Article Contents

Industry Insight: Diffused Led Light Strip

The Rise of Dot-Free, Continuous-Line LED Strips in Commercial & Industrial Projects

Why “Diffused” is No Longer Optional

Architects and lighting specifiers have shifted from “pixel-free” as a luxury to “dot-free” as a baseline expectation. In coves, wall-wash channels, refrigerated displays, clean-room ceilings and high-bay racking, a visible diode or brightness spike now reads as a defect. A properly diffused LED strip must therefore deliver:

Luminous uniformity ≥ 0.85 (min/max ratio) over the entire run

Binning tightness ≤ 3 SDCM to eliminate colour shift

Continuous length ≥ 10 m without voltage-drop shadows

Ingress rating ≥ IP54 for warehouse or cold-chain use

Certification files ready for AHJ (Authority Having Jurisdiction) in North America and the EU

Anything less triggers re-works, re-inspections and schedule penalties—costs that dwarf the savings from low-grade reels.

Certification Risk: The Hidden Cost of Non-Listed Strip

Import statistics show that >28 % of LED strip shipments into the EU and 35 % into North America are detained each year for non-compliant documentation (TARIC & CBP data, 2023). Typical findings:

| Detention Cause | Average Delay | Cost Impact (per container) |

|---|---|---|

| Missing EN 60598-2-21 test report (EU) | 18 days | €9 800 |

| False UL 2108 / ETL listing number (US) | 22 days | US $12 400 |

| Incorrect IP rating on label | 7 days | US $3 500 |

A factory that already holds ETL (UL 2108) and TUV CE (EN 60598-2-21, EN 62031, IEC/TR 62778) removes that risk from day one.

Beauty STC Lighting – Industrial-Grade Supply Since 1998

Established in 1998, Beauty (STC) Manufacturing Co., Ltd. has produced over 280 million metres of flexible PCB to date. Located in Jiangmen’s High-Tech Zone (Guangdong, CN), the 32 000 m² campus houses SMT lines (Yamaha & Juki), an in-house photometry lab (2 m integrating sphere, 30 m goniometer) and an IEC 60529 water/dust test tunnel. All diffused strip families are designed for OEM/ODM programmes: PCB width, CCT, CRI, output and connector position are adjusted without MOQ surcharges for annual orders > US $50 k.

| Core Capability | Data Point |

|---|---|

| First ISO 9001 registration | 2003 |

| ETL control number | 5020535 (US & Canada) |

| TUV CE file | 05910002-01 |

| Continuous run length (24 V) | 15 m @ < 5 % drop |

| Binning | 2 SDCM MacAdam (Cree, Samsung, Seoul) |

| IP process | Full IP20–IP68 in same profile family |

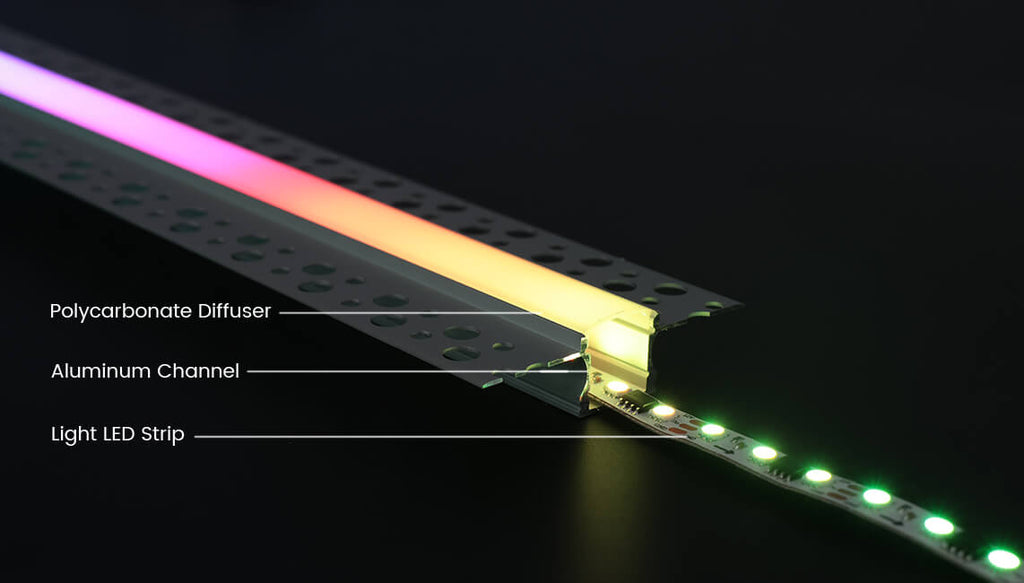

Engineering Notes: How We Remove the “Dotted” Effect

- Side-view 3014 or 2835 diodes mounted at 120 pcs/m give 1.25 mm centre-to-centre spacing—below the 2 mm visual resolution threshold at 1 m viewing distance.

- 90 % transmission polycarbonate diffuser with 0.3 mm laser micro-prism extracts ≥ 92 % of on-axis lumens while scattering the remaining 8 % to mask LED images.

- Copper-weight boost to 3 oz (105 µm) on 20 mm PCB keeps diode temperature < 55 °C at 14.4 W/m, extending L70 to >54 000 h (TM-21, 85 °C/85 % RH).

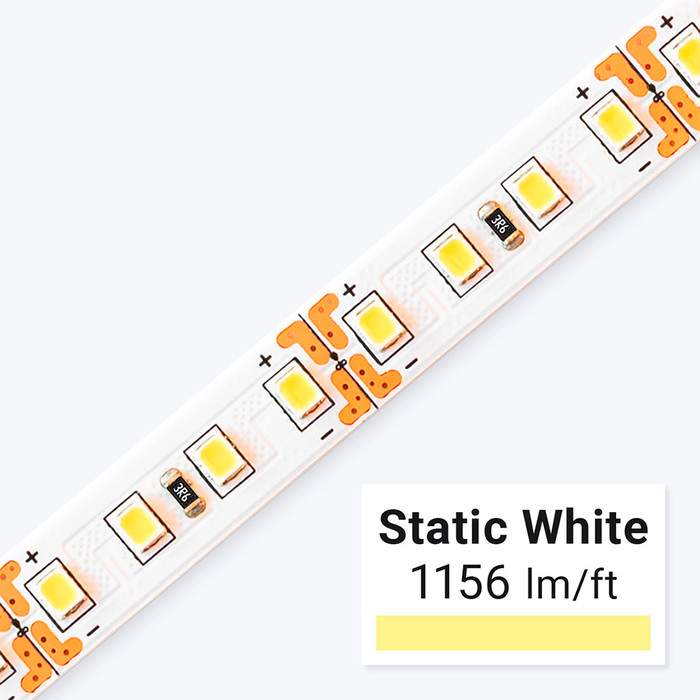

Specification Snapshot – Standard Industrial Diffused Strip

| Parameter | 24 V Standard | 24 V High-Output |

|---|---|---|

| LED type | Samsung LM301B | Seoul 3030 2 W |

| LEDs/m | 120 | 120 |

| Power/m | 14.4 W | 21.6 W |

| Flux/m | 1 650 lm | 2 450 lm |

| Efficacy | 115 lm/W | 113 lm/W |

| CCT range | 2 200 – 6 500 K | 2 400 – 5 000 K |

| CRI | Ra ≥ 90 optional | Ra ≥ 80 |

| Max run | 15 m | 10 m |

| Profile width | 8 mm / 10 mm / 12 mm | 12 mm |

| IP rating | IP20 – IP68 | IP20 – IP68 |

| Certifications | ETL, TUV CE, RoHS, REACH, LM-80 | ETL, TUV CE, RoHS, REACH, LM-80 |

Takeaway for Distributors, Contractors & Project Managers

When the lighting schedule calls for “continuous, dot-free, certified,” the cheapest reel is rarely the lowest-cost solution. Partnering with a 1998-established, ETL- and TUV CE-listed factory eliminates documentation surprises, speeds field installation and protects margin. Beauty STC Lighting supplies the diffused LED strip—and the compliance file—ready for immediate inspection release in 50+ countries.

For OEM profiles, length-specific kits or matched aluminium channels, contact:

[email protected] | +86-139-0288-5704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Precision Diffused LED Strip Lighting

When evaluating diffused LED strip lighting for commercial and architectural applications, technical specifications must align with project requirements. Beauty STC Manufacturing Co., Ltd. leverages 25+ years of industrial expertise to deliver certified, high-performance solutions that meet stringent international standards. Below is a comparative analysis of critical parameters where our certified products outperform generic market alternatives.

Key Technical Parameters and Industry Comparison

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens/Watt Efficiency | 80–100 lm/W | 100–120+ lm/W (verified via ETL/TÜV testing) |

| Color Rendering Index (CRI Ra) | 80–85 (inconsistent batch-to-batch) | >90 (typically 95+, certified per IESNA LM-79) |

| IP Rating Certification | Unverified claims; typically IP20 for indoor use only | IP65/IP67 certified (ETL/TÜV tested for wet/dust environments) |

| PCB Specifications | 0.6mm single-layer, 1oz copper | 1.0mm+ double-layer, 2oz copper with thermal vias and flame-retardant (UL94 V-0) substrate |

Rigorous Quality Assurance for Consistent Performance

Beauty STC’s manufacturing processes adhere to ISO 9001 standards, with each production batch subject to 100% electrical testing, thermal stress validation, and optical uniformity checks. Our in-house testing facility replicates real-world conditions—including thermal cycling (−20°C to +60°C), humidity exposure, and 1,000-hour accelerated aging tests—to ensure longevity and performance stability. All products carry verifiable ETL (USA/Canada) and TÜV CE (Europe) certifications, with full traceability from raw materials to finished goods via serialized production records.

As a certified OEM/ODM partner since 1998, we maintain identical quality benchmarks for custom projects. Whether sourcing standard diffused strips or engineering bespoke solutions for architectural installations, our technical team validates specifications against client requirements prior to production, ensuring compliance with regional safety standards and project-specific demands. This commitment to precision engineering has enabled consistent delivery to 50+ countries across commercial, industrial, and retail markets.

For technical documentation or custom specification validation, contact our engineering team at [email protected] or +86-13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Beauty (STC) Manufacturing Co., Ltd.

41th Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen, Guangdong, China

Certified: ETL (US/Canada) • TUV CE (EU) • ISO9001 since 1998

H2 | SMT-Driven Flexible Strip Line (10 000 m²)

Our 25-year-old facility is arranged as a vertically-integrated, single-site campus: raw PCB reel in → diffused strip reel out. Key stations are summarized below.

| Process Zone | Equipment Qty | Core Function | QA Gate |

|---|---|---|---|

| SMT-1 High-speed | 4 × Yamaha YSM-20R | 45 000 cph, 0201–8 mm pitch | 100 % 3-D AOI |

| SMT-2 Flexible | 2 × Panasonic NPM-WX | Handles 5–12 mm wide FPC, 0.2 mm thickness | 100 % 2-D SPI |

| Secondary Reflow | 2 × Heller 1912 MK5 | Lead-free, 10-zone, ΔT ≤ 5 °C | X-ray sampling |

| Silicone Extrusion | 3 × 90 mm L/D 28:1 | 120 °C–150 °C, 5 m min⁻¹, 180 °C steam cure | Dimensional ±0.1 mm |

| Aging Tunnel | 4 × 40 m, 50 °C–55 °C | 4 h burn-in @ 220 VAC, 0.7× rated current | 0.1 % failure threshold |

| Integrating Sphere | 2 × Everfine 2 m | LM-80 compliant, 5 nm optical resolution | CRI, CCT, lm, x,y |

| Packaging Cell | 4 lines | Anti-static reel + moisture-barrier bag | Drop-test 1 m/6 sides |

Daily capacity: 180 000 m of 10 mm PCB (24 h × 3 shifts).

Lead-time: 2–3 weeks standard, 7 days expedite.

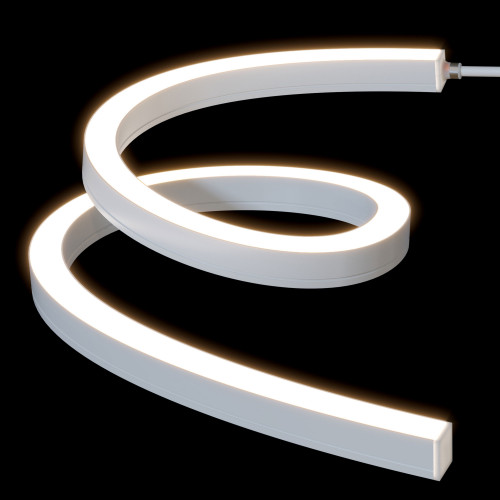

H3 | Diffusion & Dot-Free Optics

- Phosphor-in-silicone co-extrusion: phosphor platelet pre-mixed in 5000 cP silicone; eliminates secondary optic.

- Laser ablation micro-lens: 160° beam, 5 % luminance variance across 5 m.

- FPC copper weight 3 oz, keeps junction ≤ 65 °C @ 14.4 W m⁻¹, ensuring L₇₀ > 54 000 h (LM-80 @ 55 °C).

H2 | OEM / ODM Customisation Matrix

| Attribute | Standard Range | Engineering Notes |

|---|---|---|

| Length / Cut | 50 mm – 50 m continuous | 24 V design, 5 % voltage compensation every 2 m |

| CCT | 1800 K – 6500 K | 3 SDCM binning, TM-30 Rf > 90 optional |

| CRI | Ra 80 – 98 | Special R9 > 90 for museum, R15 > 95 for skin tone |

| Luminous Flux | 300 – 2 200 lm m⁻¹ | Drive current 0.2 – 1.5 A, efficacy up to 165 lm W⁻¹ |

| PCB Width | 5 mm, 8 mm, 10 mm, 12 mm, 20 mm | Double-layer, 3 oz Cu, white solder mask |

| IP Rating | IP20, IP54, IP65, IP67, IP68 | Extruded silicone or PU nano-coating |

| Packaging | 5 m reel, 50 m bulk reel, blister kit, colour sleeve | Bar-code & QR traceability, anti-static tray |

| Certification File | ETL/cETL, CE-EMC/LVD, RoHS, REACH, ERP | Technical construction file kept 10 years |

Private-label MOQ: 1 000 m per CCT / wattage.

Tooling fee: waived when annual forecast ≥ 50 km.

Artwork & driver label: 48 h turnaround.

H3 | QC & Traceability Protocol

IQC: 22-point PCB incoming checklist (dielectric, copper peel, dimensional).

IPQC: AOI data auto-uploaded to MES; CpK ≥ 1.33 required.

OQC: AQL 0.65 II, 100 % hi-pot 1 500 VAC, 100 % luminous flux vs. bin limit.

Serialisation: Each reel laser-marked with date-time + operator code; keeps full backward traceability to LED reel lot.

Reliability: 500-cycle on/off (-10 °C↔60 °C), 1000 h damp-heat 85 °C/85 % RH.

H2 | Logistics & Export Readiness

Jiangmen plant sits 90 min from Shenzhen port; weekly FCL consolidation to Hamburg, Los Angeles, and Dubai. All cartons pass 1 m drop, 28-day salt-spray simulation, and comply with Amazon SIOC Tier-2 when requested.

For project quotations, DXF / IES files, or UL-inspection appointments, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Strategic Applications for Diffused LED Strip Lighting

Diffused LED strip lighting delivers uniform, shadow-free illumination critical for professional environments. Engineered for precision and reliability, these solutions eliminate visible “hotspots” while meeting stringent global compliance standards. Below are industry-specific applications and technical best practices for contractors and project stakeholders.

Hospitality & Luxury Interiors

In high-end hospitality settings, diffused LED strips provide seamless, glare-free illumination that enhances guest experience without compromising safety compliance. Key applications include:

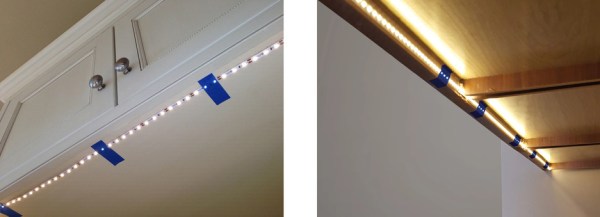

Cove lighting in hotel lobbies and corridors for ambient, non-distracting illumination

Under-bed lighting in suites to create warm, intimate atmospheres without harsh shadows

Spa and wellness area accents with tunable color temperatures (2700K–6500K) for therapeutic environments

Technical Advantage: All Beauty STC strips feature ≥90 CRI for accurate color rendering and ETL/TUV CE certifications, ensuring compliance with international hotel safety standards (e.g., NEC, IEC 60598).

Commercial Retail Environments

Retail spaces demand precise color accuracy and subtle illumination to highlight merchandise. Diffused strips excel in:

Display case backlighting for jewelry, cosmetics, and luxury goods

Backlit signage and brand logos with consistent luminance across all angles

Ceiling coves in shopping malls for energy-efficient ambient lighting

Technical Advantage: High CRI (≥90) ensures true-to-life color representation, while IP65-rated strips resist dust and moisture in high-traffic retail zones. Certifications guarantee compliance for EU and North American retail projects.

Modern Office Spaces

Office environments require adaptable lighting that supports productivity and well-being. Diffused strips are ideal for:

Perimeter cove lighting to eliminate glare on workstations and monitors

Under-desk task lighting with dimmable options for circadian rhythm support

Conference room accents and partition edges for flexible, glare-free illumination

Technical Advantage: OEM customization supports unique office layouts, including integrated DALI dimming systems. All products comply with IEC 62471 photobiological safety standards for workplace lighting.

Architectural Facades & Exterior Accents

For permanent outdoor installations, diffused strips deliver weather-resistant performance without compromising aesthetics:

Building outlines and structural accents for commercial complexes

Landscaping and pathway illumination in public plazas

Bridge and monument lighting requiring long-term durability

Technical Advantage: IP67-rated strips withstand rain, snow, and UV exposure. Certifications ensure adherence to IEC 60598-2-22 for outdoor luminaires, critical for global infrastructure projects.

Professional Installation Best Practices

Optimal performance requires adherence to technical standards. Contractors should follow these guidelines:

| Installation Aspect | Technical Guidance |

|---|---|

| Power Supply Sizing | Calculate total wattage + 20% headroom. For runs >10m, use parallel wiring or 18 AWG conductors to prevent voltage drop. |

| Heat Management | Mount strips in aluminum channels (minimum 10mm depth) to dissipate heat. Avoid thermal stress in enclosed spaces. |

| Cutting & Joining | Cut only at marked points. Use solderless connectors for secure, moisture-resistant joints. Never exceed 15m continuous runs without power injection. |

| Waterproofing | For outdoor use, apply silicone sealant on all joints and install IP67-rated junction boxes. Ensure conduit entries are sealed per NEC Article 314. |

| Compliance Documentation | ETL/TUV CE certifications simplify regulatory approvals. Provide test reports for projects requiring IEC 62031 or EN 62471 compliance. |

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| IP Rating | IP65 (indoor), IP67 (outdoor) |

| Max Continuous Length | 15 meters (without voltage drop) |

| Color Temperature Range | 2700K–6500K (adjustable dimming to 1800K for warm glow) |

| CRI (Color Rendering Index) | ≥90 |

| Certifications | ETL (USA/Canada), TUV CE (Europe), RoHS compliant |

| OEM Support | Custom lengths, connectors, diffuser types, color temperatures |

Engineered for global commercial projects since 1998, Beauty STC Lighting delivers factory-direct solutions validated by rigorous international testing. Our 25+ years of manufacturing expertise ensures reliability, compliance, and scalability for large-scale deployments.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – 25 Years of Factory-Driven Reliability

Why Global Specifiers Choose Our Diffused LED Strips

| Decision Factor | Beauty STC Advantage | Typical Market Offer |

|---|---|---|

| Regulatory Coverage | Dual ETL & TUV-CE (USA/Canada/EU) | Often single-certificate |

| Continuous Run Length | Up to 15 m dot-free on 24 V class | 5 m reels, visible hot-spots |

| L70 Lifetime | 54 000 h @ 45 °C Tc | 30 000 h average |

| Binning Tolerance | 3-SDCM MacAdam ellipse | 5–7 SDCM |

| OEM Lead-Time | 3-week repeat, 5-week NPI | 6–8 weeks |

| Export Footprint | 50+ countries, inc. EU/NAFTA | Regional only |

Capabilities You Can Audit

1998-built ISO-9001 factory, 12 000 m² Jiangmen HQ

In-house extrusion & PCB SMT lines—no subcontract diffusion

ETL-listed driver co-design (Class 2, 120–277 V)

TUV-CE EN 60598-2-20 for 24 V SELV strips, IP20–IP67

Full OEM/ODM package: photometry, mechanical, packaging, label

Ready-to-Ship Diffused Strip Platforms

| Part Code | Voltage | CCT | CRI | Output | Diffusion | IP | Reel |

|---|---|---|---|---|---|---|---|

| BSTC-D24-27 | 24 V | 2700 K | 97 | 1100 lm/m | Dot-free silicone | IP65 | 5 m |

| BSTC-D24-30 | 24 V | 3000 K | 97 | 1200 lm/m | Dot-free silicone | IP65 | 5 m |

| BSTC-D24-40 | 24 V | 4000 K | 97 | 1300 lm/m | Dot-free silicone | IP65 | 5 m |

| BSTC-D24-TW | 24 V | 1800–3000 K | 95 | 1050 lm/m | Pixel-free tunable | IP65 | 5 m |

Custom lengths, CCT, CRI 80–98, and printed FPC available on request.

Next Step—Engineering Sample or Project Quote

Email your specification sheet or drawing to [email protected]

Direct line: +86-13902885704 (English / Español / Русский)

We ship weekly to EU, US West & East Coast, Australia, Japan, Korea, Russia—DDP incoterms available.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).