Article Contents

Industry Insight: Adhesive For Led Light Strips

In the rapidly evolving landscape of commercial and industrial lighting, LED light strips have become a cornerstone of energy-efficient, flexible, and scalable illumination solutions. As demand grows for seamless integration in architectural features, signage, cold storage facilities, and manufacturing environments, the reliability of adhesive systems used to mount LED strips has become a critical factor in long-term performance. Industrial-grade adhesives must not only provide strong initial bonding across diverse substrates—such as metal, concrete, and composite materials—but also maintain integrity under temperature fluctuations, humidity, and continuous operational stress. Compliance with safety and performance standards such as ETL and CE is essential, ensuring that adhesive-backed LED products meet rigorous requirements for electrical safety, environmental resistance, and fire performance in commercial installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED lighting solutions for industrial and commercial applications. With over two decades of engineering expertise, Beauty STC specializes in high-performance LED strips and integrated mounting systems designed for durability and ease of installation in demanding environments. The company’s commitment to quality is reflected in its ETL- and CE-certified product lines, which are trusted by contractors, OEMs, and facility managers worldwide. As a leader in adhesive-backed LED technology, Beauty STC continues to set industry benchmarks for reliability, compliance, and technical support in large-scale lighting deployments.

Technical Specs & Certifications

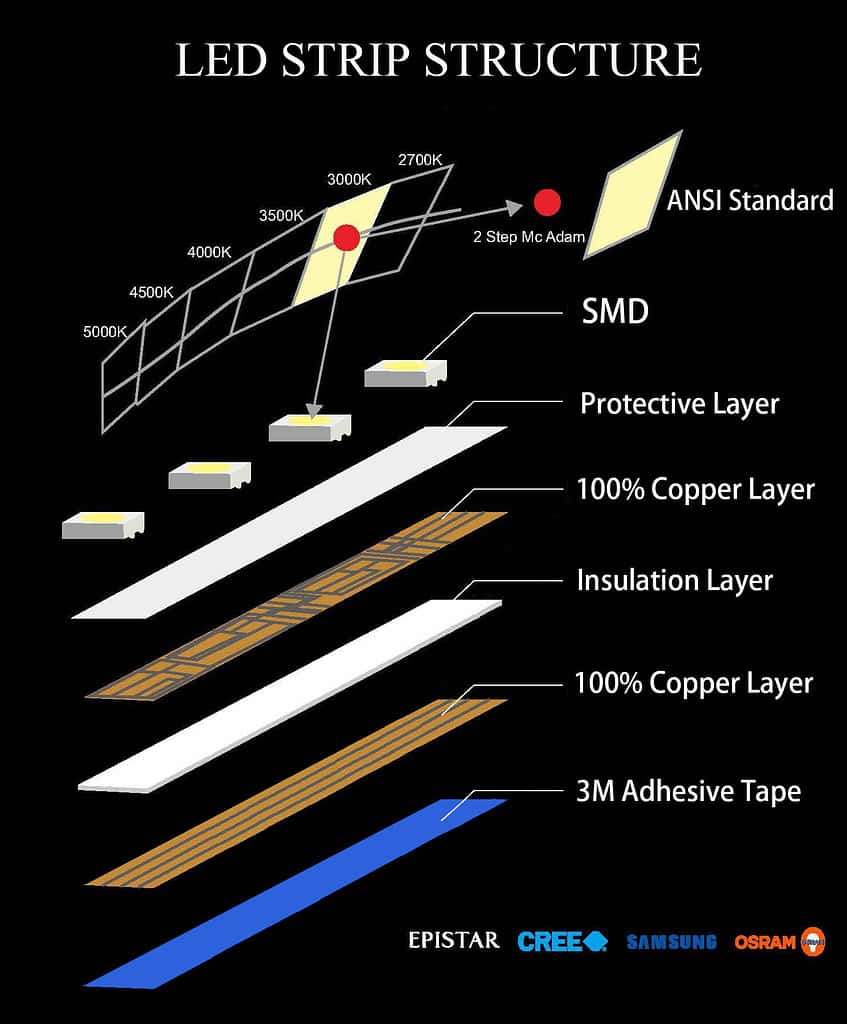

Beauty STC Manufacturing Co., Ltd. emphasizes that the adhesive backing applied to LED light strips is a critical mounting component but does not possess inherent optical properties such as lumens per watt or Color Rendering Index (CRI). These metrics are solely determined by the LED semiconductor chips, driver electronics, and optical design of the light strip itself. The adhesive’s role is purely mechanical and environmental protection. Confusing adhesive properties with LED performance specifications is a common technical misunderstanding.

Lumens per watt (efficacy) and CRI >90 are specifications strictly associated with the LED module. Beauty STC achieves high efficacy, typically ranging from 110 to 130 lumens per watt for our standard high-CRI strips, through the use of premium Epistar or Samsung LED chips combined with optimized constant-current drivers. Our strips consistently deliver CRI values exceeding 90 Ra, with many products reaching 95 Ra or higher, ensuring accurate and vibrant color representation essential for retail, hospitality, and high-end residential applications. This optical performance is independent of the adhesive system.

The adhesive backing significantly influences the achievable Ingress Protection (IP) rating when the strip is installed correctly. Beauty STC utilizes high-performance acrylic pressure-sensitive adhesives (PSAs) specifically engineered for LED applications. These adhesives offer strong initial tack and develop a permanent, durable bond to common substrates like aluminum channels, painted drywall, and PVC after full cure. For IP65 and IP67 rated strips, the adhesive works in conjunction with the strip’s silicone or PVC jacket. The adhesive must maintain bond integrity under thermal cycling and resist degradation from moisture and UV exposure to prevent water ingress at the mounting interface. Our adhesives are rigorously tested to withstand operating temperatures from -20°C to +60°C and exhibit excellent UV resistance to prevent yellowing or bond failure when exposed to sunlight, which is crucial for maintaining the specified IP rating over the product’s lifetime.

Beauty STC’s commitment to quality is evident in our adhesive selection and validation process. We do not source generic adhesives. Each formulation undergoes extensive in-house testing, including 1000+ hour thermal cycling tests, 500+ hour salt spray exposure, and continuous humidity testing at 85°C/85% RH to simulate harsh environments. We verify bond strength retention after aging and ensure compatibility with our strip encapsulants to prevent delamination. This stringent quality control, part of our ISO 9001 certified manufacturing process, guarantees that the adhesive performs reliably as an integral component of the complete lighting system, directly supporting the longevity and environmental protection promised by our IP-rated products. The adhesive is a foundational element enabling the strip to deliver its specified optical performance and durability in real-world installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

At the core of the production line are advanced SMT (Surface Mount Technology) machines, which enable precise and automated placement of electronic components onto PCBs used in LED strips and modules. These SMT lines are fully automated, featuring high-speed pick-and-place machines, reflow soldering systems, and automated optical inspection (AOI) equipment. This ensures consistent soldering quality, high yield rates, and the ability to handle complex, high-density circuit designs required for modern LED applications.

The Jiangmen facility also includes a comprehensive aging and reliability testing area. Every batch of LED light strips undergoes rigorous aging tests under controlled conditions, typically operating at elevated temperatures and full load for durations ranging from 24 to 72 hours. This process helps identify early failures, verify thermal management performance, and ensure long-term reliability before products are shipped. Additional testing capabilities include photometric measurements, waterproof testing (for IP-rated strips), and electrical safety checks, all conducted in accordance with international standards.

Regarding OEM capabilities, Beauty STC has extensive experience in providing customized solutions, including the development and production of specialized adhesive for LED light strips. The company can formulate and apply adhesives tailored to specific requirements such as enhanced thermal conductivity, UV resistance, strong bonding on various substrates (e.g., plastic, metal, glass), or improved flexibility for curved installations. This adhesive can be applied inline during the manufacturing process, ensuring uniformity and strong adhesion critical for both performance and durability. Clients can leverage Beauty STC’s R&D team to co-develop proprietary adhesive solutions under private labels, with full support in packaging, branding, and compliance documentation.

Overall, the Jiangmen factory combines automation, stringent quality assurance, and flexible customization to serve global clients in residential, commercial, and industrial lighting markets.

Application Scenarios

Adhesive for LED light strips primarily refers to the pressure-sensitive tape pre-applied to the back of most flexible LED strip products, not a separate adhesive product. This tape is almost always a high-performance acrylic-based adhesive like 3M VHB or equivalent. Its correct application is critical for longevity and safety in commercial settings. For installations requiring additional bonding beyond the strip’s integrated tape—such as in high-moisture zones or with heavy-profile channels—a neutral-cure silicone sealant (rated for plastics) may supplement the primary tape, but never replace it on non-waterproof strips as it traps heat.

In hotels, this integrated adhesive is essential for discreet ambient lighting. Apply strips under guest room bed frames for gentle night lighting, within cove details of lobbies for indirect illumination, and along vanity mirror perimeters in bathrooms. Crucially, in bathroom applications, ensure the strip has an IP67 rating and seal all cut ends and connectors with silicone before installation to prevent moisture ingress behind the strip. Never rely solely on the adhesive tape in wet zones; it bonds the strip to the surface but does not seal electrical components.

Malls demand robust and visually clean installations for high-impact areas. Use the adhesive tape to mount strips inside display window trim for product highlighting, along the underside of escalator handrails for safety guidance, and within ceiling coves in food courts for diffuse lighting. Surface preparation is non-negotiable here—thoroughly clean painted drywall or metal surfaces with isopropyl alcohol to remove dust and oils from high foot traffic. For glass installations like storefronts, confirm the adhesive is compatible with the glass type; some low-iron glass requires specific tapes. Always allow full 72-hour cure time before mall opening hours to prevent strip detachment from vibration.

Offices utilize adhesive-mounted strips for functional and aesthetic purposes. Install them under desk edges for glare-free task lighting, along the top edge of partition walls for subtle wayfinding, and above whiteboards for shadow-free illumination. Key considerations include avoiding direct sunlight exposure on strips near windows, as UV degrades adhesive over time, and ensuring strips are mounted on thermally conductive surfaces like aluminum channels when used for primary task lighting—never adhere directly to insulation or flammable materials. In partition installations, verify local electrical codes permit low-voltage strips within office furniture; many jurisdictions require listed mounting channels.

Installation universally requires meticulous surface preparation. Clean all substrates with acetone or high-purity isopropyl alcohol, removing all grease, dust, and loose particles. Apply firm, consistent pressure along the entire strip length using a roller tool—finger pressure is insufficient for reliable adhesion. Allow a minimum 30-minute dwell time at room temperature before powering the strips. For critical overhead or vertical installations in these commercial spaces, mechanically secure the strip ends with clips or brackets during the initial 24-hour adhesive cure period, as thermal expansion can cause end-lifting. Always operate strips within their specified temperature range during installation; cold environments below 10°C drastically reduce initial bond strength. Remember that adhesive failure almost always stems from inadequate surface prep or premature thermal stress, not tape quality.

Why Choose Beauty STC Lighting

Looking for a reliable adhesive solution for your LED light strips? Partner with Beauty STC, a trusted leader in LED lighting manufacturing. Our high-performance adhesives are engineered to ensure strong, durable bonding for all types of LED strip installations. Whether you’re working on residential, commercial, or industrial projects, Beauty STC delivers quality you can count on.

Take the next step in enhancing your lighting solutions. Contact us today at [email protected] to discuss how we can support your needs with superior adhesive products and expert service.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.