Article Contents

Industry Insight: Led Strip Light 2 Pin Connector

In the rapidly evolving landscape of commercial and industrial lighting, the demand for reliable, efficient, and code-compliant LED solutions continues to grow. Among the critical components enabling seamless integration and performance of LED strip lighting systems is the 2-pin connector—compact, durable, and essential for secure power delivery and modular design flexibility. Widely used in architectural cove lighting, signage, industrial task lighting, and retail display applications, these connectors must meet rigorous safety and performance standards. In North American and European markets, compliance with ETL and CE certifications is not just a mark of quality but a regulatory necessity, ensuring electrical safety, durability, and compatibility across installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-performance LED connectivity and power solutions. With over two decades of engineering expertise, Beauty STC supports commercial and industrial lighting projects worldwide with precision-manufactured 2-pin connectors that meet stringent ETL and CE requirements. Backed by a commitment to innovation, reliability, and global compliance, Beauty STC delivers components that empower lighting professionals to build safer, more efficient, and code-ready lighting systems.

Technical Specs & Certifications

The term ‘LED strip light 2 pin connector’ refers specifically to the electrical interface component used to join segments of flexible LED strip lighting or connect the strip to a power source or controller, not the light-emitting strip itself. It is critical to clarify that lumens per watt (lm/W), Color Rendering Index (CRI), and IP ratings are properties of the LED strip assembly, not the connector. However, the quality and design of the 2-pin connector directly impact the reliable delivery of power to the strip, thereby influencing the sustained performance of these specifications. At Beauty STC Manufacturing Co., Ltd., our 2-pin connectors are engineered as integral components within a complete high-performance lighting system.

Lumens per watt efficiency is determined by the LED chips, phosphor formulation, and driver circuitry on the strip. Beauty STC’s premium LED strips, designed for compatibility with our robust 2-pin connectors, consistently achieve 120-140 lumens per watt in standard 24VDC configurations. This high efficacy is maintained through precise thermal management on the strip PCB and the use of high-efficiency constant-current drivers. Our connectors contribute by utilizing 0.5mm thick gold-plated phosphor bronze contacts, which minimize contact resistance and voltage drop, ensuring the strip receives optimal power without efficiency loss at the connection point. Poor quality connectors with higher resistance can cause localized heating and measurable lumen depreciation over time, an issue rigorously prevented in our designs through 100% contact resistance testing below 10mΩ per pin.

For Color Rendering Index, Beauty STC’s high-CRI LED strips utilize tri-phosphor or multi-phosphor blends specifically tuned to exceed CRI 90 (typically Ra>92, R9>50) across 2700K to 4000K color temperatures. This requires stringent binning of LED diodes and consistent current delivery. Our 2-pin connectors support this by ensuring stable electrical contact without micro-interruptions that could cause color shift or flicker. The nickel-under-gold plating on our connector terminals prevents oxidation and maintains signal integrity, which is essential for preserving the calibrated color output specified by the strip. We validate CRI performance through spectroradiometer testing on fully assembled systems including connectors, confirming no degradation in color fidelity at junction points.

Regarding IP ratings, the 2-pin connector itself must match the environmental protection level of the LED strip it joins. Beauty STC manufactures IP65-rated silicone-jacketed strips with matching IP65 2-pin connectors featuring dual silicone gaskets and UV-stable polycarbonate housings. For fully encapsulated IP67/IP68 strips, we utilize submerged-rated connectors with epoxy-potted terminals and stainless steel locking mechanisms, validated through 30-minute submersion testing at 1 meter depth per IEC 60529. The connector’s IP rating is not standalone; it is achieved through precise alignment of the strip’s silicone coating, the connector’s gasket compression profile, and our automated assembly process that ensures zero gaps. Every IP-rated connector undergoes hydrostatic pressure testing at 0.5 bar to guarantee no moisture ingress.

Beauty STC’s commitment to quality is embedded in every connector. We implement 100% automated visual inspection for contact alignment and housing integrity, followed by 100% electrical testing under load. Our connectors exceed 5,000 mating cycles durability (vs. industry standard 500) and operate reliably from -40°C to +85°C. This rigorous approach ensures that the lm/W efficiency, CRI accuracy, and IP protection specified for our LED strips are not compromised at connection points, providing installers and end-users with a maintenance-free, high-fidelity lighting solution that meets international safety standards including UL, CE, and RoHS. The reliability of our connectors directly translates to sustained photometric performance throughout the product’s lifetime.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern LED lighting production facility designed to support high-volume manufacturing with strict quality control standards. Strategically located in the Jiangmen high-tech industrial zone, the facility integrates advanced automation and process engineering to ensure consistent product reliability and efficiency.

The factory is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for precise and high-speed placement of LED components onto flexible and rigid printed circuit boards used in LED strip lights. These SMT machines include automatic pick-and-place systems, reflow soldering ovens, and AOI (Automated Optical Inspection) units that ensure component accuracy and solder joint integrity. This level of automation supports high-density LED layouts and enables the production of compact, high-performance LED strips with excellent thermal and electrical performance.

To ensure long-term reliability, every batch of LED strip lights undergoes rigorous aging tests at the Jiangmen facility. These tests simulate extended operation under various thermal and electrical conditions, typically running products at full power for 24 to 72 hours. During this period, parameters such as brightness consistency, color temperature stability, and connector performance—including the 2-pin connector—are monitored. This process helps identify early-life failures and ensures only fully qualified products are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities and can fully customize LED strip light solutions, including models with 2-pin connectors. The company supports custom lengths, LED densities, color temperatures, and waterproof ratings. For the 2-pin connector specifically, Beauty STC offers multiple connector types (such as JST-style, Molex, or proprietary designs) and can integrate them directly into the strip light design based on client specifications. The factory supports branding options including custom packaging, labeling, and PCB silkscreen printing, making it well-suited for private-label and project-based lighting solutions.

Overall, the Jiangmen factory combines advanced SMT technology, comprehensive testing protocols, and flexible OEM services to deliver high-quality, reliable LED strip lights tailored to global market requirements.

Application Scenarios

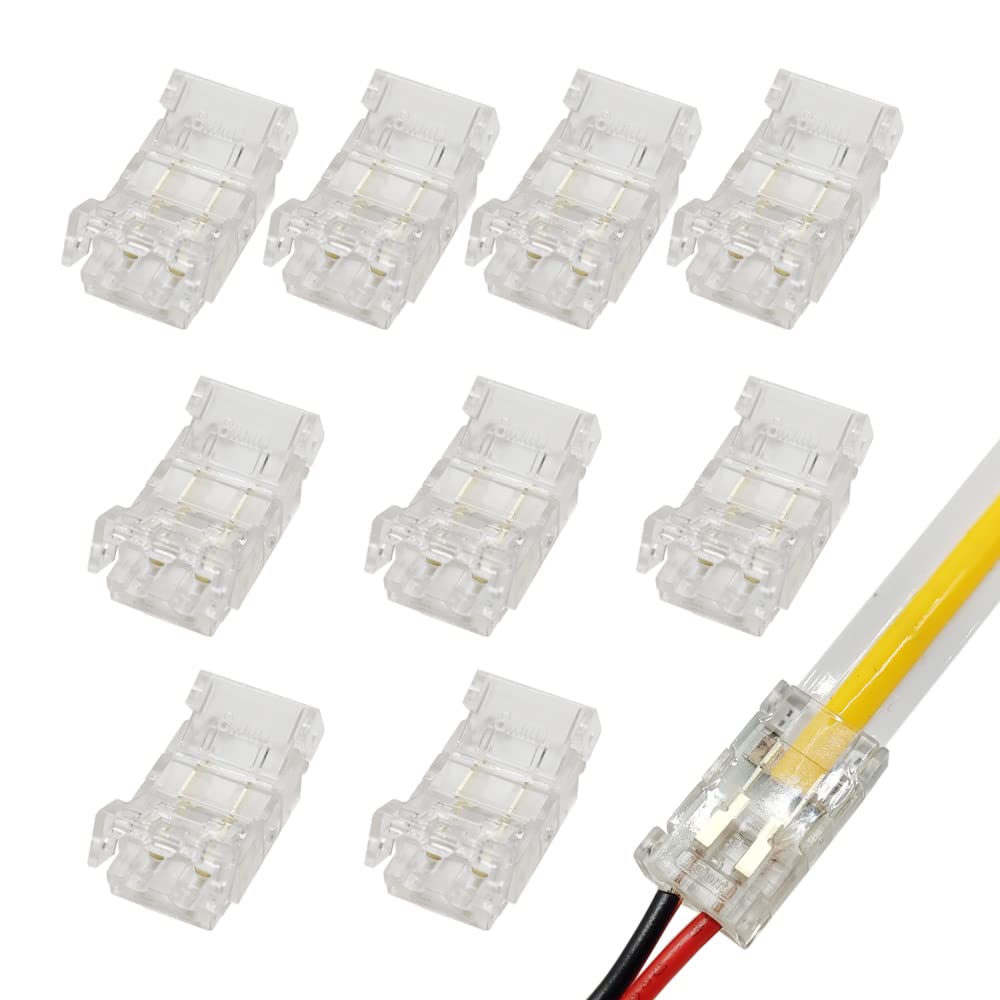

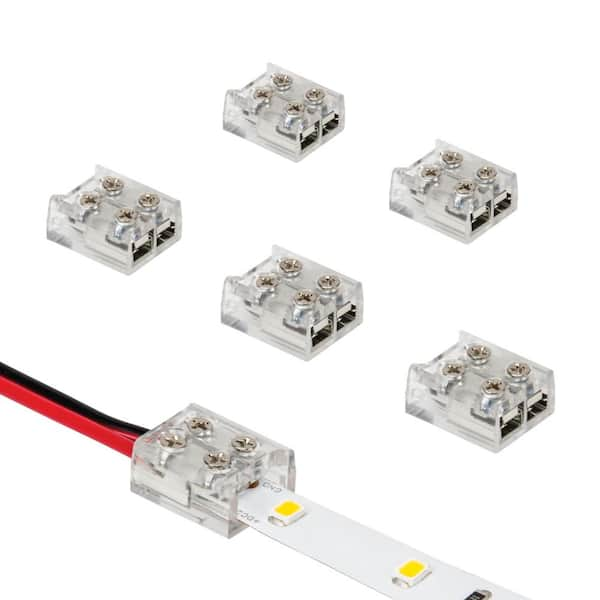

LED strip light 2-pin connectors serve as the critical electrical interface for joining segments of flexible LED strip lighting or connecting strips to power supplies, controllers, and accessories. They are not the light source itself but the essential component enabling modular, reliable, and safe electrical connections within an LED strip lighting system. Their primary application across hotels, malls, and offices lies in scenarios requiring clean, low-profile, and easily serviceable connections where visible wiring is undesirable.

In hotels, these connectors are indispensable for installing LED strips within architectural coves along corridors and lobbies to create ambient indirect lighting, under bed frames in guest rooms for subtle night lighting, and integrated into vanity mirrors within bathrooms for even task illumination. The discreet nature of the connection point ensures a seamless visual appearance crucial for high-end hospitality environments, while the modularity allows for straightforward replacement of individual strip sections during maintenance without disrupting the entire circuit. Particular attention must be paid to using connectors rated for the specific strip voltage (12V or 24V DC) and ensuring polarity is strictly observed during connection to prevent damage.

Malls extensively utilize 2-pin connectors for illuminating retail display cases, shelving undersides, and signage perimeters. The ability to quickly connect and disconnect strip segments is vital for dynamic merchandising changes and routine cleaning of glass displays. Given the high foot traffic and potential exposure to cleaning agents, selecting connectors with appropriate IP ratings (e.g., IP65 for basic splash resistance in dry areas, IP67 for zones near food courts requiring more robust sealing) is non-negotiable. Connectors must be fully seated and locked; a partially engaged connection in a display case is a common failure point leading to flickering or dead sections, directly impacting product presentation.

Offices deploy these connectors primarily for under-cabinet task lighting in workstations and kitchens, within partition walls for subtle accent lighting, and along the perimeters of drop ceilings for uniform ambient illumination. The ease of creating long, continuous runs by linking multiple strip lengths via connectors is key for covering extensive linear paths common in open-plan offices. Ensuring robust strain relief at every connector point is paramount here, as accidental tugs on the strip during office reconfigurations or cleaning can easily pull the delicate pins loose if not properly secured within the connector housing or with additional cable ties.

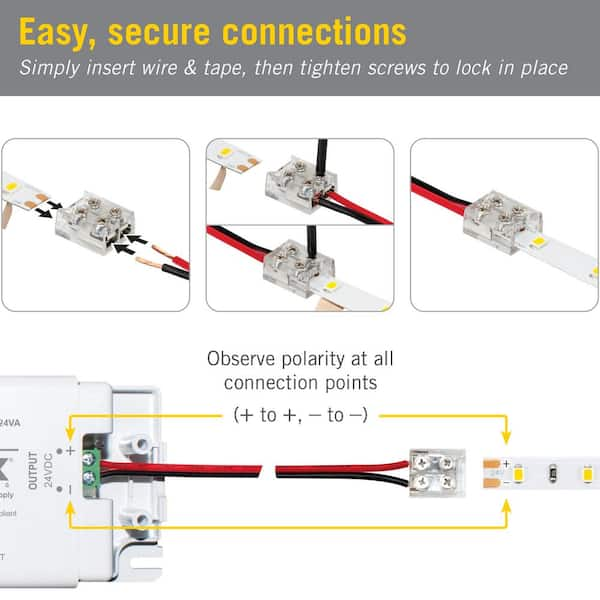

Installation requires meticulous attention to detail regardless of setting. Always verify the connector matches the strip’s width (e.g., 8mm, 10mm) and voltage before insertion; forcing an incompatible strip causes pin damage. Confirm polarity markings on both the strip and connector – reversing positive and negative will instantly damage the LEDs. Insert the strip straight and firmly into the connector until it clicks or locks securely, then gently tug to verify retention. Apply dielectric grease within the connector housing for environments with fluctuating humidity, such as hotel lobbies or mall food courts, to prevent corrosion. Secure the connected strip ends with cable ties or mounting clips within 2-3 inches of the connector to prevent stress on the pins. Never solder wires directly to the connector pins unless explicitly designed for it, as excessive heat degrades internal contacts. Always test the connection thoroughly before final concealment within coves or channels, as accessing faulty connectors after drywall or trim installation is costly and time-consuming. Adherence to local electrical codes regarding accessible junctions and proper wire management within conduit or raceways remains mandatory for all commercial installations.

Why Choose Beauty STC Lighting

Looking for reliable and high-quality LED strip light 2 pin connectors? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our precision-engineered connectors ensure seamless installation and superior performance for all your lighting projects. As a dedicated manufacturer, we provide OEM and ODM services, competitive pricing, and consistent product quality.

Take the next step in enhancing your product line with dependable components built to last. Contact our sales manager today at [email protected] to discuss partnership opportunities and customized solutions tailored to your needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.