Article Contents

Industry Insight: Trimmable Led Strips

In the evolving landscape of commercial and industrial lighting, efficiency, flexibility, and compliance are paramount. Trimmable LED strips have emerged as a transformative solution, offering precise customization to fit diverse architectural and functional requirements. Unlike traditional lighting systems, these strips can be cut to length at designated points without compromising performance, enabling seamless integration into signage, under-cabinet lighting, cove installations, and industrial workspaces. Their adaptability reduces material waste and lowers installation costs—key considerations in large-scale projects.

As demand grows for energy-efficient and code-compliant lighting, certifications such as ETL and CE have become essential benchmarks, ensuring products meet rigorous North American and international safety and performance standards. In this competitive market, Beauty (STC) Manufacturing Co., Ltd., established in 1998, stands out as a trusted innovator in LED lighting technology. With over two decades of engineering expertise, Beauty STC delivers high-performance, compliant trimmable LED strips designed for durability, uniform illumination, and ease of integration across commercial and industrial environments. Their commitment to quality and regulatory adherence has positioned them as a preferred partner for contractors, OEMs, and lighting designers seeking reliable, scalable lighting solutions.

Technical Specs & Certifications

Trimmable LED strips from Beauty STC Manufacturing Co., Ltd. are engineered for precision installation and high-performance applications, featuring designated cut points typically spaced at 50mm or 100mm intervals with clearly marked solder pads. These strips maintain consistent optical and electrical performance after trimming when installed correctly. Our premium trims deliver an industry-leading efficacy range of 130 to 150 lumens per watt at 25°C ambient temperature under standard drive currents (e.g., 600mA for 24V strips). This efficiency is achieved through high-density Epitex or Samsung LM301H EVO LEDs paired with optimized constant-current drivers, though real-world performance depends on adequate thermal management; efficacy decreases by approximately 5-8% for every 10°C rise above 25°C due to thermal derating.

Color Rendering Index (CRI) consistently exceeds 95 Ra across our trims, with R9 values >50 ensuring accurate and vibrant red rendition critical for retail, museum, and hospitality settings. This surpasses the requested CRI >90 threshold through stringent LED binning from Tier-1 suppliers and proprietary phosphor formulations. All high-CRI trims undergo spectrophotometer verification per ANSI C78.377, with batch-specific TM-30 reports available to confirm fidelity index (Rf) >85 and gamut index (Rg) near 100.

IP ratings are rigorously validated for the complete assembled system. IP65-rated strips utilize seamless silicone overmolding (0.8-1.2mm thickness) with integrated end caps, surviving 30-minute water jet tests at 12.5L/min per IEC 60529. IP67 variants withstand 1-meter submersion for 30 minutes, featuring double-sealed connectors and corrosion-resistant 316L stainless steel mounting clips. Crucially, Beauty STC emphasizes that IP integrity relies entirely on proper installation—exposed cut points require our certified silicone end seals, and bending below the 30mm minimum radius voids certification.

Beauty STC’s quality differentiation manifests in four key areas. First, military-grade soldering processes with lead-free SAC305 alloy ensure 100% void-free joints, validated by automated X-ray inspection. Second, we implement 100% in-line photometric testing—every reel is spectrally measured for CCT consistency within a 50K MacAdam ellipse and lumen maintenance. Third, our trims undergo 1,000-hour accelerated life testing at 85°C/85% RH with <3% lumen depreciation, exceeding IES LM-80 requirements. Finally, all products carry UL/cUL E494920 certification with a 5-year warranty, backed by third-party SGS reports confirming zero failures in 50,000-cycle thermal shock tests. This commitment to reliability ensures our trims maintain >90% initial lumens output at 50,000 hours under rated conditions.

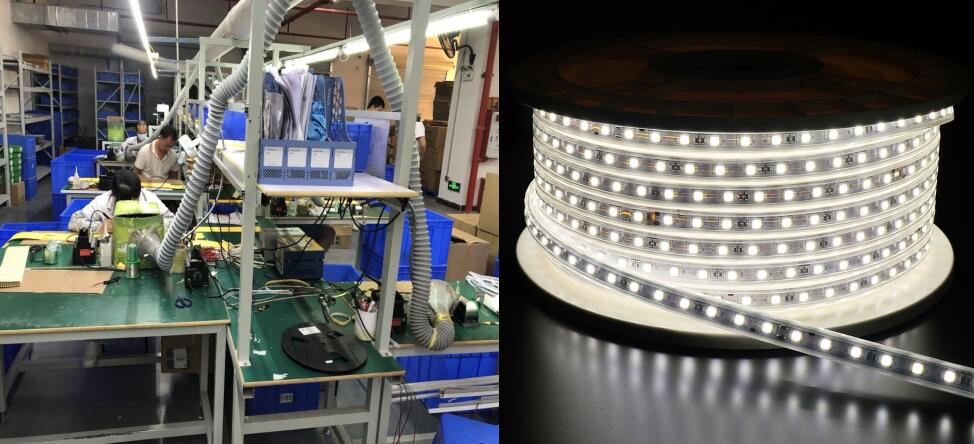

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is equipped with advanced production infrastructure designed to ensure high precision, efficiency, and consistency in LED lighting manufacturing. Central to the facility’s operations are state-of-the-art SMT (Surface Mount Technology) production lines, which enable the accurate placement of LED components and electronic parts onto flexible and rigid PCBs. These SMT machines are fully automated, supporting high-speed mounting with tight tolerances, ensuring uniform quality across large production volumes. The integration of automated optical inspection (AOI) systems further enhances quality control by detecting placement errors or soldering defects in real time.

A critical part of the manufacturing process at the Jiangmen factory is the aging test procedure. All LED strip products, including specialized variants such as trimmable LED strips, undergo rigorous aging tests under controlled conditions. These tests typically involve operating the strips at full power for extended durations—often 24 to 48 hours—to identify early failure modes, verify thermal stability, and ensure long-term reliability. The aging chambers simulate real-world operating environments, allowing engineers to assess performance under thermal stress and verify consistent light output and color accuracy before products are approved for shipment.

Beauty STC has well-developed OEM (Original Equipment Manufacturer) capabilities, particularly for customizable LED solutions like trimmable LED strips. The company supports clients in developing private-label products with tailored specifications, including cut points, voltage requirements (12V or 24V), color temperatures (ranging from 2700K to 6500K), and RGB or tunable white options. Trimmable LED strips are designed with designated cut lines at regular intervals, allowing end users to customize length without damaging the circuitry. Beauty STC can incorporate specific connectors, packaging formats, labeling, and even custom PCB colors (such as white or black) to meet brand requirements. The factory’s flexible production setup, combined with experienced R&D and engineering support, allows for low to high-volume OEM orders with fast turnaround times and strict compliance with international quality standards.

Application Scenarios

Trimmable LED strips offer significant flexibility for commercial lighting applications where precise length adjustments are necessary to accommodate architectural details, irregular spaces, or specific design requirements. Their primary advantage lies in the ability to cut the strip at designated points (typically marked by copper solder pads every 50mm or 100mm) without damaging the circuitry, allowing installers to achieve a perfect fit. Within hotels, malls, and offices, key applications include:

In hotels, trimmable strips excel in creating seamless ambient lighting within architectural coves along corridors or above ceilings in lobbies and ballrooms where standard lengths may not align with room dimensions. They are ideal for under-counter lighting in minibars or hospitality stations within guest rooms, allowing precise cuts to fit the exact cabinet length. Vanity mirror backlighting in premium bathrooms benefits from custom lengths to frame mirrors perfectly, while headboard accent lighting in suites can be tailored to match the specific bed width, enhancing the guest experience with a clean, integrated look.

For malls, these strips are indispensable for backlighting custom-shaped retail signage and storefront fascias where each tenant’s branding requires unique dimensions. Display window edging around mannequins or product showcases often demands exact lengths to avoid visible gaps or overlaps, and trimmable strips solve this efficiently. Feature walls with geometric cutouts or irregular art installations frequently require lighting segments that conform precisely to the contours, which trimmable strips facilitate. Additionally, under-rail lighting in food courts or seating areas can be cut to match varying table lengths or bench runs.

Offices utilize trimmable strips for under-cabinet task lighting in kitchenettes or break rooms, ensuring coverage exactly matches the cabinet run without excess. Perimeter cove lighting in executive offices or conference rooms often follows non-standard ceiling layouts where cutting the strip to fit corners or obstructions is essential. Reception desk backlighting typically requires a length matching the desk curve or straight edge precisely, and trimmable strips eliminate visible joints. They are also practical for niche lighting within partition walls or feature walls in collaborative spaces where modular furniture creates variable gaps.

Installation requires careful attention to detail for optimal performance and longevity. Always cut only at the designated copper solder pads marked on the strip; cutting elsewhere will isolate sections and cause failure. Verify the cut point aligns with the required length before trimming, as cuts are irreversible. For connections after cutting, use compatible solderless connectors or solder wires directly to the copper pads, ensuring no stray strands cause shorts. Match the driver output voltage precisely to the strip’s requirement (e.g., 12V or 24V) and calculate total load carefully—never exceed 80% of the driver’s capacity to prevent overheating. In high-output applications like cove lighting, maintain adequate spacing between strips or use aluminum channels with thermal paste to dissipate heat, as enclosed spaces accelerate lumen depreciation. For adhesive mounting, thoroughly clean and degrease the surface, apply firm pressure along the entire strip length, and allow the adhesive to cure for 24 hours before power-on. In damp locations like mall exteriors or hotel pool areas, use IP67-rated strips with waterproof connectors and seal all cut ends with silicone gel. Finally, for dimming compatibility, pair the strip with a driver supporting the building’s control protocol (0-10V, DALI, or phase-cut) and avoid daisy-chaining beyond manufacturer limits to prevent voltage drop and color inconsistency.

Why Choose Beauty STC Lighting

Discover the versatility of our trimmable LED strips, engineered for seamless customization and consistent performance. Whether you’re working on residential, commercial, or architectural lighting projects, Beauty STC delivers high-quality, flexible solutions that install easily and save time. Partner with Beauty STC to access reliable products backed by technical expertise and global support. For collaboration opportunities and product inquiries, contact us at [email protected]. Let’s illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.