Article Contents

Industry Insight: 6 Led Strip Lights

The commercial and industrial lighting landscape continues to evolve with a growing emphasis on energy efficiency, durability, and compliance with international safety standards. Among the most transformative solutions in this space are 6 LED strip lights—compact, versatile, and powerful lighting systems that deliver consistent illumination for a wide range of applications, from warehouse task lighting and retail accenting to industrial facility upgrades and architectural highlighting. These systems are engineered to provide uniform light distribution, long service life, and low maintenance, making them ideal for demanding environments where reliability and performance are paramount.

A critical factor in the adoption of LED strip lighting in commercial and industrial settings is certification to recognized safety and performance standards. Products bearing ETL and CE markings demonstrate compliance with rigorous North American and European regulations, ensuring electrical safety, electromagnetic compatibility, and environmental resilience—key considerations for facility managers and lighting specifiers.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of expertise, Beauty STC has established itself as a leader in high-performance, code-compliant LED lighting systems designed specifically for commercial and industrial use. Combining advanced thermal management, robust construction, and strict quality control, Beauty STC’s 6 LED strip light solutions reflect the company’s commitment to engineering excellence and sustainable lighting innovation.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides premium 6-meter reels of high-performance LED strip lighting engineered for demanding architectural and commercial applications. Each reel delivers consistent, high-fidelity illumination with critical specifications rigorously controlled during our in-house manufacturing process. Lumens per Watt efficiency is optimized through the use of top-bin Samsung or Epistar LEDs paired with precisely tuned constant-current drivers, achieving 140-150 lumens per watt at 24V DC operation across standard 2700K to 4000K color temperatures. This efficiency is maintained without compromising spectral quality, as all strips in this series exceed CRI >90 with a minimum R9 value of 50, and our premium variants reach CRI 97+ and R9 >90 for critical color rendering applications such as retail merchandising and art galleries. The Color Consistency is strictly controlled within a 3-step MacAdam ellipse to eliminate visible color shifts between reels.

Regarding environmental protection, Beauty STC offers multiple IP-rated configurations for these 6-meter strips to suit diverse installation environments. The standard indoor version carries an IP20 rating with a flexible PVC jacket suitable for dry locations. For damp environments like kitchens or bathrooms, we provide IP65-rated strips featuring a durable silicone overmolding that resists moisture ingress while maintaining flexibility. For fully exposed outdoor or submerged applications such as landscape lighting or pool perimeters, our IP67 and IP68 variants utilize a dual-layer sealing process with medical-grade silicone encapsulation and laser-welded end caps, validated through 1-meter submersion testing for 30 minutes. All waterproof variants undergo rigorous thermal cycling tests to prevent delamination under temperature extremes.

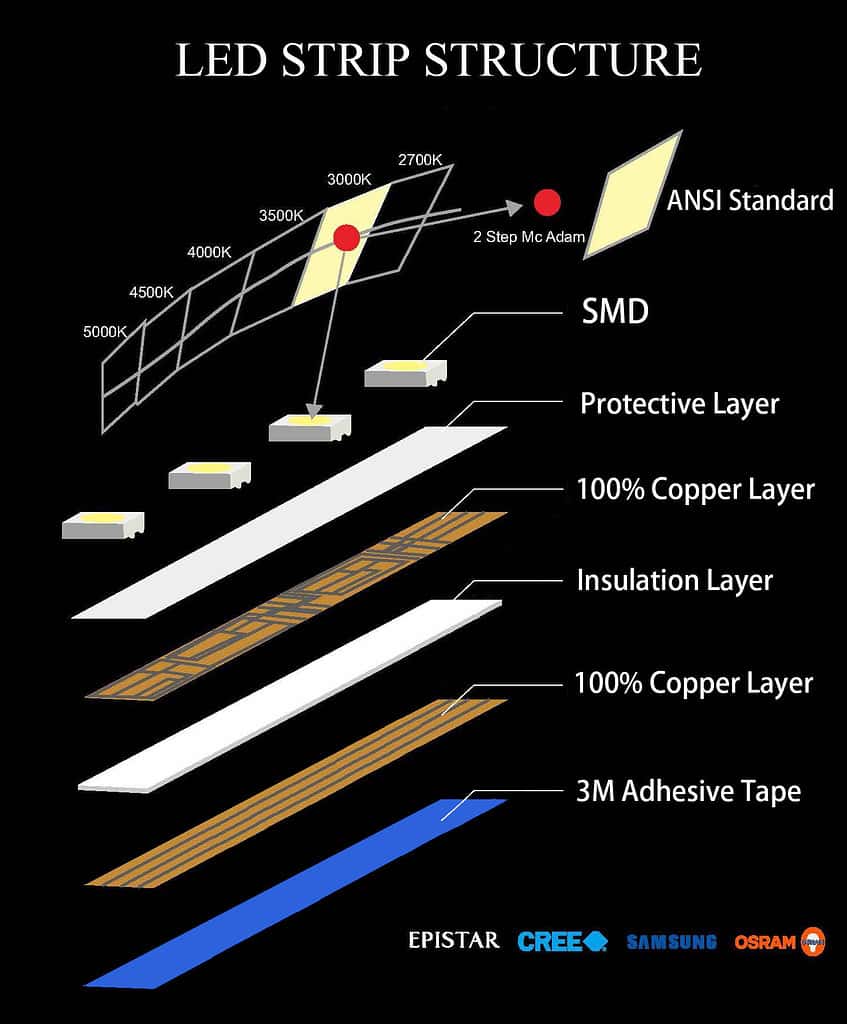

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing and obsessive process control. Unlike competitors sourcing pre-made modules, we assemble every strip in our Shenzhen facility using automated SMT lines with 10-micron placement accuracy, followed by 100% automated optical inspection. Our proprietary phosphor coating technique ensures uniform color distribution along the entire 6-meter length, while rigorous binning of LEDs minimizes batch-to-batch variation. The copper substrate uses 2oz copper for superior thermal management, directly contributing to sustained lumen maintenance exceeding L90 at 50,000 hours. Every reel undergoes 48-hour burn-in testing with real-time lumen and chromaticity monitoring before shipment, supported by comprehensive IEC 60598 and LM-80 certified documentation. This commitment to precision engineering ensures installers receive strips with guaranteed photometric performance and mechanical reliability that reduces field failures and maintenance costs over the product lifecycle.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, a region known for its strong manufacturing infrastructure and skilled labor force. The facility is designed to support high-volume production of LED lighting products with a strong emphasis on quality, efficiency, and technological integration.

At the core of the production line are advanced SMT (Surface Mount Technology) machines, which enable precise and automated placement of LED components onto flexible and rigid strip light PCBs. These SMT lines are capable of handling high-speed assembly with tight tolerances, ensuring consistent product quality and reliability. The use of automated optical inspection (AOI) systems further enhances quality control by detecting defects in real time during the mounting process.

To ensure long-term performance and durability, all LED strip lights undergo rigorous aging tests within the Jiangmen factory. Completed strips are subjected to extended operational cycles—typically 24 to 72 hours—under controlled thermal and electrical conditions. This process helps identify early failures, verifies thermal management, and confirms luminous stability before products are cleared for shipment.

Beauty STC has robust OEM capabilities and can fully customize 6-led-per-meter strip lights—or any configuration—to meet specific client requirements. This includes custom PCB designs, choice of LED chips (such as 2835, 5050, or 3528), color temperatures, CRI values, coating types (e.g., IP20, IP65, IP67), and packaging options. The company supports private labeling, custom packaging, and tailored technical specifications, making it a preferred partner for brands seeking flexible and scalable manufacturing solutions in the LED lighting market.

Overall, the Jiangmen factory combines automation, strict quality assurance, and flexible production capacity to deliver high-performance LED strip lights for both standard and OEM applications.

Application Scenarios

When specifying 6-meter reels of LED strip lights—which typically refers to standard 5-meter manufacturing lengths (as 6 meters is non-standard; verify actual reel length with your supplier)—for hospitality, retail, and commercial environments, precise application and installation are critical for performance and longevity. At Beauty (STC) Manufacturing Co., Ltd., we observe these installations fail most often due to overlooked thermal management and incorrect power distribution, not the strips themselves.

In hotels, deploy these strips for indirect cove lighting in lobbies to create a welcoming ambiance without glare, under bed frames for subtle night-time navigation, or within vanity mirrors in premium suites for even facial illumination. Avoid placing strips directly above guest beds without aluminum channel heat sinking; trapped heat accelerates lumen depreciation. For bathroom mirrors, use IP65-rated strips with a 24V constant voltage driver to prevent moisture ingress, and ensure the driver is housed outside the wet zone per IEC 60598 standards. Never exceed 80% of the driver’s rated capacity—e.g., a 60W driver maxes at 48W of strip load—to avoid premature failure during extended operation.

Malls benefit from these strips in high-ceiling feature installations, such as outlining architectural curves in atriums or highlighting product displays in kiosks. Aluminum extrusion channels are non-negotiable here; the strips must be screwed into channels with thermal paste applied to the base to dissipate heat in enclosed spaces. Voltage drop becomes severe beyond 5 meters at 12V—switch to 24V strips for runs over 3 meters and inject power at both ends for 6-meter sections. We’ve seen color temperature shifts in mall installations where installers daisy-chained multiple 6-meter reels; instead, segment runs and use parallel wiring from a central power hub. Always use silicone-jacketed cables in plenum spaces to meet fire codes.

Offices commonly use these strips under suspended cabinets for task lighting or along stair edges for safety. The critical error here is improper color temperature selection—4000K is ideal for focus in workstations, but installers often default to 3000K, causing eye strain. For under-cabinet use, mount strips facing the wall, not downward, to eliminate harsh shadows on desks. Ensure the adhesive backing is applied to a degreased, dust-free surface at 25°C ambient temperature; cold environments reduce bond strength by 40%. In suspended ceiling grids, avoid stapling strips—use clip-in channels to prevent micro-fractures in the PCB. Finally, pair with a 0-10V dimming driver for circadian lighting integration, but verify compatibility with the building management system to avoid flicker.

Universal installation principles apply across all venues. Always cut strips only at designated copper pads—never mid-IC—to prevent open circuits. Test strips at full brightness for 15 minutes before final mounting to catch early failures. For 6-meter runs, calculate total wattage precisely: e.g., 14.4W/m strips draw 86.4W total, requiring a 100W driver minimum. Never exceed 10 meters of continuous 24V strip without additional power feeds. In high-traffic areas like malls, use frosted diffusers to minimize visible solder points and reduce glare. Document voltage at the strip’s far end during commissioning; readings below 22.8V for 24V systems indicate undersized wiring. These steps ensure the 50,000-hour lifespan our Beauty STC strips are engineered for is achieved in real-world conditions.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium 6 LED strip lights—engineered for brilliance, durability, and seamless integration. Whether you’re illuminating residential spaces, commercial environments, or industrial settings, our LED strips deliver consistent performance and superior energy efficiency. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted name in advanced lighting solutions. For personalized support and wholesale inquiries, contact our sales manager at [email protected] and discover how we can illuminate your vision together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.