Guide to Waterproof Light Strips Led

- Introduction: Navigating the Global Market for waterproof light strips led

- Understanding waterproof light strips led Types and Variations

- Key Industrial Applications of waterproof light strips led

- Strategic Material Selection Guide for waterproof light strips led

- In-depth Look: Manufacturing Processes and Quality Assurance for waterproof light strips led

- Comprehensive Cost and Pricing Analysis for waterproof light strips led Sourcing

- Spotlight on Potential waterproof light strips led Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for waterproof light strips led

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the waterproof light strips led Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of waterproof light strips led

- Strategic Sourcing Conclusion and Outlook for waterproof light strips led

Introduction: Navigating the Global Market for waterproof light strips led

Waterproof LED light strips have rapidly become an essential component in diverse commercial and industrial lighting applications worldwide. For B2B buyers operating in dynamic markets across Africa, South America, the Middle East, and Europe—including emerging hubs like Indonesia and Colombia—understanding the nuances of waterproof LED strip technology is critical to securing reliable, durable, and cost-effective lighting solutions. These products not only enhance aesthetic appeal but also meet stringent environmental demands where moisture, dust, and outdoor exposure pose significant challenges.

This comprehensive guide is designed to empower international buyers with actionable insights into the full spectrum of waterproof LED strip options. It covers key aspects such as various IP ratings and their practical implications, materials and manufacturing methods that ensure longevity and performance, and rigorous quality control standards that safeguard against premature failure. Additionally, the guide delves into sourcing strategies, supplier evaluation criteria, and cost considerations tailored to diverse regional markets.

By navigating complex technical specifications and market variables, buyers will be equipped to make well-informed purchasing decisions that optimize both product quality and return on investment. Whether procuring for architectural projects, industrial installations, or outdoor commercial spaces, this resource offers a strategic roadmap to identify the right waterproof LED strips that align with specific environmental conditions and regulatory requirements. Ultimately, it serves as a vital tool for international B2B buyers seeking to enhance their product offerings and maintain competitive advantage in a rapidly evolving global lighting market.

Understanding waterproof light strips led Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IP20 Non-Waterproof | No waterproofing, basic indoor use | Indoor decorative lighting | Low cost, versatile indoor use; unsuitable for moisture exposure |

| IP52 Silicone Coated | Silicone layer on LED beads, partial water resistance | Dry/wet indoor areas (kitchens, bathrooms) | Affordable, dustproof; limited splash resistance, slight color shift |

| IP65 Silicone Tube | Fully encased in silicone sleeve, dust and splash proof | Wet indoor areas, semi-outdoor under eaves | Good splash protection, minimal color shift; not suitable for full outdoor exposure |

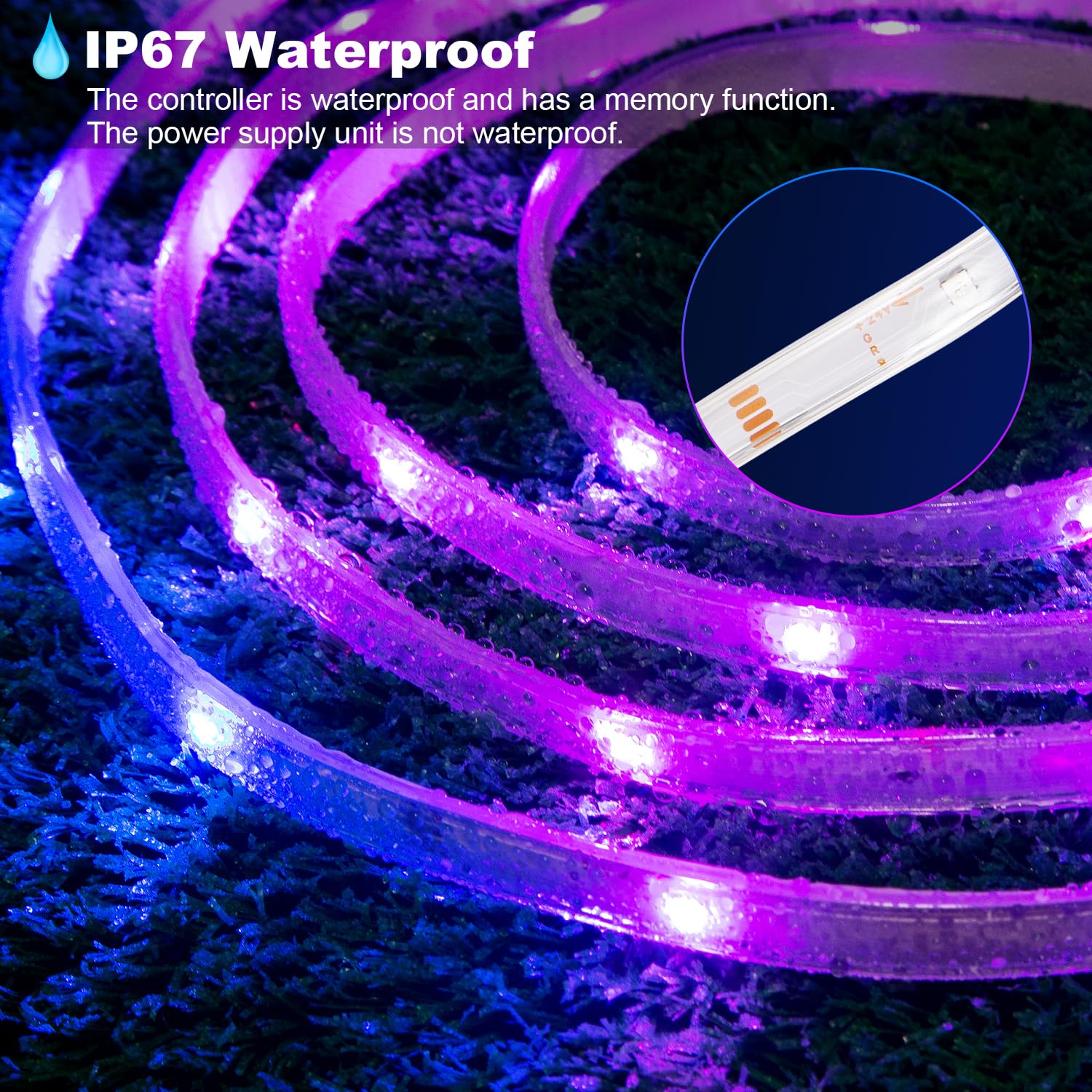

| IP67 Full Silicone Encased | Silicone-filled hollow tube, high water resistance | Outdoor use, damp environments | Strong waterproofing, durable; color shift, brightness loss, not ideal for underwater use |

| IP68 Submersible Grade | Fully sealed, suitable for submersion | Underwater lighting, pools, fountains | Highest waterproof rating, long-term durability underwater; higher cost, requires precise installation |

IP20 Non-Waterproof LED Strips

These are basic LED strips without any waterproof protection, designed strictly for indoor environments. They offer flexibility and cost efficiency for general decorative lighting projects where moisture is not a concern. B2B buyers should consider these for dry indoor applications such as office interiors or retail spaces but avoid them in kitchens, bathrooms, or outdoor settings to prevent premature failure.

IP52 Silicone Coated LED Strips

Featuring a silicone coating over the LED beads, IP52 strips provide dust protection and limited resistance against light water splashes. Ideal for indoor spaces with occasional moisture like kitchens and bathrooms, these strips balance cost and protection. Buyers should note a slight color temperature shift and moderate brightness loss, which may affect lighting design fidelity in premium projects.

IP65 Silicone Tube LED Strips

Encased in a silicone sleeve, IP65 strips are dust-tight and resistant to splashing water, making them suitable for wet indoor areas and semi-covered outdoor zones like eaves. This type is popular for commercial kitchens, outdoor signage under shelter, and bathrooms. Buyers must account for slightly increased dimensions when integrating these strips into aluminum profiles or fixtures.

IP67 Full Silicone Encased LED Strips

These strips are fully sealed within a silicone-filled tube, offering robust waterproofing for outdoor applications exposed to rain or humidity. While they protect well against water ingress, buyers should be aware of potential color shifts and a brightness reduction of up to 15%. These strips are best suited for outdoor architectural lighting, garden pathways, and commercial facades but are not recommended for underwater use due to silicone’s vulnerability to chlorine and prolonged moisture exposure.

IP68 Submersible LED Strips

Designed for continuous underwater use, IP68 strips are hermetically sealed to prevent any water ingress, suitable for pools, fountains, and aquatic installations. This highest waterproof rating ensures long-term durability in fully submerged environments. For B2B buyers, IP68 strips represent a premium solution with higher costs and require precise installation techniques, making them ideal for specialized hospitality, leisure, and public space projects demanding reliable underwater illumination.

Related Video: How to Cut, Solder, and Join Silicone-Coated Waterproof LED Strip Lights | Step-by-Step Guide

Key Industrial Applications of waterproof light strips led

| Industry/Sector | Specific Application of waterproof light strips led | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Offshore | Deck and hull lighting for ships and offshore platforms | Enhances safety and visibility in wet, corrosive environments | High IP rating (IP67/IP68), corrosion resistance, UV stability |

| Agriculture & Horticulture | Controlled environment lighting in greenhouses and irrigation channels | Supports plant growth and operational efficiency under humid conditions | Waterproof grade (IP65+), energy efficiency, flexible installation |

| Hospitality & Leisure | Outdoor and poolside ambiance lighting in resorts and hotels | Creates attractive, durable lighting for guest areas exposed to water and weather | Waterproof rating, color consistency, ease of maintenance |

| Transportation & Infrastructure | Tunnel, bridge, and railway platform lighting | Improves safety and operational reliability in damp or exposed locations | Robust waterproofing, impact resistance, compliance with local standards |

| Industrial Manufacturing | Wet area task lighting and equipment illumination in factories | Ensures continuous operation and safety in washdown or humid environments | Chemical resistance, IP rating, thermal management |

Waterproof LED light strips are increasingly integral to the marine and offshore industry, where lighting must withstand saltwater exposure, constant moisture, and mechanical stress. These strips are installed on ship decks, hulls, and offshore platforms to improve visibility and safety during night operations or adverse weather. Buyers, especially from coastal regions in Africa and South America, need to prioritize IP67 or IP68 rated products with corrosion-resistant materials and UV stability to ensure longevity and reduce maintenance costs.

In agriculture and horticulture, waterproof LED strips are used inside greenhouses and along irrigation channels to provide supplemental lighting that promotes plant growth and enhances operational efficiency. These applications demand flexible, energy-efficient strips with at least IP65 waterproof ratings to resist humidity and occasional water exposure. For buyers in tropical climates like Indonesia or Colombia, sourcing products with stable color temperature and easy installation options is critical to maximize crop yield and reduce downtime.

The hospitality and leisure sector, particularly resorts and hotels in regions like the Middle East and Europe, deploy waterproof LED strips for outdoor ambiance lighting around pools, walkways, and garden areas. These strips must maintain consistent color rendering and brightness despite exposure to splashing water and sunlight. International buyers should focus on products that offer both aesthetic appeal and durability, ensuring that the lighting system enhances guest experience while minimizing frequent replacements.

In transportation and infrastructure, waterproof LED strips are essential for lighting tunnels, bridges, and railway platforms where exposure to moisture and dust is common. These strips enhance safety for commuters and workers by providing reliable illumination in challenging environments. Buyers must consider products with robust waterproofing, impact resistance, and compliance with regional safety standards to ensure seamless integration and long-term performance.

Finally, in industrial manufacturing environments, waterproof LED strips are employed for task lighting in wet areas such as washdown zones or humid production lines. These strips help maintain operational continuity and worker safety. Buyers should prioritize chemical-resistant materials, high IP ratings, and effective thermal management to withstand harsh industrial conditions, particularly in sectors prevalent in Africa and South America where industrial modernization is ongoing.

Related Video: How to Install LED Light Strips

Strategic Material Selection Guide for waterproof light strips led

When selecting materials for waterproof LED light strips, international B2B buyers must weigh performance, durability, and environmental compatibility to ensure product longevity and customer satisfaction. The choice of material directly influences waterproof rating, resistance to environmental stressors, and installation versatility, which are critical in diverse markets such as Africa, South America, the Middle East, and Europe.

Silicone Encapsulation

Key Properties: Silicone offers excellent flexibility, high thermal stability (operating temperatures typically from -60°C to 200°C), and good resistance to UV radiation and moisture ingress. It provides a tight seal against water and dust, contributing to high IP ratings such as IP67 and IP68.

Pros: Silicone encapsulation ensures superior waterproofing and flexibility, making it ideal for outdoor and semi-submerged applications. It resists corrosion and chemical degradation, which is beneficial in harsh environments like coastal regions or industrial areas common in the Middle East and parts of South America.

Cons: Silicone encapsulation can cause a noticeable color shift and a brightness reduction of up to 15%, which may affect lighting quality. It is also more expensive and involves complex manufacturing processes compared to simpler coatings.

Application Impact: Best suited for outdoor installations exposed to rain, humidity, or occasional submersion. However, it is less resistant to chlorine and certain chemicals, limiting its use in swimming pools or highly chlorinated environments.

International B2B Considerations: Buyers in regions with stringent certification requirements (e.g., DIN in Europe or ASTM standards in South America) should verify silicone grades and manufacturing compliance. Silicone’s UV resistance is a key advantage for African and Middle Eastern markets with high sun exposure.

Polyurethane (PU) Coating

Key Properties: PU coatings provide a durable, flexible waterproof layer with moderate chemical resistance and good abrasion resistance. They typically withstand temperatures from -40°C to 120°C.

Pros: PU coatings are cost-effective and provide a smooth finish that minimally impacts LED brightness and color fidelity. They are easier to apply in manufacturing, enabling scalable production for bulk orders.

Cons: PU coatings may degrade faster under prolonged UV exposure and are less flexible than silicone, potentially leading to cracking in extreme temperature fluctuations.

Application Impact: Suitable for indoor and semi-outdoor applications where direct water immersion is unlikely but splashes or humidity are expected, such as kitchens and bathrooms.

International B2B Considerations: PU coatings align well with buyers targeting indoor markets in Europe and South America. However, for outdoor use in tropical climates like Indonesia or coastal Africa, additional UV stabilization treatments may be necessary to meet durability expectations.

Heat Shrink Tubing (Polyolefin)

Key Properties: Heat shrink tubing made from polyolefin offers a tight, protective seal with good electrical insulation and moderate waterproofing (typically up to IP65). It tolerates temperatures roughly between -55°C and 125°C.

Pros: This material maintains LED brightness with minimal color shift and adds mechanical protection without significantly increasing the strip’s dimensions. It is relatively low cost and widely available.

Cons: Heat shrink tubing is less effective for prolonged water immersion and may not withstand aggressive chemicals or prolonged UV exposure, limiting outdoor and underwater applications.

Application Impact: Ideal for protecting LED strips in splash-prone indoor environments or temporary outdoor setups where full submersion is not expected.

International B2B Considerations: Buyers in regions with moderate climates, such as parts of Europe and South America, may find heat shrink tubing a balanced choice for cost and performance. Compliance with IEC or JIS standards for electrical insulation is often required.

Silicone Sleeve with PU Filling (Hybrid)

Key Properties: This hybrid approach combines a hollow silicone sleeve filled with polyurethane or similar materials, enhancing waterproofing and mechanical strength. It offers high IP ratings (IP67/IP68) with improved chemical resistance.

Pros: Provides robust waterproofing suitable for outdoor and some underwater applications, with better resistance to chlorine and chemicals than pure silicone. The hybrid design reduces color shift compared to full silicone encapsulation.

Cons: Manufacturing complexity and costs are higher due to multi-material processing. The added thickness may require compatible aluminum profiles for mounting.

Application Impact: Suitable for demanding environments such as outdoor architectural lighting, marine applications, and areas with chemical exposure.

International B2B Considerations: This material is attractive for buyers in coastal or industrial regions of Africa, the Middle East, and Europe where durability against harsh conditions is critical. Ensuring compliance with international waterproofing and safety standards (e.g., IP testing, REACH compliance in Europe) is essential.

| Material | Typical Use Case for waterproof light strips led | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Encapsulation | Outdoor, semi-submerged, high-humidity environments | Excellent waterproofing and UV resistance | Color shift, brightness loss, higher cost | High |

| Polyurethane (PU) Coating | Indoor wet areas, splash zones like kitchens and bathrooms | Cost-effective, minimal color shift | UV degradation, less flexible | Medium |

| Heat Shrink Tubing (Polyolefin) | Splash-prone indoor or temporary outdoor use | Low cost, maintains brightness | Limited water immersion resistance, UV sensitivity | Low |

| Silicone Sleeve with PU Filling | Harsh outdoor, marine, and chemically aggressive environments | Robust waterproofing, improved chemical resistance | Higher manufacturing complexity and cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for waterproof light strips led

Manufacturing Processes for Waterproof LED Light Strips

The production of waterproof LED light strips involves a series of carefully controlled stages designed to ensure high durability, consistent performance, and resistance to environmental factors such as moisture and dust. For international B2B buyers, understanding these manufacturing stages provides insight into product quality and supplier reliability.

1. Material Preparation

The process begins with selecting high-quality raw materials:

– Flexible Printed Circuit Boards (PCB): Typically made from flexible polyimide or PET substrates with copper traces, designed to endure bending and maintain electrical integrity.

– LED Chips and Components: Sourced from reputable manufacturers to ensure consistent luminous efficiency and lifespan.

– Waterproofing Materials: Silicone, polyurethane (PU), epoxy resins, or heat shrink tubes are chosen based on desired waterproof ratings (IP65, IP67, IP68).

– Adhesives and Sealants: Specialized adhesives that maintain adhesion under moisture and temperature fluctuations.

2. PCB Fabrication and Soldering

- Circuit Patterning: The copper circuit paths are etched on the flexible PCB substrate.

- Component Placement: Automated pick-and-place machines position LEDs, resistors, and connectors with precision.

- Soldering: Reflow soldering or wave soldering techniques secure components, ensuring strong mechanical and electrical connections.

- Protective Coating: A conformal coating may be applied to protect circuitry from oxidation and moisture before waterproofing.

3. Waterproofing and Encapsulation

This critical stage differentiates waterproof LED strips:

– Silicone Coating: A layer of silicone is applied directly to the LED strip, providing IP52-level protection suitable for damp environments.

– Silicone or PU Sleeving: The strip is inserted into a silicone or polyurethane tube or sleeve, sealed by extrusion or manual insertion, achieving IP65 or IP67 ratings.

– Full Silicone Encapsulation: The strip is placed in a hollow silicone tube which is then filled with silicone gel or resin, offering IP67 or IP68 protection for outdoor and underwater applications.

– Heat Shrink Tubing: A heat shrink tube is applied over the strip and heated to shrink tightly around it, providing a waterproof barrier without significant dimensional changes.

Each waterproofing method impacts brightness, color temperature, and physical dimensions, and these variations should be considered for specific applications.

4. Cutting, Testing, and Finishing

- Cutting: LED strips are cut into standard or custom lengths along designated cut points without damaging circuits.

- Connector Assembly: End connectors, cables, or terminals are attached, often with waterproof sealing.

- Labeling and Packaging: Products are labeled with batch numbers, IP ratings, and certifications, then packaged to prevent damage during shipment.

Quality Assurance and Control (QA/QC) in Waterproof LED Strip Production

Robust QA/QC protocols are essential to ensure product reliability, especially for international buyers who require compliance with various regional standards and performance criteria.

Relevant International and Industry Standards

- ISO 9001: A foundational quality management system standard ensuring consistent manufacturing processes and continual improvement.

- Ingress Protection (IP) Ratings: Defined by IEC 60529, indicating the level of protection against solids and liquids, critical for waterproof LED strips.

- CE Marking: Mandatory for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restriction of hazardous substances, important for buyers concerned with environmental regulations.

- UL and ETL Certifications: Relevant for North American markets, ensuring electrical safety and performance.

- Additional Local Certifications: Depending on target markets, e.g., SASO for Saudi Arabia, INMETRO for Brazil, or SNI for Indonesia, buyers should verify compliance.

Key QC Checkpoints

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components before production begin, including PCB quality, LED chip performance, and waterproof materials verification.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly stages to detect defects early, such as solder joint integrity, LED positioning accuracy, and waterproofing application consistency.

- Final Quality Control (FQC): Comprehensive testing of finished products, including visual inspection, functional tests, and waterproofing efficacy.

Common Testing Methods

- Visual and Dimensional Inspection: Ensures correct assembly, no visible damage, and adherence to size specifications.

- Electrical Testing: Verification of voltage, current, and luminous output to ensure LEDs operate within specified parameters.

- Waterproof Testing:

- IP Testing Chambers: Simulate water jets, immersion, and dust exposure to verify the IP rating.

- Salt Spray Test: Evaluates corrosion resistance for outdoor applications.

- Thermal Testing: Assesses heat dissipation and operating temperature range.

- Color Consistency Testing: Ensures uniform color temperature and brightness across production batches.

How B2B Buyers Can Verify Supplier Quality Control

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should adopt rigorous supplier evaluation strategies to mitigate risks and ensure product quality.

1. Supplier Audits

- Factory Visits: Direct inspection of manufacturing facilities to evaluate equipment, process controls, and worker expertise.

- Process Audits: Review of documented procedures for manufacturing and QC to ensure compliance with ISO 9001 and industry best practices.

- Sample Testing: Request product samples for independent laboratory testing to verify waterproof ratings and electrical performance.

2. Documentation and Certification Review

- Request and verify copies of certifications such as ISO 9001, CE, RoHS, and any region-specific approvals.

- Review QC reports detailing inspection results at IQC, IPQC, and FQC stages.

- Seek transparency on material sourcing and batch traceability.

3. Third-Party Inspection Services

- Engage independent inspection agencies to conduct pre-shipment inspections, including random sampling and testing.

- Utilize testing labs accredited to international standards for waterproof and electrical compliance verification.

Illustrative Image (Source: Google Search)

QC and Certification Nuances for International Markets

Understanding regional market requirements is crucial for B2B buyers to avoid compliance issues and ensure product suitability.

- Africa: Growing demand for durable, cost-effective lighting solutions. Buyers should emphasize IP ratings suitable for humid and dusty environments and check for compliance with local electrical standards.

- South America: Import regulations often require INMETRO certification; waterproof LED strips must comply with regional safety and environmental rules.

- Middle East: Strict adherence to SASO standards and often requires CE marking. High ambient temperatures necessitate robust thermal management and waterproofing.

- Europe: High environmental and safety standards mean CE and RoHS compliance are mandatory. Buyers often require detailed documentation and traceability for green procurement policies.

- Southeast Asia (e.g., Indonesia): SNI certification is important; buyers should verify supplier adherence to both waterproofing quality and electrical safety standards.

Conclusion

For international B2B buyers, a deep understanding of the manufacturing processes and stringent quality assurance practices behind waterproof LED light strips is vital. Prioritizing suppliers with transparent QC systems, valid certifications, and proven waterproofing expertise will ensure reliable product performance and regulatory compliance across diverse markets. Conducting thorough audits, insisting on comprehensive testing, and leveraging third-party inspections are essential steps to mitigate risks and secure long-term partnerships.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for waterproof light strips led Sourcing

Cost Structure Breakdown for Waterproof LED Light Strips

When sourcing waterproof LED light strips, understanding the key cost components is essential for effective budgeting and negotiation:

-

Materials: The primary cost driver includes LED chips (commonly 2835 or 5050 SMD types), PCB substrates, silicone or epoxy waterproof coatings (e.g., silicone tubes for IP65-IP67 ratings), and additional protective layers. Higher IP ratings typically require more or better-quality sealing materials, increasing costs.

-

Labor: Skilled labor is involved in assembly, soldering, waterproof encapsulation, and quality checks. Labor costs vary significantly by manufacturing region, impacting final pricing.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and indirect labor. Automated production lines reduce overhead per unit but require higher initial investment.

-

Tooling: Custom molds for silicone extrusion or heat shrink tubes and PCB design tooling add upfront costs, which are amortized over production volume.

-

Quality Control (QC): Rigorous QC processes, including IP testing, lumen output verification, and color temperature consistency, add to costs but ensure product reliability and compliance.

-

Logistics: International shipping, customs duties, and insurance must be factored in, especially for buyers from Africa, South America, the Middle East, and Europe where freight routes and tariffs vary widely.

-

Margin: Suppliers include profit margins that vary by brand reputation, order size, and market demand.

Key Price Influencers in Waterproof LED Strip Procurement

Several factors influence the pricing dynamics for waterproof LED strips in B2B transactions:

-

Order Volume / MOQ: Larger orders typically secure lower per-unit pricing due to economies of scale. Minimum order quantities (MOQs) can range from hundreds to thousands of meters, depending on supplier policies.

-

Specifications & Customization: Custom color temperatures, specific LED densities, unique IP ratings (e.g., IP67 vs. IP68), and special features like dim-to-warm or addressable RGB increase costs. Custom packaging or branding also add to price.

-

Material Quality: Premium-grade LEDs (high CRI, low lumen depreciation), advanced waterproofing materials, and certifications (CE, RoHS, UL) justify higher prices but reduce long-term risks and failures.

-

Supplier Location & Reputation: Established suppliers with proven quality may charge premiums, while manufacturers in lower-cost regions offer competitive pricing but may require more stringent QC oversight.

-

Incoterms & Payment Terms: FOB, CIF, EXW, and DDP shipping terms impact who bears logistics costs and risks. Favorable payment terms (e.g., letters of credit, net 30) can improve cash flow but may influence pricing.

Strategic Tips for International B2B Buyers

To optimize procurement costs and ensure value, buyers—particularly from Africa, South America, the Middle East, and Europe—should consider the following:

-

Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, factor in installation complexity, expected lifespan, maintenance costs, and warranty terms. For example, IP67 strips may cost more upfront but reduce replacement frequency in outdoor environments.

-

Request Samples & Third-Party Testing: Verify waterproof ratings and light performance before large orders, especially for critical applications like outdoor or underwater lighting.

-

Leverage Volume Discounts & Long-Term Contracts: Consolidate orders or commit to multi-order agreements to unlock better pricing tiers.

-

Understand Regional Import Duties & Certification Requirements: Some regions have strict electrical safety and environmental standards. Ensuring compliance upfront prevents costly delays or product rejections.

-

Consider Supplier Proximity & Shipping Routes: For buyers in regions like Indonesia or Colombia, choosing suppliers with established logistics to their region can reduce lead times and freight costs.

-

Clarify Warranty & After-Sales Support: Reliable post-sale service can save costs associated with defective products or technical support.

Indicative Pricing Context

Prices for waterproof LED strips can vary widely based on IP rating, LED type, and customization. For example, standard IP65 LED strips may range from $2 to $5 per meter in bulk, while high-end IP68 variants with advanced features can exceed $8 per meter. These figures are indicative and subject to market fluctuations, supplier terms, and global supply chain conditions.

Illustrative Image (Source: Google Search)

By comprehensively evaluating these cost and pricing factors, international B2B buyers can make informed decisions, negotiate effectively, and achieve optimal value when sourcing waterproof LED light strips for diverse applications.

Spotlight on Potential waterproof light strips led Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘waterproof light strips led’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for waterproof light strips led

Key Technical Properties of Waterproof LED Light Strips

1. Ingress Protection (IP) Rating

The IP rating is a critical specification that indicates the level of protection the LED strip offers against dust and water ingress. It is expressed as “IP” followed by two digits—for example, IP65 or IP67. The first digit defines protection against solids (like dust), and the second digit specifies water resistance. For B2B buyers, choosing the correct IP rating ensures the product suits the intended environment, whether indoor, outdoor, or underwater, minimizing returns and failures.

2. Material and Encapsulation Method

Waterproof LED strips use different materials and methods for protection, such as silicone coatings, silicone tubes, or heat shrink tubing. These affect durability, flexibility, and resistance to environmental factors like UV light, chlorine, or saltwater. Understanding these materials helps buyers select strips that meet longevity requirements and comply with local regulations, especially for outdoor or industrial applications.

3. Brightness and Lumen Output

Waterproofing layers can reduce the light output by 4% to 15%, depending on the encapsulation method. B2B buyers must consider this lumen depreciation to ensure lighting projects meet brightness specifications. For example, IP67 silicone-encased strips may lose more brightness than IP65 silicone tube options, which impacts energy efficiency calculations and overall lighting design.

4. Color Temperature and Color Shift

Waterproof coatings can alter the perceived color temperature (measured in Kelvin). Some waterproofing materials cause a color shift, meaning LEDs with a nominal color temperature (e.g., 2700K) may appear warmer or cooler after encapsulation. This is critical for applications requiring precise color rendering, such as retail or hospitality lighting. Buyers should request samples or detailed technical datasheets to verify color accuracy.

5. Dimensional Tolerances and Size Changes

Encapsulation adds thickness and sometimes width to LED strips, typically increasing dimensions by 1.5 to 2 mm or more. This affects compatibility with mounting profiles, channels, or enclosures. International buyers should verify dimensional specifications to ensure seamless integration with architectural or industrial fittings, avoiding costly retrofits or installation delays.

6. Operating Voltage and Power Consumption

Most waterproof LED strips operate at 12V or 24V DC, but power consumption varies with LED density and waterproofing layers. Buyers must confirm power requirements to correctly size power supplies and ensure safety compliance, especially in regions with strict electrical standards. This also impacts shipping costs and customs classifications.

Common Trade Terminology for B2B LED Strip Transactions

OEM (Original Equipment Manufacturer)

OEM refers to products manufactured by one company but branded and sold by another. Many LED strip suppliers offer OEM services, allowing buyers to customize product specifications, packaging, and branding. This is especially relevant for distributors or large-scale projects seeking unique or private-label solutions.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier will accept per order. Understanding MOQ helps buyers plan inventory, manage cash flow, and negotiate better pricing. For buyers in emerging markets or smaller businesses, suppliers offering flexible MOQs can reduce upfront investment risk.

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent by a buyer to suppliers requesting detailed pricing, lead times, and terms for specific products. It is the foundation of transparent procurement processes and competitive sourcing. Well-prepared RFQs include technical requirements and certifications to ensure supplier compliance.

Incoterms (International Commercial Terms)

Incoterms define responsibilities and risk allocation between buyers and sellers during shipping. Common terms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding Incoterms is essential for international buyers to control costs, customs clearance, and delivery timelines.

Lead Time

Lead time indicates the duration between order confirmation and product shipment. For waterproof LED strips, lead time can vary based on customization, production capacity, and shipping mode. Accurate lead time forecasts enable buyers to synchronize supply with project schedules and avoid costly delays.

Certification and Compliance

Terms like CE, RoHS, UL, or IP ratings represent product compliance with safety and environmental standards. International buyers must verify certifications relevant to their region to ensure legal market entry and avoid liability issues.

By mastering these technical properties and trade terms, international B2B buyers can make informed purchasing decisions for waterproof LED strip lights, ensuring product suitability, regulatory compliance, and optimized supply chain management.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the waterproof light strips led Sector

Market Overview & Key Trends

The global market for waterproof LED light strips is experiencing robust growth, driven by increasing demand for versatile, energy-efficient lighting solutions across residential, commercial, and industrial sectors. This demand is particularly strong in regions with diverse climate challenges such as Africa, South America, the Middle East, and Europe, where moisture resistance and durability are critical for outdoor and wet-area installations.

Key market drivers include urbanization, infrastructure development, and the rise of smart cities, which are promoting the adoption of advanced lighting technologies. The trend towards customizable lighting—incorporating RGB and addressable LED strips—caters to aesthetic and functional needs, making waterproof LED strips highly attractive for architectural, hospitality, and retail projects.

From a sourcing perspective, international B2B buyers are increasingly prioritizing suppliers who offer a variety of IP-rated waterproof options (IP65 to IP68) to suit different environmental demands. The integration of flexible mounting profiles and connectors enhances installation ease and adaptability, which is a critical consideration in markets like Indonesia and Colombia where diverse application scenarios exist.

Emerging trends include the incorporation of smart controls compatible with IoT platforms, enabling remote management and energy optimization. Additionally, multi-row and high-density LED strips are gaining traction for applications requiring higher luminosity and uniformity, such as in commercial façades and public spaces. Buyers should also be aware of evolving certification standards and quality assurances, which vary by region, to ensure compliance and reduce import/export risks.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal factor in procurement decisions within the waterproof LED strip sector. The environmental impact of LED manufacturing—covering raw material extraction, production energy consumption, and end-of-life disposal—necessitates a shift towards greener supply chains. International buyers are increasingly demanding products made with eco-friendly materials such as lead-free solder and recyclable aluminum profiles.

Ethical sourcing is critical, especially in regions where labor and environmental regulations may vary. Transparent supply chains that verify responsible sourcing of components help mitigate risks related to forced labor, conflict minerals, and environmental degradation. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), and Energy Star compliance are essential markers for buyers seeking sustainable waterproof LED strips.

Moreover, manufacturers adopting circular economy principles—designing products for longevity, ease of repair, and recyclability—are gaining preference. This is particularly relevant for markets in Europe and the Middle East, where regulatory frameworks increasingly emphasize product lifecycle management and carbon footprint reduction. B2B buyers should engage suppliers who provide environmental impact data and demonstrate commitment to continuous improvement in sustainability practices.

Evolution of Waterproof LED Light Strips

Waterproof LED light strips have evolved significantly over the past decade, transitioning from basic indoor lighting solutions to sophisticated, durable products capable of withstanding harsh environments. Initially, LED strips were primarily non-waterproof and limited to indoor decorative use. As demand grew for outdoor and wet-area applications, manufacturers developed various waterproofing techniques, from silicone coatings to fully encapsulated designs rated up to IP68.

Advancements in materials science introduced silicone extrusion and heat shrink tubing, enhancing both protection and flexibility. This evolution has enabled a wide range of applications, from underwater pool lighting to architectural façade illumination. The increasing integration of smart technology and modular designs reflects the sector’s ongoing innovation, offering B2B buyers enhanced functionality and adaptability to meet diverse project requirements globally.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of waterproof light strips led

-

How can I effectively vet suppliers of waterproof LED light strips for international B2B purchases?

When sourcing waterproof LED strips internationally, especially from regions like Asia or Europe, prioritize suppliers with verifiable certifications (CE, RoHS, IP ratings). Request product samples to verify quality and waterproof integrity. Check their production capacity and history of exporting to your region (Africa, South America, Middle East). Use third-party inspection services or factory audits to ensure compliance. Additionally, review customer references and online feedback to assess reliability and after-sales support. A clear understanding of their warranty policies and technical support capabilities is critical for long-term partnerships. -

What customization options are typically available for waterproof LED strip lights in B2B orders?

Most manufacturers offer customization including LED density, color temperature, IP waterproof rating (IP65, IP67, IP68), strip length, PCB width, and connector types. You can also request specific packaging, branding (private label), and certifications tailored to your market’s regulatory needs. For markets like Europe or the Middle East, ensure compliance with local standards. Discuss technical details upfront to ensure the waterproof encapsulation matches your application (outdoor, underwater, industrial). Custom firmware or control protocols (DMX, addressable LEDs) may also be available for advanced lighting solutions. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders?

MOQs vary widely depending on customization and supplier scale but generally range from 500 to 2,000 meters per order. Lead times for standard waterproof LED strips typically range from 3 to 6 weeks, longer for customized products. Payment terms often require a 30-50% deposit upfront, with balance paid before shipment or upon delivery via secure methods like LC (Letter of Credit) or escrow services. Negotiate terms based on supplier reliability and your import regulations. For buyers in Africa or South America, factor in potential customs delays and shipping transit times when planning orders. -

Which quality assurance measures and certifications should B2B buyers request for waterproof LED strips?

Request detailed IP rating test reports (IP65, IP67, IP68) to verify waterproof capabilities. Ask for CE and RoHS certifications to ensure compliance with European and international safety and environmental standards. UL certification may be important for Middle East and North American markets. Additionally, inquire about thermal management testing, lumen maintenance reports, and LED binning consistency. A supplier with ISO 9001 quality management certification often demonstrates robust production controls. Conducting random batch inspections or third-party lab testing before shipment can reduce risks of defective products. -

How should I manage logistics and shipping for large orders of waterproof LED strip lights internationally?

Coordinate with suppliers to consolidate shipments for cost efficiency and avoid partial deliveries that increase customs clearance complexity. Choose between sea freight for cost savings (longer lead times) or air freight for urgent orders. Ensure proper packaging to prevent moisture ingress during transit, especially for high-IP rated products. Work with freight forwarders experienced in handling electronics and understand import regulations, duties, and VAT in your country. Track shipments actively and prepare customs documentation in advance to minimize delays, particularly in regions with complex import procedures like Africa and South America. -

What steps can B2B buyers take to handle disputes or quality issues with waterproof LED strip suppliers?

Establish clear contract terms covering product specifications, quality standards, delivery schedules, and penalties for non-compliance before ordering. In case of disputes, document all communications and inspect products immediately upon receipt. Use third-party quality inspection reports to support your claims. Negotiate amicably first, seeking partial refunds, replacements, or rework options. If unresolved, escalate via trade dispute resolution mechanisms such as arbitration or mediation under international trade laws. Maintaining strong communication and building supplier relationships can prevent many conflicts. -

Are there specific considerations for waterproof LED strips when sourcing for markets with harsh environments like Africa or the Middle East?

Yes, buyers should prioritize LED strips with higher IP ratings (IP67 or IP68) and UV-resistant materials to withstand dust, heat, and sand exposure common in these regions. Confirm the supplier’s waterproofing method ensures long-term durability under such conditions, and verify resistance to chlorine or salt corrosion if near coastal areas. Consider LED strips with enhanced thermal management to maintain performance in high temperatures. Also, check local electrical standards and power supply compatibility to avoid installation issues. -

How can international B2B buyers optimize cost without compromising quality when purchasing waterproof LED strips?

Leverage volume discounts by consolidating orders and committing to multi-year contracts. Balance the IP rating needed with application requirements—higher waterproof grades cost more but may be unnecessary for indoor or semi-outdoor use. Negotiate payment terms and shipping arrangements to reduce financial burden and logistics costs. Request supplier proposals including warranty and after-sales service to avoid hidden costs from defects. Partnering with reliable manufacturers that offer transparent pricing and certifications helps maintain quality while optimizing budget, especially important for emerging markets in South America or Africa.

Strategic Sourcing Conclusion and Outlook for waterproof light strips led

Waterproof LED strip lights represent a dynamic and evolving product category essential for diverse applications across commercial, industrial, and outdoor environments. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of IP ratings, waterproofing methods, and material performance is critical to sourcing solutions that align with specific environmental and operational requirements.

Key strategic takeaways include:

- Assessing IP Ratings: Select LED strips with appropriate IP ratings (IP65, IP67, IP68) based on exposure to moisture, dust, and submersion needs, ensuring longevity and compliance with local standards.

- Material and Construction Quality: Prioritize suppliers who offer robust silicone encasements or advanced nano-coatings to balance brightness retention with waterproofing durability.

- Customization and Application Fit: Opt for manufacturers that provide tailored solutions, including color temperature calibration and dimensional compatibility with existing fixtures or aluminum profiles.

- Supply Chain Resilience: Build relationships with reliable suppliers who can navigate logistical challenges and provide consistent quality, especially for regions with complex import/export environments.

Looking ahead, international B2B buyers should embrace strategic partnerships and leverage emerging innovations in waterproof LED technology to enhance product differentiation and operational efficiency. Proactively engaging with manufacturers to co-develop solutions tailored to regional climates and application demands will unlock new market opportunities and drive sustainable growth. Act now to secure competitive advantage by sourcing intelligently and adapting to evolving industry trends.