Article Contents

Industry Insight: Light Strip Connectors

In the evolving landscape of commercial and industrial lighting, seamless integration and reliability are paramount—particularly when it comes to flexible LED light strip systems. Light strip connectors have emerged as critical components in these installations, enabling quick, secure, and consistent electrical connections between LED strips without the need for soldering or complex wiring. As facility managers, lighting designers, and contractors demand faster installation times and long-term durability, the performance and certification of these connectors have become increasingly important. Industry standards such as ETL and CE mark a product’s compliance with rigorous safety and electromagnetic compatibility requirements, ensuring suitability for use in North American and international commercial environments.

At Beauty (STC) Manufacturing Co., Ltd., established in 1998, we have built a reputation as a trusted innovator in LED lighting solutions for industrial and commercial applications. With over two decades of engineering expertise, Beauty STC specializes in high-performance connectors and accessories designed to meet the demanding needs of large-scale lighting projects. Our light strip connectors are engineered for precision, durability, and code-compliant safety, supporting reliable performance in warehouses, manufacturing facilities, retail spaces, and beyond. As the industry moves toward modular and scalable lighting systems, Beauty STC continues to deliver the connectivity solutions that power efficient, future-ready environments.

Technical Specs & Certifications

Light strip connectors themselves do not possess lumens per watt (Lm/W) values or Color Rendering Index (CRI) specifications. These photometric and color quality metrics are inherent properties of the LED light strips they connect, not the connectors. Connectors are passive electrical and mechanical interfaces designed to join segments of LED tape or link strips to power sources and controllers. Their primary function is to ensure reliable electrical continuity and physical integrity without degrading the performance of the LED system they serve. Confusing connector specifications with LED strip specifications is a common misconception; the connector’s role is to preserve the strip’s designed output.

Connectors critically impact system performance by maintaining the electrical integrity required for the LED strip to operate at its specified efficiency and color quality. Poorly designed connectors introduce resistance, leading to voltage drop, localized heating, and reduced lumen output along the strip. This directly undermines the Lm/W efficiency of the entire installation, as energy is wasted as heat at the connection point rather than converted to light. Similarly, inconsistent power delivery can cause color shift in LEDs, potentially lowering the effective CRI below the strip’s rated value (>90) in connected sections. Beauty STC addresses this through rigorous connector design, utilizing high-conductivity copper alloys with thick gold plating on contact points to minimize resistance and prevent oxidation. Our connectors are engineered to handle the full current rating of high-density LED strips without significant voltage drop, ensuring the connected system consistently delivers the strip’s specified lumen output and maintains CRI >90 performance across all junctions.

IP (Ingress Protection) ratings are highly relevant for light strip connectors, especially in demanding environments. The IP rating of a connector must match or exceed the rating of the LED strip it joins to maintain the overall system’s environmental protection. Beauty STC offers connectors across a comprehensive IP spectrum. IP20 connectors are suitable for dry, indoor applications with no dust or moisture exposure. For damp locations like kitchens or bathrooms, IP65-rated connectors provide robust protection against low-pressure water jets and complete dust ingress prevention. For outdoor use, submerged applications, or high-moisture industrial settings, Beauty STC’s IP67 and IP68 connectors are essential. IP67 withstands temporary immersion up to 1 meter for 30 minutes, while IP68 signifies protection against continuous submersion beyond 1 meter, validated through extended testing beyond standard requirements. All Beauty STC IP-rated connectors utilize precision-molded silicone gaskets and robust housings that form watertight seals upon proper installation, ensuring the integrity of the entire lighting system’s environmental rating.

Beauty STC’s commitment to quality is evident in every connector we manufacture. We prioritize materials and construction that prevent common failure points. Our connectors feature corrosion-resistant, high-purity copper contacts with industry-leading gold plating thickness, significantly reducing contact resistance and eliminating the voltage drop that plagues cheaper alternatives. This directly safeguards the lumen maintenance and efficiency (Lm/W) of the connected LED strips. The silicone used in our IP-rated gaskets is UV-stable and maintains flexibility across extreme temperature ranges (-40°C to +85°C), preventing seal degradation and ensuring long-term ingress protection. Rigorous in-house testing, including 100% continuity checks, high-potential (hi-pot) dielectric strength testing, and accelerated lifecycle testing under thermal cycling and humidity, guarantees reliability. Beauty STC connectors are not mere accessories; they are engineered components critical to preserving the photometric performance, color fidelity, and environmental resilience of the entire LED lighting installation, reflecting our dedication to delivering systems that perform as specified for the lifetime of the product.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is equipped with advanced surface mount technology (SMT) production lines featuring high-precision SMT machines from leading manufacturers. These machines ensure accurate placement of components on printed circuit boards (PCBs) used in LED lighting products, including light strips. The SMT lines are fully automated, supporting high-volume production with consistent quality, minimal defects, and efficient throughput.

The Jiangmen factory incorporates comprehensive quality assurance protocols, including rigorous aging tests for all LED light strip products. Units undergo extended operational testing under varied thermal and electrical conditions to verify performance, luminous stability, and longevity. This aging process typically spans 24 to 72 hours, allowing the team to identify and eliminate early failures, thereby ensuring product reliability before shipment.

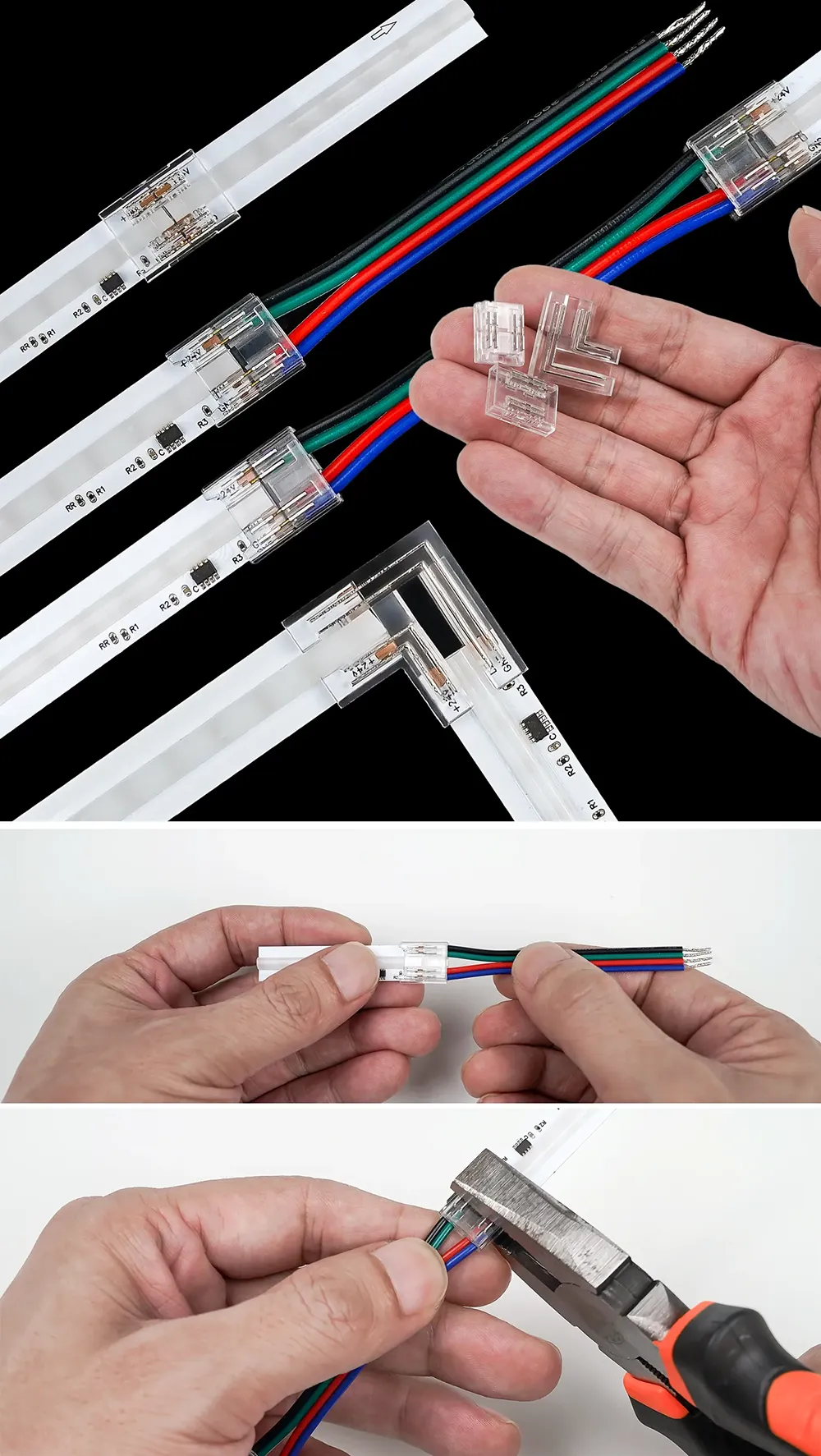

Beauty STC has strong OEM capabilities, particularly for light strip connectors and related accessories. The company supports custom designs, branding, packaging, and engineering modifications to meet client specifications. This includes the development and production of proprietary connectors that ensure secure, durable, and user-friendly installation for LED strip systems. With in-house R&D, tooling, and molding resources, the factory can rapidly prototype and scale production for OEM partners across residential, commercial, and industrial lighting markets. The combination of automation, quality control, and flexible manufacturing makes the Jiangmen facility well-suited for serving global lighting brands with tailored solutions.

Application Scenarios

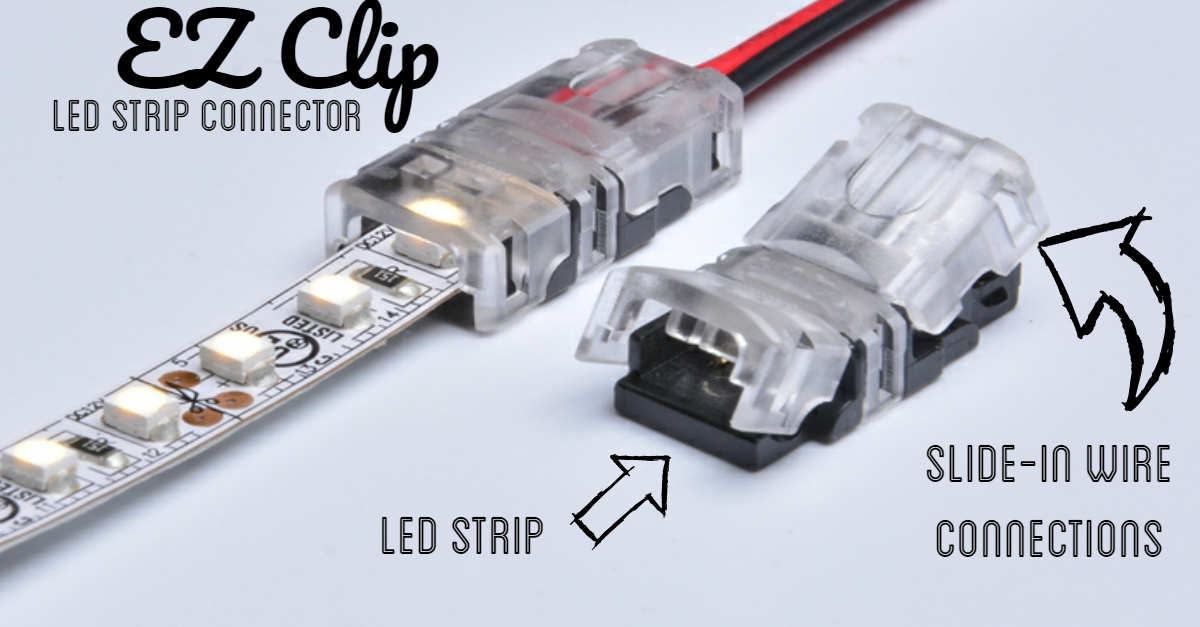

Light strip connectors serve as essential components for extending, branching, or repairing LED strip lighting systems across commercial environments, eliminating the need for time-consuming soldering while maintaining electrical integrity and light quality. Their strategic use is critical in hotels, malls, and offices where flexible, scalable, and reliable lighting solutions are paramount. In hotels, connectors are indispensable for creating seamless cove lighting in lobbies to enhance architectural features, under-cabinet illumination in minibars or hospitality suites for ambient warmth, and linear accents along corridors for wayfinding. They enable precise customization in guest room headboards or bathroom vanities where dimmable, low-voltage strips require easy installation and future serviceability without damaging drywall. Malls leverage connectors extensively for dynamic retail displays, allowing retailers to rapidly reconfigure illuminated signage, shelving highlights, or feature walls during seasonal changes; they are equally vital for connecting long runs of facade or canopy lighting where voltage drop must be minimized through strategic mid-run power injection points. Offices utilize connectors for under-desk task lighting to reduce glare, continuous perimeter cove lighting in conference rooms for video-conference-friendly illumination, and suspended linear fixtures in open-plan areas where modular assembly streamlines installation across large ceiling grids.

Installation demands meticulous attention to detail to ensure longevity and performance. Always verify compatibility between the connector, strip voltage (12V/24V), and IP rating—using waterproof connectors even in dry indoor areas prevents moisture ingress from HVAC systems or cleaning. Before insertion, power off the entire circuit and thoroughly clean the strip’s copper pads with isopropyl alcohol to remove oxidation or debris that compromises contact. Align the strip precisely within the connector housing, ensuring polarity matches (positive to positive) as reversed orientation instantly damages LEDs; gently but firmly close the connector latch until it audibly clicks, avoiding excessive force that cracks solder points. For high-current applications like long strip runs, solder connections remain ideal, but where solderless speed is necessary, select connectors with gold-plated contacts and robust spring mechanisms to resist loosening from thermal cycling. Test the connected section thoroughly before final mounting—check for consistent brightness, color temperature, and flicker—since poor contact often manifests as intermittent failure only after adhesive sets. Finally, secure the connector itself with additional mounting tape or clips where vibration occurs, such as near elevators or HVAC units, to prevent wire strain that leads to failure. Adhering to these practices ensures the invisible reliability that defines professional-grade LED installations in demanding commercial spaces.

Why Choose Beauty STC Lighting

Looking for reliable light strip connectors for your next project? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting solutions. Our precision-engineered connectors ensure seamless installation and long-lasting performance. Contact us today at [email protected] to discuss your requirements and discover how we can support your business with superior products and professional service.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.