Introduction: Navigating the Global Market for solar led strip lights outdoor

Solar LED strip lights designed for outdoor use represent a transformative opportunity for businesses seeking sustainable, energy-efficient lighting solutions. Their adaptability, combined with solar power technology, enables cost-effective illumination for a wide range of commercial and industrial applications—from architectural accent lighting to security perimeter lighting. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of this product category is critical to securing high-quality, durable solutions that align with regional environmental conditions and regulatory standards.

This comprehensive guide delivers expert insights into the diverse types of solar LED strip lights available on the global market, emphasizing key features such as waterproof ratings, battery capacity, and LED efficiency. It also covers essential considerations in materials selection, manufacturing processes, and quality control protocols that ensure product longevity and performance under outdoor conditions. Buyers will gain strategic guidance on evaluating and selecting suppliers, taking into account factors like certification compliance, production capacity, and after-sales support.

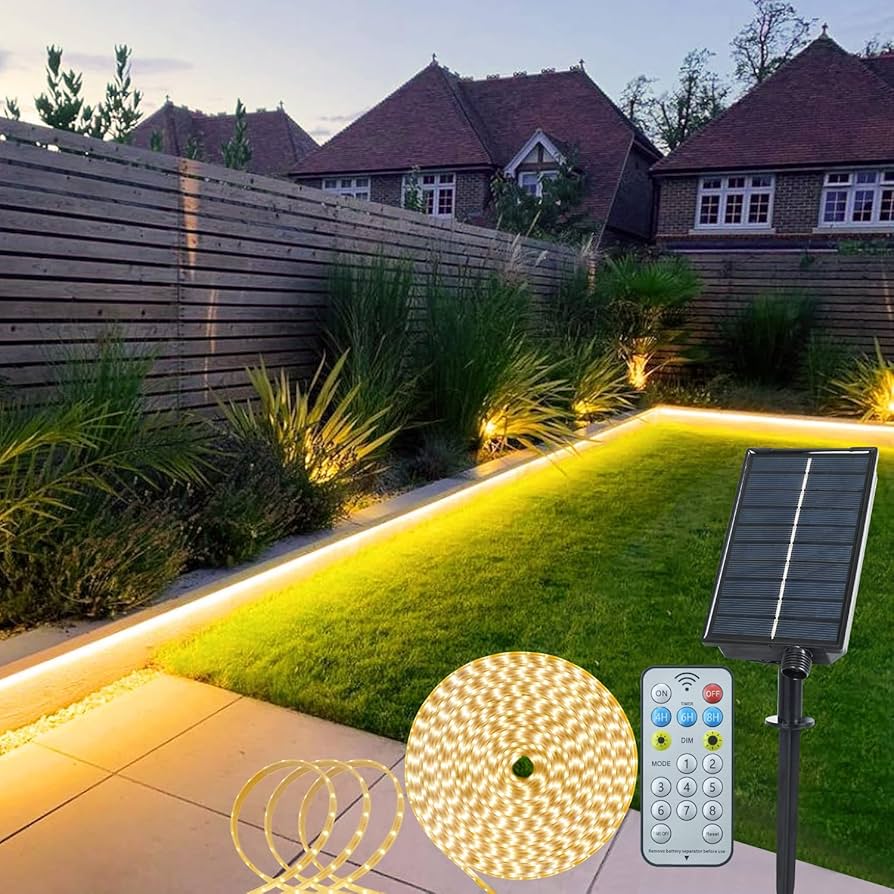

Illustrative Image (Source: Google Search)

Cost analysis and financing options are explored in detail, enabling purchasers to weigh upfront investments against long-term savings and sustainability goals. Additionally, the guide addresses current market trends and emerging opportunities, helping businesses from regions such as Spain and Germany to Africa and the Middle East identify competitive advantages in their procurement strategies. A dedicated FAQ section further clarifies common concerns, empowering buyers to make informed decisions that support operational efficiency and environmental responsibility.

By leveraging this resource, international B2B buyers can confidently navigate the complexities of sourcing outdoor solar LED strip lights, ensuring their projects benefit from cutting-edge technology, reliable supply chains, and optimal cost performance.

Understanding solar led strip lights outdoor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Solar LED Strip | Bendable, weatherproof strips with integrated solar cells | Architectural lighting, signage, outdoor décor | Pros: Easy installation, adaptable shapes; Cons: Lower brightness than rigid strips |

| Rigid Solar LED Strip | Sturdy, fixed-form strips with high-efficiency solar panels | Industrial outdoor lighting, commercial facades | Pros: Durable, high output; Cons: Less flexible, heavier |

| Waterproof Solar LED Strip | Enhanced IP65-IP68 ratings, sealed against water and dust | Landscape lighting, pathway illumination | Pros: Reliable in harsh environments; Cons: May have higher cost due to sealing |

| RGB Solar LED Strip | Multi-color LEDs with solar power, customizable lighting effects | Event venues, outdoor advertising | Pros: Versatile color options, energy-saving; Cons: Requires controller, higher complexity |

| Integrated Battery Strip | Built-in rechargeable batteries for extended night operation | Remote locations, security lighting | Pros: Longer autonomy, reduces external components; Cons: Battery lifespan limits |

Flexible Solar LED Strip

These strips are designed to be bendable and adaptable to various surfaces, making them ideal for architectural details and outdoor decorative lighting. Their flexibility allows integration into curved or irregular structures, which is valuable for creative commercial projects. Buyers should assess the quality of the solar cells and waterproofing to ensure durability in diverse climates, particularly in regions with intense sun exposure or seasonal rains.

Rigid Solar LED Strip

Rigid strips offer superior durability and higher light output, suitable for industrial or commercial outdoor lighting applications where robustness is critical. Their fixed form factor supports consistent illumination over large areas like building facades or parking zones. B2B buyers should prioritize energy efficiency ratings and the strength of the mounting hardware to maximize lifespan and minimize maintenance costs.

Waterproof Solar LED Strip

With IP ratings ranging from IP65 to IP68, these strips are engineered to withstand water, dust, and extreme weather conditions. This makes them a preferred choice for landscape lighting, garden pathways, and coastal environments. International buyers must verify certification standards and material quality to ensure compliance with local environmental regulations and long-term performance.

RGB Solar LED Strip

Featuring multi-color LED options powered by solar energy, RGB strips are popular for event spaces, outdoor advertising, and hospitality sectors aiming for dynamic lighting effects. These systems often include controllers for color customization and sequencing, adding complexity but enhancing visual appeal. Buyers should evaluate compatibility with existing lighting controls and the reliability of the solar charging system.

Integrated Battery Strip

These solar LED strips come with built-in rechargeable batteries, providing extended illumination time after sunset, crucial for remote or security lighting applications. The integrated design reduces the need for external components, simplifying installation and maintenance. B2B buyers need to consider battery capacity, replacement ease, and warranty terms to ensure operational continuity and cost-effectiveness.

Related Video: Transform Your Outdoor Space: Solar Powered Strip Lights by Luhlee

Key Industrial Applications of solar led strip lights outdoor

| Industry/Sector | Specific Application of solar led strip lights outdoor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Greenhouse and perimeter lighting for crop protection and extended working hours | Enhances crop security and enables night-time operations, reducing losses | Durability against weather, energy autonomy, ease of installation, and light spectrum |

| Hospitality & Tourism | Outdoor ambiance and pathway lighting in resorts and hotels | Creates attractive, eco-friendly environments improving guest experience | Aesthetic design options, IP rating for weather resistance, and energy efficiency |

| Retail & Commercial | Illuminated outdoor signage and storefront decoration | Increases visibility and brand recognition while lowering energy costs | Brightness levels, customization options, and integration with solar power systems |

| Infrastructure & Urban Development | Public space lighting such as parks, walkways, and bus stops | Reduces municipal energy expenses and enhances public safety | Longevity, vandal resistance, and compliance with local lighting regulations |

| Transportation & Logistics | Loading docks and outdoor storage area lighting | Improves operational safety and efficiency during night shifts | Robustness, battery capacity, and ease of maintenance |

Agriculture

Solar LED strip lights outdoor are increasingly used in greenhouses and around farm perimeters to provide consistent lighting that extends working hours and deters pests or intruders. For agricultural businesses in regions like Africa and South America, where grid power may be unreliable or expensive, solar-powered lighting offers a sustainable solution. Buyers should prioritize products with high durability against moisture, dust, and temperature fluctuations, as well as light spectrums conducive to plant growth and security.

Hospitality & Tourism

Resorts and hotels across the Middle East and Europe benefit from solar LED strip lights to enhance outdoor ambiance, illuminate pathways, and highlight architectural features without increasing electricity bills. These lights contribute to a sustainable brand image, a growing demand among eco-conscious travelers. B2B buyers must focus on IP-rated fixtures for weather resilience, customizable color temperatures for mood setting, and seamless integration with existing solar infrastructure.

Retail & Commercial

Outdoor solar LED strip lights are used to backlight signage and decorate storefronts, providing vibrant illumination that attracts customers while reducing operational costs. In urban centers like Spain and Germany, where energy efficiency is heavily regulated, solar lighting helps businesses comply with sustainability goals. Buyers should evaluate brightness, color rendering, and modularity to tailor lighting solutions to varied commercial facades and signage needs.

Infrastructure & Urban Development

Municipalities and urban planners deploy solar LED strip lights in parks, pedestrian walkways, and bus stops to improve safety and reduce public lighting expenses. This application is particularly relevant in emerging urban areas in Africa and South America, where extending grid infrastructure is costly. Buyers must ensure products meet local standards for brightness, vandal resistance, and have long battery life to maintain consistent lighting through varying weather conditions.

Transportation & Logistics

Outdoor solar LED strip lights are essential in loading docks and storage yards to enable safe operations during nighttime hours. For logistics hubs in Europe and the Middle East, these lights reduce dependency on grid power and minimize operational downtime caused by power outages. B2B buyers should prioritize robust, weatherproof designs with high battery capacity and easy maintenance to ensure uninterrupted illumination in demanding environments.

Related Video: Top 10 Best Outdoor Solar LED Lights You NEED

Strategic Material Selection Guide for solar led strip lights outdoor

Aluminum

Key Properties: Aluminum is lightweight, exhibits excellent corrosion resistance, and has good thermal conductivity, which helps dissipate heat generated by LEDs. It typically withstands temperatures up to 150°C and resists oxidation, making it suitable for outdoor environments.

Pros & Cons: Aluminum’s durability and corrosion resistance make it a preferred choice for outdoor solar LED strip light housings. It is relatively easy to manufacture with extrusion and anodizing processes, offering good design flexibility. However, aluminum can be more expensive than plastics and requires surface treatment to maintain aesthetics and corrosion resistance in highly saline or industrial atmospheres.

Impact on Application: Aluminum is ideal for solar LED strip lights installed in coastal regions or areas with high humidity, such as parts of Africa and the Middle East, due to its resistance to rust and corrosion. Its thermal management capabilities also enhance LED lifespan, critical for markets demanding long-term reliability.

B2B Considerations: Buyers from Europe (e.g., Germany, Spain) often require compliance with ASTM B209 or DIN EN standards for aluminum alloys, ensuring consistent quality and performance. In South America and Africa, suppliers should verify anodizing quality to withstand local environmental stresses. Aluminum’s recyclability aligns well with sustainability goals prevalent in European procurement policies.

Polycarbonate (PC)

Key Properties: Polycarbonate is a high-impact, transparent thermoplastic with excellent UV resistance and temperature tolerance ranging from -40°C to 120°C. It offers good dimensional stability and is highly resistant to weathering and chemical exposure.

Pros & Cons: Polycarbonate’s strength and clarity make it an excellent choice for protective covers and diffusers on solar LED strip lights. It is lighter and less expensive than aluminum but can be prone to scratching and may yellow over prolonged UV exposure if not UV-stabilized. Manufacturing complexity is moderate, requiring injection molding or extrusion.

Impact on Application: Polycarbonate is suitable for installations requiring lightweight and shatter-resistant materials, such as in urban outdoor lighting in South America and Africa. Its UV resistance is critical for regions with intense sunlight, but buyers must ensure UV stabilization additives are included.

B2B Considerations: International buyers should verify compliance with ISO 4892-2 for UV aging and ASTM D638 for tensile properties. In the Middle East, where temperatures can be extreme, confirming polycarbonate’s thermal stability is essential. Polycarbonate’s cost-effectiveness appeals to budget-sensitive projects without compromising durability.

Silicone Rubber

Key Properties: Silicone rubber is highly flexible, resistant to extreme temperatures (-60°C to 230°C), and offers excellent waterproofing and UV resistance. It maintains elasticity over long periods and resists ozone and chemical degradation.

Pros & Cons: Silicone is commonly used for sealing and encapsulating LED strips to ensure waterproofing and dust resistance (IP65 to IP68 ratings). It provides superior protection against harsh weather and mechanical stress but is more expensive than typical plastics and requires specialized molding processes.

Impact on Application: Silicone rubber is ideal for solar LED strip lights deployed in harsh outdoor environments, including desert areas in the Middle East and tropical climates in Africa and South America. Its flexibility allows for curved installations and vibration resistance, enhancing product longevity.

B2B Considerations: Buyers should confirm compliance with ASTM D2000 for rubber materials and ensure suppliers provide certifications for UV and weather resistance. In Europe, adherence to REACH regulations regarding chemical safety is critical. Silicone’s higher cost must be justified by the application’s durability requirements.

Copper (for Conductive Components)

Key Properties: Copper offers excellent electrical conductivity, good thermal conductivity, and corrosion resistance when properly coated. It withstands temperatures up to 200°C and is often used in wiring and circuit boards within LED strips.

Pros & Cons: Copper’s superior conductivity enhances energy efficiency and reduces power loss in solar LED strip lights. However, it is susceptible to oxidation and corrosion if exposed, necessitating protective coatings like tin or nickel plating. Copper is relatively costly and adds complexity to manufacturing.

Impact on Application: Copper is essential for reliable electrical performance in solar LED strip lights, especially in regions with fluctuating power conditions like parts of Africa and South America. Proper insulation and coating are critical in humid or coastal environments to prevent corrosion.

B2B Considerations: International buyers should require compliance with IPC standards for electronic materials and ensure suppliers use RoHS-compliant coatings. In Europe, copper sourcing must align with environmental regulations, and traceability is often required. The added cost is justified by improved electrical performance and product lifespan.

| Material | Typical Use Case for solar led strip lights outdoor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and heat dissipation components | Excellent corrosion resistance and thermal management | Higher cost and requires surface treatment in harsh environments | High |

| Polycarbonate | Protective covers and diffusers | Lightweight, UV resistant, and impact resistant | Prone to scratching and potential yellowing without UV stabilization | Medium |

| Silicone Rubber | Waterproof sealing and encapsulation | Superior flexibility, waterproofing, and UV resistance | Higher material and processing cost | High |

| Copper | Electrical conductors and wiring within LED strips | Outstanding electrical and thermal conductivity | Susceptible to corrosion if uncoated; higher cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for solar led strip lights outdoor

Manufacturing solar LED strip lights for outdoor use involves a series of precise, quality-driven steps designed to ensure durability, efficiency, and safety under various environmental conditions. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding these manufacturing processes and quality assurance (QA) mechanisms is critical to sourcing reliable products that meet regional standards and project requirements.

Key Manufacturing Stages and Techniques

1. Material Preparation

The process begins with sourcing high-quality raw materials, including flexible printed circuit boards (PCBs), LED chips, solar cells, batteries, and encapsulating materials. PCBs are typically made from durable, weather-resistant substrates such as polyimide or fiberglass to withstand outdoor conditions. Solar cells (usually monocrystalline or polycrystalline silicon) are selected based on efficiency and cost considerations. Battery types often include lithium-ion or lithium iron phosphate for longevity and temperature resilience.

2. Forming and PCB Assembly

The flexible PCB is fabricated to design specifications, with copper traces etched to allow for electrical conductivity. Automated Surface Mount Technology (SMT) machines place LEDs and other electronic components precisely onto the PCB. This stage demands high accuracy to prevent defects such as solder bridging or component misalignment, which can compromise product lifespan.

3. Integration of Solar and Battery Components

Solar panels and batteries are integrated with the LED strip circuitry, often requiring soldering or connector assembly. Protective circuitry including charge controllers and voltage regulators are installed to manage power flow efficiently and protect against overcharging or short circuits.

4. Encapsulation and Sealing

To ensure waterproofing and UV resistance, the LED strips and solar components are encapsulated with silicone or epoxy resins. This sealing process is crucial for outdoor products to withstand rain, dust, and extreme temperatures. The final product often undergoes curing in controlled environments to ensure adhesion and durability.

5. Final Assembly and Packaging

After encapsulation, the strips are cut to length, fitted with connectors or mounting hardware, and packaged with necessary accessories such as mounting clips and user manuals. Packaging is designed to protect the product during transit and storage, often incorporating anti-static and moisture barrier materials.

Quality Assurance Framework and International Standards

ISO 9001 Certification

ISO 9001 is a globally recognized quality management standard that ensures manufacturers maintain consistent processes, continuous improvement, and customer satisfaction. Buyers should prioritize suppliers with ISO 9001 certification as it reflects a systematic approach to quality control.

Industry-Specific and Regional Certifications

– CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

– RoHS Compliance: Restricts hazardous substances in electrical equipment, essential for European markets like Germany and Spain.

– IP Ratings (Ingress Protection): Critical for outdoor solar LED strips, typically requiring IP65 or higher to guarantee water and dust resistance.

– API and IEC Standards: Some regions may require compliance with International Electrotechnical Commission (IEC) standards or specific API certifications for electrical safety and performance.

Quality Control Checkpoints

Incoming Quality Control (IQC)

Materials and components undergo rigorous inspection upon arrival, including visual checks, electrical testing of LEDs, and verification of solar panel efficiency. This step prevents defective inputs from entering production.

In-Process Quality Control (IPQC)

During assembly, automated optical inspection (AOI) systems and manual spot checks monitor solder joints, component placement, and circuit continuity. Environmental stress testing may be conducted mid-process to detect early failures.

Final Quality Control (FQC)

Finished products are tested for full functionality, including:

– Electrical Testing: Ensuring correct voltage, current, and light output.

– Environmental Testing: Exposure to simulated rain, dust, UV light, and temperature cycling to verify durability.

– Battery Performance: Capacity and charge/discharge cycle testing to guarantee longevity.

– Waterproof Testing: Pressure and immersion tests to confirm IP rating compliance.

Testing Methods Commonly Used

- Photometric Testing: Measures luminous intensity and color temperature to ensure lighting meets design specifications.

- Thermal Imaging: Identifies hotspots that could indicate poor soldering or component failure.

- Accelerated Life Testing: Simulates extended outdoor exposure to detect potential degradation.

- Electromagnetic Compatibility (EMC) Testing: Verifies that the product does not emit or is not susceptible to electromagnetic interference, crucial for regulatory compliance in Europe and parts of the Middle East.

How B2B Buyers Can Verify Supplier Quality Assurance

Factory Audits

Conducting on-site audits—either independently or through third-party inspection agencies—allows buyers to assess production capabilities, QA processes, and working conditions firsthand. For buyers in Africa and South America, partnering with reputable inspection firms familiar with local and international standards is advisable.

Reviewing Quality Documentation

Request comprehensive QC reports, including material certificates, test results, and batch traceability records. Certified labs’ reports add credibility, especially when evaluating new suppliers.

Third-Party Inspections

Engaging independent quality control firms to perform random sampling and testing before shipment offers an unbiased assessment of product quality and compliance.

Certifications Verification

Buyers should verify the authenticity and validity of ISO, CE, RoHS, and other certifications through official registries or certifying bodies. This step is particularly important for buyers in Europe, where regulatory scrutiny is stringent.

Nuances in Quality Assurance for Different Regions

-

Africa & South America: Given diverse climates and infrastructure challenges, buyers should emphasize product robustness, long battery life, and ease of maintenance. Quality assurance should focus on environmental resistance and reliability under high temperatures and humidity. Suppliers with experience exporting to these regions often have tailored QA protocols.

-

Middle East: Harsh desert environments demand solar LED strips with high IP ratings and heat-resistant materials. Buyers should insist on rigorous thermal and UV testing. Compliance with regional standards, such as Gulf Cooperation Council (GCC) regulations, is a plus.

-

Europe (Spain, Germany): European buyers face strict regulatory environments and demand comprehensive certifications (CE, RoHS, WEEE). Additionally, sustainability credentials such as compliance with the EU’s EcoDesign Directive can influence procurement decisions. Quality assurance must include detailed documentation and product lifecycle assessments.

In summary, international B2B buyers must prioritize manufacturers with transparent, well-documented production processes and robust quality assurance systems. Understanding the intricacies of material selection, assembly techniques, and comprehensive testing helps mitigate risks related to product failure and regulatory non-compliance. Verifying certifications, conducting audits, and engaging third-party inspections are indispensable steps to ensure the procurement of high-quality solar LED strip lights designed to perform reliably across diverse outdoor environments.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for solar led strip lights outdoor Sourcing

When sourcing solar LED strip lights for outdoor applications, understanding the detailed cost structure and pricing dynamics is essential for international B2B buyers aiming to optimize procurement value. The pricing of these products is influenced by multiple factors that go beyond the base manufacturing expenses, especially for buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Key Cost Components

- Materials

The core materials include high-efficiency solar panels, LED chips, flexible PCB substrates, weatherproof casings (often silicone or specialized plastics), batteries (typically lithium-ion or lithium iron phosphate), and wiring. Material quality directly impacts durability and performance, particularly outdoor resistance to UV exposure, moisture, and temperature fluctuations.

Illustrative Image (Source: Google Search)

-

Labor and Manufacturing Overhead

Labor costs vary significantly by manufacturing location. Assembly of solar LED strip lights involves precise soldering, integration of solar cells, battery installation, and waterproof sealing. Overhead includes factory utilities, equipment maintenance, and quality control processes. -

Tooling and Equipment

Initial tooling costs for molds, extrusion dies, and assembly jigs can be substantial, especially for custom designs or advanced waterproofing features. These costs are amortized over production volume and affect unit pricing. -

Quality Control (QC) and Testing

Rigorous QC processes—such as waterproof testing (IP rating verification), electrical safety, and illumination performance—add to costs but ensure compliance with international standards and certifications like CE, RoHS, and IEC. -

Logistics and Import Costs

Shipping expenses depend on the order volume, packaging requirements, and destination port. Customs duties, taxes, and compliance with local import regulations (e.g., CE marking for Europe) also influence landed costs. -

Supplier Margin

Margins vary by supplier strategy, market positioning, and negotiation leverage. High-volume buyers can often secure better pricing, but margins reflect supplier risk, brand reputation, and after-sales service commitments.

Price Influencers for B2B Buyers

-

Order Volume and Minimum Order Quantity (MOQ)

Larger orders typically unlock volume discounts, reducing per-unit cost. However, buyers from emerging markets should balance MOQ with inventory carrying costs and market demand. -

Technical Specifications and Customization

Customized lengths, brightness levels, battery capacities, and control options (e.g., remote dimming, motion sensors) increase complexity and cost. Standardized products generally offer better pricing. -

Material Grade and Certifications

Premium materials and certifications add upfront cost but enhance product lifespan and reduce warranty claims, crucial for outdoor installations in harsh environments. -

Supplier Location and Reputation

Established suppliers in China and Southeast Asia dominate pricing but vary in quality assurance. European and Middle Eastern suppliers might charge premiums but offer faster lead times and localized support. -

Incoterms and Payment Terms

The choice of Incoterms (e.g., FOB, CIF, DDP) impacts who bears the cost and risk of freight, insurance, and customs clearance. Favorable payment terms (such as letters of credit or net-30) can improve cash flow management.

Practical Buyer Tips for Cost-Efficiency

-

Negotiate Based on Total Cost of Ownership (TCO)

Look beyond unit price. Consider product durability, warranty terms, energy savings, and maintenance costs to assess true value. -

Leverage Volume Consolidation and Long-Term Contracts

Pool orders or commit to longer contracts to secure better pricing and priority production slots. -

Request Samples and Third-Party Testing Reports

Verify quality claims before large purchases to avoid costly returns or rejections. -

Understand Local Regulatory Requirements

Ensure products meet import standards to prevent customs delays and fines, especially important in Europe’s strict compliance environment. -

Factor in Currency Fluctuations and Logistics Delays

Budget for potential price adjustments due to exchange rates or shipping disruptions, common in volatile regions.

Indicative Pricing Disclaimer

Prices for solar LED strip lights outdoor can vary widely based on specifications and market conditions. As a general reference, standard models range from approximately $5 to $15 per meter at FOB China prices for mid-range quality. Custom or premium products can exceed this range. Buyers should request detailed quotations and factor in all ancillary costs for accurate budgeting.

By thoroughly analyzing these cost elements and pricing influencers, international B2B buyers can develop effective sourcing strategies that balance quality, cost, and operational needs—ensuring sustainable and profitable investments in solar LED strip lighting solutions for outdoor projects.

Spotlight on Potential solar led strip lights outdoor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solar led strip lights outdoor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for solar led strip lights outdoor

Critical Technical Properties of Solar LED Strip Lights for Outdoor Use

1. IP Rating (Ingress Protection)

The IP rating indicates the level of protection the LED strip light has against dust and water. For outdoor solar LED strips, a minimum of IP65 is recommended, ensuring resistance to water jets and dust ingress. Higher ratings like IP67 or IP68 offer even better waterproofing, critical for harsh weather conditions in regions such as Africa’s tropical climates or Europe’s rainy seasons. B2B buyers must prioritize IP ratings to ensure product longevity and reduce maintenance costs.

2. Solar Panel Efficiency

This measures how effectively the solar panel converts sunlight into electrical energy, usually expressed as a percentage. Higher efficiency panels (15% and above) generate more power in less sunlight, which is crucial in areas with variable sunlight exposure like parts of the Middle East or northern Europe. Selecting efficient solar panels ensures reliable lighting performance and shorter charging times, directly impacting operational uptime.

3. Battery Type and Capacity

The battery stores the energy harvested by the solar panel. Lithium-ion batteries are preferred for their higher energy density, longer lifespan (typically 3-5 years), and better performance under extreme temperatures compared to lead-acid alternatives. Capacity, measured in milliampere-hours (mAh) or watt-hours (Wh), determines how long the lights can operate without sunlight. For B2B buyers, understanding battery specs helps in evaluating autonomy and maintenance cycles.

4. LED Chip Quality and Brightness (Lumens)

The LED chip’s quality affects brightness, color consistency, and energy consumption. Brightness is measured in lumens; outdoor solar LED strips generally range from 300 to 1000 lumens per meter. High-quality LEDs provide uniform illumination and better color rendering, enhancing aesthetic and safety applications. Buyers should assess lumen output relative to project requirements to balance illumination needs with energy efficiency.

5. Material Grade and Durability

Materials like UV-resistant silicone or polycarbonate coatings protect the strip lights from sun damage, corrosion, and mechanical wear. Durable materials extend product life, especially important for installations exposed to intense sunlight or salty coastal air (e.g., Mediterranean regions). For B2B procurement, specifying material grades ensures compliance with local environmental conditions and reduces replacement frequency.

6. Operating Temperature Range

Solar LED strip lights must function reliably across wide temperature ranges, often from -20°C to +60°C or higher. This specification is vital for buyers sourcing for markets with extreme climates, such as cold winters in Germany or hot deserts in the Middle East. Understanding temperature tolerance helps avoid early product failures and supports warranty negotiations.

Key Trade Terminology for International B2B Buyers

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components which are then branded and sold by another company. For buyers, partnering with OEMs can mean access to customizable solar LED strips and potentially better pricing. It is essential to clarify OEM capabilities and quality assurances during supplier negotiations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and manage cash flow, especially for smaller businesses or pilot projects in emerging markets like South America. Buyers should negotiate MOQ terms to balance cost efficiency with demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to obtain pricing and terms for specific product requirements. For solar LED strip lights, a detailed RFQ including technical specs ensures accurate bids and facilitates supplier comparison. Well-prepared RFQs reduce procurement risks and streamline decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowing Incoterms enables buyers to understand cost structures and logistics liabilities, critical for cross-border transactions involving regions like Africa or Europe.

5. CE Certification

CE marking signifies compliance with European safety, health, and environmental protection standards. For buyers in Europe or trading with European partners, CE certification is often mandatory. It assures product quality and regulatory adherence, mitigating import risks.

6. Lumen Maintenance (L70)

L70 indicates the number of operating hours until the LED brightness falls to 70% of its original output, a key measure of LED longevity. Buyers should request L70 data to evaluate product lifespan and warranty validity, crucial for long-term investment decisions.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that solar LED strip lights meet project requirements, regulatory standards, and budget constraints while optimizing supply chain efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solar led strip lights outdoor Sector

Market Overview & Key Trends

The global market for solar LED strip lights outdoor is rapidly expanding, driven by the increasing demand for energy-efficient, low-maintenance lighting solutions in commercial, industrial, and municipal applications. Key market drivers include rising electricity costs, growing environmental regulations, and the urgent need for sustainable infrastructure, especially in regions with abundant sunlight such as Africa, South America, and the Middle East. European markets, including Spain and Germany, are also experiencing growth fueled by ambitious renewable energy targets and smart city initiatives.

For B2B buyers, technological advancements are reshaping sourcing strategies. Integrated solar panels with high-efficiency monocrystalline cells, coupled with durable weatherproof LED strips, offer longer lifespans and better performance in harsh outdoor environments. Smart features such as IoT-enabled controls and adaptive lighting based on ambient conditions are becoming increasingly common, allowing for remote management and energy optimization.

Sourcing trends emphasize partnerships with manufacturers who provide customizable solutions tailored to specific project needs, such as modular lengths, color temperature options, and brightness levels. Buyers from emerging markets prioritize suppliers with strong local support and flexible logistics to overcome infrastructure challenges. Meanwhile, European buyers focus on compliance with stringent quality and safety standards (e.g., CE certification) alongside innovation.

Market dynamics also reflect a competitive landscape where cost-effectiveness and sustainability credentials are critical differentiators. Bulk purchasing agreements and long-term supplier relationships help buyers secure favorable pricing and ensure consistent product quality. Additionally, the availability of financing models such as leasing or power purchase agreements (PPAs) facilitates larger-scale deployments without heavy upfront capital expenditure.

Sustainability & Ethical Sourcing in B2B

Sustainability is a cornerstone in the procurement of solar LED strip lights outdoor. These lighting systems inherently reduce carbon footprints by harnessing renewable solar energy, which is particularly impactful for regions with unreliable grid access or high fossil fuel dependency. However, the environmental benefits extend beyond operational energy savings. Buyers must evaluate the entire supply chain, including the sourcing of raw materials, manufacturing processes, and end-of-life recyclability.

Ethical sourcing involves selecting suppliers committed to responsible labor practices and transparent environmental policies. This includes adherence to international standards such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability). For international buyers, especially in Africa and South America, partnering with suppliers who demonstrate compliance with these certifications mitigates risks related to reputational damage and regulatory non-compliance.

Materials used in solar LED strip lights, such as lead-free solder, recyclable aluminum casings, and durable UV-resistant polymers, contribute significantly to product sustainability. Green certifications like RoHS (Restriction of Hazardous Substances) and Energy Star provide assurance of environmentally friendly design and energy efficiency.

Moreover, circular economy principles are gaining traction. B2B buyers increasingly seek suppliers offering take-back programs or modular designs that facilitate repair and upgrade rather than replacement. This reduces electronic waste and supports long-term sustainability goals, aligning with corporate social responsibility commitments prevalent in European markets.

Evolution and Historical Context

The evolution of solar LED strip lights outdoor reflects broader trends in solar technology and LED advancements over the past two decades. Early models were limited by bulky, inefficient solar panels and low-lumen LEDs, restricting their use to decorative or temporary applications. Innovations in photovoltaic efficiency and LED chip design have transformed these products into viable solutions for permanent, high-performance outdoor lighting.

Initially popular in off-grid or remote regions, solar LED strip lights have transitioned into mainstream commercial and urban projects due to decreasing costs and improved reliability. The incorporation of flexible strip formats allowed for versatile installation on architectural features, signage, and landscape elements, expanding their market appeal.

Today, the convergence of solar power with smart lighting controls represents the latest chapter in this evolution, enabling international B2B buyers to implement scalable, energy-conscious lighting systems that meet the complex demands of modern infrastructure and sustainability mandates.

Frequently Asked Questions (FAQs) for B2B Buyers of solar led strip lights outdoor

-

How can international B2B buyers effectively vet suppliers of solar LED strip lights for outdoor use?

Begin by requesting detailed product specifications, certifications (e.g., CE, RoHS, IP ratings), and test reports to verify quality. Check supplier credentials through trade platforms, references, and reviews from other international buyers. For regions like Africa and South America, ensure the supplier understands local climate challenges, such as high humidity or dust. Conduct sample testing before large orders and consider suppliers with transparent production processes and strong after-sales support to minimize risks. -

What customization options are typically available for outdoor solar LED strip lights, and how should buyers approach them?

Common customizations include strip length, LED color temperature, brightness levels, waterproof ratings, and solar panel capacity. Buyers should clearly communicate their project requirements and environmental conditions to suppliers to tailor products accordingly. Negotiate minimum order quantities (MOQs) for customized items upfront, and confirm lead times, as customization often extends production schedules. Detailed technical drawings and prototypes can help align expectations and reduce costly revisions. -

What are standard MOQs and lead times for solar LED strip lights in international B2B transactions, especially for buyers in Europe and the Middle East?

MOQs vary widely but typically range from 500 to 2,000 units depending on product complexity and customization. Lead times usually span 4 to 8 weeks, influenced by order size, customization, and supplier location. Buyers in Europe and the Middle East should account for additional shipping time and customs clearance. Early communication about MOQs and scheduling with suppliers is critical to align with project timelines and avoid delays. -

Which payment terms are most common and secure when sourcing solar LED strip lights internationally?

Letters of Credit (L/C) and Telegraphic Transfers (T/T) are widely used payment methods. L/Cs offer higher security for large orders by ensuring payment only upon verified shipment, making them suitable for first-time or high-value transactions. T/T payments are faster but riskier; partial upfront payments (30% deposit) with balance on delivery are common. Buyers should negotiate clear payment milestones linked to product inspection and shipment to mitigate financial risks.

-

What quality assurance certifications should B2B buyers prioritize when sourcing solar LED strip lights for outdoor applications?

Prioritize internationally recognized certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), and IP65/IP67 ratings for waterproofing. ISO 9001 certification for quality management systems indicates reliable manufacturing processes. For buyers in Africa and South America, confirm that products meet local standards and environmental regulations. Insist on factory audits and third-party testing reports to ensure consistent product quality and durability in harsh outdoor conditions. -

How can buyers optimize logistics and shipping when importing solar LED strip lights from Asia to regions like Africa or Europe?

Choose suppliers with experience in international logistics and access to major ports or airports. Consolidate shipments to reduce freight costs and consider using sea freight for large orders to balance cost and speed. Factor in customs duties, import taxes, and local regulations early to avoid delays. Engage reliable freight forwarders familiar with solar lighting products and ensure proper packaging to prevent damage during transit, especially for sensitive solar panels and electronics. -

What steps should international buyers take to handle disputes or quality issues with solar LED strip light suppliers?

Establish clear contractual terms covering product specifications, delivery schedules, and dispute resolution mechanisms before purchase. Maintain detailed documentation including purchase orders, inspection reports, and communication records. For quality issues, request evidence such as photos or test results and negotiate remedies like replacements, refunds, or discounts. Utilizing third-party inspection services before shipment can preempt disputes. If necessary, leverage trade platform mediation or legal arbitration aligned with the supplier’s jurisdiction. -

Are there regional considerations for solar LED strip lights that B2B buyers from the Middle East or South America should be aware of?

Yes, regional climate conditions such as intense sunlight, high temperatures, or humidity impact product selection. Buyers should specify high UV resistance, robust waterproofing (IP67 or above), and durable battery systems suitable for local weather. For the Middle East, dust resistance and heat tolerance are critical, while South American buyers should consider corrosion resistance in coastal areas. Also, verify that suppliers provide appropriate warranties and after-sales support tailored to regional usage conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solar led strip lights outdoor

The strategic sourcing of solar LED strip lights for outdoor applications offers international B2B buyers a compelling opportunity to advance sustainability goals while optimizing operational costs. Key takeaways emphasize the importance of prioritizing product quality—especially durable materials and efficient solar cells—and verifying supplier reliability through certifications and transparent manufacturing processes. Buyers from Africa, South America, the Middle East, and Europe should carefully evaluate regional climatic conditions and installation environments to select solutions that maximize energy capture and longevity.

Leveraging a thorough understanding of market dynamics, including cost drivers and financing options, empowers buyers to negotiate favorable terms and identify innovative products that meet evolving regulatory standards. Strategic partnerships with manufacturers who demonstrate technological innovation and commitment to after-sales support will further enhance value and reduce risks associated with procurement.

Looking ahead, the demand for eco-friendly outdoor lighting solutions is poised to grow as governments and industries intensify their focus on clean energy adoption. International buyers are encouraged to adopt a proactive sourcing approach—incorporating rigorous supplier vetting, continuous market monitoring, and flexible procurement strategies—to capitalize on emerging trends and foster resilient supply chains. By doing so, businesses can not only secure competitive advantages but also contribute meaningfully to global sustainability efforts.