Article Contents

Industry Insight: Led Back Lights

The commercial and industrial lighting sector continues to undergo significant transformation, driven by the relentless pursuit of energy efficiency, operational longevity, and enhanced visual environments. Within this landscape, LED backlighting solutions have evolved far beyond simple signage illumination, becoming integral components for architectural accents, high-end retail displays, precision task lighting in industrial settings, and sophisticated wayfinding systems. These applications demand not only superior optical performance and thermal management but also unwavering reliability under continuous operation. Crucially, adherence to stringent safety and performance standards is non-negotiable for market access and end-user confidence. Certifications such as ETL for the North American market and CE marking for Europe represent critical compliance markers, verifying that products meet essential electrical safety, electromagnetic compatibility, and environmental requirements. Failure to secure these certifications effectively bars entry into major global markets and exposes specifiers and facility managers to significant liability risks.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution for over 25 years. As a specialized manufacturer deeply rooted in the technical demands of commercial and industrial LED applications, we understand the exacting standards required for backlighting solutions deployed in demanding environments. Our engineering focus centers on developing robust, certified LED backlighting systems that deliver consistent performance, simplify installation, and provide long-term value. Leveraging our extensive experience, Beauty STC is committed to being a trusted partner, supplying solutions that not only meet but anticipate the evolving needs of architects, lighting designers, and facility managers worldwide.

Technical Specs & Certifications

LED back lights manufactured by Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability, particularly in applications requiring precise color rendering and consistent illumination. These back lights are commonly used in display lighting, signage, and architectural accenting, where visual clarity and energy efficiency are critical.

In terms of luminous efficacy, Beauty STC’s LED back lights achieve an industry-leading range of 110 to 130 lumens per watt, depending on the specific model and thermal management design. This high efficiency is accomplished through the use of advanced SMD (Surface Mount Device) LED chips and optimized driver circuitry, ensuring minimal energy loss while maintaining stable light output over extended operation periods.

Color Rendering Index (CRI) is a key focus for Beauty STC, especially in applications where accurate color representation is essential. All LED back lights in the premium series are designed with a CRI greater than 90, with select models offering CRI values up to 95. This high color fidelity is achieved using phosphor-coated blue LEDs with tightly controlled spectral distribution, enabling truer color perception and improved visual comfort.

Regarding environmental protection, Beauty STC offers LED back lights with IP ratings ranging from IP20 for indoor dry locations to IP65 and IP66 for semi-outdoor or high-moisture environments. The higher-rated models feature sealed housings and conformal-coated PCBs to resist dust, moisture, and corrosion, making them suitable for use in retail displays, transportation hubs, and hospitality settings where durability is required.

Beauty STC maintains rigorous quality control throughout the manufacturing process, adhering to international standards such as ISO 9001 and IECQ. Components are sourced from trusted suppliers and subjected to in-house testing for thermal performance, lumen maintenance, and longevity. Each batch undergoes accelerated life testing, ensuring a minimum rated life of 50,000 hours at L70, under standard operating conditions.

The combination of high lumens per watt, excellent color rendering, robust IP protection, and consistent manufacturing quality underscores Beauty STC’s commitment to delivering reliable, high-performance LED back lights for demanding applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant pillar of our LED backlight production capacity. This modern factory is strategically located within a specialized electronics manufacturing cluster, providing efficient access to supply chains and skilled technical labor. The facility is purpose-built for high-volume, precision LED assembly, with a strong emphasis on the backlight modules critical for LCD displays across consumer electronics, commercial signage, and industrial applications.

Within the Jiangmen factory, our Surface Mount Technology (SMT) production lines are a core strength. We operate multiple state-of-the-art Fuji NXT III modular SMT platforms, renowned for their speed, accuracy, and flexibility in handling the demanding requirements of LED backlight assembly. These machines are configured to place ultra-small components down to 01005 metric size with exceptional precision, essential for densely packed mini-LED and standard LED backlight units. The lines integrate fully automated optical inspection (AOI) systems immediately post-reflow, ensuring real-time detection of placement errors, solder defects, and component issues before products proceed to subsequent stages. This high-accuracy SMT capability is fundamental to achieving the tight tolerances and reliability demanded by modern backlight designs.

Rigorous aging and reliability testing are non-negotiable elements of our quality control process at the Jiangmen site. All LED backlight assemblies undergo comprehensive aging procedures before shipment. This includes a mandatory 48-hour continuous burn-in test conducted under controlled thermal conditions, typically at elevated temperatures around 70°C, simulating accelerated operational stress. Units are monitored for lumen output stability, color consistency, and any early failures. Additionally, we perform constant current aging tests on critical components and sub-assemblies to verify long-term lumen maintenance and thermal management performance. This dual-phase aging protocol, combined with in-line electrical functional testing, ensures that every backlight module shipped meets or exceeds the stringent lifespan and performance expectations of our customers.

Our Jiangmen factory is fully equipped and staffed to provide comprehensive OEM services for LED backlight solutions. We possess end-to-end capability, starting from the initial customer concept or specification through to final packaged shipment. This encompasses engineering collaboration on optical design, thermal management, and mechanical integration; sourcing of qualified components including LEDs, PCBs, and optical films; precision SMT assembly; rigorous in-house testing including photometric and electrical validation; and customized packaging. The facility holds ISO 9001 and ISO 14001 certifications, underpinning our commitment to consistent quality management and environmental responsibility throughout the OEM process. Our engineering team works closely with clients to adapt designs for manufacturability, ensuring cost-effective production without compromising on the critical uniformity, brightness, and reliability parameters that define high-performance LED backlights.

Application Scenarios

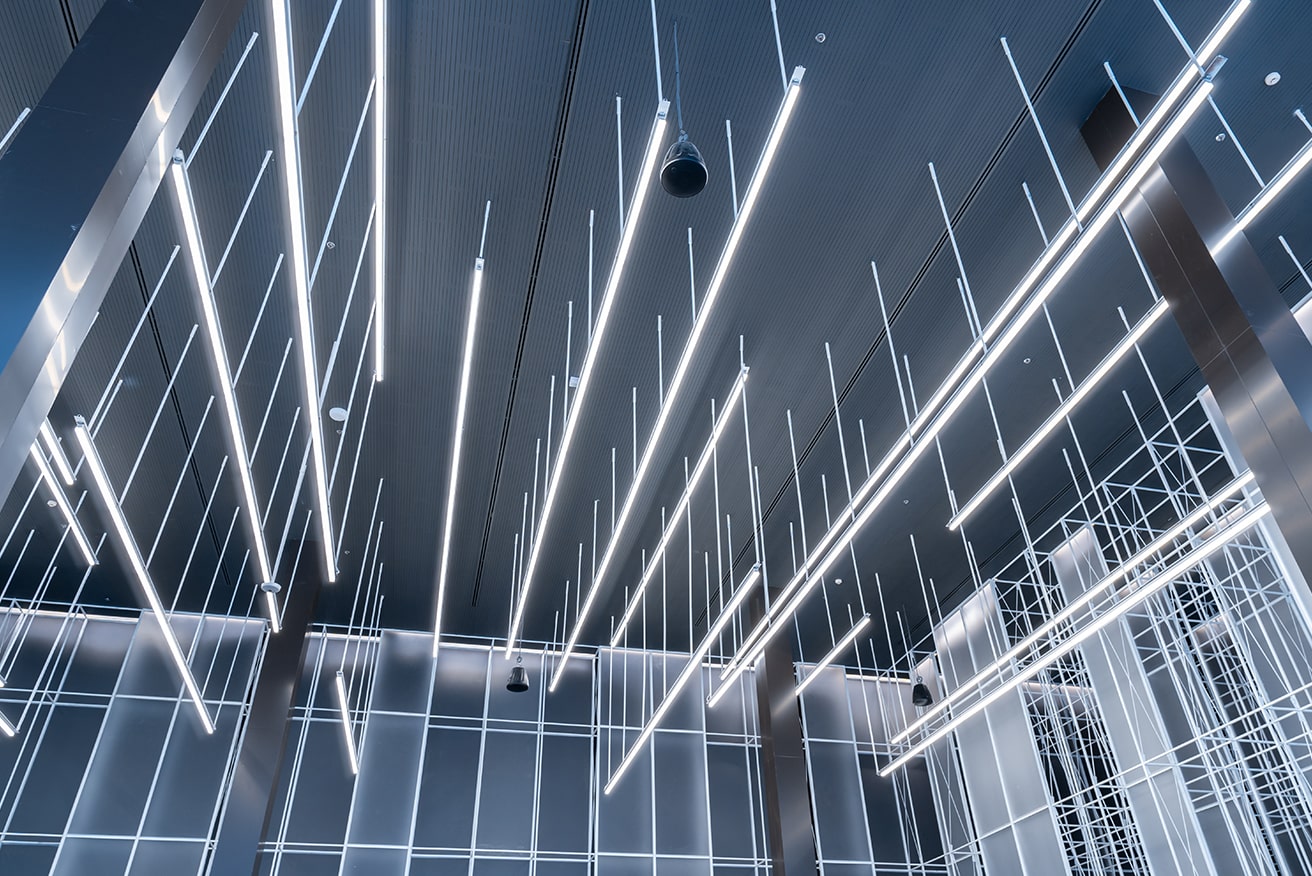

LED back lights are versatile lighting solutions that enhance aesthetics, improve visibility, and create ambiance in various commercial and public spaces. They are commonly used in hotels, malls, and offices due to their energy efficiency, long lifespan, and design flexibility.

In hotels, LED back lights are often installed behind headboards, under cabinets, in cove lighting, around mirrors in bathrooms, and along corridors or staircases. They contribute to a luxurious and welcoming atmosphere, especially in lobbies and guest rooms. Backlit signage at reception desks or behind feature walls adds elegance and guides guests subtly through the space.

In malls, LED back lights are ideal for illuminating signage, display windows, and architectural features. They draw attention to retail stores, promotional areas, and directional signage. Backlit lightboxes and channel letters at storefronts ensure high visibility and brand recognition, even in well-lit environments. The uniform glow enhances the shopping experience and creates a modern, upscale feel.

In offices, LED back lights are used in reception areas, above false ceilings, behind partitions, and in conference rooms to create a professional and inviting environment. They reduce harsh shadows and provide indirect lighting that minimizes eye strain. Backlit panels in drop ceilings or behind logo walls add a contemporary touch while maintaining functional illumination.

For installation, ensure the surface is clean, dry, and smooth to promote proper adhesion and heat dissipation. Use mounting clips or double-sided tape designed for LED strips to secure them firmly. Always follow the manufacturer’s recommended maximum run length to avoid voltage drop. Connect LEDs to a compatible low-voltage power supply and use connectors or soldering for reliable joints. In high-humidity areas like bathrooms, choose IP65-rated or higher waterproof strips. Finally, test the setup before finalizing the installation and consider using a dimmer for adjustable lighting levels to suit different times of day or functions.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co. Ltd I understand the critical role high-performance LED backlighting plays in delivering exceptional visual clarity and reliability across displays signage and architectural applications Our engineering team specializes in precision-engineered LED backlight solutions designed to meet rigorous industry standards for color accuracy uniformity and thermal stability

Partnering with Beauty STC means gaining access to our decade-long expertise in advanced thermal management and optical design ensuring your backlighting systems achieve optimal luminance while maintaining industry-leading energy efficiency We rigorously test all components for longevity under demanding environmental conditions so you receive products that perform consistently in real-world installations

For custom LED backlight projects or volume production requirements contact our dedicated engineering management team directly at [email protected] to discuss technical specifications compliance requirements and scalable manufacturing solutions We prioritize seamless integration with your existing workflows while providing responsive technical support throughout the partnership lifecycle Let us help you elevate your backlighting performance through engineered excellence and reliable collaboration

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.