Article Contents

Industry Insight: Bendable Led Lights

The commercial and industrial lighting sector is undergoing a significant transformation driven by the demand for adaptable, high-performance illumination solutions that meet the complex architectural and functional requirements of modern spaces. Bendable LED lights have emerged as a critical innovation, directly addressing the persistent challenge of effectively lighting curved surfaces, irregular architectural features, cove details, and dynamic retail or exhibition displays where traditional rigid fixtures fall short. This flexibility is no longer a niche feature but a fundamental requirement for achieving both aesthetic cohesion and optimal light distribution in demanding environments like airports, high-end retail, museums, and advanced manufacturing facilities. Crucially, the adoption of such innovative products hinges on unwavering reliability and strict adherence to safety standards; therefore, compliance with mandatory certifications such as ETL for North American markets and CE marking for Europe is non-negotiable, ensuring electrical safety, performance consistency, and regulatory acceptance for facility managers and specifiers. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of dedicated LED engineering expertise to develop robust, certified bendable lighting systems that deliver the durability, precise light quality, and installation versatility demanded by professional commercial and industrial applications.

Technical Specs & Certifications

Bendable LED lights from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability in both residential and commercial applications. These flexible lighting solutions are designed with advanced SMD LED technology, typically utilizing 2835 or 5630 diodes, to deliver exceptional luminous efficacy. The lumens per watt (lm/W) output ranges from 110 to 130 lm/W, depending on the color temperature and configuration, ensuring energy-efficient operation while maintaining bright, consistent illumination.

A key feature of Beauty STC’s bendable LED strips is the high Color Rendering Index (CRI), consistently rated above 90. This ensures accurate and vibrant color reproduction, making them ideal for environments where true color representation is critical—such as retail displays, art galleries, kitchens, and makeup areas. The high CRI is achieved through premium phosphor coatings and strict binning processes during manufacturing, reflecting Beauty STC’s commitment to optical quality.

In terms of environmental protection, Beauty STC offers bendable LED lights in multiple IP (Ingress Protection) ratings to suit diverse installation conditions. IP20 variants are suitable for dry, indoor environments, while IP65-rated strips are encapsulated in silicone to resist dust and low-pressure water jets, making them appropriate for kitchens, bathrooms, or outdoor signage. For fully waterproof applications such as pool lighting or outdoor architectural features, IP67 and IP68 rated options are available, capable of withstanding temporary submersion or continuous damp exposure.

Beauty STC maintains rigorous quality control throughout production, adhering to international standards including ISO 9001 and IEC certifications. Their bendable LED lights undergo extensive testing for thermal management, lumen maintenance (L70 > 50,000 hours), and electrical safety, ensuring long-term durability and performance consistency. With UL, CE, and RoHS compliance, Beauty STC’s products are trusted globally for their reliability, efficiency, and superior light quality.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as a core production hub for our advanced LED lighting solutions, including specialized bendable LED light products. The factory is a modern, ISO 9001-certified operation designed for high precision and scalability, featuring dedicated cleanroom environments for critical assembly processes. Central to our production capability are multiple state-of-the-art Yamaha YS Series SMT lines, configured with dual-lane setups to maximize throughput. These machines handle components down to 0201 metric size with exceptional placement accuracy of ±25μm, essential for the dense circuitry required in flexible and bendable LED modules. Each line integrates 3D Solder Paste Inspection (SPI) systems for paste volume and alignment verification, coupled with high-speed 3D Automated Optical Inspection (AOI) stations post-reflow to ensure zero-defect assembly of flexible PCBs and miniature LEDs.

Rigorous aging and reliability testing form a non-negotiable part of our quality control protocol at the Jiangmen site. All bendable LED light products undergo mandatory 24-hour continuous burn-in testing at elevated temperatures (typically 60°C ±5°C) across multi-tiered aging racks capable of simultaneously validating thousands of units. This initial stress test is followed by structured accelerated life testing in environmental chambers, simulating 5,000+ hours of operation under variable thermal cycling and humidity conditions per IES LM-80 standards. For bendable-specific validation, we employ dynamic flexing testers that repeatedly curve and straighten products to 5mm bend radii over 10,000 cycles while monitoring electrical continuity and lumen maintenance, ensuring mechanical resilience for installations requiring tight contours. Thermal imaging cameras also map heat distribution across bent configurations to verify safe operating temperatures.

Our OEM capabilities for bendable LED lights are a significant strength, supported by dedicated R&D and engineering teams co-located with production in Jiangmen. We offer comprehensive customization from initial concept through volume manufacturing, including tailored PCB flex designs (single-layer, double-layer, or rigid-flex hybrids), proprietary silicone or PVC jacketing formulations for enhanced flexibility and UV resistance, and custom optical lenses for beam control on curved surfaces. Clients can specify unique dimensions, color temperatures, dimming protocols (DALI, 0-10V, PWM), and IP ratings up to IP67, with our facility handling all tooling, prototyping, and compliance testing in-house. The factory operates with no minimum order quantity for qualified partners, leveraging our SMT flexibility and modular production cells to accommodate both high-volume runs and low-volume bespoke orders without line reconfiguration delays. Full technical documentation, including photometric reports and safety certifications (UL, CE, TÜV), is provided with every OEM project, ensuring seamless integration into clients’ end products.

Application Scenarios

Bendable LED lights are highly versatile and are increasingly used across various commercial environments due to their flexibility, energy efficiency, and aesthetic appeal. In hotels, these lights are ideal for creating ambient lighting in lobbies, hallways, and guest rooms. They can be installed under furniture, along curved architectural features, or behind headboards to produce a soft, welcoming glow that enhances the overall guest experience. Their ability to conform to irregular shapes makes them perfect for accentuating design elements such as reception desks or feature walls.

In malls, bendable LED lights are commonly used to highlight retail displays, signage, and cove lighting in corridors and food courts. Their flexibility allows for seamless integration into curved ceilings and dynamic architectural forms, contributing to an inviting and modern shopping atmosphere. They are also effective in illuminating staircases and escalator edges, improving both safety and visual appeal.

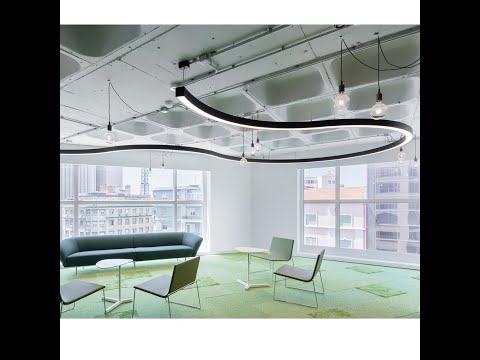

Offices benefit from bendable LED lights in both functional and decorative applications. They can be installed under shelves, along partitions, or within drop ceilings to provide indirect lighting that reduces glare and creates a comfortable work environment. In reception areas and meeting rooms, they add a contemporary touch while maintaining a professional aesthetic.

When installing bendable LED lights, ensure the surface is clean and dry to promote strong adhesion of the backing tape. For best results, use additional mechanical supports such as clips or brackets at regular intervals, especially in areas with vibrations or where the strip may sag over time. Avoid sharp bends that exceed the manufacturer’s minimum bend radius to prevent damage to the LEDs or circuitry. Always plan the power supply and connections carefully—use appropriate drivers and connectors, and avoid running the strip beyond its maximum recommended length to maintain consistent brightness. For environments with high humidity or temperature fluctuations, select waterproof or insulated variants and ensure all connections are properly sealed. Lastly, test the lighting layout before final installation to confirm alignment and performance.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s innovative bendable LED lights engineered for unmatched flexibility and performance. Our advanced flexible strips maintain consistent brightness and color accuracy even when curved around complex contours, eliminating visible dots and ensuring seamless integration into any architectural or decorative application. As a trusted manufacturing partner with over 15 years of specialized LED expertise, we deliver custom solutions that meet rigorous international standards while accelerating your time to market.

Partner with Beauty STC to leverage our precision engineering capabilities and scalable production capacity for your next-generation lighting designs. Contact our dedicated partnership manager today at [email protected] to discuss technical specifications, volume pricing, and how our bendable LED technology can elevate your product offerings. Let us help you turn creative visions into reliable, market-ready lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.