Article Contents

Industry Insight: Led Light Strip Wiring

The commercial and industrial LED lighting landscape increasingly relies on the flexible, energy-efficient solution of LED light strips for architectural accents, task lighting, and functional illumination in retail spaces, warehouses, and offices. However, the successful and safe deployment of these systems hinges critically on proper wiring practices, a factor often underestimated during specification and installation. Unlike simple residential applications, commercial and industrial environments demand rigorous adherence to electrical codes, robust connection methodologies, and stringent safety certifications to ensure system longevity, prevent fire hazards, and avoid costly downtime or liability issues. Compliance with recognized safety standards like ETL (indicating compliance with North American safety requirements) and CE (demonstrating conformity with European health, safety, and environmental standards) is not optional; it is a fundamental requirement for any product entering these professional markets, providing essential assurance of electrical safety and performance under demanding conditions. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise specifically to this critical intersection of LED technology and electrical safety. We understand that the true value of an LED light strip solution is only realized when its wiring architecture is designed and executed to the highest commercial and industrial standards, forming the reliable backbone of a safe, efficient, and code-compliant lighting installation.

Technical Specs & Certifications

LED light strip wiring involves proper electrical connections and configurations to ensure optimal performance, longevity, and safety. When specifying high-quality LED strips such as those manufactured by Beauty (STC) Manufacturing Co., Ltd., several key technical parameters must be considered, particularly lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings.

Lumens per watt is a critical efficiency metric that indicates how much visible light is produced for each watt of electrical power consumed. Beauty STC’s LED light strips typically deliver between 100 to 130 lumens per watt, depending on the LED density and binning specifications. This high efficiency ensures reduced energy consumption while maintaining excellent brightness, making them ideal for both residential and commercial lighting applications. The LED chips used are rigorously tested to ensure consistent lumen output over the rated lifespan, often exceeding 50,000 hours under proper thermal management and drive current conditions.

Color Rendering Index (CRI) measures the ability of a light source to reveal the true colors of objects compared to natural light. Beauty STC prioritizes visual quality by offering LED strips with a CRI greater than 90, and in many premium series, achieving CRI values of 95 or higher. This high CRI performance is achieved through the use of advanced phosphor coatings and carefully selected LED diodes, ensuring accurate color representation in environments such as retail displays, art galleries, and high-end residential interiors where color fidelity is essential.

In terms of environmental protection, Beauty STC’s LED light strips are available in various IP ratings to suit different installation conditions. IP65-rated strips feature a silicone coating that protects against dust and low-pressure water jets, making them suitable for outdoor eaves, signage, and damp indoor areas like kitchens and bathrooms. For fully waterproof applications, IP67 and IP68-rated strips are available, capable of withstanding temporary or prolonged submersion in water, ideal for pool lighting, marine environments, and landscape installations. These ratings are achieved through seamless encapsulation techniques and high-purity silicone materials, ensuring long-term durability even in harsh conditions.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Each LED strip undergoes comprehensive testing for electrical performance, thermal stability, and optical consistency. Components are sourced from trusted suppliers, and manufacturing adheres to international standards including ISO 9001 and RoHS compliance. The combination of high lm/W efficiency, superior CRI, robust IP protection, and stringent quality assurance makes Beauty STC’s LED light strips a reliable and premium choice for demanding lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in Jiangmen, Guangdong Province, China. This modern factory spans approximately 25,000 square meters and serves as the company’s core production hub for LED lighting solutions, including specialized products like flexible LED light strips. The facility is designed for high-volume, precision manufacturing and adheres strictly to ISO 9001 quality management standards, ensuring consistency and reliability in every output.

The Surface Mount Technology (SMT) production lines within the Jiangmen factory are a cornerstone of our capability. We operate multiple state-of-the-art Fuji NXT III modular placement systems. These machines feature high-speed, multi-head configurations capable of placing components at rates exceeding 100,000 components per hour (CPH) with exceptional precision down to 25-micron accuracy. Equipped with advanced 3D solder paste inspection (SPI) and automated optical inspection (AOI) systems both pre- and post-reflow, these lines ensure near-zero defect rates for the complex circuitry required in LED light strips, handling everything from ultra-small 0201 metric passives to intricate ICs and LEDs.

Rigorous quality control is enforced through our comprehensive aging and burn-in testing protocols. All LED light strip assemblies undergo a mandatory 72-hour continuous operational aging test under controlled environmental conditions within dedicated thermal chambers. During this period, strips operate at 110% of rated voltage while temperature, current, and luminous output are continuously monitored. Any units exhibiting flux, color shift, or performance deviation beyond stringent thresholds are automatically flagged and removed from the production flow. This extended stress testing significantly reduces infant mortality rates and guarantees field reliability for our customers.

Our OEM capability for LED light strips is highly developed and flexible, extending far beyond basic wiring assembly. We offer full turnkey solutions starting from client specifications or reference designs. This includes custom PCB layout and fabrication for flexible strips, selection and sourcing of LEDs and drivers per performance requirements, precise SMT assembly of all components including specialized wiring harnesses and connectors, silicone encapsulation or coating, and final functional testing. We support extensive customization in length, color temperature, CRI, voltage, dimming protocols, IP rating, and mechanical form factor. Clients can provide complete designs for replication, or collaborate with our engineering team for co-development, including prototyping, DFM optimization, and compliance testing for global markets. All OEM projects operate under strict confidentiality agreements, with dedicated production cells ensuring intellectual property protection and traceability throughout the manufacturing process.

Application Scenarios

LED light strip wiring is widely used across various commercial and hospitality environments due to its flexibility, energy efficiency, and aesthetic appeal. In hotels, LED light strips are commonly installed in guest rooms to highlight headboards, under cabinets, or along cove ceilings for ambient lighting. They are also used in lobbies, hallways, and restrooms to create a welcoming atmosphere and enhance architectural features. In malls, LED strips are ideal for illuminating signage, display windows, escalator handrails, and ceiling coves to draw attention and improve the overall shopping experience. Offices benefit from LED light strips in reception areas, under shelving, in conference rooms, and along corridors to provide both functional and decorative lighting that supports productivity and modern design.

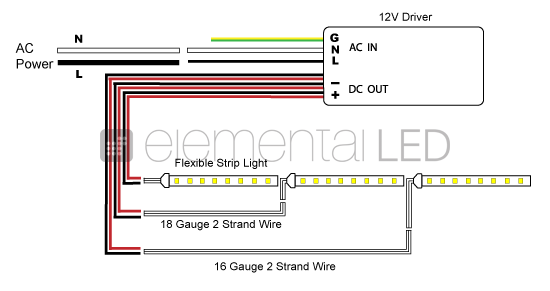

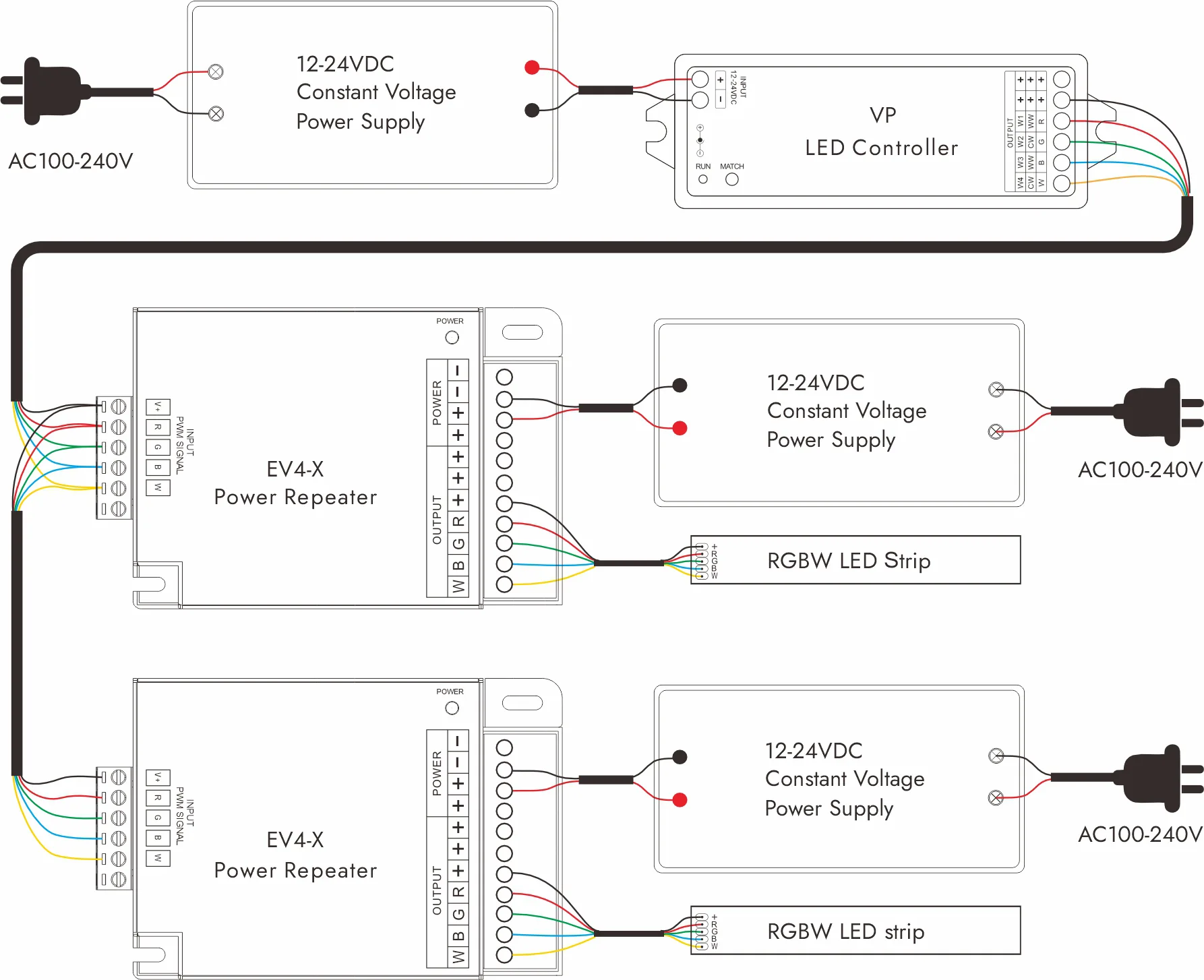

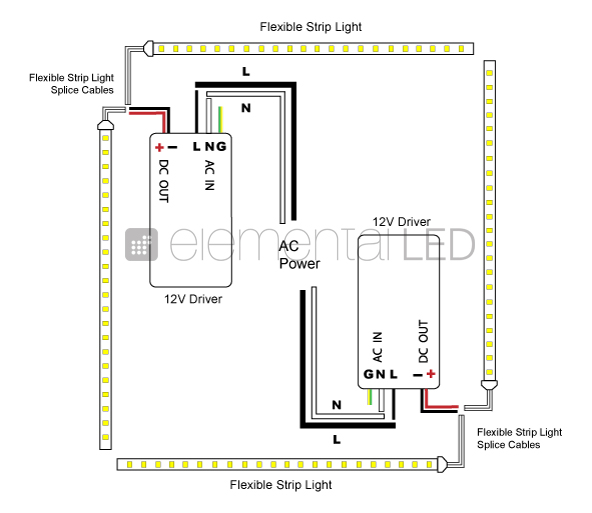

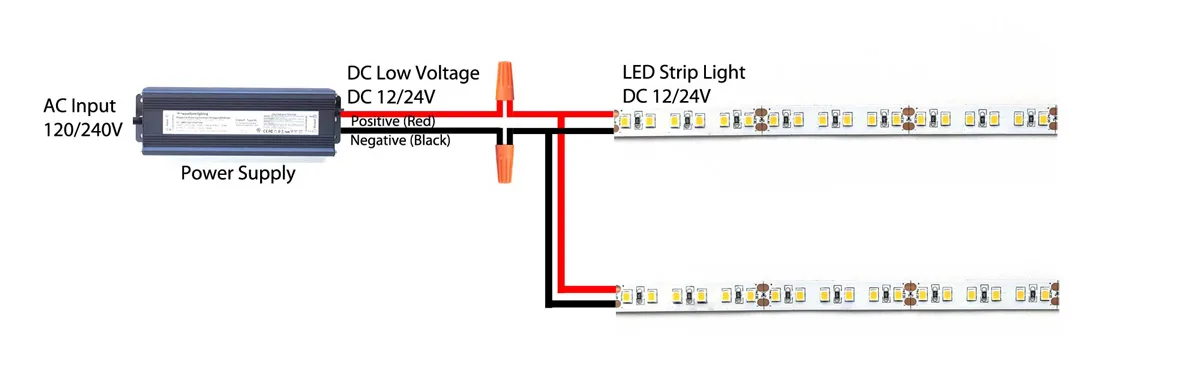

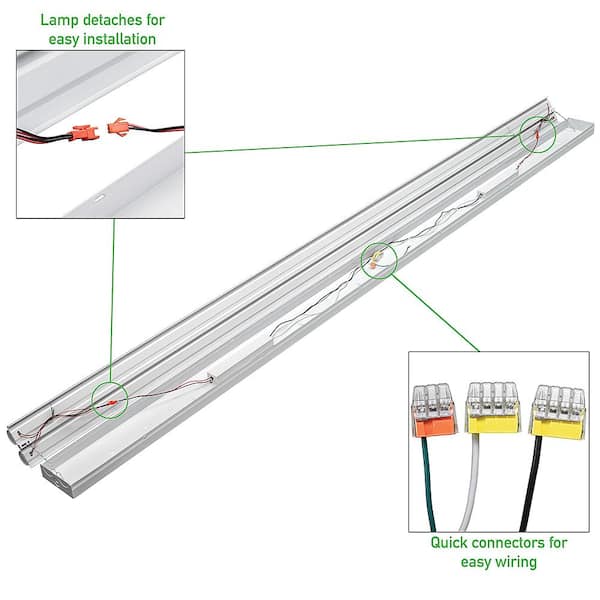

When installing LED light strip wiring, proper planning is essential. Begin by measuring the area where the strips will be installed to determine the required length and power supply capacity. Ensure the surface is clean, dry, and free of dust for optimal adhesion. Most LED strips come with a self-adhesive backing, but for long-term reliability, consider using additional mounting clips or aluminum channels, especially in high-traffic or high-temperature areas. Always follow the manufacturer’s specifications for maximum run length to avoid voltage drop, which can cause dimming at the far end of the strip. Use appropriate connectors for joining strips or making corners, and avoid cutting the strip except at designated cut points. For safety and performance, connect the power supply to a grounded electrical source and use a dimmer or controller if desired. In commercial settings like hotels, malls, and offices, it’s advisable to consult a licensed electrician to ensure compliance with local electrical codes and safety standards.

Why Choose Beauty STC Lighting

For professionals seeking reliable and expert solutions in LED light strip wiring applications partner with Beauty STC Manufacturing Co. Ltd. Our engineering team delivers precision-engineered wiring systems designed for optimal performance safety and seamless integration across residential commercial and industrial projects. We provide comprehensive technical support custom configuration options and rigorous quality assurance to ensure your lighting installations meet the highest industry standards.

Elevate your next project with wiring solutions built on decades of specialized LED manufacturing expertise. Contact our dedicated partnership manager today at [email protected] to discuss your specific requirements and discover how Beauty STC can become your trusted wiring solutions provider.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.