Article Contents

Industry Insight: Led Stripe Batterie

The commercial and industrial lighting sector is increasingly demanding flexible, reliable, and rapidly deployable illumination solutions, particularly for temporary worksites, emergency egress paths, and retrofit scenarios where fixed wiring is impractical or cost-prohibitive. Battery-powered LED linear lighting systems, often referred to as self-contained or emergency LED strip lights, are emerging as a critical innovation addressing these needs. These systems offer significant advantages including tool-free installation, inherent portability, and uninterrupted operation during power failures, making them indispensable for safety compliance and operational continuity in dynamic environments like construction zones, warehouses, and industrial facilities. Crucially, adoption in professional settings hinges on rigorous safety and performance validation, with certifications such as ETL (indicating compliance with North American safety standards, including UL 924 for emergency lighting) and CE (demonstrating adherence to European health, safety, and environmental requirements) serving as non-negotiable benchmarks for specifiers and facility managers.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing and refining such advanced lighting technologies for the professional market. With over twenty-five years of dedicated engineering expertise, the company has built a reputation for producing robust, code-compliant LED solutions specifically engineered for the demanding rigors of commercial and industrial applications. Beauty STC’s deep understanding of global regulatory landscapes ensures that its battery-powered LED linear systems consistently meet and exceed critical certifications like ETL and CE, providing end-users with confidence in safety, reliability, and long-term performance. This unwavering commitment to quality and compliance stems from decades of collaboration with architects, electrical contractors, and facility operators facing real-world lighting challenges.

As the industry evolves towards smarter, more resilient infrastructure, the role of certified, high-performance battery-operated LED linear lighting becomes increasingly vital. Beauty STC leverages its extensive heritage and technical mastery to deliver solutions that not only meet current safety standards but also anticipate the future needs of commercial and industrial lighting professionals, ensuring spaces remain illuminated, safe, and productive under any circumstances.

Technical Specs & Certifications

The LED stripe battery-powered lighting solutions offered by Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance, reliability, and superior light quality, making them ideal for both residential and commercial applications. These products are designed with a strong emphasis on energy efficiency, color accuracy, and environmental protection.

In terms of luminous efficacy, Beauty STC’s LED stripe batteries deliver an output ranging from 90 to 110 lumens per watt, depending on the specific model and configuration. This high lumens-per-watt ratio ensures optimal energy savings without compromising brightness, making the strips suitable for prolonged use in accent lighting, under-cabinet installations, display lighting, and architectural detailing.

Color Rendering Index (CRI) is a critical factor in achieving natural and vibrant illumination. Beauty STC ensures that its premium LED stripe battery lines feature a CRI greater than 90, with select models reaching up to CRI 95. This high color fidelity allows true-to-life representation of colors, which is especially important in retail environments, art galleries, kitchens, and beauty applications where accurate color perception is essential.

Regarding environmental protection, Beauty STC provides LED stripe battery options with various IP (Ingress Protection) ratings to suit different installation conditions. Common ratings include IP20 for indoor dry locations, IP65 for resistance against dust and low-pressure water jets (ideal for kitchens or covered outdoor areas), and IP67 for full dust tightness and temporary immersion in water, making them suitable for damp or semi-outdoor environments. These robust sealing standards ensure long-term durability and safe operation in challenging conditions.

Beauty STC is recognized for its stringent quality control processes, utilizing high-grade components such as Samsung or Epistar LEDs, constant-current drivers, and premium flexible PCBs to ensure consistent light output, minimal lumen depreciation, and extended lifespan—typically rated at 30,000 to 50,000 hours. The company adheres to international standards including CE, RoHS, and REACH, reflecting its commitment to safety, sustainability, and performance excellence. With precise binning of LEDs and rigorous aging tests, Beauty STC’s LED stripe battery products offer uniform color temperature and reliable operation across diverse applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in the Jiangmen National High-Tech Industrial Development Zone within Guangdong Province. This modern, purpose-built factory spans over 30,000 square meters and serves as the central hub for our LED lighting production, integrating advanced automation with stringent quality control processes. The Jiangmen site is designed for high-volume output while maintaining flexibility for complex custom orders, featuring dedicated clean rooms for critical assembly stages and comprehensive in-house testing laboratories.

Our Surface Mount Technology (SMT) production lines form the backbone of LED component assembly. We operate multiple state-of-the-art Fuji NXT III modular placement machines, renowned for their precision and versatility in handling components from 01005 passives up to large LED packages and complex ICs. These lines feature high-speed placement heads capable of exceeding 100,000 components per hour per machine, coupled with 3D solder paste inspection (SPI) systems and automated optical inspection (AOI) stations after reflow soldering. This setup ensures exceptional accuracy for densely populated LED strip PCBs and driver circuits, critical for the reliability of our products. The SMT area operates under strict environmental controls for temperature and humidity, minimizing defects during the soldering process.

Aging and reliability testing are rigorously implemented at multiple stages. All finished LED strip products, particularly battery-powered variants, undergo mandatory aging tests within our environmental simulation chambers. These tests subject products to extended operational periods, typically 72 hours minimum, under controlled elevated temperatures (ranging from 40°C to 60°C depending on the product specification) and full operational load. We monitor critical parameters including lumen maintenance, chromaticity shift, thermal performance, and driver stability throughout this burn-in phase. Products failing to meet our stringent internal thresholds for performance consistency or exhibiting early failures are automatically quarantined for root cause analysis. This proactive aging protocol significantly reduces infant mortality rates in the field and is a cornerstone of our quality assurance for battery-operated strips where thermal management is paramount.

Regarding OEM capability for battery-powered LED strip products, Beauty STC possesses extensive experience and flexible manufacturing infrastructure. We support full turnkey OEM solutions where we handle everything from component sourcing and PCB design to final assembly, testing, and packaging based on client specifications. Our engineering team works closely with partners to integrate specific battery types – commonly including lithium-ion polymer (LiPo), lithium iron phosphate (LiFePO4), or standard alkaline battery configurations – directly into the strip design or its accompanying controller/driver unit. We accommodate custom requirements for battery compartment integration, voltage regulation, low-voltage cut-off circuits, charging interfaces, and specialized control protocols like Bluetooth or RF for battery-powered operation. This includes designing and validating the thermal interface between the LED strip, driver electronics, and the battery pack to ensure safe and optimal performance throughout the battery discharge cycle, a critical factor for reliable portable or cordless lighting applications. Our Jiangmen facility’s integrated capabilities allow us to efficiently scale production from prototyping through to mass manufacturing for these specialized OEM products.

Application Scenarios

The term “led stripe batterie” likely refers to LED strip lights powered by batteries, often used for flexible, low-voltage lighting solutions in various environments. These battery-powered LED strips are ideal in locations where access to a permanent power source is limited or where temporary, portable, or discreet lighting is needed. Below are the typical applications in hotels, malls, and offices, followed by practical installation tips.

In hotels, battery-powered LED strips are commonly used in under-cabinet lighting in minibars or service counters, inside wardrobes or drawers for guest convenience, and for accent lighting in corridors or behind headboards to create ambient mood lighting. They are also useful during renovations or temporary setups where electrical wiring is not yet complete. Their portability allows for creative lighting in event spaces or pop-up lounges within the hotel premises.

In malls, these LED strips are often used for temporary promotional displays, window mannequin highlights, or inside kiosks where permanent power isn’t available. They are also effective for seasonal decorations such as holiday themes, where easy installation and removal are essential. Retail brands within the mall may use them to highlight products in temporary booths or during flash sales.

In offices, battery-powered LED strips can be installed under desks to provide subtle task lighting, inside filing cabinets or storage units for visibility, or in meeting rooms for accent lighting during presentations. They are especially useful in co-working spaces or modular office setups where lighting needs to be flexible and reconfigurable without major electrical work.

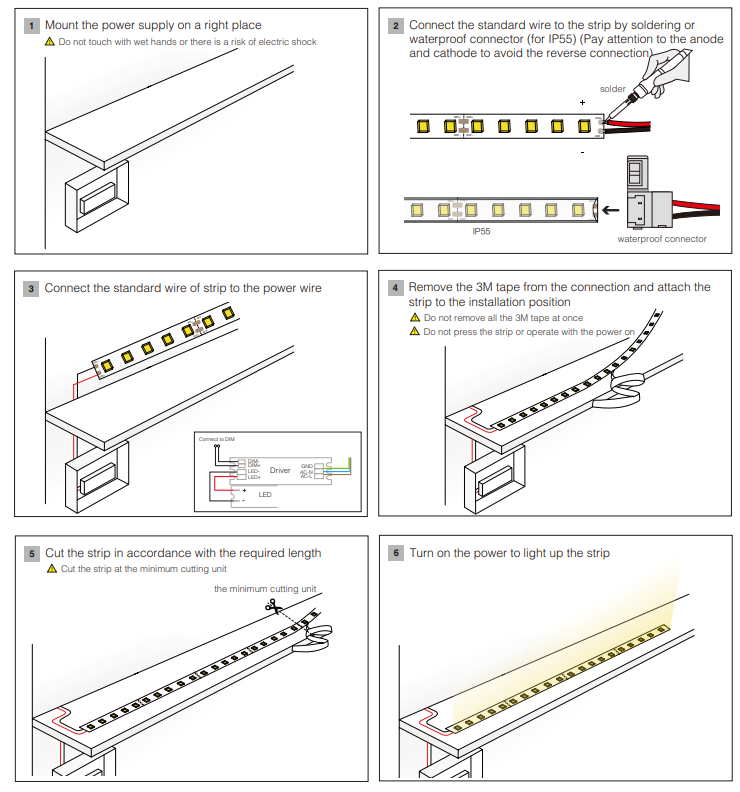

When installing battery-powered LED strips, start by ensuring the surface is clean, dry, and free of dust or grease to allow the adhesive backing to bond properly. Use rubbing alcohol to wipe down the area before application. Avoid installing on textured or uneven surfaces, as this may reduce adhesion. For longer runs or heavier strips, consider using mounting clips or double-sided tape for added support.

Choose LED strips with remote controls or motion sensors for added convenience, especially in areas like closets or under cabinets. Opt for strips with rechargeable battery packs when possible to reduce maintenance and environmental waste. Always check the battery life and keep spares on hand, particularly in high-usage areas.

Finally, avoid placing battery-powered LED strips in high-temperature or high-humidity environments unless they are specifically rated for such conditions. Regularly inspect the connections and battery compartment for corrosion or wear, especially in commercial settings with frequent use. Proper planning and quality components will ensure reliable, attractive lighting across hotels, malls, and offices.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with Beauty STC’s premium battery-powered LED strip solutions engineered for reliability and performance. As a leading manufacturer with over 15 years of expertise in energy-efficient lighting systems we deliver custom battery-integrated LED strips that solve critical challenges like thermal management extended cycle life and seamless voltage compatibility. Our engineering team rigorously tests every component to ensure consistent brightness zero flicker and safe operation across diverse environments from retail displays to architectural installations. Partner with Beauty STC to access scalable production capabilities flexible MOQs and dedicated technical support that transforms your design concepts into market-ready products. Contact our partnership manager directly at [email protected] to discuss specifications volume requirements or request a sample kit for evaluation. Let us handle the engineering complexities so you can focus on delivering exceptional lighting experiences to your clients.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.