Article Contents

Industry Insight: Lumens Vs K

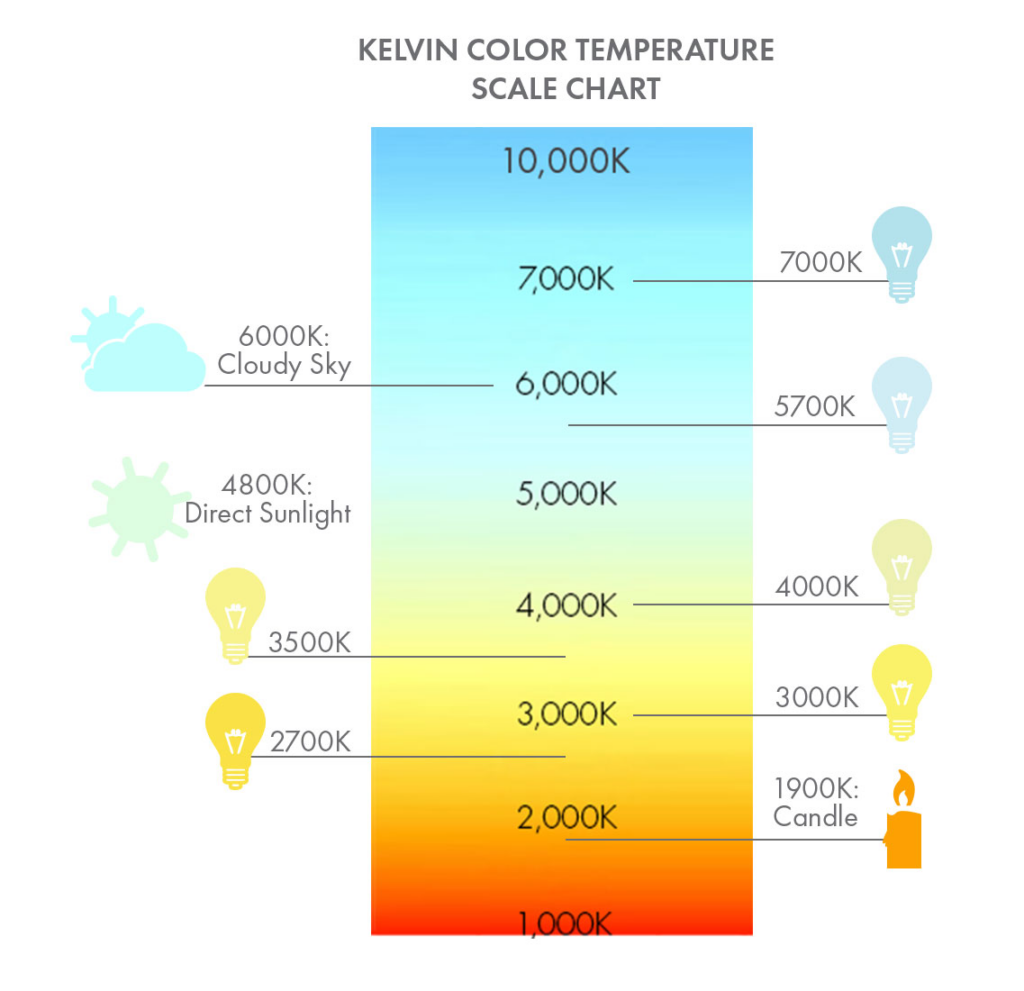

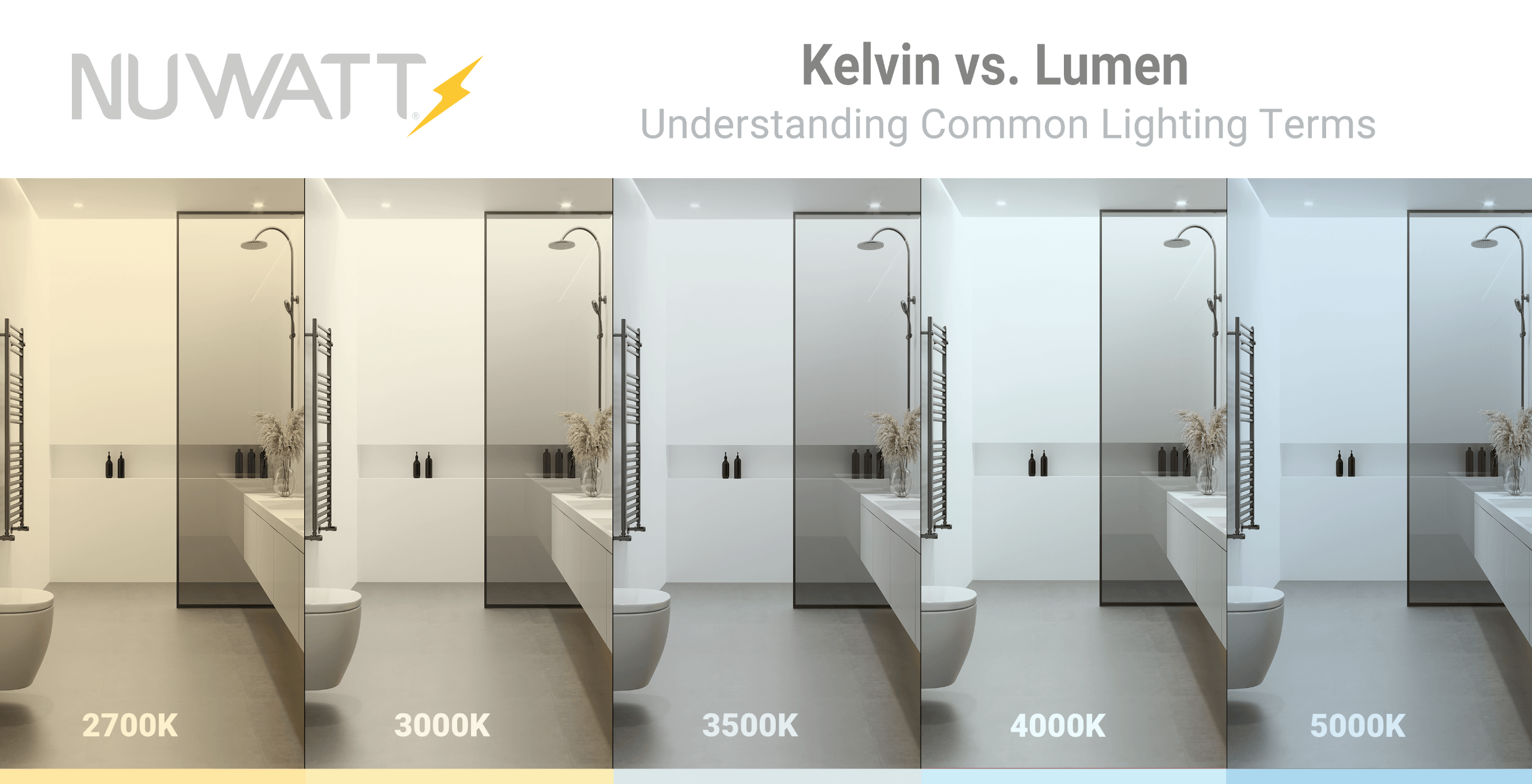

In the commercial and industrial lighting sectors, understanding the distinction between lumens and color temperature (measured in Kelvins, or K) is critical to achieving optimal illumination for functionality, safety, and energy efficiency. Lumens quantify the total visible light output of a fixture—essentially its brightness—while Kelvin values define the hue of that light, ranging from warm white (2700K–3000K) to cool daylight (5000K–6500K). In industrial environments such as warehouses, manufacturing plants, and distribution centers, higher lumens and cooler color temperatures are typically preferred to enhance visibility and alertness. Conversely, commercial spaces like retail stores or office lobbies may balance brightness with warmer tones to create a welcoming atmosphere. Regardless of application, compliance with international safety and performance standards such as ETL and CE certification ensures reliability, electrical safety, and market accessibility.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been a trusted innovator in LED lighting solutions tailored for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC delivers high-lumen, thermally efficient luminaires that meet rigorous ETL and CE standards, combining performance with long-term durability. By prioritizing intelligent lighting design and regulatory compliance, Beauty STC continues to empower facilities worldwide with solutions that maximize visibility, reduce energy consumption, and support sustainable operations.

Technical Specs & Certifications

Lumens measure total visible light output while Kelvin (K) denotes correlated color temperature (CCT), indicating the light’s warmth or coolness (e.g., 2700K warm white, 4000K neutral, 6500K daylight). These are distinct photometric properties; lumens quantify brightness, Kelvin defines appearance. The critical efficiency metric is Lumens per Watt (lm/W), representing efficacy—how much light is produced per unit of electrical power. At Beauty STC, our LED luminaires consistently achieve 150–180 lm/W in standard CCT ranges (3000K–4000K), optimized through high-efficiency Samsung/Lumileds chips, precision thermal management via extruded aluminum heatsinks, and >92% efficient Mean Well drivers. Efficacy decreases slightly at warmer CCTs (e.g., 2700K) due to phosphor conversion losses, but our SpectraMax technology minimizes this gap, maintaining >140 lm/W even at 2700K.

For color fidelity, we prioritize CRI (Color Rendering Index) >90 across all architectural and retail product lines, verified via Konica Minolta CA-410 spectroradiometers. Crucially, we exceed basic CRI requirements by ensuring R9 (saturated red) >50 and incorporating TM-30-15 metrics (Rf >90, Rg ~100) to guarantee natural, vibrant color rendering—essential for applications like retail displays or healthcare. This is achieved through violet-pump LED platforms with multi-phosphor blends, rigorously binned to ±5 SDCM for consistency. Beauty STC’s quality control mandates third-party LM-79/LM-80 testing, with all high-CRI products undergoing 1,000-hour lumen maintenance validation to prevent spectral shift.

IP (Ingress Protection) ratings define resistance to dust and moisture, unrelated to photometric performance but critical for environmental durability. Beauty STC luminaires are engineered to stringent IP standards: IP65 for outdoor wall packs (dust-tight, low-pressure water jets), IP66 for stadium lights (powerful water jets), and IP67 for underground/burial-grade fixtures (1m submersion for 30 minutes). Our sealed optical chambers use silicone gaskets rated for -40°C to 85°C, with conformal-coated PCBs to prevent corrosion. Unlike competitors, we validate IP ratings per IEC 60529 via independent labs—not just design targets—and extend warranties to 7 years for IP66+ fixtures, reflecting confidence in our thermal and sealing integrity.

Beauty STC’s quality differentiation lies in systems engineering: we integrate lm/W, CRI, and IP performance without compromise. Our ISO 9001-certified processes include 100% end-of-line photometric testing, automated solder paste inspection, and accelerated lifecycle testing (85°C/85% RH for 1,000 hours). This ensures luminaires sustain >90% lumen maintenance (L90) at 50,000 hours even in harsh environments, with zero field failures attributed to color shift or ingress—proven in global deployments from Riyadh retail malls to Singapore MRT stations. We deliver not just specifications, but guaranteed real-world performance.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern LED lighting production facility designed to support high-volume manufacturing with a strong emphasis on quality control and technical precision. Strategically located in the Jiangmen industrial zone, the facility benefits from streamlined logistics and access to a skilled manufacturing workforce, enabling efficient operations for both domestic and international markets.

The factory is equipped with advanced SMT (Surface Mount Technology) production lines, which are critical for the accurate and reliable assembly of LED circuit boards. These SMT machines are automated and feature high-speed placement heads, precision optical alignment systems, and real-time quality inspection capabilities. This ensures consistent soldering and component placement, which directly impacts the performance and longevity of LED lighting products. The integration of automated optical inspection (AOI) systems further enhances product reliability by detecting defects early in the production process.

To ensure product durability and performance consistency, the Jiangmen facility conducts comprehensive aging tests. Completed LED luminaires undergo extended burn-in periods—typically 48 to 72 hours—under controlled thermal and electrical conditions that simulate real-world usage. During these tests, parameters such as lumen output, color temperature stability, and driver performance are continuously monitored. This rigorous aging process allows Beauty STC to identify and eliminate early-life failures, significantly improving field reliability and customer satisfaction.

Beauty STC also offers robust OEM (Original Equipment Manufacturing) capabilities, including customized solutions for key photometric specifications such as lumens versus Kelvin (lumens vs. K). This means the company can tailor LED products to meet specific client requirements regarding light output (measured in lumens) and color temperature (measured in Kelvin), ranging from warm white (2700K–3000K) to cool daylight (5000K–6500K). These customizations are supported by in-house optical design tools, thermal modeling, and photometric testing using integrating spheres and goniophotometers. Clients can therefore receive fully branded, performance-verified lighting solutions that align precisely with their application needs—whether for residential, commercial, or industrial use.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to engineering excellence, scalable manufacturing, and customer-driven innovation in the competitive LED lighting market.

Application Scenarios

Lumens and Kelvin (K) are distinct lighting metrics that must be considered together for effective design in commercial spaces, not as competing choices. Lumens measure total visible light output (brightness), while Kelvin denotes color temperature (warmth to coolness of white light). Confusing them leads to poor lighting outcomes. Below is application guidance for hotels, malls, and offices, followed by critical installation tips.

Hotels require layered lighting strategies where lumens and Kelvin serve specific experiential goals. In lobbies and restaurants, use 2700K–3000K Kelvin for warm, inviting ambience, but ensure sufficient lumens for safety and task visibility—300–500 lux on flooring and 500–750 lux at dining tables. Guest rooms need tunable systems: 3000K Kelvin for relaxation in the evening (200–300 lux ambient), shifting to 4000K Kelvin for morning readiness with higher lumen output (300–400 lux at desks). Bathrooms demand 3000K Kelvin to render skin tones accurately, paired with high lumen density (500–750 lux) around mirrors. Corridors require 350–500 lux at floor level with 3000K Kelvin to balance safety and comfort, avoiding the clinical feel of higher Kelvin temperatures.

Malls prioritize visual merchandising and customer comfort through strategic lumen and Kelvin combinations. General circulation areas need uniform illumination of 500–750 lux with 3500K–4000K Kelvin for alertness and spatial clarity. Retail storefronts and high-end boutiques use 3000K Kelvin to enhance warm-toned products like textiles or wood, but require intense, focused lumens—1000–2000 lux on displays—to create visual drama without glare. Jewelry or tech stores benefit from 4000K–4500K Kelvin to emphasize metallics and screens, coupled with precise high-lumen spotlights (1500+ lux) on key items. Food courts should maintain 4000K Kelvin for freshness perception, with lumen levels of 300–400 lux at seating to encourage lingering, while service counters need 750+ lux for safety.

Offices must optimize for productivity and well-being, making Kelvin and lumen balance non-negotiable. Open-plan workspaces require 3500K–4000K Kelvin to support concentration, with a minimum of 500 lux on desks—achieved through high-lumen indirect/direct fixtures to minimize glare. Task lighting should supplement with adjustable 4000K Kelvin sources (300–500 lux focused). Conference rooms need tunable systems: 4000K Kelvin at 500 lux for presentations, shifting to 3000K Kelvin at 300 lux for relaxed discussions. Circulation zones require 300 lux with 3500K Kelvin for consistent visual flow. Critical error: avoiding overly cool Kelvin temperatures (e.g., 5000K+) which increase eye strain despite high lumen output.

Installation must address thermal, optical, and control challenges. Always verify fixture thermal management—recessed downlights in insulated ceilings require IC-rated housings and 50mm clearance to prevent lumen depreciation. Position linear fixtures in offices parallel to desks to avoid screen glare, maintaining a 0.8–1.0 uniformity ratio for visual comfort. In malls, align track lighting optics precisely with display heights; a 24° beam angle at 3m height typically delivers optimal lumen density on merchandise. For hotels, dimming systems must support 1–10V or DALI protocols calibrated to maintain Kelvin consistency during dimming—test at 10%, 50%, and 100% output. Ensure all emergency lighting complies with local codes, providing 1 lux minimum on exit paths with 2700K–3000K to avoid disorientation. Finally, conduct on-site lux meter validation: measure at multiple points during commissioning to confirm lumen delivery matches calculations, adjusting fixture spacing or output as needed. Neglecting these steps risks uneven illumination, premature failure, and occupant dissatisfaction.

Why Choose Beauty STC Lighting

Discover the difference between lumens and Kelvin and how they impact your lighting performance. At Beauty STC, we specialize in high-quality LED solutions tailored to your project needs. Partner with us to ensure precision, efficiency, and reliability in every luminaire. Contact our team today at [email protected] to discuss your requirements and elevate your lighting projects with expert support and innovative technology.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.