Article Contents

Industry Insight: Led Lights No Plug

In the evolving landscape of commercial and industrial lighting, the demand for efficient, flexible, and code-compliant solutions continues to rise. One innovation gaining significant traction is LED lights without integrated plugs—fixture designs that eliminate the need for standard plug-and-cord configurations in favor of direct wire or hardwired installations. These systems offer enhanced safety, streamlined aesthetics, and improved energy performance, making them ideal for warehouses, manufacturing facilities, cold storage units, and large-scale retail environments. As building codes and energy standards become more stringent, compliance with recognized safety certifications such as ETL and CE is paramount. These certifications ensure that LED lighting products meet rigorous North American and international safety and performance benchmarks, giving facility managers and electrical contractors confidence in their long-term reliability and code adherence.

At the forefront of this shift is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-performance, code-compliant lighting systems tailored to the demanding requirements of commercial and industrial applications. Specializing in direct-wire and plugless LED technologies, the company combines cutting-edge thermal management, robust construction, and global compliance to support sustainable, low-maintenance lighting infrastructures across diverse industrial environments.

Technical Specs & Certifications

Beauty STC Manufacturing Co. Ltd. designs and produces high-performance hardwired LED lighting fixtures specifically engineered for commercial, industrial, and premium residential applications where integrated plugs are not required or permitted. Our “no plug” solutions encompass recessed downlights, surface-mounted panels, troffers, and track heads intended for direct connection to building wiring via junction boxes, ensuring clean integration and compliance with electrical codes. Key technical specifications for these products are rigorously controlled to exceed industry standards.

Luminous efficacy for our standard hardwired LED fixtures consistently achieves 120-140 lumens per watt across common CCT ranges (2700K to 4000K) in standard configurations. High-efficacy models reach 150+ lm/W through optimized driver efficiency, advanced COB (Chip-on-Board) or SMD 2835/3030 LED arrays, and precision thermal management using extruded aluminum heat sinks. This efficiency is validated under LM-79 testing at 25°C ambient, with real-world performance maintained through Beauty STC’s proprietary thermal runaway protection circuits that sustain output even at elevated temperatures up to 60°C ambient.

All hardwired fixtures targeting premium architectural and retail applications deliver a minimum CRI of 92, with R9 (saturated red) values exceeding 50 as standard. We achieve this through multi-phosphor LED chips and strict binning protocols, ensuring consistent color fidelity critical for retail merchandising, healthcare, and hospitality environments. For specialized applications, our TruColor Pro series offers CRI 95+ and TM-30 Rf >85 with Rg >98, verified via spectroradiometer testing per IES TM-30-20.

IP ratings are application-specific and clearly defined per fixture type. Recessed downlights for standard dry locations carry IP20 certification. Fixtures intended for damp environments (e.g., covered outdoor soffits, bathrooms) achieve IP65 through gasketed lens systems and sealed driver compartments. Our industrial high-bay and outdoor wall packs are rated IP66 or higher, utilizing robust polycarbonate lenses, silicone seals, and corrosion-resistant housings tested to IEC 60529 standards with 12.5mm nozzle spray at 100L/min for 3 minutes. Crucially, Beauty STC validates all IP claims through third-party lab testing, not theoretical design assessments.

Beauty STC’s quality differentiation lies in our vertical integration and uncompromising engineering controls. We manufacture critical components in-house, including custom drivers with 0-10V/PWM dimming compatibility (tested to 20,000 cycles) and proprietary thermal interface materials. Every fixture undergoes 100% photometric validation on our NIST-traceable integrating sphere, 100% burn-in testing at 45°C for 12 hours, and rigorous surge immunity testing to IEC 61000-4-5 (6kV line-earth). Our commitment to longevity is evidenced by L70 lifetimes of 100,000 hours at L70/B50, backed by comprehensive 7-year warranties – a benchmark achieved through MIL-STD-883 thermal cycling validation and HALT (Highly Accelerated Life Testing) protocols that exceed standard LM-80 requirements. This systematic approach ensures consistent performance where lm/W, CRI stability, and environmental resilience are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-volume, precision manufacturing of LED lighting products, incorporating advanced automation and strict quality control processes throughout production.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which ensure high-speed and high-accuracy placement of electronic components onto PCBs (printed circuit boards). These SMT lines are fully automated, featuring pick-and-place machines, reflow soldering systems, and AOI (Automated Optical Inspection) units that detect defects in real time. This advanced setup allows for consistent product quality, efficient throughput, and the ability to handle complex circuit designs required for modern LED lighting solutions.

Quality assurance is a priority at the Jiangmen facility, particularly through comprehensive aging tests. Completed LED light units undergo extended operational testing—typically 4 to 12 hours under elevated temperatures and full load—to identify early failures and ensure long-term reliability. This aging process simulates real-world usage conditions and helps maintain a high standard of product performance before shipment.

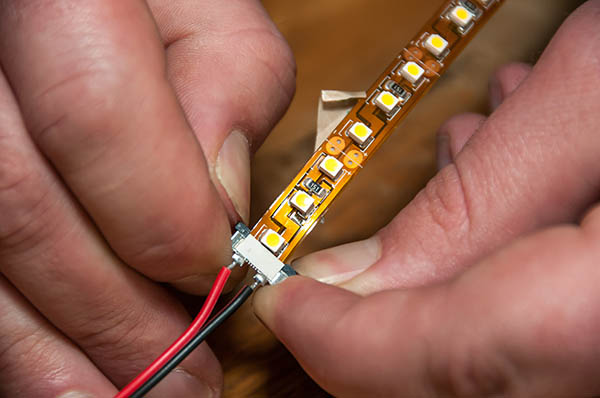

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, particularly for customized LED lighting products. The company specializes in manufacturing LED lights without plugs—such as LED strips, modules, downlights, and bare-ended fixtures—designed for integration into larger systems or for use in markets where local plug standards vary. With in-house R&D, tooling, and engineering support, Beauty STC can tailor specifications including voltage, color temperature, lumen output, IP rating, and form factor to meet client requirements. Their OEM services also cover private labeling, custom packaging, and compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines advanced automation, rigorous testing, and flexible manufacturing to deliver reliable, high-quality LED lighting solutions for global partners under OEM arrangements.

Application Scenarios

The term “LED lights no plug” typically refers to hardwired or direct-wire LED fixtures designed for permanent electrical installation, eliminating the need for a standard plug and receptacle. These are standard in commercial and institutional settings due to safety regulations, building codes, and aesthetic requirements. Plug-in LED solutions are generally prohibited in these environments for critical reasons including fire safety, electrical code compliance (such as NEC Article 410 in the US), and professional installation standards. Below are specific applications and essential installation guidance for hotels, malls, and offices.

Hotels require hardwired LED lighting throughout guest corridors, lobbies, meeting rooms, and guest rooms. Corridor lighting must be hardwired to meet fire code requirements for emergency egress, ensuring continuous operation during power failures when paired with emergency drivers. In guest rooms, hardwired cove lighting, recessed downlights, and vanity mirrors provide seamless integration and eliminate tripping hazards from cords. Lobbies demand high-CRI (Color Rendering Index) hardwired fixtures for accurate color representation in high-traffic areas, while avoiding visible cords maintains a premium aesthetic. Guest room task lighting under cabinets or in wardrobes must also be hardwired to comply with electrical codes prohibiting plug-in fixtures in fixed locations.

Malls extensively use hardwired LED systems for high-bay fixtures in atriums, track lighting in retail spaces, and emergency exit signage. High-ceiling applications require hardwired high-lumen fixtures for safety and maintenance efficiency, as plug-in solutions are impractical and non-compliant at height. Retail display lighting relies on hardwired track or monorail systems to highlight merchandise without cord clutter, ensuring a clean visual presentation. Crucially, all emergency lighting and exit signs must be hardwired to dedicated circuits with battery backups per life-safety codes, making plug-in options strictly illegal. Mall common areas also mandate hardwired solutions to prevent tampering and ensure consistent illumination for security.

Offices deploy hardwired LED fixtures in suspended ceiling troffers, under-cabinet task lighting, and wall-washer systems. Open-plan offices use hardwired linear suspended fixtures for uniform illumination without cord management issues across large floor areas. Private offices and conference rooms require hardwired recessed or surface-mounted downlights for professional appearance and code adherence, as plug-in fixtures violate NEC restrictions on permanent lighting installations. Under-desk task lighting must be hardwired into the building circuit via in-floor or under-floor raceways, not standard outlets, to avoid tripping hazards and code violations. Critical areas like server rooms use hardwired LED strips with proper thermal management to prevent overheating near sensitive equipment.

Installation of hardwired LED systems demands strict adherence to safety and code requirements. Always engage a licensed electrician to verify correct circuit voltage, ensure proper grounding, and confirm compatibility with existing dimming systems before installation. Plan fixture placement meticulously using lighting design software to avoid glare and ensure uniform illuminance, maintaining appropriate spacing for recessed fixtures to prevent thermal buildup in insulated ceilings. During mounting, secure all junction boxes to building structure per local codes and use wire nuts or lever nuts rated for the conductor size, never relying on fixture wire nuts alone. Post-installation, verify thermal performance by checking fixture temperatures under full load and ensure all emergency lighting undergoes 90-minute duration testing as mandated by NFPA 101. Crucially, only use UL-listed or ETL-certified fixtures with appropriate wet/damp location ratings for the application, and maintain clear access to all electrical junctions for future maintenance. Never bypass safety certifications to cut costs, as non-compliant installations risk fire hazards and void insurance coverage.

Why Choose Beauty STC Lighting

Transform your lighting projects with innovative LED solutions that go beyond traditional designs—explore our plug-free LED lighting systems engineered for seamless integration and superior performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in advanced LED technology. For inquiries and collaboration opportunities, contact our sales manager at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

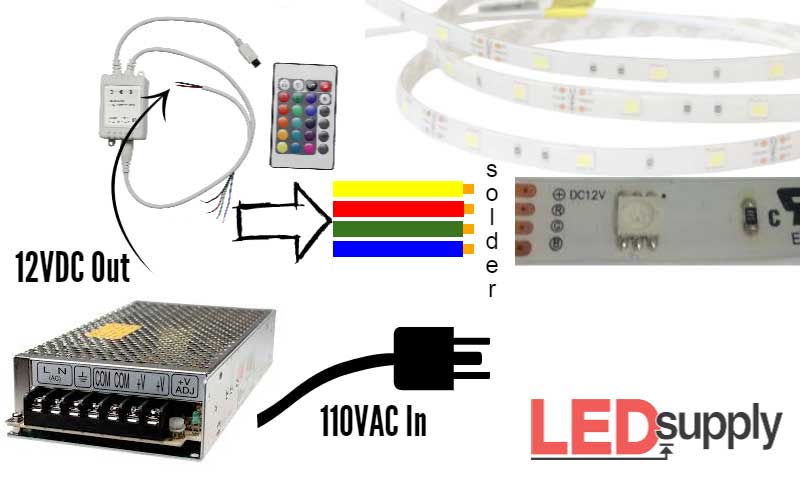

Estimate the power supply needed for your LED strip project.