Article Contents

Industry Insight: Flood Vs Spotlight

In the commercial and industrial lighting sector, selecting the right fixture type—floodlight or spotlight—can significantly impact both operational efficiency and safety. Floodlights deliver broad, even illumination ideal for large outdoor areas such as warehouses, construction sites, and parking lots, while spotlights provide focused, directional lighting suited for accenting architectural features or securing perimeter zones. As energy efficiency and regulatory compliance become increasingly critical, specifying fixtures that meet stringent standards such as ETL and CE marks is essential for ensuring safety, performance, and code adherence across North American and international markets.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in high-performance LED lighting solutions tailored for demanding commercial and industrial environments. With a commitment to innovation, durability, and regulatory compliance, Beauty STC designs and manufactures an extensive range of flood and spotlight fixtures engineered to exceed the requirements of modern infrastructure projects. By integrating advanced thermal management, robust housing materials, and precision optics, Beauty STC delivers lighting systems that combine long service life with optimal lumen output—ensuring reliable performance in even the most challenging conditions.

Technical Specs & Certifications

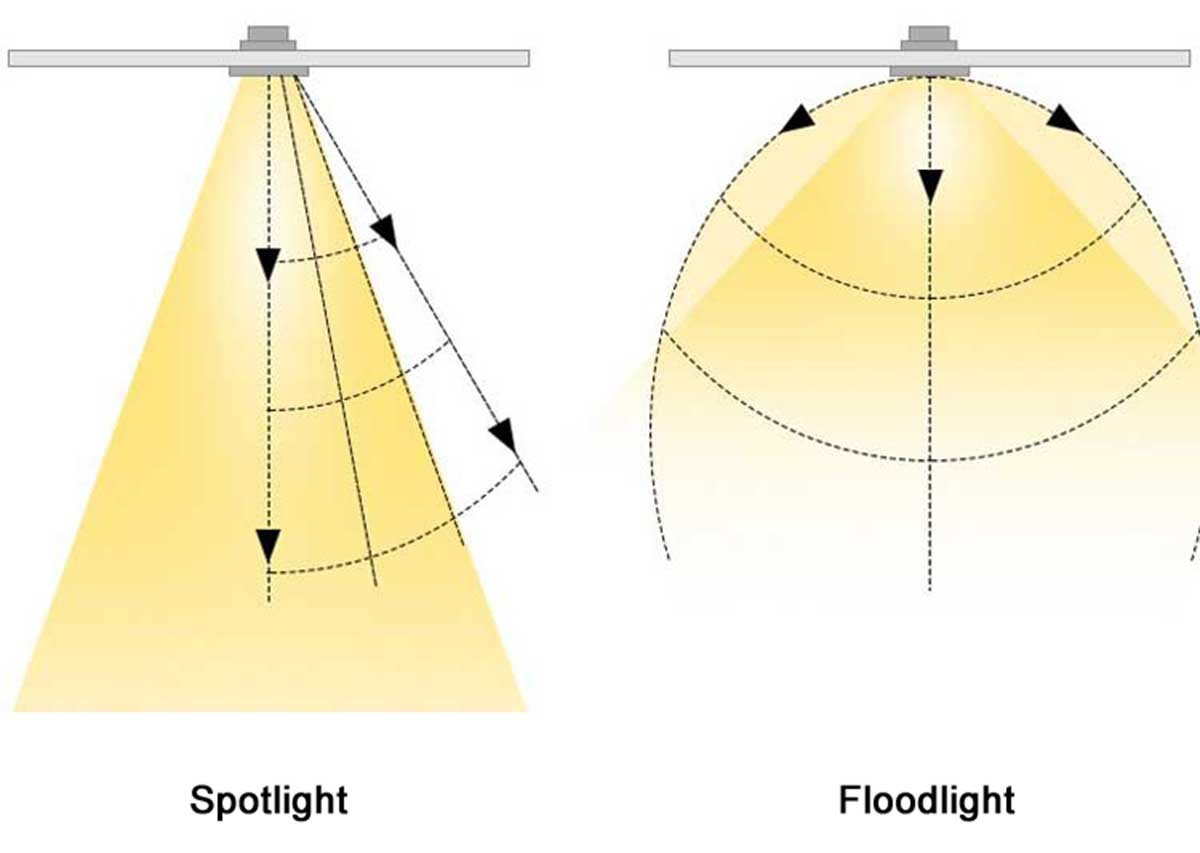

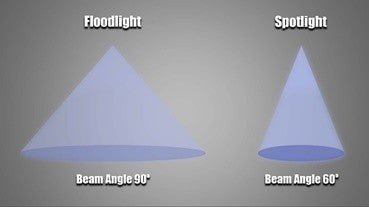

Floodlights and spotlights serve distinct illumination purposes, defined primarily by their beam angles, which directly influence key technical specifications including lumens per watt, CRI, and IP ratings. Floodlights typically feature wide beam angles exceeding 100 degrees, designed to uniformly illuminate broad areas such as building facades, parking lots, or large retail spaces. Spotlights, conversely, produce narrow, concentrated beams ranging from 15 to 45 degrees, intended for accent lighting, highlighting architectural features, or long-throw applications like stadium lighting or security perimeters. This fundamental difference in optical design impacts performance metrics.

Regarding lumens per watt efficacy, both fixture types from reputable manufacturers like Beauty STC achieve high efficiency, but subtle differences exist due to optical losses. Modern LED floodlights commonly deliver 130-150 lumens per watt at the system level, with wider beam optics sometimes incurring marginally higher losses from reflectors or diffusers compared to spotlights. Spotlights, utilizing more focused reflectors or lenses, often reach 140-160 lumens per watt as less light is散射 during collimation. Beauty STC consistently exceeds 140 lm/W across both product lines through the use of high-efficiency COB (Chip-on-Board) LEDs and proprietary thermal management systems that prevent lumen depreciation under sustained operation, ensuring long-term efficacy stability.

Critical for applications demanding accurate color representation such as retail displays, art galleries, or high-end hospitality, both flood and spotlight fixtures must maintain a CRI (Color Rendering Index) above 90. Beauty STC mandates a minimum CRI of 92 with R9 (saturated red) values exceeding 50 across its professional-grade luminaires. This is achieved through precisely tuned phosphor-converted LEDs and rigorous binning processes during manufacturing. It is essential to verify CRI measurements are conducted at the intended operating temperature and drive current, as substandard products often report inflated lab results under ideal conditions that degrade in real-world use. Beauty STC’s commitment includes full spectral data validation to ensure consistent color fidelity throughout the product lifecycle.

IP (Ingress Protection) ratings are application-dependent but differ in typical requirements between flood and spotlight installations. Floodlights, frequently mounted outdoors on poles or building exteriors, commonly require IP65 or IP66 ratings, providing complete dust protection and resistance against low-pressure water jets from any direction, suitable for exposed locations like parking structures. Spotlights used in landscape or security roles often demand higher resilience, typically IP67, which guarantees protection against temporary immersion in water up to 1 meter, critical for fixtures installed at ground level or in flood-prone zones. Beauty STC rigorously tests all outdoor-rated fixtures beyond baseline IEC 60529 standards, employing seamless silicone gaskets, corrosion-resistant die-cast housings, and conformal-coated drivers to ensure IP integrity withstands harsh environments including coastal salt spray and extreme temperature cycling.

Beauty STC’s quality differentiation lies in its engineering-first approach. Unlike budget alternatives that compromise on thermal design or component selection, our flood and spotlight luminaires feature aerospace-grade aluminum heat sinks with optimized fin structures, ensuring junction temperatures remain below 85°C even in 50°C ambient conditions. This thermal discipline directly supports sustained high CRI performance and lumen maintenance, with all products rated L70/B50 at 50,000 hours. Every fixture undergoes 100% photometric validation and 100% wet-condition IP testing on the production line, a standard exceeding industry norms. We prioritize real-world reliability over marginal cost savings, resulting in luminaires that maintain specified lumens per watt, CRI, and IP protection throughout their service life, reducing total cost of ownership for demanding commercial and industrial applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from streamlined logistics and access to a skilled manufacturing workforce, supporting both domestic and international supply chains.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, which ensure precision and consistency in assembling LED components onto circuit boards. These SMT machines are automated and capable of handling high-volume production with tight tolerances, enabling efficient mounting of small and complex LED chips and drivers. The integration of automated optical inspection (AOI) systems further enhances quality control by detecting soldering defects and component misalignment in real time.

To ensure product reliability and longevity, the Jiangmen factory conducts comprehensive aging tests on all finished LED luminaires. Products undergo extended operation under controlled conditions—typically 24 to 72 hours at elevated temperatures and full power—to simulate long-term use. This process helps identify early failure modes and ensures that only units meeting strict performance standards are shipped to customers.

The factory has robust OEM (Original Equipment Manufacturing) capabilities, allowing it to customize LED lighting solutions according to client specifications. This includes tailored designs for both flood and spotlight configurations. For floodlight applications, the factory produces wide-beam-angle fixtures ideal for area illumination such as parking lots, warehouses, and building facades. For spotlight applications, optical engineering ensures narrow, focused beams suitable for accent lighting, architectural highlighting, or targeted outdoor illumination. Customization extends to lumen output, color temperature, beam angle, housing design, and branding, enabling clients to offer differentiated products under their own labels.

Overall, the Jiangmen factory combines advanced automation, rigorous testing, and flexible OEM services to deliver reliable, high-performance LED lighting solutions for diverse global markets.

Application Scenarios

Floodlights and spotlights serve distinct purposes in commercial lighting design, and their correct application significantly impacts functionality, aesthetics, and energy efficiency in hotels, malls, and offices. Floodlights emit a wide beam angle (typically 60 degrees or more), providing broad, even illumination over large areas with minimal shadows. Spotlights produce a narrow, focused beam (usually under 30 degrees), ideal for accentuating specific objects, features, or zones while creating dramatic contrast. Misapplication leads to poor visibility, visual discomfort, or wasted energy.

In hotels, floodlights are essential for general ambient lighting in lobbies, hallways, and guest room ceilings where uniform light coverage is critical for safety and comfort. Use them in conference room ceilings to eliminate shadows on tables during presentations. Spotlights excel in highlighting architectural details like reception desks, artwork, or feature walls in lobbies, and in guest room vanity areas to provide precise task lighting for grooming without glare. Avoid spotlights in corridors—they create hazardous pools of light between dark zones—and never use floods for retail displays in hotel boutiques, as they dilute product appeal.

For malls, floodlights are indispensable across expansive walkways, food courts, and general retail floors to ensure consistent, shadow-free illumination that guides customer movement safely. Deploy them in high-ceiling anchor stores for baseline coverage. Spotlights are mandatory in boutique windows, jewelry cases, and luxury brand displays to intensify product colors and textures, drawing attention through controlled contrast. Critical tip: In department stores, use adjustable spotlights on track systems for flexible merchandising, but avoid narrow beams in children’s play areas where broad, gentle light reduces visual strain. Never spotlight entire escalator landings—floods prevent tripping hazards.

Offices demand strategic separation: floodlights suit open-plan workspaces, meeting rooms, and corridors to minimize eye fatigue with diffused light that reduces screen glare. They’re optimal for suspended ceiling grids in call centers. Spotlights should be reserved for executive office accent walls, reception desk logos, or presentation stages to add hierarchy and focus. Crucially, never install spotlights over individual workstations—they cause disabling glare and headaches. In collaborative zones, floodlights with 90+ CRI ensure accurate color perception for design teams.

Installation requires precise technical execution. For floodlights in high-ceiling malls (over 6 meters), calculate spacing using the height-to-width ratio: fixtures should be spaced 1.5 times the mounting height apart to avoid dark corridors. Always use 100+ degree beams in warehouse-style hotel back-of-house areas. Spotlight placement demands exact aiming; in retail, position them 1.5 times the display height away from merchandise at a 30-degree angle to prevent hotspots. Thermal management is non-negotiable—ensure 15cm clearance around LED spotlights in insulated office ceilings to prevent lumen depreciation. Finally, verify beam overlap: in hotel lobbies, adjacent floodlights should blend seamlessly with no visible transitions, while spotlight groupings on art require 10% beam overlap to avoid double shadows. Always commission with a lux meter—malls need 300 lux on walkways, offices 500 lux on desks—and adjust tilt incrementally using STC’s beam-spread templates before final mounting.

Why Choose Beauty STC Lighting

Discover the key differences between flood and spotlight lighting solutions to enhance your next project with precision and style. Whether you need broad illumination or focused brightness, Beauty STC delivers high-performance LED lighting tailored to your requirements. Partner with Beauty STC today and experience innovative design, superior quality, and reliable engineering. For expert guidance and customized lighting solutions, contact our team at [email protected]. Let us illuminate your vision together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.