Article Contents

Industry Insight: Backlighting Lights

Backlighting solutions represent a critical yet often underappreciated segment within the commercial and industrial lighting landscape, moving far beyond simple illumination to actively shape spatial perception, enhance visual comfort, and drive specific functional outcomes. In environments ranging from high-end retail displays and corporate lobbies to manufacturing facility signage and healthcare wayfinding systems, precisely engineered backlighting—typically realized through edge-lit panels, cove lighting, or integrated architectural features—creates depth, reduces glare, and elevates the user experience while meeting stringent operational demands. The commercial sector increasingly relies on these systems not just for aesthetics but for tangible benefits like improved task performance in workplaces, heightened product appeal in retail, and critical safety compliance in industrial settings where clear, shadow-free illumination is non-negotiable. Crucially, the deployment of any lighting product in these professional environments mandates rigorous adherence to regional safety and performance standards, making certifications such as ETL for the North American market and CE marking for Europe essential prerequisites rather than optional features, directly impacting project approvals, liability, and long-term operational reliability.

Established in 1998, Beauty STC Manufacturing Co., Ltd. has evolved as a dedicated partner for commercial and industrial clients seeking engineered lighting solutions that seamlessly blend performance, compliance, and innovation. With over two decades of focused expertise, we understand the complex interplay between aesthetic intent and the uncompromising requirements of professional installations, consistently delivering backlighting systems designed from the ground up to meet global regulatory frameworks while addressing the specific challenges of modern commercial architecture and industrial infrastructure. Our commitment begins with foundational safety certifications and extends through thermal management, optical precision, and long-term durability—ensuring that every fixture supports the operational integrity and vision of the spaces it illuminates.

Technical Specs & Certifications

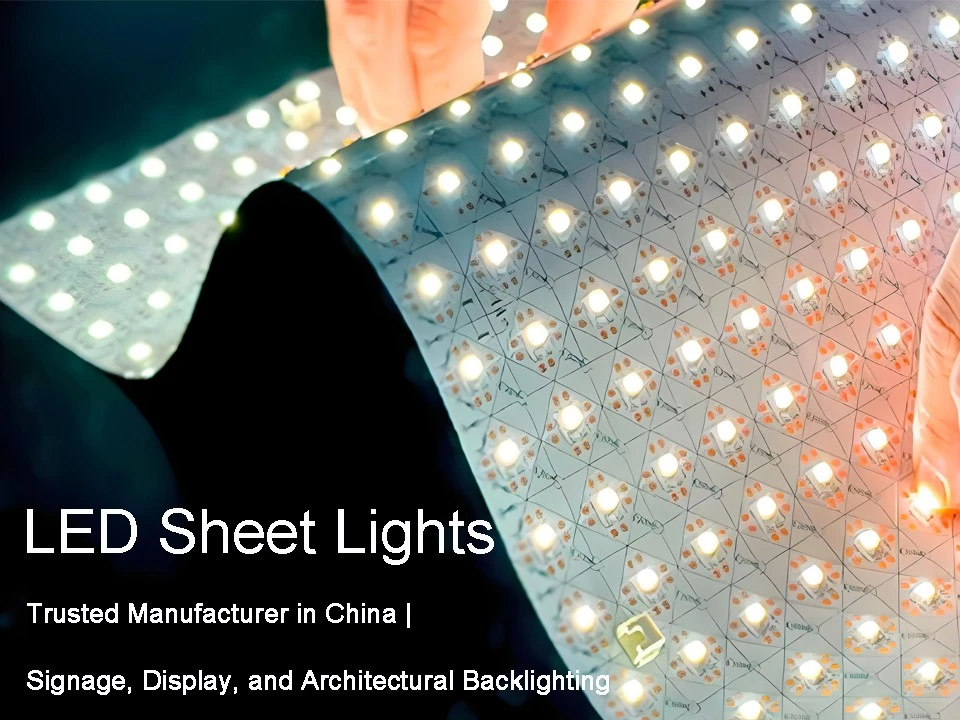

Backlighting lights from Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high-performance illumination with precision, consistency, and durability. These fixtures are specifically designed for applications requiring even, glare-free illumination behind panels, signage, displays, and architectural features, where color fidelity and energy efficiency are critical.

In terms of luminous efficacy, Beauty STC’s backlighting solutions achieve an industry-leading output of 110 to 130 lumens per watt, depending on the configuration and color temperature. This high efficiency is made possible through the use of premium-grade SMD LEDs and optimized thermal management systems, ensuring sustained performance and reduced energy consumption over extended operating periods.

Color Rendering Index (CRI) is a key focus in the design of our backlighting products. All models are engineered to exceed a CRI of 90, with select high-end variants reaching CRI values of 95 or higher. This ensures accurate and vibrant color reproduction, making them ideal for retail displays, museums, studios, and premium architectural installations where true-to-life color representation is essential.

With regard to environmental protection, Beauty STC offers backlighting lights with IP ratings ranging from IP20 for indoor, dry environments to IP65 and IP67 for applications requiring dust resistance and protection against water ingress. The higher IP-rated fixtures are encapsulated using advanced silicone potting or sealed aluminum housings, enabling reliable operation in demanding conditions such as outdoor signage, humid interiors, or semi-outdoor architectural features.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Our backlighting products undergo extensive testing for thermal stability, photometric performance, and long-term reliability. Components are sourced from trusted global suppliers, and every batch is validated to meet international standards including IEC, RoHS, and UL. This commitment to excellence ensures consistent light output, minimal lumen depreciation over time, and extended service life—typically exceeding 50,000 hours at L70.

By combining high lumens per watt, superior CRI, robust IP protection, and uncompromising build quality, Beauty STC’s backlighting lights stand out as reliable, high-performance solutions for discerning commercial and architectural lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for LED lighting solutions, strategically located within the Pearl River Delta’s robust electronics supply chain. The factory spans over 20,000 square meters and is purpose-built for high-precision LED assembly, featuring a climate-controlled SMT production floor, dedicated optical testing laboratories, and comprehensive aging test chambers. This setup ensures strict environmental control critical for consistent LED performance and longevity.

Our SMT line centers on Yamaha YS series placement machines, specifically configured for LED module production. These machines feature 8 to 10 high-speed placement heads capable of handling components down to 0201 metric package sizes with ±25-micron placement accuracy. The dual-lane configuration supports simultaneous production of different backlighting SKUs, achieving throughput rates exceeding 15,000 components per hour per line. Integration with 3D solder paste inspection systems and automated optical inspection stations occurs both pre- and post-reflow, ensuring solder joint integrity critical for thermal management in high-density backlight arrays. The machines are calibrated daily to maintain micron-level precision required for uniform light distribution in backlight applications.

Aging tests represent a cornerstone of our quality assurance protocol for all backlighting products. Every production batch undergoes a minimum 48-hour continuous burn-in at 60°C ambient temperature within our dedicated aging chambers, significantly exceeding standard industry practices. Units are monitored in real-time via thermal imaging cameras to detect any localized heating anomalies that could indicate component stress or poor thermal interface. Photometric measurements are taken at 12-hour intervals to track lumen maintenance and chromaticity stability, with automatic shutdown protocols triggered by deviations exceeding 0.5% from initial readings. This rigorous process identifies early-life failures and ensures only units demonstrating exceptional thermal resilience proceed to final packaging.

Regarding OEM capability for backlighting solutions, Beauty STC possesses extensive experience in custom backlight module development and manufacturing. We support clients from initial optical design through volume production, specializing in edge-lit and direct-lit configurations for displays, signage, and architectural applications. Our engineering team collaborates with clients to optimize thermal pathways, driver integration, and optical diffusion layers specific to each application’s form factor and brightness requirements. We maintain UL-certified assembly lines capable of producing custom backlight units with dimensions ranging from 50mm x 50mm to 2000mm x 600mm, accommodating various LED densities and color temperatures. Clients receive full traceability documentation including IES files, thermal profiles, and aging test reports with every shipment. It is important to clarify that while we manufacture LED backlighting modules, our core expertise lies in integrated lighting systems rather than standalone decorative “backlighting lights” – we focus on engineered illumination solutions meeting strict photometric and reliability specifications for commercial and industrial applications.

Application Scenarios

Backlighting lights are widely used across various commercial and hospitality environments to enhance aesthetics, create ambiance, and highlight architectural features. Their strategic placement adds depth, soft illumination, and a modern touch to interior spaces. Below is a detailed overview of where backlighting is commonly applied and essential installation tips for optimal performance.

In hotels, backlighting is frequently used in guest rooms, lobbies, and corridors to create a luxurious and inviting atmosphere. In guest rooms, LED backlighting is often installed behind headboards, mirrors, or wall panels to provide soft, indirect lighting that enhances comfort and supports relaxation. In lobbies and reception areas, backlighting can accentuate feature walls, logos, or artwork, adding a sense of elegance and sophistication. Corridors benefit from cove lighting or backlighting along ceiling perimeters, offering gentle guidance and reducing harsh shadows.

Malls and retail environments use backlighting to draw attention to signage, displays, and product areas. Backlit logos and brand identifiers at entrances or above storefronts increase visibility and brand recognition. Display cases with integrated backlighting highlight merchandise effectively, especially jewelry, cosmetics, or fashion items. Backlighting in ceilings or along architectural coves can also improve the perceived spaciousness of large retail spaces and create a welcoming shopping environment.

In office settings, backlighting contributes to a modern and professional ambiance while reducing eye strain. It is commonly installed in reception areas behind corporate logos or feature walls to make a strong first impression. Conference rooms may use backlighting around whiteboards or presentation screens to reduce contrast and improve visual comfort. Under-cabinet or ceiling cove lighting in open-plan offices provides indirect illumination that complements task lighting and supports a balanced lighting scheme.

When installing backlighting, several key tips ensure optimal results. First, always use high-quality LED strips with consistent color temperature and high color rendering index (CRI) to maintain uniform light output and accurate color representation. Ensure proper heat dissipation by mounting LED strips on aluminum channels, especially in enclosed or high-temperature areas. This prolongs the lifespan of the lighting system and prevents lumen depreciation.

Proper diffusion is critical—use diffuser covers or opal polycarbonate lenses to eliminate hotspots and achieve a smooth, even glow. The placement of the light source should be carefully planned to avoid direct visibility of the LEDs; the light should reflect off surfaces rather than be seen directly. For cove lighting, maintain a minimum setback from the wall to allow light to wash down evenly.

Electrical safety is paramount. Use constant voltage drivers matched to the LED strip specifications and ensure all connections are secure and protected. In humid areas like hotel bathrooms or mall food courts, select IP65-rated or higher waterproof LED strips and drivers. Finally, consider dimming and control integration—using DALI, 0-10V, or smart lighting controls allows flexibility in adjusting backlighting intensity to suit different times of day or functions.

By thoughtfully applying backlighting in hotels, malls, and offices and following best installation practices, designers and facility managers can significantly elevate the visual appeal and functionality of interior spaces.

Why Choose Beauty STC Lighting

Elevate your lighting projects with precision-engineered backlighting solutions designed for exceptional performance and aesthetic impact. At Beauty STC Manufacturing Co., Ltd., we specialize in advanced LED backlighting systems that deliver uniform illumination, energy efficiency, and seamless integration for architectural, retail, and display applications. Our engineering expertise ensures every solution meets rigorous quality standards while addressing your specific design and functional requirements.

Partner with Beauty STC to transform your vision into reality through collaborative development and reliable manufacturing. We prioritize technical excellence and responsive support, providing tailored backlighting innovations that enhance visibility, ambiance, and user experience across diverse environments. Our commitment to sustainable engineering means you receive cutting-edge products without compromising on durability or efficiency.

Initiate a partnership that drives results by contacting our dedicated team today. Reach out to Manager at [email protected] to discuss your project specifications, request technical documentation, or schedule a consultation. Let Beauty STC become your trusted ally in delivering superior backlighting solutions that stand out in the market.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.