Article Contents

Industry Insight: Wall Glue Strips

The commercial and industrial lighting sector continuously evolves, demanding solutions that prioritize not only energy efficiency and illumination quality but also rapid, clean, and secure installation methods. Within this context, adhesive mounting systems, particularly high-performance wall glue strips, have transitioned from a niche convenience to an increasingly critical component in modern fixture deployment. Specifiers and contractors face significant pressure to minimize installation time, avoid structural damage to walls and ceilings, and achieve seamless, professional aesthetics across diverse settings like retail spaces, offices, warehouses, and healthcare facilities. Crucially, the adoption of such adhesive solutions hinges entirely on demonstrable reliability and compliance within the stringent regulatory landscape governing commercial electrical products. This means adhesive systems must consistently meet rigorous safety and performance standards, with independent certifications like ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) being non-negotiable prerequisites for specification and use in professional lighting projects. Trust in the adhesive’s ability to securely hold fixtures for the product’s lifetime, under varying environmental conditions and without compromising electrical safety, is paramount.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, operates at the forefront of this evolution. With over 25 years of dedicated experience engineering and manufacturing high-quality LED lighting solutions specifically for the demanding commercial and industrial markets, we understand the intricate balance between innovative design, practical installation, and uncompromising safety. Our commitment extends beyond the light engine itself to encompass the entire ecosystem of components that ensure a successful, long-term installation, including the critical interface between fixture and structure. We recognize that reliable, certified adhesive mounting solutions are no longer optional extras but fundamental enablers of efficient project execution and end-user satisfaction in today’s fast-paced construction and renovation environment.

Technical Specs & Certifications

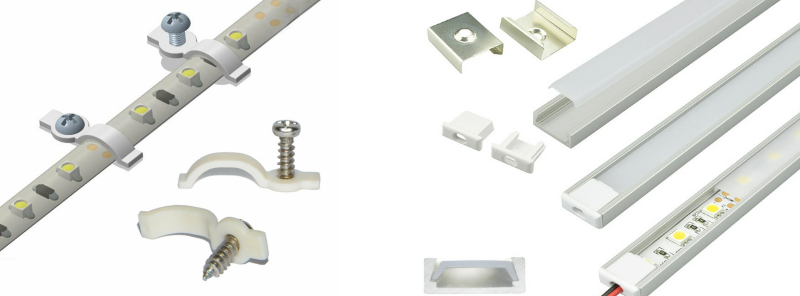

Wall glue strips from Beauty (STC) Manufacturing Co., Ltd. are high-performance LED lighting solutions designed for seamless integration into modern architectural and decorative applications. These adhesive-backed LED strips offer exceptional luminous efficacy, color quality, and environmental protection, making them ideal for both residential and commercial installations.

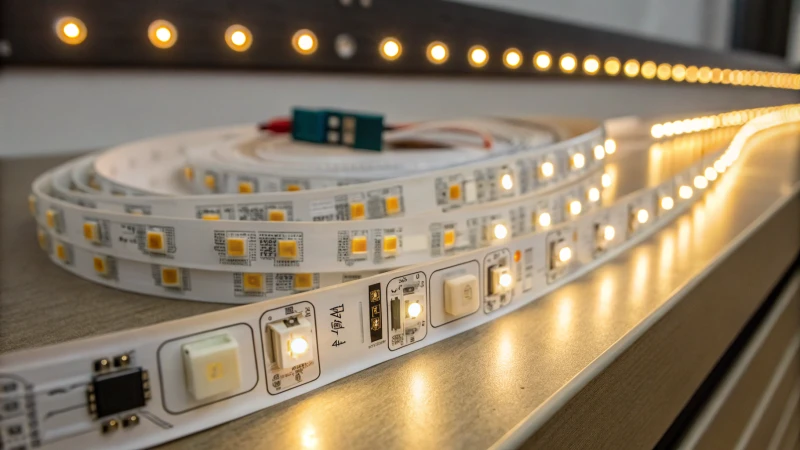

In terms of efficiency, Beauty STC’s wall glue strips deliver a luminous output ranging from 100 to 130 lumens per watt, depending on the specific model and color temperature. This high lumens-per-watt ratio ensures energy-efficient operation without compromising brightness, contributing to reduced power consumption and long-term cost savings. The strips utilize high-grade SMD LED chips—typically 2835 or 3528 series—engineered for optimal thermal management and consistent light output over extended periods.

Color rendering is a key strength of Beauty STC’s wall glue strips. All premium models feature a Color Rendering Index (CRI) greater than 90, with select versions achieving CRI values of 95 or higher. This ensures accurate and vibrant color representation, making them particularly suitable for retail displays, art galleries, kitchens, and other environments where true color perception is critical. The high CRI is achieved through the use of advanced phosphor coatings and stringent binning processes during LED manufacturing.

Regarding environmental protection, Beauty STC offers wall glue strips in various Ingress Protection (IP) ratings to suit different application needs. The standard non-encapsulated strips are rated IP20, suitable for dry indoor environments. For damp or outdoor applications, silicone-coated versions are available with IP65 ratings, providing protection against dust and low-pressure water jets. Fully encapsulated versions achieve IP67 or even IP68 ratings, making them waterproof and suitable for installation in bathrooms, coves exposed to moisture, or outdoor façades where exposure to rain or humidity is expected.

Beauty STC is recognized for its commitment to quality and reliability. Each wall glue strip undergoes rigorous testing for solder joint integrity, adhesive bond strength, thermal cycling, and long-duration burn-in. The company adheres to ISO 9001 quality management standards and its products comply with CE, RoHS, and REACH certifications. The consistent performance, durable construction, and superior optical characteristics of Beauty STC’s LED strips reflect the company’s engineering excellence and position in the global market as a trusted manufacturer of high-end LED lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in Jiangmen, Guangdong Province, China, strategically positioned within the Pearl River Delta region for efficient logistics and access to a skilled technical workforce. This modern factory serves as the company’s core production hub for LED lighting products, including flexible LED strip lights. The facility is equipped with advanced Surface Mount Technology (SMT) production lines featuring multiple high-speed Yamaha YS series placement machines. These SMT lines are capable of handling ultra-fine pitch components down to 0201 metric package sizes, essential for the dense LED arrays and miniaturized drivers used in contemporary flexible strip designs. The machines operate under strict environmental controls for temperature and humidity, ensuring consistent solder paste application and component placement accuracy critical for the reliability of thin, flexible circuit boards.

Rigorous aging and reliability testing form a non-negotiable part of the production process at the Jiangmen factory. Every batch of LED strip lights, including adhesive-backed variants, undergoes comprehensive aging procedures. This involves subjecting the strips to continuous operational loads at elevated temperatures within specialized environmental chambers for a minimum of 72 hours. The aging process simulates extended real-world use under stressed conditions, allowing early detection of infant mortality failures in LEDs, drivers, or solder joints. Parameters such as light output maintenance, color consistency, and thermal performance are meticulously monitored throughout the test. Strips failing to meet stringent internal specifications – typically maintaining over 98% lumen output and exhibiting no visible defects after aging – are automatically rejected, ensuring only units with proven longevity reach customers. This commitment to burn-in testing significantly reduces field failure rates and underpins product warranty commitments.

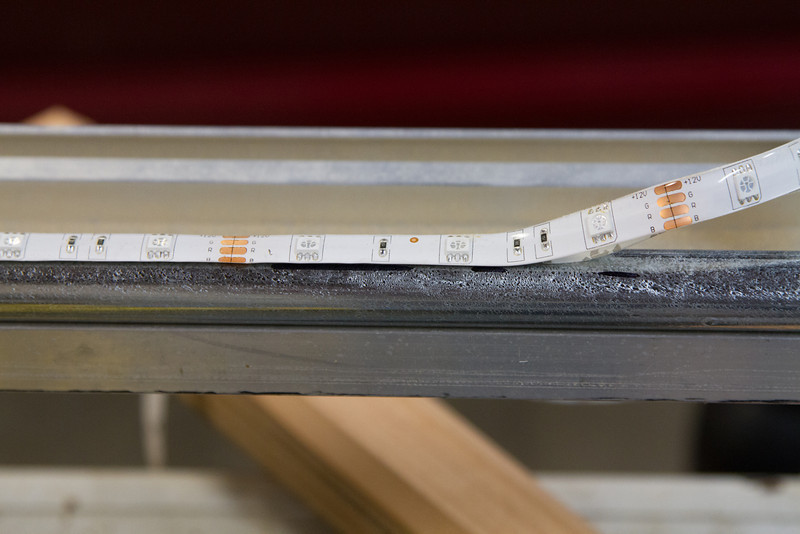

The Jiangmen facility possesses substantial OEM manufacturing capability specifically tailored for adhesive-backed LED strip lights, commonly referred to internally and by customers as “wall glue strips” or adhesive-mount LED modules. Beauty STC offers extensive customization options under OEM agreements, including precise strip length cutting, specific LED density configurations (e.g., 60, 120, 240 LEDs per meter), tailored color temperatures (2700K to 6500K), various IP ratings (from IP20 to IP67), and custom voltage requirements (DC 12V, 24V, or AC variants). Crucially, the factory manages the entire adhesive integration process in-house, applying high-bond-strength, temperature-resistant pressure-sensitive adhesive tapes with protective liners suitable for diverse wall substrates. The OEM service encompasses custom labeling, private branding on packaging and product reels, bespoke reel lengths, and tailored documentation to meet specific client requirements. Supported by robust quality management systems certified to ISO 9001 and product safety standards including UL, CE, and RoHS, the Jiangmen factory provides end-to-end OEM solutions from prototyping through to high-volume production, with a typical sample turnaround time of 7-15 days for custom adhesive strip configurations.

Application Scenarios

Wall glue strips are versatile adhesive solutions commonly used in hotels, malls, and offices for mounting lightweight fixtures, signage, and decorative elements without damaging walls or requiring drilling. In hotels, they are ideal for securing room number plates, wall signs, mirrors, or decorative panels in guest rooms and hallways where a clean, damage-free installation is essential for maintenance and aesthetic consistency. In malls, wall glue strips support temporary or permanent signage, promotional displays, directory boards, and artwork in high-traffic areas, offering a quick and removable mounting option that accommodates frequent layout changes. In office environments, they are frequently used to attach whiteboards, cable organizers, nameplates, motivational posters, or lightweight shelves to painted walls, glass, or tiles without compromising the building’s structure or finish.

When installing wall glue strips, proper surface preparation is critical. Ensure the wall is clean, dry, and free of dust, grease, or wax—use isopropyl alcohol for best results on smooth surfaces. Press the strip firmly onto the back of the item for at least 30 seconds to activate the adhesive bond. Then, align the item carefully on the wall and apply firm, even pressure for another 30 seconds to ensure maximum adhesion. Avoid placing excessive weight on the strip beyond its rated capacity—typically listed by the manufacturer. For optimal performance, allow 24 hours before subjecting the mounted item to stress or movement, especially in environments with fluctuating temperatures or humidity. In high-moisture areas such as hotel bathrooms or mall restrooms, opt for moisture-resistant adhesive strips designed for such conditions. Always follow the manufacturer’s guidelines for weight limits and surface compatibility to ensure long-term reliability and prevent accidental detachment.

Why Choose Beauty STC Lighting

Upgrade your LED strip installations with Beauty STC’s premium wall glue strips engineered for flawless, long-lasting adhesion. Our specialized mounting solutions eliminate slippage and damage, ensuring your lighting projects maintain a clean, professional finish while withstanding thermal cycles and environmental stress. Trusted by industry leaders for consistent performance and ease of application, these strips simplify complex installations without compromising structural integrity or aesthetics.

Partner with Beauty STC to integrate reliable mounting technology into your next project and experience the difference precision engineering delivers. Reach out to our dedicated support team today at [email protected] to discuss custom solutions, volume pricing, and technical specifications tailored to your requirements. Let us help you achieve seamless installations that exceed client expectations every time.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.