Article Contents

Industry Insight: Bed Frame Led Lights

The integration of LED lighting into bed frames has evolved beyond residential novelty to become a significant consideration within commercial and industrial lighting sectors, particularly in hospitality, healthcare, and senior living facilities. This shift is driven by the demonstrable benefits of integrated task lighting for guest safety, patient comfort, and operational efficiency in environments where nighttime navigation and low-level illumination are critical. Unlike consumer-grade solutions, commercial applications demand rigorous adherence to international safety and performance standards, making certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) non-negotiable prerequisites for procurement. These certifications assure facility managers and specifiers that the lighting systems meet stringent electrical safety, electromagnetic compatibility, and reliability benchmarks essential for high-occupancy, round-the-clock environments where failure is not an option.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized expertise in designing and manufacturing high-performance LED lighting solutions tailored specifically for the demanding requirements of the commercial and industrial markets. Our deep understanding of the regulatory landscape, including the critical importance of ETL and CE compliance, ensures that our bed frame LED lighting systems are not only innovative and aesthetically integrated but also engineered for the durability, safety, and consistent performance required in professional settings. We focus on providing reliable, code-compliant illumination that enhances user experience while meeting the exacting specifications of architects, designers, and facility operators worldwide.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance LED lighting solutions integrated into modern bed frame designs, emphasizing energy efficiency, color accuracy, and durability. Our bed frame LED lights are engineered for ambient and functional illumination in residential and hospitality environments, meeting stringent technical standards.

Each LED module in our bed frame lighting systems delivers a minimum of 90 lumens per watt, ensuring optimal energy efficiency without compromising brightness. This high luminous efficacy reduces power consumption while maintaining consistent light output over extended operation periods, making it ideal for low-energy lighting applications.

Color rendering is a critical focus in our design process. All bed frame LED lights feature a Color Rendering Index (CRI) exceeding 90, with select models achieving CRI values of 95+. This ensures accurate and natural color representation, enhancing the visual comfort of bedroom environments. High CRI lighting supports circadian wellness and is especially beneficial in settings where color perception matters, such as dressing areas or reading spaces adjacent to the bed.

With regard to environmental protection and safety, Beauty STC’s bed frame LED lights are typically rated at IP44 or higher. This level of ingress protection ensures resistance to dust and splashing water, making the fixtures suitable for a range of indoor conditions, including high-humidity rooms. The robust sealing also contributes to longer lifespan and reliability, particularly in concealed or under-bed mounting locations where maintenance access may be limited.

Quality is central to Beauty STC’s manufacturing philosophy. Our LED systems undergo rigorous testing for thermal management, electrical safety, and long-term photometric performance. We utilize premium-grade SMD LEDs, stable constant-current drivers, and aluminum heat dissipation structures to ensure consistent output and extended service life—typically exceeding 30,000 hours. All products comply with international safety and EMC standards, including CE, RoHS, and REACH certifications.

In summary, Beauty STC’s bed frame LED lights combine high efficiency (90+ lm/W), superior color fidelity (CRI >90), and reliable protection (IP44+), backed by our commitment to engineering excellence and product durability.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is situated within the Jiangmen National High-Tech Industrial Development Zone in Guangdong Province. This strategically located factory spans over 20,000 square meters and operates under stringent ISO 9001 and IATF 16949 quality management systems. The facility is purpose-built for high-volume, precision LED lighting production, featuring climate-controlled clean rooms for critical processes and dedicated zones for R&D, SMT assembly, final assembly, testing, and logistics. Its modern infrastructure supports efficient material flow and scalable production to meet global demand.

The Surface Mount Technology (SMT) production line forms the core of our electronics manufacturing capability. We utilize multiple high-speed Yamaha YS series placement machines, specifically the YS12F and YS24 models, configured for maximum flexibility and throughput. These machines handle components down to the 0201 metric package size with exceptional placement accuracy, crucial for densely populated LED driver and control boards. The line includes fully automated solder paste printers, reflow soldering ovens with precise thermal profiling, and AOI (Automated Optical Inspection) systems after solder paste application and post-reflow to ensure solder joint integrity and component placement correctness before proceeding to assembly. This setup guarantees the consistent quality and reliability required for embedded lighting applications.

Rigorous aging and reliability testing is integral to our quality assurance process, particularly for products like bed frame LED lights designed for long-term, continuous operation in residential environments. We operate a dedicated environmental testing laboratory equipped with multiple large-scale aging chambers. Finished LED light strips and integrated bed frame lighting modules undergo mandatory 72-hour continuous aging tests at elevated temperatures, typically 50-60°C, significantly exceeding standard room temperature operation. During this period, units are powered at rated voltage while monitored for light output consistency, color stability, thermal performance, and any early failures. This extended burn-in process effectively screens out infant mortality units, ensuring only robust products reach customers and directly contributing to our industry-leading field reliability metrics.

Our OEM capability for bed frame LED lighting solutions is a significant strength, developed through years of specialized experience. We offer comprehensive turnkey services starting from initial concept and optical/mechanical design support through to final packaged product. Our engineering team works closely with furniture manufacturers to integrate LED systems seamlessly into diverse bed frame structures, addressing challenges like flexible PCB routing within frame cavities, low-voltage DC power distribution, discreet driver placement, and user-friendly control interfaces. We excel in customizing light output profiles, color temperatures, dimming protocols, and physical form factors to match specific furniture aesthetics and functional requirements. The process includes rapid prototyping, DFM optimization, strict adherence to safety certifications like UL, CE, and FCC, and flexible production volumes from mid to high scale. This deep integration expertise ensures the LED lighting becomes a reliable, high-value feature of the final bed frame product without compromising the furniture manufacturer’s production efficiency.

Application Scenarios

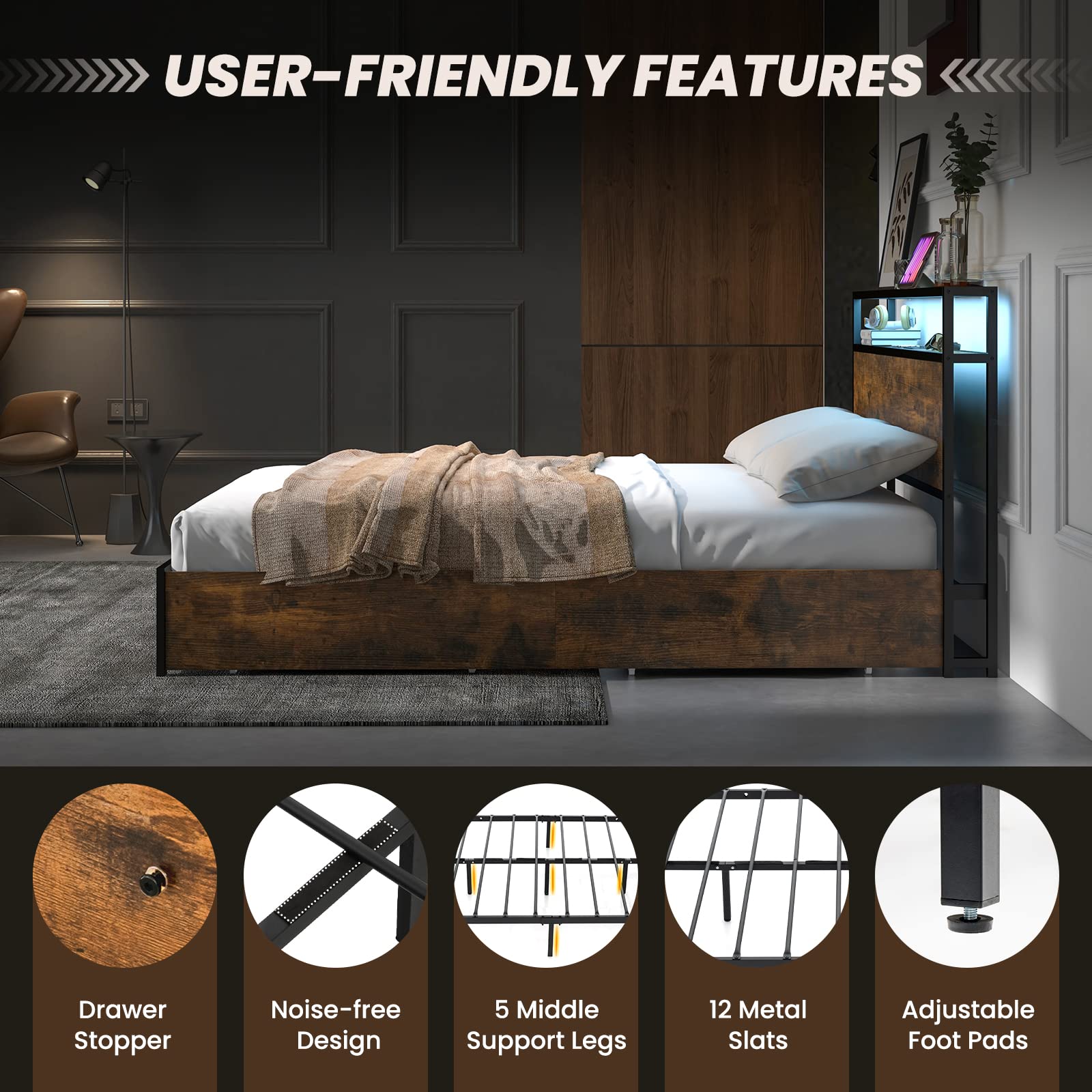

Bed frame LED lights are primarily designed for residential or hospitality bedroom environments and are not typically suited for large commercial spaces such as malls or offices. However, their most appropriate application within commercial settings would be in hotel guest rooms, where comfort, ambiance, and aesthetic appeal are important.

In hotels, bed frame LED lights can be used beneath the bed frame or along the headboard to create a soft, ambient glow. This enhances the guest experience by adding a modern, luxurious feel to the room. The lighting can serve both decorative and functional purposes—providing subtle illumination for nighttime navigation without disrupting sleep patterns. It is especially effective in boutique hotels, premium suites, or wellness-focused accommodations where mood lighting contributes to relaxation.

These lights are generally not recommended for malls or offices. Malls require bright, uniform illumination for safety, visibility, and product presentation, which bed frame LEDs cannot provide. Similarly, office environments demand task-oriented, glare-free lighting that supports productivity and meets workplace lighting standards—conditions that bed frame LEDs are not designed to fulfill.

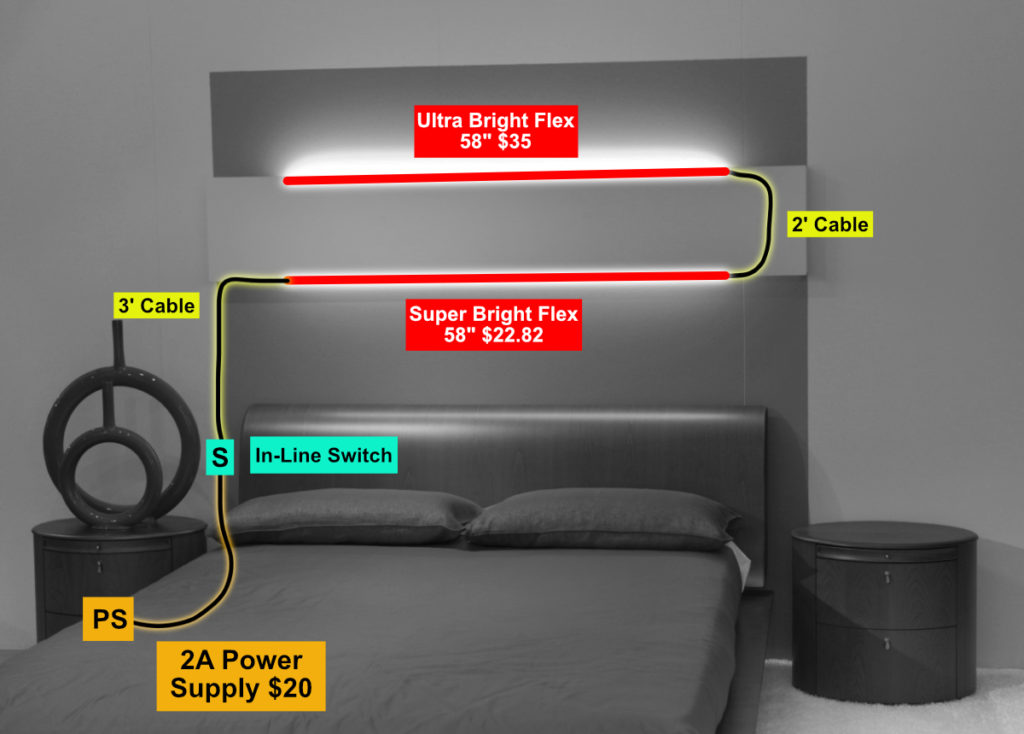

When installing bed frame LED lights, consider the following tips:

Ensure the bed frame has sufficient clearance from the floor to accommodate the light strip and allow for proper heat dissipation. Most LED strips perform best with at least 2 to 3 inches of space beneath the frame.

Clean the surface thoroughly before applying the LED strip. Dust, grease, or debris can reduce adhesive effectiveness. Use isopropyl alcohol to wipe the mounting area for optimal adhesion.

Plan the power source and wiring route in advance. For permanent installations, conceal the power cable along the bed frame legs or through channels to maintain a clean, professional look. Use cable clips or conduits where necessary.

Choose LED strips with a color temperature that complements the room’s décor—typically 2700K to 3000K for a warm, inviting glow. For added versatility, consider RGB or tunable white LEDs that allow guests or users to adjust the color or brightness.

Use a reliable low-voltage power supply that matches the LED strip’s voltage and current requirements. Overloading or underpowering can lead to flickering or premature failure.

For hotel applications, consider integrating the lights with a smart control system or touch sensor for ease of use and energy efficiency. Timers or motion sensors can also enhance functionality by turning the lights on automatically when someone approaches the bed at night.

Always follow the manufacturer’s installation guidelines and local electrical codes, especially in commercial installations. Where applicable, consult a licensed electrician for hardwired setups.

Why Choose Beauty STC Lighting

Elevate your bed frame designs with integrated LED lighting solutions engineered for precision and aesthetic appeal. At Beauty STC Manufacturing Co. Ltd we specialize in crafting high-quality customizable LED systems tailored specifically for furniture applications including seamless under-bed cove lighting adjustable headboard accents and energy-efficient ambient illumination. Our engineering expertise ensures reliable performance thermal management and effortless integration into your manufacturing process while meeting global safety and efficiency standards. Partner with us to access innovative lighting technology that enhances product value drives consumer demand and sets your bed frames apart in a competitive market.

Take the next step toward a collaborative partnership that delivers exceptional lighting experiences. Contact our dedicated team today at [email protected] to discuss your project requirements technical specifications and how Beauty STC can become your trusted manufacturing ally. We look forward to helping you illuminate innovation in sleep furniture.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.