overheating.

Impact on Application: Polycarbonate is commonly used for light covers and diffusers in under cabinet lighting, providing uniform light distribution and protection. In regions with high ambient temperatures like the Middle East or parts of Africa, UV-stabilized grades are essential to prevent degradation. Its electrical insulating properties simplify safety compliance in various markets.

International Considerations: Buyers should ensure polycarbonate components comply with flame retardancy standards such as UL 94 V-0 or EN 13501-1. In South America and Europe, certifications for food-safe or BPA-free materials may be required if lighting is used in kitchen environments. Suppliers offering UV-stabilized and anti-yellowing PC grades will provide better long-term performance.

Stainless Steel

Key Properties: Stainless steel provides excellent mechanical strength, corrosion resistance, and aesthetic appeal. It withstands high humidity and chemical exposure, making it suitable for harsh environments.

Pros & Cons: Stainless steel fixtures are highly durable and resistant to tarnishing or rust, ideal for premium or industrial-grade under cabinet lighting. However, stainless steel is heavier and more expensive to manufacture than aluminum or plastics. Machining and finishing processes add to lead times and costs, which may be a consideration for large-volume orders.

Impact on Application: Stainless steel is preferred for commercial kitchens, laboratories, or environments requiring stringent hygiene and durability standards. Its robustness suits buyers in coastal or industrial regions in Africa and the Middle East, where corrosion resistance is paramount. Stainless steel also supports compliance with hygiene standards like NSF/ANSI in food-related applications.

International Considerations: Buyers should specify grade (e.g., 304 or 316) based on corrosion resistance needs and regional environmental conditions. European and Turkish markets often require compliance with EN 10088 standards. The higher cost may be offset by longer product life and reduced maintenance, appealing to high-end or institutional buyers.

Aluminum Composite Panels (ACP)

Key Properties: ACPs consist of two aluminum sheets bonded to a non-aluminum core, combining rigidity with lightweight properties. They offer good thermal stability and corrosion resistance, depending on the core material.

Pros & Cons: ACPs allow for creative design flexibility and excellent surface finishes, including color coatings that resist fading. They are lighter than solid aluminum but may have lower thermal conductivity and require additional heat management solutions. Manufacturing complexity is higher due to lamination processes, impacting cost and lead time.

Impact on Application: ACPs are suitable for decorative under cabinet lighting housings where aesthetics and weight reduction are priorities. In markets with strict design codes or where visual appeal drives purchasing decisions (e.g., Europe, Turkey), ACPs provide a competitive edge. However, buyers must ensure that heat dissipation is adequately addressed to maintain LED performance.

International Considerations: Compliance with fire safety standards such as ASTM E84 or EN 13501 is critical, especially for core materials. Buyers in Africa and South America should verify local regulations on composite materials and consider potential import tariffs. ACP suppliers offering certifications and test reports will facilitate smoother procurement and market entry.

| Material | Typical Use Case for best led under cabinet lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Linear fixtures, heat sinks, light bars | Excellent thermal conductivity and corrosion resistance | Requires anodizing for corrosion resistance; moderate cost | Medium |

| Polycarbonate (PC) | Diffusers, lens covers, protective shields | High impact resistance and design flexibility | Lower thermal conductivity; potential UV yellowing | Low |

| Stainless Steel | Premium fixtures, commercial kitchens, harsh environments | Superior durability and corrosion resistance | Heavier and higher manufacturing cost | High |

| Aluminum Composite Panels (ACP) | Decorative housings, lightweight structural components | Lightweight with aesthetic versatility | Lower thermal conductivity; higher manufacturing complexity | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for best led under cabinet lights

Manufacturing and quality assurance of LED under cabinet lights are critical factors that international B2B buyers must understand to ensure product reliability, safety, and compliance with global standards. This insight is particularly valuable for buyers from Africa, South America, the Middle East, and Europe, where regulatory environments and market expectations vary. Below is a detailed overview of typical manufacturing stages, quality control protocols, and practical tips for verifying supplier quality.

Manufacturing Processes for LED Under Cabinet Lights

The production of high-quality LED under cabinet lights generally follows a structured process, encompassing four main stages:

1. Material Preparation

- Component sourcing: High-grade materials such as aluminum or steel for housing, LED chips (often from reputable brands like Cree or Nichia), electronic drivers, and PCBs (printed circuit boards) are procured. Buyers should inquire about suppliers’ sourcing policies to ensure traceability and consistency.

- Pre-inspection: Incoming raw materials undergo initial quality checks (Incoming Quality Control, IQC) to verify dimensions, material properties, and certifications (e.g., RoHS compliance for hazardous substances).

- Customization: For bespoke orders, materials may be tailored to specific requirements, such as heat dissipation coatings or custom LED wavelengths.

2. Forming and Fabrication

- Housing fabrication: Metals are cut, stamped, or extruded into the desired shapes, commonly linear bars or puck housings. Precision machining and CNC bending ensure tight tolerances.

- Surface treatment: Anodizing, powder coating, or painting is applied to enhance corrosion resistance, aesthetic appeal, and heat dissipation. This stage is crucial for durability, especially in humid or coastal environments common in Africa and the Middle East.

- Lens and diffuser molding: Optical components are injection molded using high-transparency plastics like PMMA or polycarbonate, designed to optimize light diffusion and reduce glare.

3. Assembly

- LED mounting: LEDs are surface-mounted on PCBs using automated pick-and-place machines to ensure precision and reduce human error.

- Driver integration: Electronic drivers and control modules (dimmable, tunable white, or smart controls) are integrated and wired.

- Sealing and waterproofing: For models requiring moisture resistance (IP44 or higher), silicone gaskets and sealants are applied.

- Connector and cable attachment: Power connectors (plug-in or hardwired) are installed based on customer specifications.

Illustrative Image (Source: Google Search)

4. Finishing and Packaging

- Functional testing: Each unit undergoes initial powering and lighting tests to check brightness, color temperature, and uniformity.

- Labeling and certification marks: Products are marked with relevant compliance logos and batch numbers for traceability.

- Protective packaging: Shockproof and moisture-resistant packaging materials are used to prevent damage during international shipping.

Quality Assurance and Control in LED Under Cabinet Light Production

Quality assurance is an ongoing process throughout manufacturing, designed to detect and eliminate defects early and ensure compliance with international and regional standards.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials and components before use.

- In-Process Quality Control (IPQC): Continuous inspection during assembly to monitor soldering quality, driver installation, and waterproof sealing.

- Final Quality Control (FQC): Comprehensive testing of finished products, including electrical safety, optical performance, and mechanical robustness.

Common Testing Methods

- Electrical safety tests: Insulation resistance, high-voltage withstand, and earth continuity tests ensure the product is safe for end-users.

- Photometric testing: Measurement of luminous flux (lumens), color rendering index (CRI), and correlated color temperature (CCT) using integrating spheres.

- Thermal testing: Evaluating heat dissipation performance through thermal imaging to prevent premature LED degradation.

- Ingress Protection (IP) rating tests: Verifying water and dust resistance according to IEC 60529 standards.

- Mechanical endurance: Vibration, drop, and impact tests to assess durability during transportation and installation.

Relevant International and Industry Standards

B2B buyers must prioritize suppliers who comply with internationally recognized standards to guarantee product quality and market acceptance.

- ISO 9001: This global quality management system standard demonstrates a supplier’s commitment to consistent manufacturing processes and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating compliance with EU safety, health, and environmental requirements.

- RoHS (Restriction of Hazardous Substances): Ensures the product is free from harmful materials like lead, mercury, and cadmium.

- UL Certification: Important for products intended for the North American market, certifying electrical safety.

- IEC Standards: Specifically IEC 60598 for luminaires and IEC 61347 for lamp control gear, covering performance and safety.

- Energy Efficiency Labels: Such as ENERGY STAR or EU energy labels, which may influence purchasing decisions in Europe and other markets.

- Additional Regional Certifications: Some markets, like Turkey, may require local certifications (e.g., TSE mark), and Middle Eastern buyers often look for SASO certification (Saudi Standards).

Verifying Supplier Quality: Practical Advice for International B2B Buyers

For buyers from regions such as Kenya, Turkey, Brazil, or the UAE, ensuring supplier quality goes beyond reviewing certificates. Here are actionable strategies:

1. Conduct Factory Audits

- On-site inspections: Physically visiting factories or hiring third-party auditors to evaluate production processes, equipment, and workforce expertise.

- Process audits: Confirm that the supplier follows standardized workflows consistent with ISO 9001.

- Social compliance audits: Verify ethical labor practices, which can be critical for corporate social responsibility.

2. Request Detailed QC Documentation

- Test reports: Ask for recent batches’ electrical safety, photometric, and environmental test results.

- Material certificates: Confirm that raw materials meet RoHS and other relevant standards.

- Production traceability: Ensure each batch can be traced back through production records.

3. Employ Third-Party Inspection Services

- Pre-shipment inspections (PSI): Independent verification of product quantity, quality, and packaging before shipment.

- Laboratory testing: Use accredited labs to validate critical parameters like lumen output and color temperature.

- Certification body verification: Confirm the authenticity of supplier certifications with issuing bodies.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

- Africa: Many African countries have emerging regulatory frameworks. Buyers should prioritize suppliers with CE, RoHS, and IEC compliance to ensure import acceptance and product safety.

- South America: Brazil and other countries often require INMETRO certification; buyers should check for compliance to avoid customs delays.

- Middle East: Countries like UAE and Saudi Arabia enforce SASO and G-Mark certifications. Products without these may face market access issues.

- Europe: The strictest region regarding compliance, demanding CE marking, RoHS, and often energy efficiency labels. Buyers should verify suppliers’ adherence to the latest EU directives (e.g., Ecodesign and REACH).

Summary for B2B Buyers

- Prioritize suppliers with established ISO 9001 certification and recognized industry marks (CE, RoHS, UL).

- Understand the full manufacturing cycle to assess supplier capabilities and identify potential quality risks.

- Insist on robust QC checkpoints and comprehensive testing, including electrical safety and photometric performance.

- Leverage factory audits and third-party inspections to mitigate risks, especially when sourcing from new suppliers.

- Be aware of regional certification requirements and ensure your supplier can provide compliant products for your target markets.

By integrating these manufacturing and quality assurance insights into your sourcing strategy, buyers can secure LED under cabinet lighting products that meet global standards, ensure long-term reliability, and satisfy the unique demands of diverse international markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for best led under cabinet lights Sourcing

Understanding the cost and pricing structure of LED under cabinet lights is essential for international B2B buyers aiming to optimize procurement strategies while ensuring product quality and competitive pricing. The pricing dynamics are influenced by multiple cost components and market factors, which vary depending on order volume, customization, and supplier location.

Key Cost Components in LED Under Cabinet Lights Manufacturing

-

Materials: The largest portion of the cost typically arises from raw materials such as high-quality LEDs, aluminum or plastic housings, drivers, and wiring. Premium materials, such as high-grade aluminum for heat dissipation or advanced LED chips (e.g., high CRI, tunable white), will increase costs but improve product longevity and performance.

-

Labor: Labor costs fluctuate significantly by manufacturing region. Countries with lower wages may offer cost advantages, but buyers should weigh this against potential quality control challenges.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with automated production lines can reduce overhead costs, passing savings to buyers.

-

Tooling and Setup: Custom fixture designs or specialized housing often require upfront tooling costs. These are generally amortized over the order quantity, so larger Minimum Order Quantities (MOQs) reduce per-unit tooling expenses.

-

Quality Control (QC): Rigorous QC processes—such as in-line testing, photometric testing, and certification compliance (e.g., CE, RoHS, UL)—add to costs but are critical for ensuring product reliability, especially in regulated markets like Europe.

-

Logistics and Import Fees: Freight, customs duties, taxes, and insurance contribute to the landed cost. Shipping mode (air vs. sea) and Incoterms (FOB, CIF, DDP) significantly affect the final price and risk allocation.

-

Supplier Margin: Suppliers typically apply a margin to cover profit and business risk. Margins vary based on supplier reputation, exclusivity of product, and competitive positioning.

Influencing Factors on Pricing

-

Order Volume and MOQ: Bulk orders substantially reduce per-unit costs due to economies of scale. Buyers from markets like Kenya or Turkey should negotiate MOQs aligned with their sales forecasts to balance inventory risk and cost savings.

-

Specifications and Customization: Custom features such as tunable color temperature, dimmability, smart controls, or specialized form factors increase production complexity and price. Standardized models generally offer better pricing and faster lead times.

-

Material Quality and Certifications: Products with international certifications command premium pricing but facilitate smoother market entry, especially in Europe and the Middle East where compliance is mandatory.

-

Supplier Location and Capabilities: Manufacturers in Asia often offer competitive pricing but may entail longer lead times and higher shipping costs. Sourcing from regional suppliers in Europe or the Middle East may reduce logistics overhead but at a higher unit cost.

-

Incoterms and Payment Terms: Understanding Incoterms is crucial. For example, FOB pricing excludes shipping, placing logistics responsibility on the buyer, whereas CIF includes freight and insurance. Negotiating favorable payment terms (e.g., LC, net 60) can improve cash flow.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Total Cost of Ownership (TCO), Not Just Unit Price: Consider warranty, energy efficiency, and maintenance costs. Higher upfront costs for premium LEDs often result in longer life spans and lower energy bills, reducing TCO.

-

Leverage Volume Discounts and Flexible MOQs: Even small buyers should explore group buying or partnerships to achieve better pricing tiers.

-

Factor in Logistics and Customs: Work with freight forwarders familiar with your region’s import regulations to avoid unexpected delays and costs.

-

Request Samples and Factory Audits: Especially important for buyers in emerging markets to verify quality before committing to large orders.

-

Clarify After-Sales Support and Warranty Terms: Reliable supplier support reduces risks related to defective products and returns.

-

Understand Pricing Fluctuations: Raw material costs (notably for electronic components and metals) can be volatile. Locking in prices through contracts or forecasting helps mitigate risk.

-

Choose Suppliers with Relevant Certifications: For buyers in Europe and the Middle East, insist on CE, RoHS, and other relevant marks to ensure compliance and reduce legal risks.

Indicative Pricing Overview

While exact pricing varies widely based on specifications and volume, typical LED under cabinet light units range from approximately $10 to $40 per unit at wholesale levels for standard models. Customized or certified products may command prices upwards of $50 or more per unit. Buyers should treat these figures as indicative and engage suppliers directly for quotes tailored to their order profiles and logistics requirements.

By carefully analyzing cost drivers and engaging in strategic negotiations, international B2B buyers—especially in regions like Africa, South America, the Middle East, and Europe—can secure competitively priced, high-quality LED under cabinet lighting solutions that align with their market needs and regulatory environments.

Spotlight on Potential best led under cabinet lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘best led under cabinet lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for best led under cabinet lights

Critical Technical Properties for LED Under Cabinet Lights

When sourcing LED under cabinet lights internationally, understanding key technical specifications is crucial for ensuring product quality, compatibility, and longevity. Below are essential properties that B2B buyers should prioritize:

-

Luminous Efficacy (Lumens per Watt)

This measures the light output relative to power consumption. Higher efficacy means brighter light with lower energy usage, which translates to cost savings and sustainability benefits. For commercial buyers, selecting fixtures with at least 80-100 lumens per watt ensures efficient illumination with reduced operational costs. -

Color Temperature (Kelvin, K)

Defines the light color tone, ranging from warm (2700K) to cool daylight (5000K+). Accurate color temperature is important to match the ambiance and task requirements. For kitchens and workspaces, 3000K to 4000K is commonly preferred for a neutral, natural light. Buyers should verify CCT (Correlated Color Temperature) consistency across batches to maintain uniformity in installations. -

Material and Build Quality

Durable materials such as aluminum housing and tempered glass or polycarbonate diffusers ensure heat dissipation and resistance to wear, moisture, and corrosion. In regions with high humidity or variable climates (e.g., coastal Africa or Middle East), IP-rated fixtures (e.g., IP44 or higher) offer protection against dust and splashes, enhancing product lifespan. -

Power Supply and Voltage Compatibility

Understanding whether fixtures operate on line voltage (e.g., 120V or 230V) or low voltage (12V/24V) systems is vital for integration with existing electrical infrastructure. Low voltage systems often require drivers but offer safer installation and flexibility. Buyers in Europe and South America must confirm voltage standards and compatibility to avoid costly retrofit or compliance issues. -

Dimmability and Control Features

Dimmable LED lights provide energy savings and adaptable ambiance. Confirm compatibility with dimming systems (e.g., TRIAC, 0-10V, or smart controls) especially for commercial or hospitality projects. Advanced features such as tunable white or smart lighting integration can add value but may increase complexity and cost. -

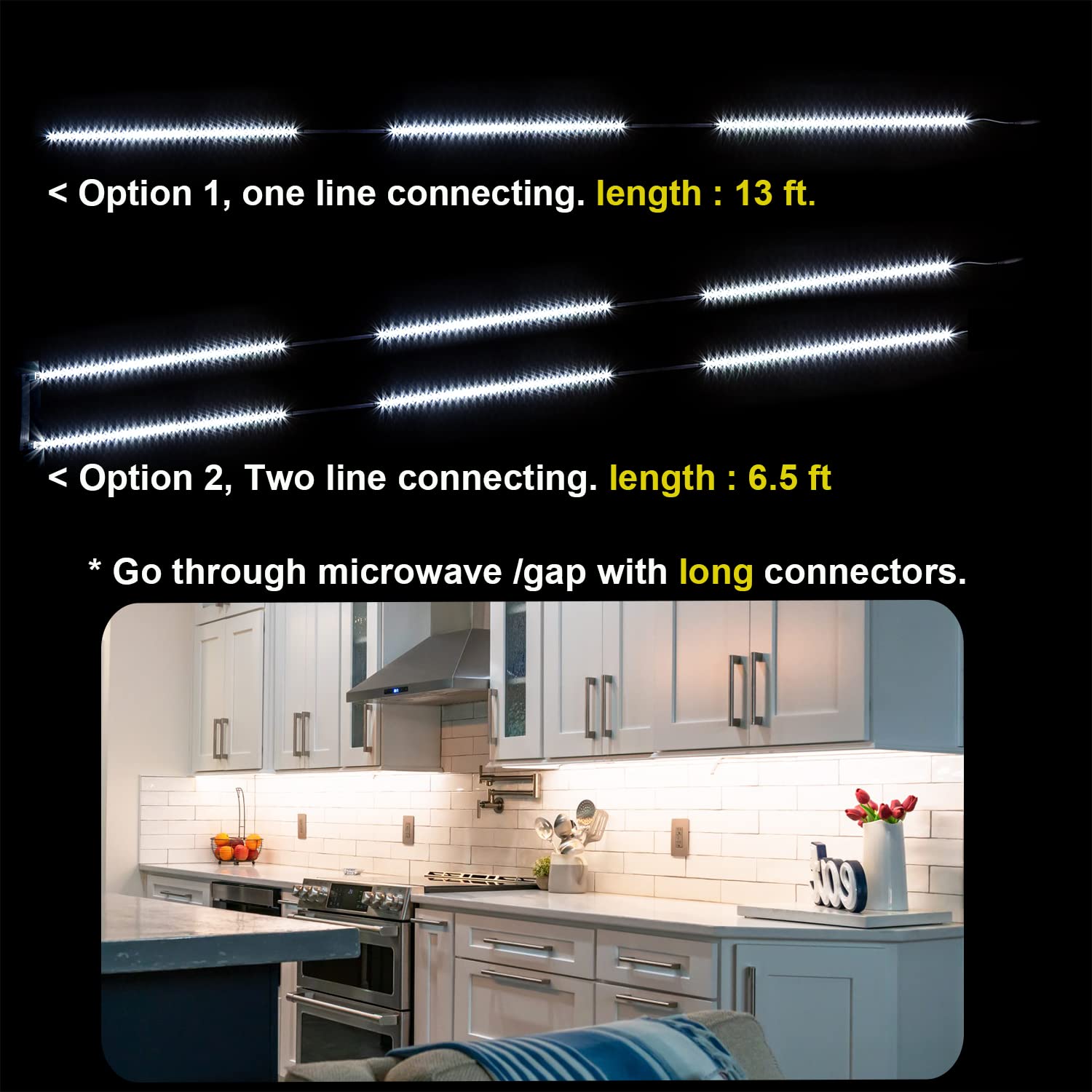

Installation Method and Form Factor

Fixtures vary from linear bars, puck lights, tape strips, to modular systems. Ease of installation (plug-in vs. hardwired) affects labor costs and project timelines. Buyers should assess mounting options (adhesive, screws, magnetic) and linkage capabilities (daisy-chaining) to optimize installation efficiency and maintenance access.

Key Industry and Trade Terms for LED Under Cabinet Lighting Procurement

Navigating international B2B transactions requires familiarity with common trade terms and industry jargon that govern purchasing, logistics, and supplier relationships:

-

OEM (Original Equipment Manufacturer)

Refers to a manufacturer that produces products or components that are purchased by another company and retailed under that company’s brand. For buyers seeking private labeling or customized LED lighting solutions, partnering with OEMs offers control over specifications and branding without investing in manufacturing facilities. -

MOQ (Minimum Order Quantity)

The smallest amount of product units a supplier is willing to sell in one order. Understanding MOQ is essential for inventory planning and budgeting, especially for small or emerging businesses in markets like Kenya or Turkey where upfront capital may be limited. -

RFQ (Request for Quotation)

A formal process where buyers solicit detailed pricing and terms from multiple suppliers based on specified product requirements. Issuing precise RFQs helps international buyers compare offers transparently and negotiate better terms. -

Incoterms (International Commercial Terms)

Standardized trade terms defined by the International Chamber of Commerce (ICC) that clarify delivery responsibilities, risk transfer, and cost allocation between buyers and sellers. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Selecting the right Incoterm affects logistics planning and total landed cost. -

Lead Time

The duration from order placement to product delivery. For LED lighting projects with tight schedules, negotiating shorter lead times or partial shipments can mitigate delays. -

IP Rating (Ingress Protection)

A standard that classifies the degree of protection against solid objects and liquids. For under cabinet lights, IP44 or higher is recommended in humid or dusty environments to ensure durability and safety compliance.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, reduce procurement risks, and secure LED under cabinet lighting solutions that meet functional, aesthetic, and regulatory requirements across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the best led under cabinet lights Sector

Market Overview & Key Trends

The global market for LED under cabinet lights is experiencing steady growth driven by rising demand for energy-efficient, versatile lighting solutions across residential, commercial, and hospitality sectors. International B2B buyers, especially from emerging and transitional economies in Africa (e.g., Kenya), South America, the Middle East, and Europe (e.g., Turkey), are increasingly prioritizing LED lighting due to its long lifespan, low power consumption, and ease of installation. These regions are witnessing urbanization and modernization of infrastructure, prompting an uptick in kitchen and workspace renovations where under cabinet lighting plays a critical functional and aesthetic role.

Key market dynamics include a shift towards smart lighting integration, with many suppliers offering IoT-enabled LED fixtures that can be controlled remotely or programmed for different lighting ambiances. This trend appeals to tech-savvy buyers and sectors focused on smart building standards. Additionally, modular designs like plug-and-play fixtures and customizable light bars or puck lights allow for flexible sourcing and installation, reducing lead times and installation costs—a major advantage for B2B buyers managing large-scale projects.

From a sourcing perspective, buyers in Africa and South America often prioritize suppliers capable of delivering cost-effective, durable products that can withstand varying power supply conditions. In the Middle East and Europe, compliance with strict safety and performance standards (such as CE marking in Europe) is a critical procurement consideration. Furthermore, the rise of low-voltage LED systems supports safer installations in areas with unstable electrical infrastructure, a factor that resonates strongly in emerging markets.

International procurement teams should also monitor the impact of global supply chain disruptions, which have highlighted the need for diversified supplier bases, including local and regional manufacturers. Strategic partnerships with manufacturers offering quick turnaround and technical support are increasingly valued, particularly when sourcing LED under cabinet lighting for commercial fit-outs and renovation projects.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable factor in the procurement of LED under cabinet lights, especially for buyers aiming to align with global environmental goals and corporate social responsibility (CSR) mandates. LED technology inherently offers significant energy savings over traditional incandescent or fluorescent lighting, often reducing electricity consumption by up to 80%. This efficiency translates into lower operational costs and a smaller carbon footprint for end-users.

Beyond energy efficiency, B2B buyers are placing greater emphasis on ethical sourcing and supply chain transparency. This includes verifying that manufacturers adhere to fair labor practices and avoid materials linked to environmental degradation or conflict regions. Certifications such as RoHS (Restriction of Hazardous Substances), Energy Star, and TÜV Rheinland provide assurance that products meet stringent environmental and safety standards, which is crucial for buyers in regulated markets like the EU and the Middle East.

Material sustainability is another focal point. Buyers are increasingly seeking fixtures that use recyclable aluminum housings, non-toxic LED chips, and halogen-free wiring to minimize environmental impact at the product’s end of life. Suppliers offering take-back or recycling programs for obsolete fixtures add value and demonstrate commitment to circular economy principles.

For regions like Africa and South America, where environmental regulations may be evolving, partnering with suppliers who proactively implement green manufacturing processes and provide compliance documentation can give buyers a competitive edge. In addition, sourcing from manufacturers with carbon-neutral operations or those using renewable energy contributes to broader sustainability goals and enhances brand reputation in global markets.

Evolution of LED Under Cabinet Lighting: A Brief Overview

The evolution of under cabinet lighting mirrors the broader advancements in LED technology over the past two decades. Initially dominated by incandescent and fluorescent options, under cabinet lighting saw a paradigm shift with the advent of high-efficiency LED fixtures that offered longer lifespans, reduced heat output, and improved light quality. Early LED systems were often bulky and lacked color temperature flexibility, but modern designs now feature slim profiles, tunable white light options, and seamless integration with smart home systems.

For B2B buyers, this evolution has translated into a broader product portfolio that caters to diverse applications—from task lighting in commercial kitchens to accent lighting in luxury retail environments. The development of plug-and-play and daisy-chainable fixtures has simplified installation and maintenance, reducing total cost of ownership. Today’s LED under cabinet lighting solutions not only enhance functionality and aesthetics but also align with global energy codes and sustainability frameworks, making them a strategic procurement choice for forward-looking businesses worldwide.

Related Video: TOP 5 BEST UNDER-CABINET LIGHTING – Under Cabinet Lights Review (2023)

Frequently Asked Questions (FAQs) for B2B Buyers of best led under cabinet lights

-

How can I effectively vet LED under cabinet light suppliers from international markets like Africa, South America, the Middle East, and Europe?

Start by verifying the supplier’s business license, certifications (such as ISO 9001 and CE), and export history. Request samples to assess product quality and consistency. Conduct background checks through trade platforms (e.g., Alibaba, Global Sources) and seek references or reviews from other international buyers. For regions like Kenya or Turkey, confirm that suppliers comply with local import regulations and standards. Engaging third-party inspection services before shipment can further mitigate risks and ensure supplier reliability. -

Is it possible to customize LED under cabinet lights in terms of size, color temperature, and installation type for different regional markets?

Yes, many manufacturers offer customization options including fixture length, color temperature (2700K to 6000K), dimmable features, and installation methods (plug-in, hardwire). For international buyers, specifying regional voltage standards (e.g., 220V for Europe, 110V for some African countries) is critical. Custom branding or packaging can also be arranged. Early communication on customization requirements helps avoid production delays and ensures compliance with local market preferences and regulations. -

What are typical minimum order quantities (MOQs) and lead times for LED under cabinet lights when sourcing internationally?

MOQs vary widely based on supplier capacity and product type but commonly range from 100 to 500 units per SKU. Lead times typically span 4 to 8 weeks, factoring in production and quality inspections. For buyers in emerging markets, longer lead times may be necessary due to shipping and customs clearance. Negotiating flexible MOQs or phased deliveries can help manage inventory risk. Confirm payment terms upfront to align with production schedules and reduce delays. -

Which quality assurance certifications should I insist on to ensure LED under cabinet lights meet international standards?

Insist on certifications such as CE (Europe), RoHS (restriction of hazardous substances), UL or ETL (North America), and ISO 9001 for quality management. For buyers in Africa and the Middle East, compliance with local electrical safety standards (e.g., SONCAP in Nigeria) is essential. Request test reports from accredited labs to verify lumen output, energy efficiency, and safety parameters. These certifications reduce liability and facilitate smoother customs clearance in your target markets. -

What payment methods are most secure and commonly accepted for international B2B transactions of LED under cabinet lighting?

Letters of Credit (LC) offer high security for both buyer and supplier by ensuring payment only upon compliance with contract terms. Other common methods include Telegraphic Transfer (T/T) with partial upfront payment and balance after inspection, and Escrow services via trade platforms. For new suppliers, start with smaller orders and safer payment methods to build trust. Always confirm payment terms in your contract and consider currency exchange risks when dealing with multiple international currencies. -

How should I plan logistics and shipping for LED under cabinet lights to minimize costs and avoid delays?

Choose shipping methods based on order size and urgency: sea freight for large volumes to reduce costs, air freight for urgent deliveries. Partner with freight forwarders experienced in your destination markets (e.g., Nairobi, Istanbul) to handle customs clearance efficiently. Consolidate shipments where possible to optimize cost. Ensure packaging is robust to prevent damage, and verify Incoterms (e.g., FOB, CIF) clearly define responsibility for freight and insurance to avoid disputes. -

What steps can I take to resolve disputes or quality issues with overseas LED under cabinet light suppliers?

Establish clear contractual terms covering quality standards, inspection procedures, and remedies for non-compliance. Use third-party inspection agencies for pre-shipment checks. In case of disputes, attempt amicable resolution through direct negotiation or mediation. If unresolved, leverage trade dispute resolution mechanisms such as arbitration clauses or engage local chambers of commerce. Maintaining detailed communication records and contracts in English and local languages supports your case. -

Are there specific considerations for sourcing LED under cabinet lights for markets with varying electrical standards and climate conditions?

Absolutely. Verify that products are rated for the correct voltage and frequency (e.g., 220-240V/50Hz in Europe and much of Africa, 110-120V/60Hz in some South American countries). Check IP ratings for moisture and dust resistance if lights will be used in humid or dusty environments. Some suppliers offer LED products with wider operating temperature ranges suitable for Middle Eastern heat or tropical climates. These technical adaptations ensure longevity and reduce warranty claims in diverse markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for best led under cabinet lights

The procurement of LED under cabinet lights offers significant opportunities for international B2B buyers aiming to enhance commercial and residential lighting solutions. Key considerations such as fixture type, power source, installation method, and energy efficiency directly impact both product performance and total cost of ownership. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that provide a diverse portfolio—including linear fixtures, puck lights, and LED tape systems—to meet varied market demands and installation environments.

Strategic sourcing in this category involves partnering with manufacturers who offer not only quality and compliance with regional standards but also flexible logistics and after-sales support. Opting for modular, energy-efficient products with options for plug-in or hardwired installations can reduce installation complexity and operational costs, essential for emerging and mature markets alike. Furthermore, sourcing from suppliers with scalable production capacity ensures readiness for fluctuating demand in diverse international markets.

Illustrative Image (Source: Google Search)

Looking ahead, the LED under cabinet lighting market will continue to evolve with smart lighting integration and enhanced customization capabilities. International buyers are encouraged to leverage strategic partnerships and invest in technologies that support sustainability goals and smart home trends. Proactively engaging with reliable suppliers now will position businesses to capitalize on growing demand and emerging applications across regions such as Kenya, Turkey, and beyond.