Article Contents

Industry Insight: Lumen Candela

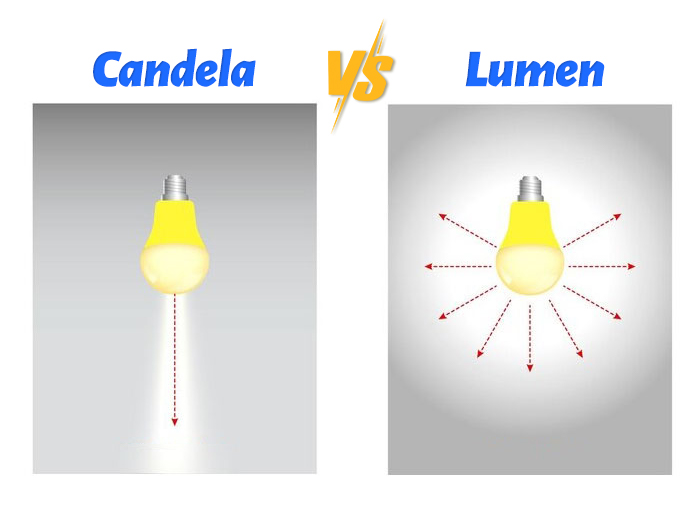

Understanding the critical distinction between lumen and candela is fundamental for specifying effective commercial and industrial lighting solutions, where performance directly impacts safety, productivity, and energy efficiency. Lumens quantify the total visible light output of a source – essential for calculating overall illumination levels across large warehouse floors, retail spaces, or office environments to meet stringent energy codes and occupant comfort standards. Candela, conversely, measures luminous intensity in a specific direction, a vital metric for task lighting, high-bay fixtures requiring precise beam control, or outdoor security lighting where glare management and targeted illumination are paramount. Confusing these units leads to suboptimal installations, wasted energy, and potential non-compliance. Rigorous third-party certifications like ETL (North America) and CE (Europe) are non-negotiable for professional installations, verifying not only electrical safety but also that photometric claims, including accurate lumen and candela measurements, adhere to international standards. Beauty STC, established in 1998, leverages over 25 years of deep expertise in LED lighting engineering to navigate these complexities. We design and manufacture high-performance commercial and industrial luminaires where precise photometric performance, certified reliability, and adherence to global regulatory frameworks like ETL and CE are core to our commitment to building superior lighting environments for our partners worldwide.

Technical Specs & Certifications

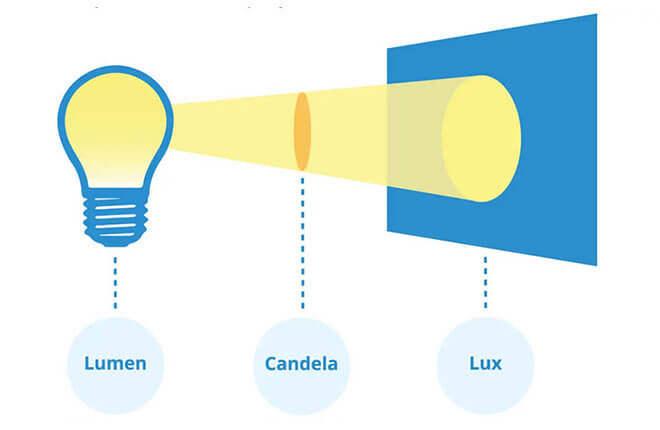

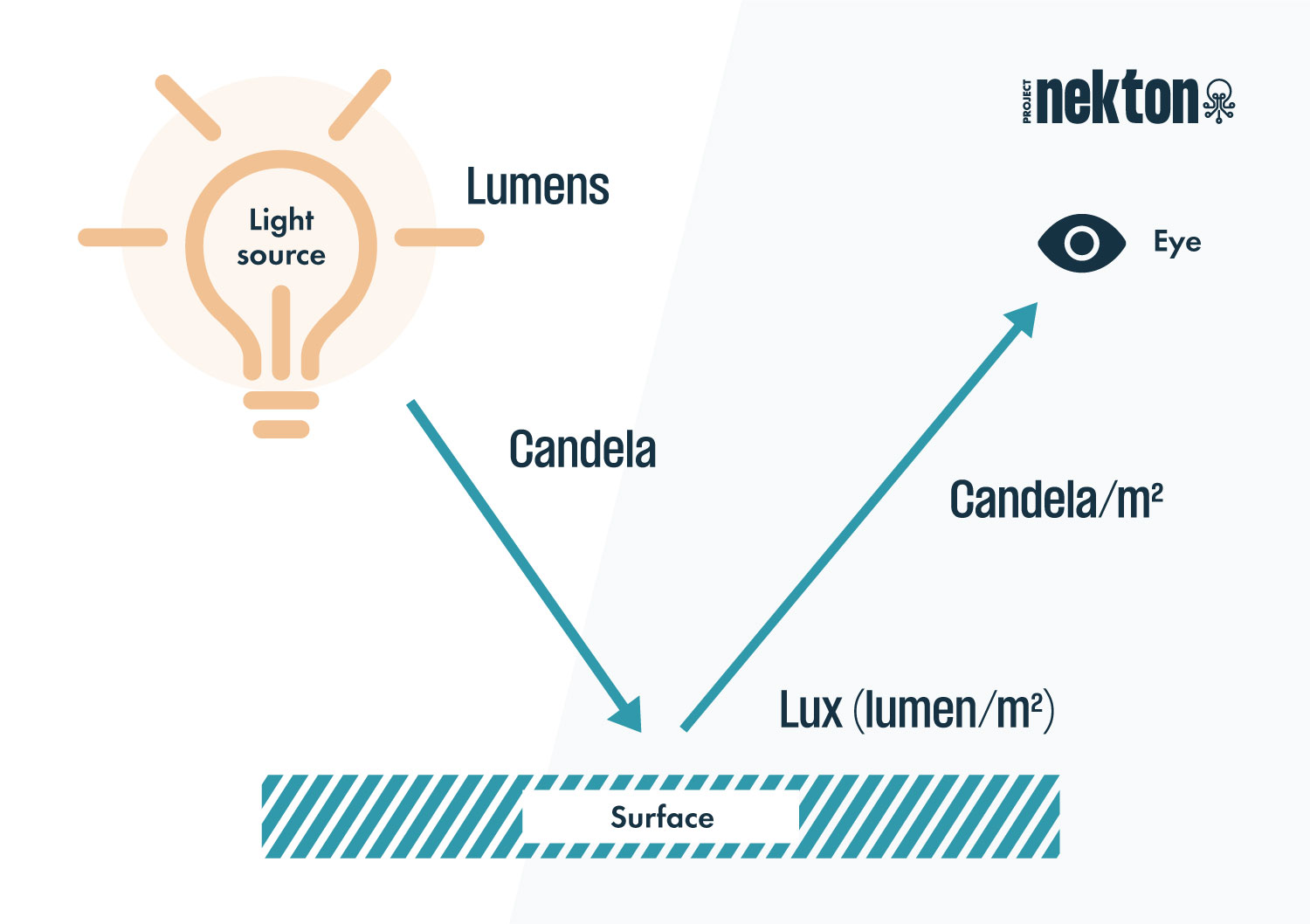

The term “lumen candela” combines two photometric units—lumens (lm), which measure total light output or luminous flux, and candela (cd), which measures luminous intensity in a specific direction. When evaluating high-performance LED lighting, particularly for professional and commercial applications, several technical specifications are critical: lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings. Beauty (STC) Manufacturing Co., Ltd. excels in delivering lighting solutions that meet and exceed these benchmarks, ensuring optimal efficiency, color accuracy, and durability.

Lumens per watt (lm/W) is a key metric for evaluating the energy efficiency of an LED luminaire. Higher lm/W values indicate more light output for less power consumption, translating to reduced energy costs and environmental impact. Beauty STC’s LED products consistently achieve high efficacy, with many fixtures delivering 120 to 150 lumens per watt or higher, depending on the optical design and thermal management. This level of performance is achieved through advanced driver technology, high-efficiency LED chips, and precision-engineered heat dissipation systems, ensuring long-term reliability and stable light output.

Color Rendering Index (CRI) measures how accurately a light source reveals the true colors of objects compared to natural light. A CRI greater than 90 is considered excellent and is essential in applications such as retail, healthcare, art galleries, and photography, where color fidelity is paramount. Beauty STC prioritizes high CRI performance across its premium product lines, utilizing high-quality phosphor coatings and binning processes to ensure consistent color quality. Many of their LED fixtures offer CRI values of 90 to 95, with options for R9 (saturated red) values above 50, further enhancing visual clarity and comfort.

Ingress Protection (IP) ratings define the level of protection a fixture provides against dust and moisture. These ratings are crucial for determining suitability in different environments. Beauty STC designs its luminaires with robust environmental protection in mind. Indoor commercial fixtures typically feature IP44 or IP54 ratings, safeguarding against dust and splashing water. Outdoor and industrial-grade products often achieve IP65, IP66, or even IP67 ratings, offering complete dust tightness and resistance to powerful water jets or temporary submersion. This makes Beauty STC fixtures ideal for harsh environments such as parking structures, wet locations, and outdoor architectural installations.

Beauty STC’s commitment to quality is evident in every stage of manufacturing—from rigorous component selection and automated production lines to comprehensive photometric testing and long-term reliability validation. Their products comply with international standards including IEC, EN, and DLC, and are backed by extensive warranty programs. With a focus on innovation, energy efficiency, and superior optical performance, Beauty (STC) Manufacturing Co., Ltd. continues to set industry benchmarks in LED lighting technology.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility represents a significant investment in modern LED lighting production capacity. Strategically located within the Jiangmen High-Tech Industrial Development Zone, the factory occupies a purpose-built, climate-controlled environment designed specifically for precision electronics assembly and stringent quality control. The facility spans over 20,000 square meters and operates under a certified ISO 9001 quality management system, ensuring consistent adherence to international standards throughout the manufacturing process.

The Surface Mount Technology (SMT) production line forms the core of our electronics assembly capability. We deploy multiple high-speed, high-precision Fuji NXT III modular placement machines. These systems handle components ranging from 0201 metric passives up to large power LEDs and complex ICs, achieving placement accuracies consistently within ±25 microns. The SMT line integrates fully automated solder paste printing with 3D SPI inspection, followed by nitrogen-reflow soldering profiles optimized for LED thermal profiles, and concludes with comprehensive automated optical inspection (AOI) to verify component placement, solder joint integrity, and polarity. This setup enables us to efficiently produce complex LED driver and module assemblies at high volumes with exceptional first-pass yield rates.

Rigorous reliability testing is non-negotiable for LED products, and our aging test procedures are a critical component of the Jiangmen factory’s quality assurance. All finished luminaires and critical sub-assemblies undergo mandatory burn-in testing. This process involves operating products at elevated temperatures, typically 50-60°C ambient within dedicated environmental chambers, while supplying power at 110% of nominal voltage for durations ranging from 24 to 72 hours depending on the product specification and client requirements. Throughout this period, automated monitoring systems track critical parameters including forward voltage, current draw, and thermal performance at multiple points on the PCB and heat sink. Units exhibiting any parameter drift beyond predefined thresholds are automatically flagged for failure analysis and corrective action before proceeding to final packaging. This intensive aging regime significantly reduces infant mortality rates in the field.

Regarding OEM capabilities, Beauty STC possesses extensive expertise in developing and manufacturing custom LED lighting solutions tailored to specific client photometric requirements. While “lumen candela” is not a standard photometric unit – lumens quantify total luminous flux (overall light output) and candela quantify luminous intensity (light concentration in a specific direction) – our Jiangmen facility is fully equipped to engineer products meeting precise specifications for both parameters. Our in-house photometric laboratory, featuring an Ulbricht integrating sphere and goniophotometer systems calibrated to LM-79 standards, allows us to measure and validate lumen output, candela distribution, color temperature, CRI, and TM-30 metrics during R&D and production. For OEM partners, we offer complete customization of optical systems including primary LED selection, secondary optics design (lenses, reflectors), and thermal management solutions to achieve the exact beam angle, intensity profile (candela distribution), and total lumen package required for the application, whether it be architectural downlighting, task lighting, or specialized industrial fixtures. This deep photometric engineering capability, combined with our SMT and aging infrastructure, forms the foundation of our value proposition for global lighting brands seeking reliable, high-performance OEM manufacturing.

Application Scenarios

The term “lumen candela” is often misunderstood as a combined unit, but in reality, lumens and candela are two distinct photometric measurements used in lighting design. Lumens (lm) measure the total amount of visible light emitted by a source (luminous flux), while candela (cd) measures the intensity of light emitted in a particular direction (luminous intensity). Understanding both is crucial when selecting and installing lighting for different environments such as hotels, malls, and offices.

In hotels, lighting plays a significant role in creating ambiance and comfort. For lobbies and reception areas, high-lumen fixtures with moderate candela are ideal to provide general illumination while maintaining visual comfort. Decorative pendant lights or chandeliers with diffused output help achieve this balance. Guest rooms require lower lumen levels for a cozy feel, with accent lighting (such as wall sconces or reading lamps) designed with appropriate candela to focus light where needed without glare. Use dimmable LED solutions to allow guests to adjust light levels based on activity.

Shopping malls demand high lumen outputs to ensure bright, inviting spaces that highlight merchandise. High-ceiling atriums and corridors often use high-lumen LED high bays or linear fixtures. Directional lighting with controlled candela values is essential in retail zones—track lights or recessed downlights with higher candela are used to spotlight displays and products, enhancing visual appeal. Uniformity and minimal shadows are critical, so proper spacing and aiming of fixtures are important during installation.

In office environments, consistent and glare-free lighting is essential for productivity and eye comfort. General ambient lighting typically uses high-lumen LED panels or troffers with even light distribution. Task lighting at workstations should combine sufficient lumens with appropriate candela to illuminate desks without creating hotspots. For open-plan offices, indirect lighting with lower candela values helps reduce glare on computer screens. Install lighting on a grid pattern to maintain uniform illumination, and consider daylight harvesting systems to integrate natural light and reduce energy use.

Installation tips include ensuring proper fixture spacing based on the beam angle and candela distribution to avoid dark spots or excessive brightness. Always refer to photometric data sheets provided by the manufacturer to understand the lumen output and candela distribution of each fixture. Use lighting simulation software when planning large installations to predict light levels and optimize fixture placement. For directional fixtures, aim carefully to focus light where needed—especially in retail or task areas. Finally, ensure all installations comply with local lighting standards and consider maintenance access for future cleaning or replacement.

Why Choose Beauty STC Lighting

Precision lighting performance hinges on understanding both lumen output and candela distribution for optimal application results. At Beauty STC Manufacturing Co., Ltd., we engineer LED solutions where photometric accuracy is non-negotiable, ensuring your projects achieve exact illumination targets through scientifically validated beam control and efficiency. Confusing lumens with candela can lead to costly miscalculations in retail displays, architectural highlighting, or industrial task lighting—our engineering team specializes in translating these metrics into real-world performance.

Partner with Beauty STC to leverage our technical expertise in photometric design, where every fixture undergoes rigorous lumen maintenance and candela intensity validation. We provide comprehensive IES files and application-specific testing data so you deploy lighting that meets stringent performance criteria from day one. Elevate your specifications with a manufacturer committed to measurable optical precision.

Contact our technical partnership manager directly at [email protected] to discuss your photometric requirements and receive tailored engineering support. Let us demonstrate how Beauty STC’s commitment to lumen efficacy and candela consistency delivers competitive advantage for your projects.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.