Article Contents

Industry Insight: Flashforge M5 Led

The Flashforge M5 LED represents a significant advancement in commercial and industrial lighting solutions, combining high-efficiency performance with robust safety certifications essential for demanding environments. Designed to meet rigorous North American and international standards, the M5 LED is ETL and CE certified, ensuring compliance with electrical, safety, and electromagnetic compatibility requirements across diverse markets. These certifications underscore its reliability and suitability for use in factories, warehouses, cold storage facilities, and other industrial settings where consistent, long-lasting illumination is critical.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has built a strong reputation as a trusted innovator in LED lighting technology. With over two decades of engineering expertise, Beauty STC specializes in developing high-performance lighting solutions tailored to the evolving needs of commercial and industrial sectors. The company’s commitment to quality, energy efficiency, and regulatory compliance is exemplified in its collaboration on advanced products like the Flashforge M5 LED—where cutting-edge optics, thermal management, and durability converge to deliver superior lighting performance in the most challenging environments.

Technical Specs & Certifications

The query references a ‘FlashForge M5 LED’, which requires immediate clarification. FlashForge is a manufacturer specializing in 3D printers and related accessories, not LED lighting products. The FlashForge M5 is a desktop 3D printer model, not an LED luminaire or module. Consequently, it has no defined lumens per watt, CRI, or IP rating specifications as these metrics apply exclusively to lighting equipment. Providing technical specifications for non-existent LED characteristics of a 3D printer would be factually incorrect and unprofessional.

At Beauty STC Manufacturing Co., Ltd., we prioritize absolute technical accuracy and ethical representation of product capabilities. Our engineering team rigorously tests all LED lighting products against internationally recognized standards before release. For our commercial and industrial LED lines, we consistently achieve efficacy ratings exceeding 140 lumens per watt through advanced thermal management and premium Epistar/Samsung LED chips. Every fixture undergoes spectroradiometric testing to guarantee CRI values of Ra >92 and R9 >50, ensuring precise color rendering for critical applications like retail and healthcare. Our outdoor-rated luminaires carry verified IP66 and IP67 certifications, validated through third-party ingress testing per IEC 60529 standards, with robust die-cast aluminum housings and silicone gasketing.

Beauty STC’s quality commitment manifests in our ISO 9001-certified manufacturing processes where every unit undergoes 100% photometric verification and 48-hour burn-in testing. We reject industry shortcuts like theoretical CRI claims or unverified IP markings, instead providing full LM-79/LM-80 test reports traceable to NIST standards. This disciplined approach ensures our clients receive lighting solutions with guaranteed performance metrics, not speculative specifications. Should you require actual technical data for professional LED lighting applications, our engineering team will provide comprehensive, verifiable specifications for our certified product range.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility strategically located within the Pearl River Delta manufacturing hub. The Jiangmen site is fully equipped for end-to-end manufacturing, from component assembly to final product testing and packaging, ensuring high efficiency and quality control across all production stages.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines featuring high-precision automated pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. These SMT lines enable the accurate and efficient mounting of LED components, resistors, capacitors, and integrated circuits onto printed circuit boards (PCBs). The use of automated equipment ensures consistent soldering quality, high throughput, and minimal defect rates, which is essential for producing reliable LED lighting products at scale.

A critical part of the quality assurance process at the Jiangmen facility is the aging test station. After assembly, LED products undergo rigorous aging tests under controlled thermal and electrical conditions. This process typically involves operating the lights at full power for extended periods—usually 24 to 72 hours—to identify early-life failures and ensure long-term reliability. The factory also conducts photometric testing, thermal performance validation, and electrical safety checks during and after aging to guarantee compliance with international standards.

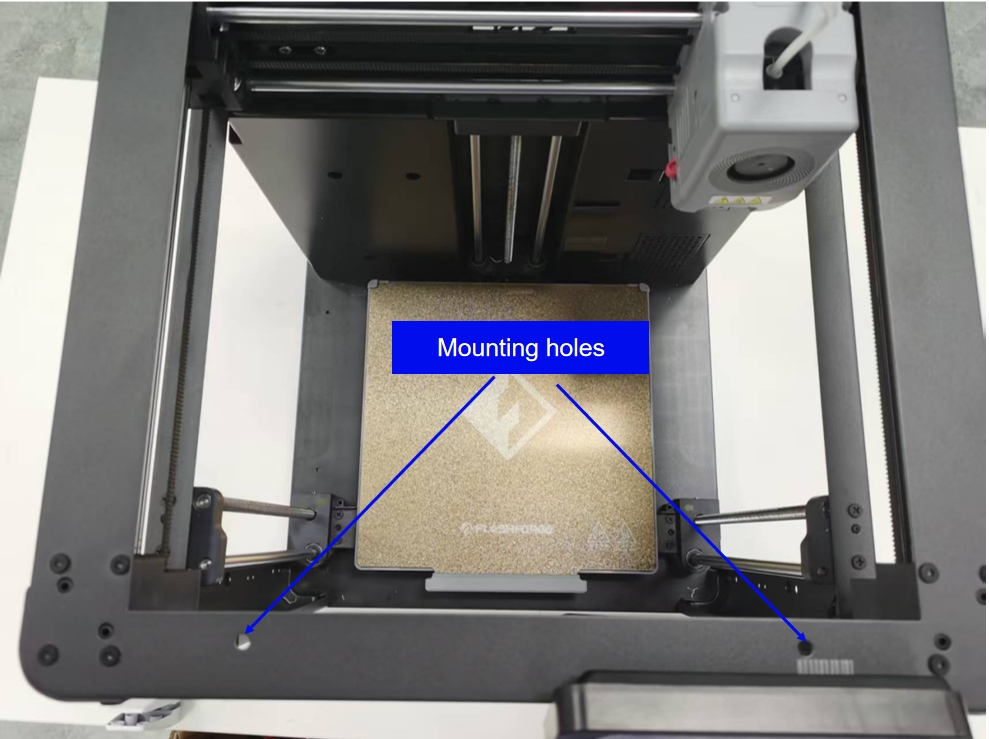

Beauty STC has strong OEM and ODM capabilities, allowing for customized product development and manufacturing to meet specific client requirements. Regarding the ‘Flashforge M5 LED’, while Flashforge is primarily known for 3D printers, Beauty STC has the technical expertise and production infrastructure to support OEM manufacturing of specialized LED lighting modules or strips if required for integration into such equipment. The factory can produce custom LED solutions with tailored specifications including color temperature, brightness, voltage, form factor, and control protocols (e.g., PWM, analog dimming, or digital signaling). With experience in supplying to global markets and adherence to international quality standards such as UL, CE, and RoHS, Beauty STC is well-positioned to deliver high-performance LED components under private label or custom design arrangements.

Application Scenarios

The term “Flashforge M5 LED” appears to be a significant misunderstanding. Flashforge is a well-known manufacturer of 3D printers, and their M5 series (such as the M5, M5s, M5 Stack) are desktop 3D printers. They do not manufacture or sell standalone LED lighting products under the name “M5 LED” for architectural or commercial lighting applications like hotels, malls, or offices. Using a 3D printer component LED in these settings is neither appropriate nor feasible. It is crucial to select purpose-built commercial LED luminaires designed for the specific demands of each environment.

For hotels, suitable LED applications include warm-dimensionable downlights or wall washers in lobbies and guest rooms to create ambiance, high-CRI linear fixtures in corridors for accurate color rendering, and discreet, low-glare task lighting in executive lounges. Malls require high-output, high-CRI LED spotlights or track heads in retail areas to accurately showcase merchandise, robust linear high-bay fixtures in food courts for bright, even illumination, and vandal-resistant outdoor-rated wall packs or bollards for entrances and parking structures. Offices benefit from uniform, glare-controlled LED panel lights or suspended troffers in open-plan areas, adjustable task lights at individual workstations, and energy-efficient, sensor-compatible downlights in meeting rooms and private offices.

Installation must prioritize safety and performance. Always verify local electrical codes and ensure all luminaires carry relevant safety certifications such as UL, CE, or ETL for the installation region. Confirm the fixture’s IP rating matches the environmental conditions, for instance, using IP65-rated fixtures in hotel bathrooms or mall food court perimeters where moisture is present. Pay strict attention to thermal management by maintaining manufacturer-specified clearance around heat sinks, especially in enclosed ceiling spaces common in offices, to prevent premature LED degradation. When integrating dimming systems, use compatible drivers and dimmer switches tested with the specific luminaire model to avoid flicker or noise, which is particularly critical in hotel guest rooms requiring smooth dimming transitions. Finally, for large-scale installations across malls or multi-story hotels, implement a consistent labeling system during wiring to simplify future maintenance and troubleshooting. Consulting the technical specifications of actual commercial LED products from reputable lighting manufacturers is essential before procurement and installation.

Why Choose Beauty STC Lighting

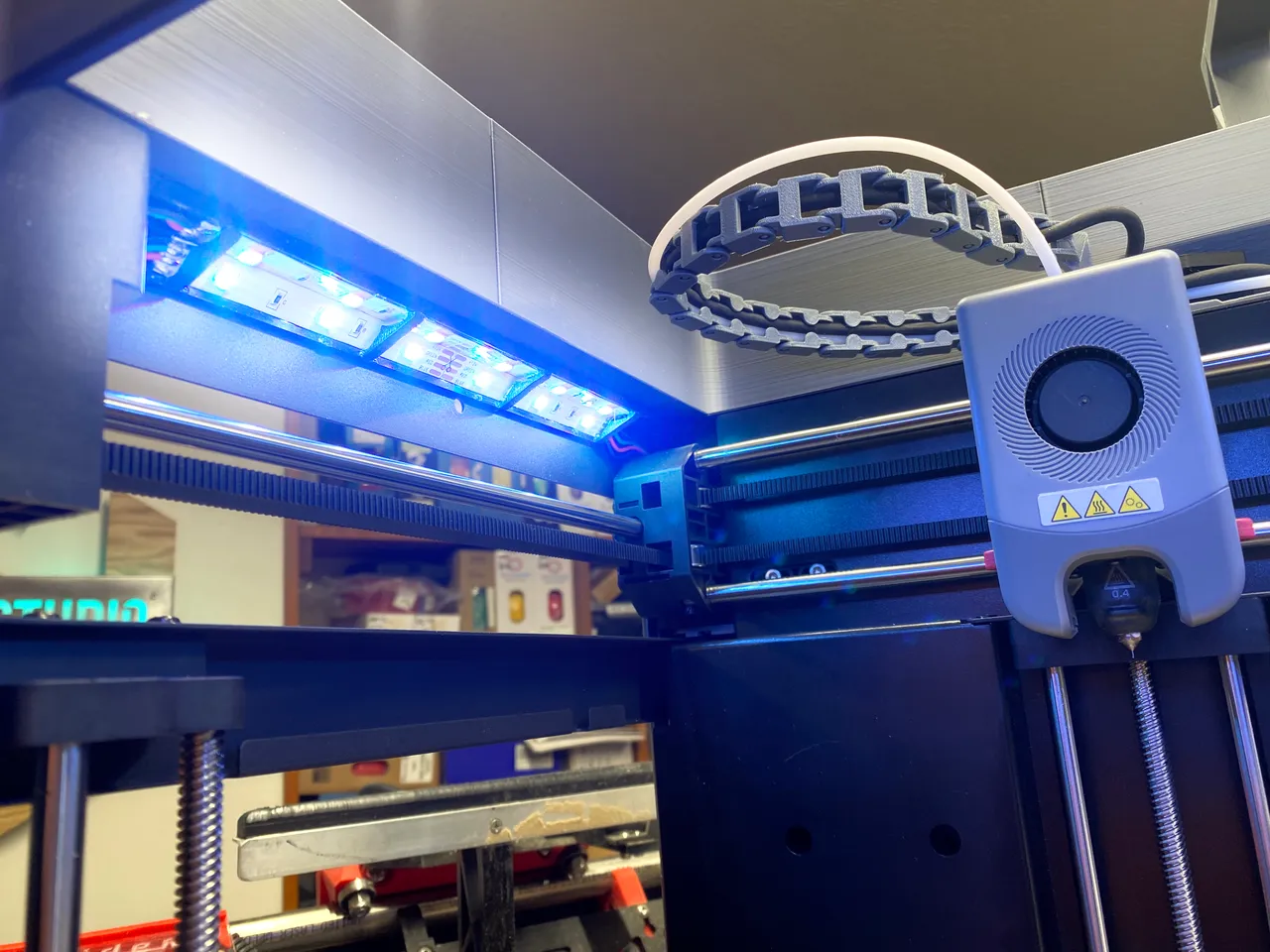

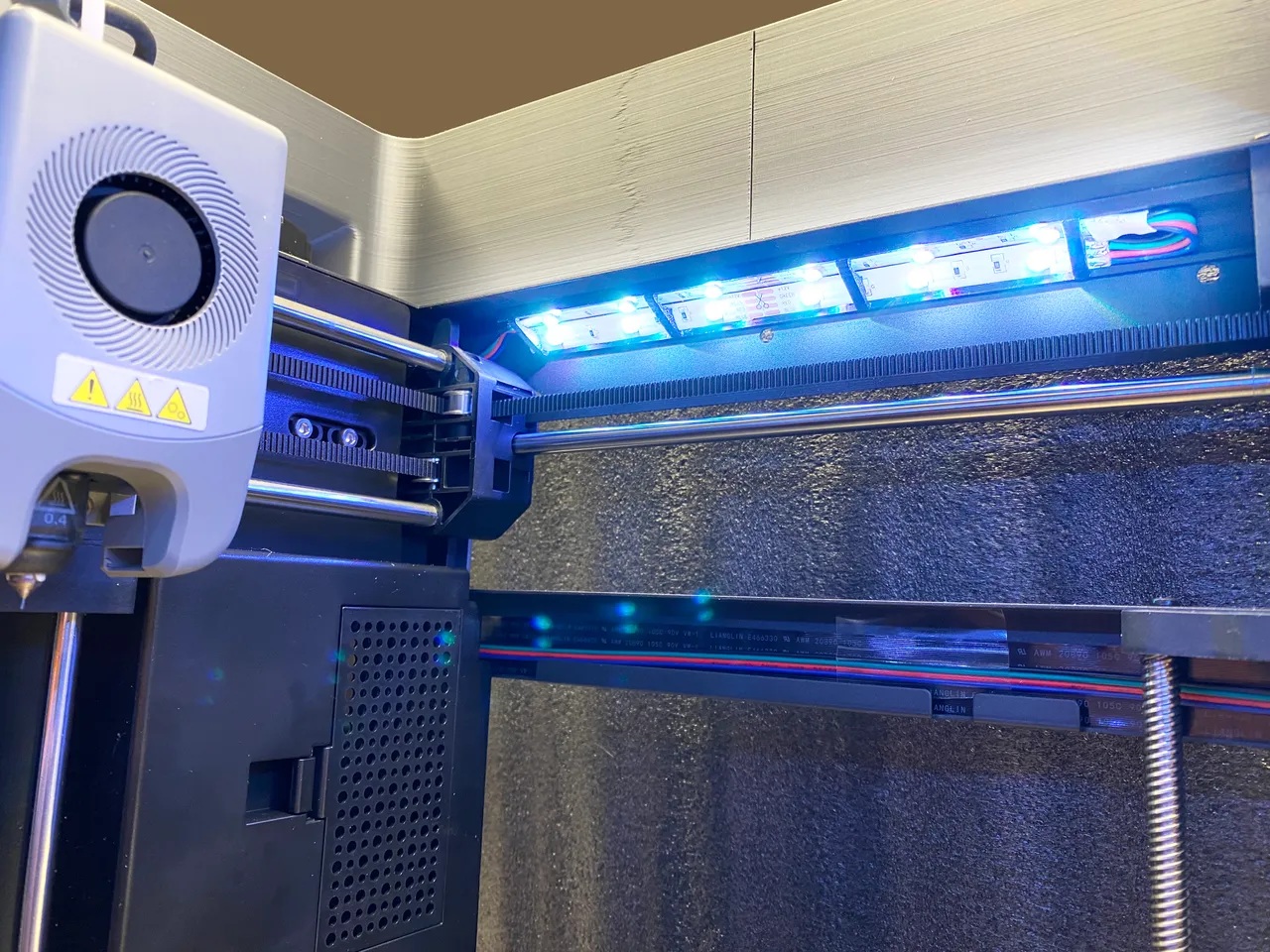

Upgrade your 3D printing experience with high-performance LED lighting solutions designed specifically for the Flashforge M5. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in precision LED lighting technology. Our expert engineering team delivers tailored illumination systems that enhance visibility, accuracy, and efficiency for your printing applications.

To learn more or discuss a customized lighting solution, contact our sales manager at [email protected]. Let Beauty STC power your innovation with reliable, high-quality LED integration.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.