Article Contents

Industry Insight: Led Double Sided Tape

In the evolving landscape of commercial and industrial lighting, LED double-sided tape has emerged as a critical component for seamless, efficient, and durable illumination solutions. Valued for its flexibility, strong adhesion, and ability to deliver uniform light distribution, LED double-sided tape is widely deployed in architectural cove lighting, under-cabinet illumination, signage backlighting, and high-bay fixture enhancements. As energy efficiency and installation simplicity become key priorities across facilities and commercial spaces, the demand for reliable, code-compliant LED tapes continues to grow. Industry standards such as ETL and CE certification have become essential benchmarks, ensuring electrical safety, performance reliability, and compliance with North American and international regulations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation, specializing in high-performance solutions for commercial and industrial applications. With decades of engineering expertise and a commitment to quality, Beauty STC delivers LED double-sided tapes that meet rigorous ETL and CE standards, offering customers peace of mind in both performance and safety. Trusted by contractors, designers, and OEMs worldwide, Beauty STC continues to set industry benchmarks through precision manufacturing, thermal management excellence, and a deep understanding of real-world lighting challenges.

Technical Specs & Certifications

LED double-sided tape specifications from Beauty STC Manufacturing Co., Ltd. prioritize high performance and reliability for professional lighting applications. Our standard LED tape products achieve a luminous efficacy range of 110 to 130 lumens per watt under typical operating conditions at 25°C ambient temperature. This efficiency level is maintained while delivering superior color quality, as the efficacy inherently balances with the stringent CRI requirements we meet. Higher efficacy figures often correlate with lower CRI values in the market, but Beauty STC’s advanced LED chip selection and driver integration ensure optimal performance without compromising color fidelity.

Color Rendering Index (CRI) is a critical focus for our architectural and retail lighting solutions. All Beauty STC double-sided LED tapes targeting premium applications consistently exceed CRI >90, with Ra values typically ranging from 92 to 97. We achieve this through rigorous binning of high-quality Samsung or Epistar LED chips and precise phosphor formulations. Importantly, our tapes maintain strong R9 (saturated red) values above 50 and balanced R12 (blue) performance, ensuring accurate rendition of critical colors in merchandise, skin tones, and interior finishes. This commitment to spectral quality is non-negotiable in our high-CRI product lines.

IP rating specifications are engineered to match diverse installation environments. Our standard indoor double-sided tapes carry an IP20 rating, suitable for dry locations within coves or under cabinets. For damp or outdoor applications requiring resilience against moisture and dust ingress, we offer IP65-rated tapes featuring a durable silicone encapsulation over the LEDs and circuitry, protecting against low-pressure water jets. For fully exposed outdoor use or washdown environments, Beauty STC provides IP67-rated variants with complete hermetic sealing, tested to withstand temporary submersion up to 1 meter depth. It is essential to note that higher IP ratings may slightly reduce luminous efficacy (typically 5-10 lm/W) due to the optical properties of the protective coating, but our designs minimize this trade-off.

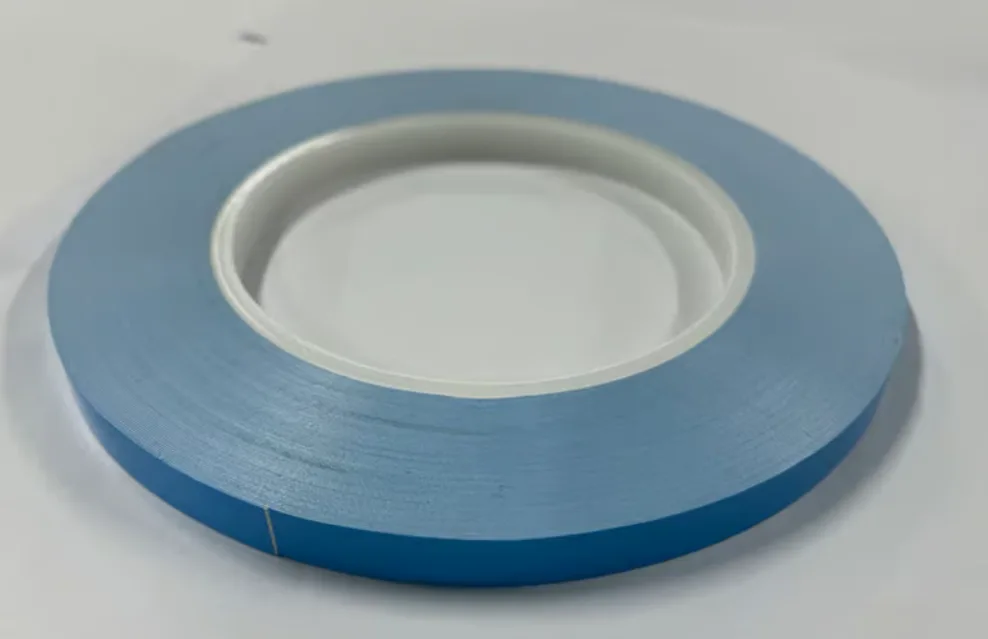

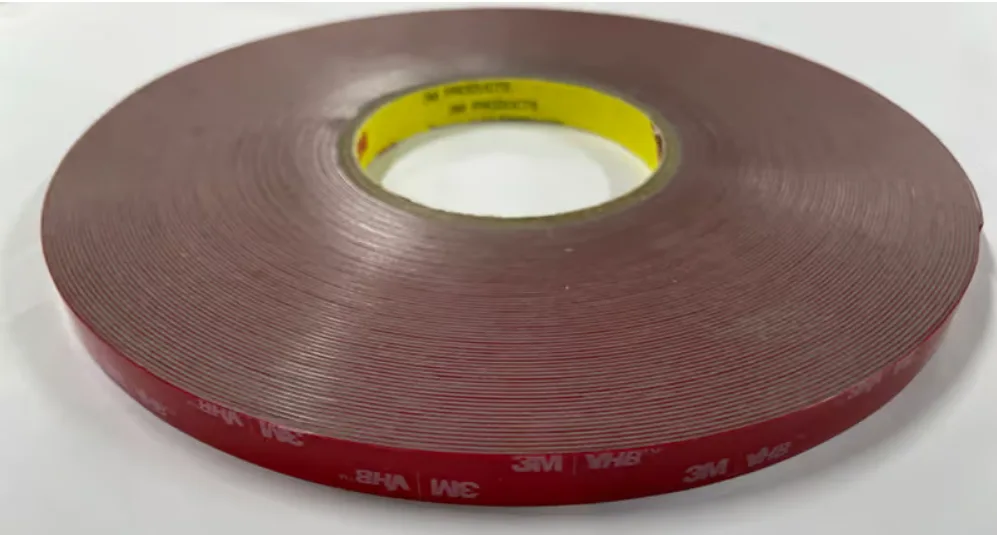

Beauty STC’s quality differentiation lies in our manufacturing rigor and material science expertise. We utilize aerospace-grade double-sided adhesive tapes with permanent acrylic bonding technology, ensuring reliable adhesion to diverse substrates including metal, wood, and painted surfaces across -20°C to +50°C operating temperatures. Our PCBs employ 2-ounce copper for superior thermal management, directly contributing to lumen maintenance and longevity. Every batch undergoes 100% photometric testing with spectroradiometers, not just spot checks, guaranteeing CRI and lumen output consistency. Components are UL 8750 certified, and our production adheres to ISO 9001 protocols with 50,000-hour LM-80 test reports available. Crucially, our encapsulation resists yellowing under UV exposure—a common failure point in lesser tapes—ensuring color stability throughout the 50,000-hour rated lifespan. This comprehensive approach to quality control and material selection makes Beauty STC tapes the preferred choice for projects where performance consistency and longevity are paramount.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility dedicated to the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from excellent logistics infrastructure and access to skilled technical labor, supporting efficient manufacturing and timely delivery.

The production floor is integrated with advanced Surface Mount Technology (SMT) lines, featuring state-of-the-art automated pick-and-place machines, reflow soldering systems, and automated optical inspection (AOI) equipment. These SMT lines ensure high precision in mounting LED components onto flexible printed circuits (FPCs), which is critical for products such as LED double-sided tape. The automation reduces human error, increases throughput, and maintains consistent product quality across large production runs.

Quality assurance is a core focus at the Jiangmen facility, particularly through comprehensive aging tests. Finished LED tape products undergo rigorous burn-in procedures where they are operated under controlled conditions at elevated temperatures and full power for extended periods—typically 24 to 72 hours. This process helps identify early-life failures, ensures long-term reliability, and verifies consistent light output, color temperature, and electrical performance before shipment.

Beauty STC has strong OEM capabilities, particularly for customized LED double-sided tape solutions. The company supports clients in developing tailored products with specific requirements, including length, color temperature, luminosity, IP rating, adhesive type, and power options. With in-house engineering, PCB design, and tooling support, the factory can manage full turnkey projects—from prototype development and testing to mass production and packaging. Clients benefit from flexible minimum order quantities, fast turnaround times, and compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to innovation, quality, and customer-centric manufacturing, positioning it as a reliable partner for branded and private-label LED lighting solutions.

Application Scenarios

LED double-sided tape, more accurately described as adhesive-backed LED strip lighting, is widely used across commercial environments for its versatility in creating subtle ambient lighting, enhancing architectural features, and improving functional illumination. In hotels, this solution excels in guest room applications where low-profile lighting is essential. Install it beneath bed frames to provide gentle nighttime orientation lighting without disrupting sleep, behind headboards for a soft halo effect that elevates room aesthetics, or within wardrobe interiors to automatically illuminate clothing selections. Reception desks benefit from discreet under-cabinet strips that reduce harsh glare while maintaining staff visibility, and corridor cove lighting using these strips guides guests with minimal visual intrusion during nighttime hours. The adhesive backing allows for quick installation on drywall, wood, or metal surfaces common in hotel renovations, though careful surface preparation remains critical for longevity.

Malls leverage adhesive LED strips extensively for both functional and marketing purposes. Retail displays gain significant visual impact when strips are mounted under shelving edges to spotlight merchandise or within glass display cases to eliminate shadows on high-value items. Escalator handrails and stair treads often incorporate these strips for enhanced safety, with the adhesive design enabling secure attachment to curved or uneven surfaces without visible fixtures. Wayfinding applications thrive in this environment, such as lining floor-level indicators in low-light zones or highlighting directory panels. Food court seating perimeters frequently use waterproof-rated adhesive strips to create inviting pool-like illumination effects. The key advantage here is the ability to retrofit existing structures during mall operating hours with minimal disruption, though installers must account for high ambient temperatures near lighting fixtures that could degrade adhesive performance over time.

Office environments deploy adhesive LED strips primarily to improve ergonomics and spatial definition. Under-desk installations provide glare-free task lighting that reduces eye strain during extended computer use, while suspended ceiling coves utilize the strips to create uniform indirect illumination that minimizes shadows on work surfaces. Storage areas and filing corridors benefit from motion-activated strips adhered to shelf undersides, offering energy-efficient lighting only when needed. Meeting room dividers and partition walls often feature vertical strips to subtly define spaces without physical barriers. In open-plan offices, the strips help delineate collaborative zones from focused work areas through differentiated color temperatures. Critical for these settings is ensuring the adhesive can withstand frequent HVAC cycling that causes surface expansion and contraction, which may require selecting high-temperature tolerance variants specified in product datasheets.

Surface preparation is the most crucial installation factor across all environments. Thoroughly clean substrates with isopropyl alcohol to remove dust, grease, or silicone residues that compromise adhesion, then allow complete drying before application. Press the strip firmly along its entire length using a roller or squeegee to ensure maximum contact, paying special attention to end points where lifting commonly occurs. Always verify the surface is flat and non-porous; textured walls or painted drywall with low-quality primer will significantly reduce hold time. For curved applications like stair edges, cut the strip at designated intervals to maintain flexibility without damaging internal circuits.

Electrical considerations demand equal attention to mechanical installation. Never exceed the power supply’s rated load capacity when connecting multiple strips, and always use the manufacturer-specified constant-voltage driver to prevent flickering or premature failure. Ensure all connections are properly insulated and routed away from high-traffic zones where cables could be damaged. In moisture-prone areas like hotel bathrooms or mall food courts, confirm the strip carries an appropriate IP65 or higher rating before installation. Test the entire circuit for at least 15 minutes prior to final mounting to identify any manufacturing defects or connection issues.

Environmental factors significantly influence performance and longevity. Avoid direct UV exposure from windows as prolonged sunlight degrades both adhesive and LED encapsulation. Maintain installation temperatures between 5°C and 40°C during application, as extreme cold reduces adhesive tack while heat can cause premature curing. In high-vibration areas such as near elevator shafts in offices, supplement adhesive mounting with mechanical clips at 300mm intervals. Always consult the specific product’s technical documentation for peel strength values and temperature tolerances, as these vary considerably between silicone-coated and PVC-jacketed variants commonly supplied for commercial projects. Adhering to these protocols ensures reliable operation while maintaining the clean aesthetic that makes adhesive LED strips valuable in premium commercial installations.

Why Choose Beauty STC Lighting

Discover the ultimate solution for seamless lighting installations with our high-quality LED double sided tape. Engineered for durability, flexibility, and superior adhesion, it’s perfect for both residential and commercial applications. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. For inquiries and collaboration opportunities, contact us at [email protected] and elevate your lighting projects today.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.