Introduction: Navigating the Global Market for red led strip lights 12v

Red LED strip lights operating at 12 volts have become indispensable components in diverse commercial and industrial applications worldwide. Their energy efficiency, vibrant color output, and flexible installation options make them a top choice for signage, architectural accents, automotive lighting, and safety indicators. For international B2B buyers—especially those sourcing from dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of these lighting solutions is critical to securing reliable products that meet local standards and project demands.

This comprehensive guide delves into every aspect of red 12V LED strip lights to empower procurement professionals and technical buyers with actionable insights. It covers the various product types, including waterproof and non-waterproof options, differing LED densities, and strip configurations tailored to specific use cases. The guide also explores material quality, manufacturing best practices, and rigorous quality control measures essential for ensuring durability and consistent performance under diverse environmental conditions.

In addition, it provides a detailed overview of reputable global suppliers and cost factors influencing purchase decisions, helping buyers optimize budgets without compromising on quality. Market trends and regional considerations are analyzed to highlight opportunities and challenges unique to target geographies such as Saudi Arabia and Mexico. Finally, practical FAQs address common technical and logistical questions, enabling buyers to confidently navigate import regulations, installation requirements, and after-sales support.

By synthesizing technical expertise with market intelligence, this guide serves as a strategic resource for international B2B buyers seeking to make informed, cost-effective sourcing decisions for red 12V LED strip lights that align with their operational goals and regional market conditions.

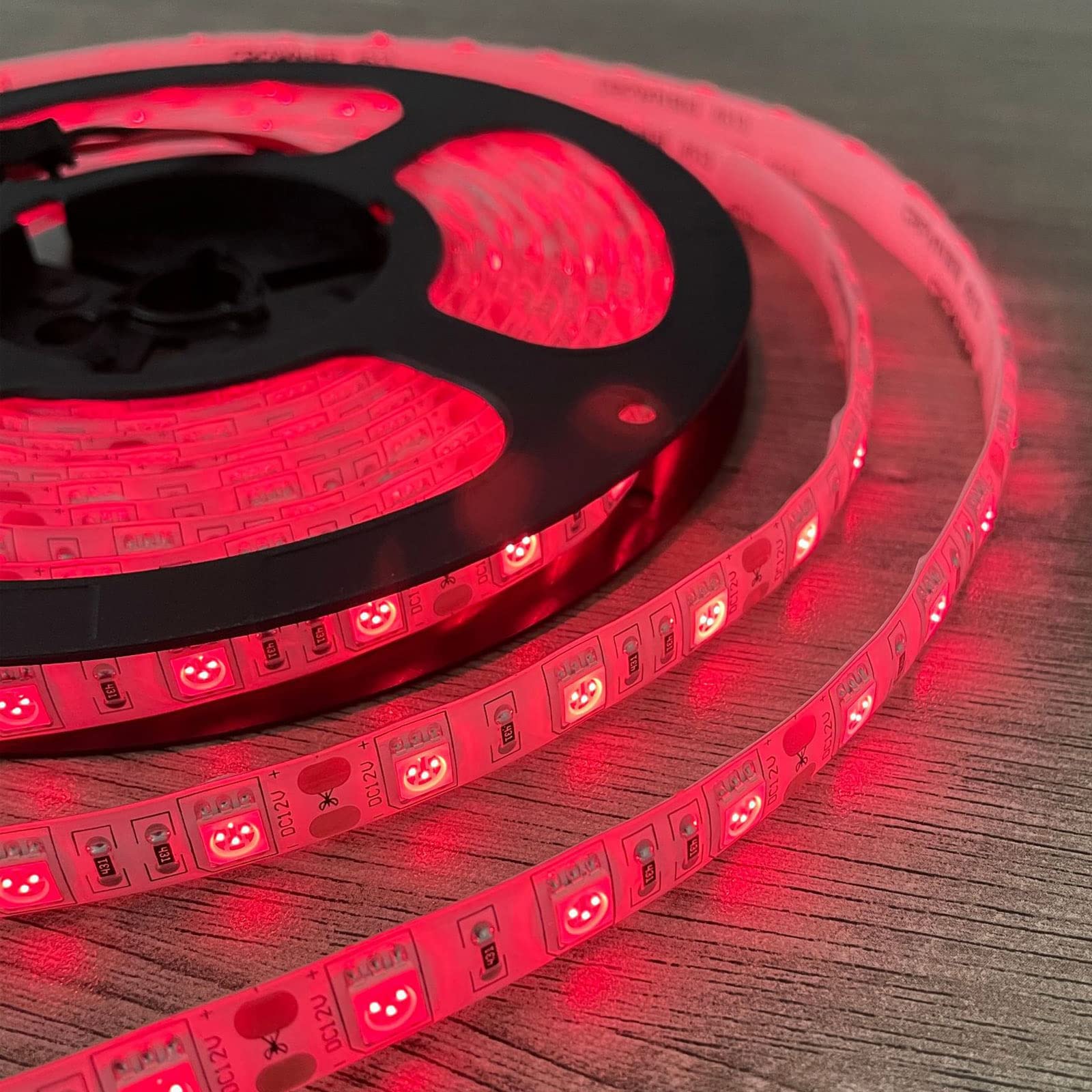

Illustrative Image (Source: Google Search)

Understanding red led strip lights 12v Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 12V Red LED Strip | Flexible PCB, fixed red LEDs, typically 60 LEDs/m, non-waterproof or IP20 | Indoor accent lighting, retail displays, signage | Pros: Cost-effective, easy installation. Cons: Limited to dry environments, lower durability. |

| Waterproof (IP65/IP67) | Silicone or epoxy coating for moisture resistance, outdoor rated | Outdoor signage, architectural lighting, marine applications | Pros: Weatherproof, durable for outdoor use. Cons: Slightly higher cost, less flexible. |

| High Brightness 12V Red LED Strip | Higher lumen output per LED, often with enhanced heat dissipation | Industrial lighting, large-scale advertising, warehouses | Pros: Superior illumination, suitable for large areas. Cons: Higher power consumption, requires robust wiring. |

| Dotless (COB) Red LED Strip | Continuous light emission without visible LED dots, flexible tape | High-end retail, hospitality, display cases | Pros: Uniform light, premium aesthetic. Cons: Higher price point, limited availability. |

| Addressable Red LED Strip | Individually controllable LEDs for dynamic lighting effects | Entertainment venues, custom installations, event staging | Pros: Versatile effects, programmable. Cons: Complex control systems, higher cost. |

Standard 12V Red LED Strip

This is the most common type, featuring a flexible printed circuit board (PCB) populated with fixed red LEDs, typically at 60 LEDs per meter. It is ideal for indoor applications such as retail displays, signage, and decorative lighting. For B2B buyers, this type offers a balance between cost and performance but is limited to dry, indoor environments. Considerations include ensuring compatibility with existing 12V power supplies and assessing the need for dimming or control options.

Waterproof (IP65/IP67) Red LED Strip

Designed with a protective silicone or epoxy coating, these strips resist moisture, dust, and weather elements, making them suitable for outdoor or harsh environments. Buyers from regions with high humidity or outdoor commercial projects (e.g., outdoor advertising in Saudi Arabia or coastal areas in South America) will find these strips essential. The slightly higher upfront cost is offset by reduced maintenance and longer lifespan in challenging conditions.

High Brightness 12V Red LED Strip

These strips deliver enhanced luminous intensity per LED, often incorporating better heat dissipation materials to maintain performance. They are well-suited for industrial or large-scale commercial applications where strong illumination is critical, such as warehouses or large signage. B2B buyers should evaluate power supply capacity and wiring infrastructure to support increased current draw and ensure consistent brightness over longer runs.

Dotless (COB) Red LED Strip

Chip-on-Board (COB) technology provides a seamless, uniform red light without the typical dot pattern of discrete LEDs. This type is favored in high-end retail and hospitality sectors where visual appeal and smooth lighting are paramount. Buyers must consider the higher price point and ensure the strip’s flexibility and cut-ability meet installation requirements.

Addressable Red LED Strip

Featuring individually controllable LEDs, addressable strips enable dynamic lighting effects and custom animations, ideal for entertainment venues, event staging, and creative installations. While offering significant versatility, these strips require sophisticated controllers and programming expertise. B2B buyers should assess technical support availability and integration capabilities with existing lighting control systems.

Related Video: THE SECRET OF GREAT LED STRIP LIGHT INSTALLS – COB

Key Industrial Applications of red led strip lights 12v

| Industry/Sector | Specific Application of red led strip lights 12v | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Warehousing | Safety and hazard indication lighting on machinery and pathways | Enhances worker safety by clearly marking danger zones and emergency exits, reducing workplace accidents and downtime | Durability under harsh conditions, IP rating for dust/water resistance, compliance with local safety standards |

| Automotive Industry | Interior ambient lighting and dashboard indicators | Improves vehicle aesthetics and driver alertness with energy-efficient, low-heat lighting solutions | Flexible strip options for curved surfaces, high-quality soldering/connectors to withstand vibration |

| Retail & Hospitality | Accent lighting for product displays and mood lighting | Attracts customers and highlights products, increasing sales conversion rates | Color consistency, dimmable options, ease of installation and maintenance |

| Agriculture & Horticulture | Supplemental lighting for plant growth and pest deterrence | Supports plant development and pest control by providing targeted red spectrum light, enhancing crop yield | Waterproof and UV-resistant strips, energy efficiency for long operational hours |

| Transportation & Infrastructure | Signal and indicator lighting in tunnels, walkways, and emergency signs | Provides clear visual cues for safety and navigation, reducing accidents and improving compliance | Robust wiring and connectors for long runs, compliance with international electrical codes |

Manufacturing & Warehousing

In manufacturing plants and warehouses, red 12V LED strip lights are widely used for safety and hazard indication. These strips are installed along machinery edges, walkways, and emergency exit routes to clearly mark danger zones and pathways. This application helps reduce workplace accidents by improving visibility in low-light or emergency situations. For international B2B buyers in regions like the Middle East or Africa, sourcing LED strips with high IP ratings ensures resistance to dust and moisture, critical for harsh industrial environments. Compliance with local safety and electrical standards is also essential to meet regulatory requirements.

Automotive Industry

The automotive sector utilizes red 12V LED strip lights predominantly for interior ambient lighting and dashboard indicators. These strips provide energy-efficient, low-heat illumination that enhances vehicle aesthetics while improving driver alertness through clear signaling. Buyers from Europe and South America should prioritize flexible, high-quality LED strips with robust soldering and vibration-resistant connectors to ensure durability in the demanding automotive environment. Additionally, sourcing from suppliers offering customization options for curved and irregular surfaces can provide a competitive edge.

Retail & Hospitality

In retail stores and hospitality venues, red LED strip lights at 12V are employed for accent lighting to highlight product displays and create mood-enhancing environments. This targeted lighting helps attract customer attention and can increase sales by emphasizing key merchandise. For buyers in diverse markets such as Saudi Arabia or Mexico, selecting LED strips with excellent color consistency and dimmable features allows for tailored lighting schemes that suit different store layouts and atmospheres. Ease of installation and maintenance also reduces operational costs.

Agriculture & Horticulture

Red LED strip lights at 12V play an important role in controlled-environment agriculture by providing supplemental red-spectrum light that promotes photosynthesis and plant growth. Additionally, red lighting can deter certain pests, supporting integrated pest management strategies. Buyers from regions with intensive agriculture, such as parts of Africa and South America, should focus on waterproof and UV-resistant LED strips capable of long operational hours with minimal energy consumption. These features ensure reliability and cost-effectiveness in challenging agricultural settings.

Transportation & Infrastructure

Red 12V LED strip lights are critical for signaling and indicator applications in transportation infrastructure including tunnels, pedestrian walkways, and emergency signage. They deliver clear visual cues that improve safety and navigation, helping to reduce accidents and ensure regulatory compliance. For international buyers, especially in Europe and the Middle East, sourcing LED strips with robust wiring solutions designed for long runs and adherence to international electrical codes is crucial. Durable connectors and power supply systems that withstand environmental stressors are also key factors to consider.

Related Video: How To Rig LED Strip Lights To 12V Battery

Strategic Material Selection Guide for red led strip lights 12v

When selecting materials for red LED strip lights operating at 12V, B2B buyers must balance performance, durability, cost, and regional compliance requirements. The choice of materials affects not only the longevity and safety of the product but also its suitability for specific applications and environments common in regions like Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in these LED strips: flexible PCB substrates, silicone encapsulants, aluminum channels, and copper wiring.

Flexible PCB Substrates (Polyimide and PET)

Flexible printed circuit boards (PCBs) are the foundational material for LED strips, typically made from polyimide or polyethylene terephthalate (PET). Polyimide offers excellent thermal stability (up to 260°C), chemical resistance, and flexibility, making it ideal for high-performance LED strips used in harsh environments. PET, while less heat-resistant (up to ~150°C), is cost-effective and suitable for indoor or less demanding applications.

Pros: Polyimide substrates provide superior durability and heat resistance, reducing risk of deformation and failure in hot climates such as the Middle East or parts of Africa. PET substrates are lightweight and lower cost, facilitating budget-conscious projects in South America and Europe.

Cons: Polyimide is more expensive and can increase manufacturing complexity. PET’s lower thermal tolerance limits its use in high-temperature or outdoor installations.

Impact on Application: For outdoor or industrial installations requiring waterproofing and UV resistance, polyimide substrates paired with silicone encapsulation are preferred. PET-based strips suit indoor decorative lighting with moderate temperature exposure.

Regional Considerations: Buyers in regions with high ambient temperatures (e.g., Saudi Arabia, northern Mexico) should prioritize polyimide substrates for compliance with local safety standards such as IEC or DIN. European buyers often require RoHS compliance, which both materials can meet when sourced properly.

Silicone Encapsulation

Silicone is widely used as a protective coating or encapsulant for red LED strips, especially for waterproof (IP65-IP67) variants. It provides excellent flexibility, UV resistance, and thermal stability (-50°C to 200°C), protecting LEDs from moisture, dust, and mechanical damage.

Pros: Silicone’s high durability and environmental resistance make it ideal for outdoor and industrial settings common in Africa and South America, where humidity and dust are concerns. It also maintains optical clarity over time, preserving light quality.

Cons: Silicone encapsulation increases production costs and can complicate repair or modification due to its strong adhesion. It may also add slight thickness, affecting installation in tight spaces.

Impact on Application: Essential for outdoor, automotive, or marine lighting applications where waterproofing is mandatory. Less critical for indoor installations but beneficial in humid or dusty environments.

Regional Considerations: Compliance with IP ratings and standards like ASTM D2000 is crucial for buyers in regions with heavy rainfall or dust storms (e.g., Middle East and parts of Africa). Silicone encapsulated strips often meet these certifications, providing assurance for long-term performance.

Aluminum Channels and Extrusions

Aluminum is commonly used for mounting channels or housings for LED strips, offering excellent heat dissipation, mechanical protection, and aesthetic enhancement. It helps extend LED lifespan by managing thermal loads, which is critical for high-brightness red LED strips.

Pros: Aluminum channels improve thermal management, reduce LED degradation, and provide robust physical protection. They also facilitate neat installation and can be anodized for corrosion resistance.

Cons: Aluminum adds to overall system cost and weight. Improperly treated aluminum may corrode in coastal or humid environments.

Impact on Application: Ideal for commercial and architectural lighting projects in Europe and the Middle East, where long-term reliability and appearance are priorities. Also beneficial in harsh environments to protect against mechanical damage.

Regional Considerations: Buyers in coastal regions of South America and Africa should specify anodized or powder-coated aluminum to prevent corrosion. Compliance with EN standards for aluminum materials is common in Europe, while ASTM standards apply in many other regions.

Copper Wiring and Connectors

Copper is the preferred conductor material for powering 12V LED strips due to its excellent electrical conductivity and flexibility. High-quality copper wiring ensures minimal voltage drop and efficient power delivery, critical for maintaining consistent brightness in long runs.

Pros: Copper wiring supports reliable electrical performance and is widely available globally. It is compatible with various connector types and easy to solder or crimp.

Cons: Copper is more expensive than aluminum wiring alternatives and can oxidize if not properly insulated or coated, potentially impacting conductivity.

Impact on Application: Essential for all professional LED strip installations, especially in parallel wiring configurations common in commercial projects. Proper gauge selection based on length and current is critical to avoid voltage drop.

Regional Considerations: Buyers in regions with high ambient temperatures or industrial pollution (e.g., Middle East, parts of Africa) should specify tinned copper wiring for enhanced corrosion resistance. Compliance with IEC or JIS electrical standards ensures safety and interoperability.

| Material | Typical Use Case for red led strip lights 12v | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide Flexible PCB | High-performance indoor/outdoor strips in hot environments | High thermal stability and chemical resistance | Higher cost and manufacturing complexity | High |

| PET Flexible PCB | Budget indoor decorative lighting | Cost-effective and lightweight | Lower heat resistance limits outdoor use | Low |

| Silicone Encapsulation | Waterproof outdoor and industrial LED strips | Excellent environmental resistance and flexibility | Increased cost and repair difficulty | Medium |

| Aluminum Channels | Architectural and commercial installations requiring heat dissipation | Superior thermal management and mechanical protection | Added cost and weight; potential corrosion | Medium |

| Copper Wiring | Power distribution in all LED strip installations | Excellent conductivity and flexibility | Higher cost and oxidation risk if unprotected | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for red led strip lights 12v

The manufacturing and quality assurance of red LED strip lights operating at 12 volts involve a series of meticulously controlled processes to ensure product reliability, longevity, and performance. For international B2B buyers—especially those from regions such as Africa, South America, the Middle East, and Europe—understanding these processes and quality checkpoints is vital for selecting trustworthy suppliers and minimizing post-purchase risks.

Manufacturing Process Overview

The production of 12V red LED strip lights typically follows four main stages: material preparation, forming, assembly, and finishing. Each stage employs specialized techniques to meet both functional and regulatory requirements.

1. Material Preparation

- Raw Materials Sourcing: High-quality LEDs, flexible printed circuit boards (FPCBs), resistors, adhesives, and protective coatings are procured. For red LEDs, manufacturers often select chips with precise wavelength specifications (~620-630 nm) to ensure consistent color output.

- Component Inspection: Incoming components undergo initial quality checks (Incoming Quality Control, IQC) for electrical characteristics, physical defects, and compliance with supplier certifications.

- PCB Fabrication: Flexible PCBs are fabricated with copper layers and insulating substrates. The copper thickness and substrate material directly influence heat dissipation and flexibility—key factors in LED strip longevity.

2. Forming

- Solder Paste Application: Automated machines apply solder paste precisely to PCB pads to ensure strong electrical and mechanical connections.

- Pick and Place: Surface-mount technology (SMT) machines place LEDs and resistors onto the PCB with micron-level accuracy, critical for uniform light distribution.

- Reflow Soldering: The assembled boards pass through reflow ovens where solder paste melts and solidifies, creating durable joints without damaging sensitive LEDs.

3. Assembly

- Cutting and Segmentation: LED strips are cut into standardized lengths, often with designated cutting marks to maintain electrical integrity.

- Waterproofing (Optional): For outdoor or harsh environment applications, strips receive silicone or epoxy coatings with IP65 to IP67 ratings.

- Connector Attachment: Power connectors and terminals are attached using soldering or crimping, ensuring compatibility with 12V power supplies and facilitating easy installation.

- Adhesive Backing: High-tack, heat-resistant adhesive tapes are applied to the strip’s backside, enabling secure mounting on various surfaces.

4. Finishing

- Final Assembly: LED strips may be integrated into aluminum extrusions or channels, enhancing heat dissipation and providing physical protection.

- Packaging: Products are packaged with anti-static materials and moisture barriers to preserve quality during transit, especially important for international shipping.

Quality Assurance Framework

Robust quality assurance (QA) systems underpin the manufacturing process, ensuring that red LED strip lights meet international standards and customer expectations.

Compliance with International Standards

- ISO 9001: Most reputable manufacturers operate under ISO 9001 certified quality management systems, which mandate systematic process controls, documentation, and continuous improvement.

- CE Marking: Essential for European markets, CE certification verifies conformity with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electronic components, critical for European and some Middle Eastern markets.

- UL/ETL Certification: Important for North American buyers and increasingly recognized globally, these certifications ensure electrical safety.

- Other Regional Standards: Buyers from Saudi Arabia, Mexico, and South America should verify compliance with local electrical and safety regulations, such as NOM certification in Mexico or SASO in Saudi Arabia.

Quality Control Checkpoints

Quality control is embedded at multiple stages to catch defects early and prevent faulty products from reaching buyers:

- Incoming Quality Control (IQC): Inspect raw materials and components for specifications, visual defects, and electrical parameters.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, LED placement accuracy, and electrical continuity tests.

- Functional Testing: Power-on tests to verify LED illumination, uniformity, and correct voltage operation at 12V.

- Final Quality Control (FQC): Comprehensive end-of-line inspections including visual inspection, waterproofing integrity (if applicable), and packaging checks.

Common Testing Methods

- Electrical Testing: Measuring voltage, current, and resistance to ensure the strip operates within design parameters.

- Lumen and Color Consistency Testing: Spectrometers and colorimeters verify that the red light output meets wavelength and brightness specifications.

- Environmental Stress Testing: Accelerated aging under heat, humidity, and vibration to simulate real-world conditions.

- Ingress Protection Testing: For waterproof strips, standardized IP testing confirms resistance to dust and water penetration.

- Mechanical Durability: Flex tests and adhesion strength measurements ensure the strip withstands installation and usage stresses.

Ensuring Supplier Quality: Actionable Insights for B2B Buyers

For international buyers, especially from emerging and regulated markets, verifying supplier quality assurance is critical. Here are actionable strategies to assess and ensure supplier QC integrity:

- Request Certifications and Audit Reports: Ask suppliers to provide up-to-date ISO 9001, CE, RoHS, and any relevant regional certificates. Third-party audit reports add credibility.

- Conduct Factory Audits: Arrange on-site or virtual factory inspections to observe manufacturing processes, QC procedures, and worker training firsthand.

- Sample Testing: Obtain product samples for independent laboratory testing to verify electrical performance, color accuracy, and durability.

- Third-Party Inspections: Engage recognized inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment quality checks tailored to your destination country’s regulations.

- Review Quality Documentation: Ensure suppliers maintain detailed QC records, including IQC, IPQC, and FQC logs, along with corrective action reports for any defects.

- Understand Regional QC Nuances:

- Africa & South America: Prioritize suppliers with certifications accepted locally and ensure compliance with import regulations, as these regions may have variable enforcement.

- Middle East (e.g., Saudi Arabia): Confirm adherence to SASO standards and obtain necessary conformity certificates to avoid customs delays.

- Europe: CE marking and RoHS compliance are non-negotiable; insist on full documentation and traceability.

Summary

The manufacturing of red LED strip lights at 12V involves sophisticated, multi-step processes that demand precise control over materials, assembly, and finishing to deliver consistent quality. Quality assurance frameworks aligned with international and regional standards safeguard product performance and regulatory compliance. For B2B buyers from Africa, South America, the Middle East, and Europe, leveraging detailed supplier audits, certifications, and independent testing is crucial to secure reliable sourcing partnerships and optimize investment in LED lighting solutions.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for red led strip lights 12v Sourcing

Key Cost Components in Sourcing Red LED Strip Lights 12V

When sourcing red LED strip lights operating at 12 volts, understanding the fundamental cost components helps international B2B buyers evaluate supplier quotes critically and optimize procurement strategies:

-

Materials: The primary expense includes high-quality LED chips, flexible PCB substrates, resistors, and encapsulation materials. Waterproofing (e.g., silicone coating or IP65/IP67 rated casing) adds to material costs. Suppliers using premium phosphors or high-CRI LEDs command higher prices but offer better performance and longevity.

-

Labor: Skilled assembly is crucial for soldering, quality inspection, and packaging. Labor costs vary significantly by country and impact final pricing. Regions with advanced manufacturing infrastructure may offer better quality control but at a higher labor premium.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines with automation reduce overhead per unit and can improve pricing competitiveness.

-

Tooling: Initial setup costs such as mold creation for extrusion profiles, custom connectors, or specialized assembly jigs are amortized over production volume. Custom or small-batch orders may incur higher per-unit tooling costs.

-

Quality Control: Rigorous testing, including voltage tolerance, waterproof integrity, and lifespan validation, adds to costs but reduces warranty claims and returns, improving Total Cost of Ownership (TCO).

-

Logistics and Freight: International shipping, customs duties, and inland transport from port to buyer facilities must be factored in. Costs fluctuate based on shipment size, transport mode (air vs sea), and destination country infrastructure.

-

Supplier Margin: Suppliers incorporate profit margins reflecting market demand, competition, and risk factors. Negotiating favorable margins is possible with volume commitments or long-term contracts.

Influencing Factors on Pricing

Several critical variables influence the pricing landscape for red 12V LED strip lights, particularly relevant to buyers in Africa, South America, the Middle East, and Europe:

-

Order Volume and MOQ: Larger orders benefit from economies of scale, reducing unit costs significantly. Many suppliers have minimum order quantities (MOQ) that may be negotiable for recurring clients or consolidated orders.

-

Technical Specifications and Customization: Custom lengths, color temperatures, brightness levels, waterproof ratings, and additional features (e.g., dimmability, adhesive backing quality) directly impact material and labor costs.

-

Material Quality and Certifications: Products certified to international standards such as CE, RoHS, UL, or IP ratings command premium pricing but assure compliance and durability essential for commercial projects, especially in regulated markets like the EU.

-

Supplier Reliability and Location: Manufacturers with strong reputations, advanced production capabilities, and proximity to major shipping routes can offer better lead times and stable pricing. Local regulations and trade agreements (e.g., free trade zones) also affect cost.

-

Incoterms and Payment Terms: FOB, CIF, DDP, and other Incoterms determine which party bears shipping and customs risks and costs. Favorable payment terms (e.g., LC, net 30) can improve cash flow but may influence pricing.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, consider warranty coverage, expected lifespan, energy efficiency, and maintenance costs. A slightly higher upfront cost may yield lower operational expenses.

-

Leverage Volume Consolidation: Pooling orders with partners or across multiple projects can unlock better pricing tiers and reduce shipping costs per unit, especially relevant for buyers in regions with higher freight expenses.

-

Clarify Specifications and Certifications Early: Ensure suppliers understand your exact technical and compliance requirements to avoid costly reworks or shipment rejections at customs.

-

Understand Regional Import Duties and Taxes: Factor in local tariffs and VAT when comparing supplier quotes. Engage local customs brokers for accurate cost forecasting.

-

Evaluate Supplier Logistics Capabilities: Suppliers offering integrated logistics solutions (including customs clearance and last-mile delivery) simplify procurement and reduce hidden costs.

-

Request Sample Orders and Pilot Runs: Validate product quality, installation compatibility, and durability before committing to large volumes. This is particularly important for new suppliers or customized products.

-

Be Aware of Pricing Volatility: Raw material prices (e.g., copper, phosphors) and shipping costs can fluctuate due to global supply chain disruptions. Locking in prices with fixed-term contracts can mitigate risks.

Indicative Pricing Disclaimer

Prices for red LED strip lights 12V vary widely based on specifications, order size, and supplier location. Typical FOB prices range from approximately USD 1 to 5 per meter for standard commercial-grade strips, excluding customization and certification premiums. Buyers should use these figures only as a general benchmark and conduct thorough supplier due diligence and cost analysis tailored to their specific procurement scenarios.

By comprehensively analyzing cost structures and pricing influencers, international B2B buyers can strategically source red LED strip lights 12V that balance quality, compliance, and cost-efficiency—ensuring successful project outcomes across diverse regional markets.

Spotlight on Potential red led strip lights 12v Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘red led strip lights 12v’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for red led strip lights 12v

Critical Technical Properties of Red LED Strip Lights 12V

When sourcing red LED strip lights operating at 12 volts, understanding these key specifications is essential for ensuring product reliability, performance, and compatibility with your projects:

-

Voltage Rating (12V DC): This indicates the operating voltage the LED strip is designed for. A 12V system is widely favored for its balance between safety and ease of installation. For buyers, confirming the voltage ensures compatibility with existing power supplies and reduces the risk of electrical issues.

-

LED Density (LEDs per Meter): This measures how many individual LEDs are mounted per meter of strip. Higher density typically means brighter, more uniform light output but can increase power consumption. Selecting the appropriate density depends on the application’s brightness requirements and energy efficiency goals.

-

IP Rating (Ingress Protection): Defines the strip’s resistance to dust and water. Common ratings include IP20 (indoor use, no water protection) and IP65/IP67 (waterproof for outdoor or humid environments). Buyers targeting diverse markets, including outdoor or industrial settings, must choose strips with suitable IP ratings to ensure durability and compliance.

-

Color Consistency and Wavelength: For red LED strips, wavelength (measured in nanometers, nm) determines the exact shade of red emitted. Typical red LEDs emit between 620-630nm. Consistency in color and wavelength is critical for applications like signage or architectural lighting where uniform appearance is mandatory.

-

Power Consumption (Watts per Meter): Indicates energy use and heat generation. This impacts overall system design, including power supply sizing and cooling considerations. Lower wattage strips can reduce operating costs, but buyers must balance efficiency with brightness needs.

-

Material Quality and PCB Thickness: The substrate material (usually flexible PCB) and its thickness affect heat dissipation and mechanical durability. High-grade copper PCBs with adequate thickness (e.g., 2 oz copper) improve lifespan and reduce voltage drop, which is vital for long runs or commercial installations.

Common Industry and Trade Terms for B2B Buyers

Understanding trade terminology accelerates procurement processes and fosters clearer communication with suppliers:

-

OEM (Original Equipment Manufacturer): Refers to manufacturers producing LED strips that other companies brand and sell. Buyers seeking customized designs or private labeling often engage OEMs to tailor specifications, packaging, or branding.

-

MOQ (Minimum Order Quantity): The smallest quantity a supplier is willing to sell per order. Knowing MOQ helps buyers, especially SMEs or regional distributors, plan budgets and inventory efficiently. Negotiating MOQ can be crucial for entering new markets without overstocking.

-

RFQ (Request for Quotation): A formal inquiry sent to suppliers requesting price, availability, and terms for specified quantities and configurations. A well-prepared RFQ ensures accurate, comparable quotes and speeds up the purchasing cycle.

-

Incoterms (International Commercial Terms): Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms is essential for managing logistics costs and risks.

-

Voltage Drop: A technical term describing the reduction in voltage along the length of the LED strip due to resistance. Excessive voltage drop leads to dimmer light at the far end. Buyers should ensure suppliers provide wiring and installation guidance to minimize this issue, especially in long runs.

-

CRI (Color Rendering Index): Measures how accurately a light source displays colors compared to natural light. While red LEDs typically have a lower CRI, high CRI red strips are available for applications requiring vibrant color fidelity. This specification is critical in retail or design-focused installations.

By mastering these technical properties and trade terms, international buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions that align with project requirements, regulatory standards, and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the red led strip lights 12v Sector

Market Overview & Key Trends

The global market for red 12V LED strip lights is experiencing robust growth driven by increasing demand across diverse sectors such as commercial lighting, automotive, retail displays, and architectural applications. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Mexico—securing reliable, energy-efficient lighting solutions is a priority to meet expanding infrastructure and modernization projects.

Key market drivers include:

- Energy Efficiency & Cost Savings: Red LED strip lights operating at 12V DC offer low power consumption with high luminous efficacy, making them attractive for projects seeking to reduce operational costs and carbon footprint.

- Customization & Integration: Advances in flexible strip designs and modular connectors facilitate tailored installations for complex layouts, essential for commercial and industrial applications prevalent in emerging markets.

- Technological Innovations: Integration with smart control systems—such as dimming, timers, and IoT-enabled automation—enhances functionality, appealing to buyers aiming for future-proof lighting solutions.

- Supply Chain Localization: To mitigate risks from global disruptions, buyers increasingly prefer suppliers with regional warehouses or manufacturing capabilities, especially in the Middle East and Europe, ensuring faster delivery and localized support.

Sourcing trends highlight:

- Preference for Parallel Wiring Configurations: For longer runs and consistent brightness, parallel wiring is favored in commercial installations. Buyers should ensure suppliers provide appropriate wiring accessories and technical support for such setups.

- Demand for Waterproof and Durable Strips: In regions with harsh environmental conditions like parts of Africa and the Middle East, waterproof (IP65 to IP67 rated) red LED strips are essential for outdoor or industrial use.

- Focus on Compliance & Certifications: International buyers prioritize products compliant with regional electrical standards (CE, RoHS, IEC) to ensure safety and interoperability.

By aligning procurement strategies with these trends, B2B buyers can optimize project outcomes, reduce maintenance costs, and leverage innovations in red LED strip lighting.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly pivotal in the red 12V LED strip lights sector, reflecting broader corporate responsibility goals and regulatory pressures worldwide. For B2B buyers, particularly in Africa, South America, the Middle East, and Europe, integrating environmentally responsible sourcing practices is both a competitive advantage and a compliance necessity.

Environmental Impact Considerations:

- LED strip lights inherently consume less energy than traditional lighting, reducing greenhouse gas emissions during operation.

- Sustainable sourcing focuses on minimizing the use of hazardous substances such as lead, mercury, and certain flame retardants commonly found in electronic components.

- Manufacturers adopting recyclable materials for strip substrates and packaging contribute to circular economy principles, reducing landfill waste.

Ethical Supply Chain Importance:

- Transparency in the supply chain helps prevent labor abuses and ensures fair working conditions, a growing concern for international buyers mindful of their corporate social responsibility (CSR).

- Certifications like ISO 14001 (Environmental Management), SA8000 (Social Accountability), and adherence to the Responsible Minerals Initiative (RMI) offer assurance of ethical practices.

- Buyers are encouraged to engage suppliers who provide detailed documentation on sourcing origins, manufacturing processes, and environmental impact assessments.

Green Certifications & Materials:

- Look for products with RoHS compliance to guarantee restriction of hazardous substances.

- Energy Star rated LED strips indicate superior energy efficiency.

- Adoption of low-VOC (Volatile Organic Compound) adhesives and coatings in strip manufacturing reduces indoor air pollution risks.

- Suppliers offering waterproof and durable red LED strips using non-toxic silicone encapsulation align with sustainable product lifecycles.

By prioritizing sustainability and ethical sourcing, B2B buyers can meet growing regulatory requirements, enhance brand reputation, and contribute positively to global environmental goals.

Brief Evolution and Industry Context

The red 12V LED strip light sector has evolved significantly since its inception in the early 2000s. Initially limited to basic indicator and decorative uses, advancements in LED chip technology and flexible circuit boards have transformed these strips into versatile lighting solutions. The shift from incandescent and fluorescent alternatives to LEDs was driven by superior energy efficiency, longer lifespan, and enhanced color stability.

Over the past decade, the introduction of waterproof designs, improved heat dissipation methods, and smart control compatibility have expanded the applications of red 12V LED strips into industrial, architectural, and automotive sectors worldwide. For B2B buyers, understanding this evolution underscores the importance of selecting suppliers who invest in R&D and offer cutting-edge, reliable products tailored to diverse regional needs.

This progression also reflects a broader trend toward integrated lighting systems that balance performance with sustainability, enabling international buyers to deploy red LED strip lighting solutions that align with modern operational and environmental standards.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of red led strip lights 12v

-

How can I effectively vet suppliers of red LED strip lights 12V for international B2B sourcing?

To vet suppliers, prioritize those with verifiable certifications such as CE, RoHS, and UL, which indicate compliance with international safety and quality standards. Request product samples to assess build quality and color consistency. Check their track record with references or reviews from other international buyers, especially those in your region. Confirm their production capacity and ability to meet your volume requirements. Finally, ensure the supplier has experience with export logistics and can provide transparent documentation like export licenses and customs paperwork. -

Is customization of red LED strip lights (length, brightness, waterproof rating) feasible for bulk international orders?

Yes, many manufacturers offer customization options tailored to B2B clients, including adjustable strip lengths, varying brightness levels (lumens), waterproof ratings (IP20 to IP67), and adhesive backing types. Early communication about your specific application and environmental conditions (e.g., outdoor use in humid climates) is crucial. Custom orders may require MOQ adjustments and longer lead times, so plan accordingly. Confirm that the supplier can provide detailed technical drawings and prototypes before mass production to avoid costly mistakes. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for red 12V LED strip light orders from international suppliers?

MOQs vary widely but typically start at 500 to 1000 meters per order for standard models. Custom or specialty strips may have higher MOQs. Lead times range from 3 to 8 weeks, depending on order complexity and current factory workload. Payment terms often include 30% upfront deposit with balance paid before shipment; however, more established suppliers may offer net payment terms or letter of credit (L/C) arrangements. Negotiate terms early to align with your cash flow and project timelines.

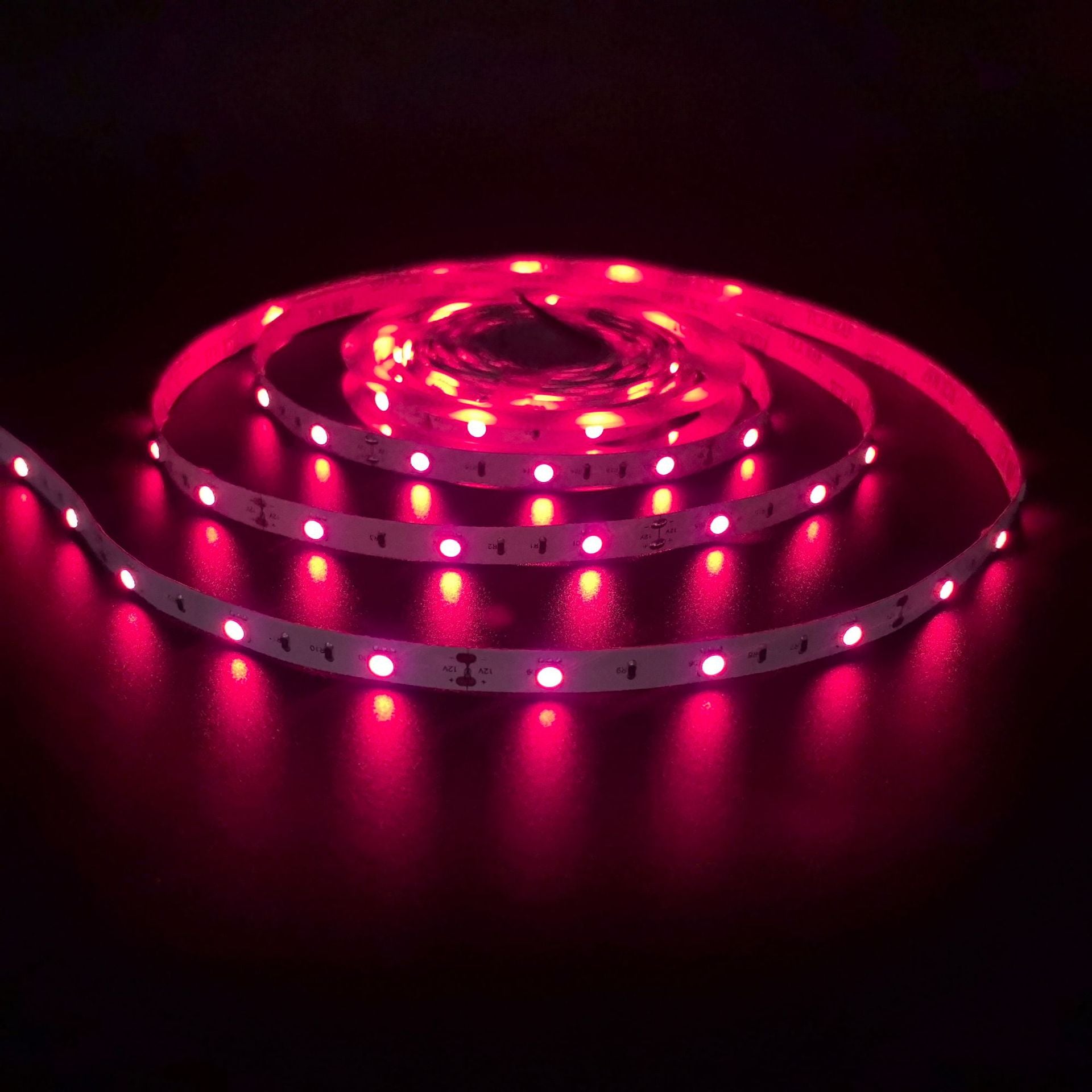

Illustrative Image (Source: Google Search)

-

What quality assurance (QA) and certifications should B2B buyers request to ensure product reliability and safety?

Request suppliers to provide certificates such as CE (European conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and ISO 9001 (quality management). These certify compliance with environmental, safety, and quality standards important in Africa, South America, the Middle East, and Europe. Additionally, insist on batch testing reports for color consistency, lumen output, and waterproofing integrity. Consider third-party inspection services to verify QA before shipment to mitigate risks of defective or substandard goods. -

How should international buyers manage shipping and logistics for red LED strip lights to regions like Africa, the Middle East, or South America?

Partner with freight forwarders experienced in handling electronics and lighting products to navigate customs, duties, and import regulations specific to your country. Choose between air freight (faster but costlier) and sea freight (more economical for bulk orders). Ensure packaging protects strips from moisture and mechanical damage during transit. Request suppliers provide detailed packing lists, commercial invoices, and certificates of origin to facilitate smooth customs clearance. Consider Incoterms carefully to define responsibilities for shipping costs and risks. -

What are common payment methods and how can buyers protect themselves against fraud in international transactions?

Common methods include wire transfers (T/T), letters of credit (L/C), PayPal for smaller transactions, and escrow services. Letters of credit offer high security by involving banks to ensure payment only upon delivery of conforming goods. For wire transfers, verify supplier credentials and use trade platforms or verified contacts. Avoid full upfront payments without contracts or verified supplier history. Employ contracts detailing product specifications, delivery schedules, and penalties for non-compliance to mitigate risks. -

How can disputes over product quality or delivery delays be effectively resolved in international B2B transactions?

Incorporate clear terms and conditions in your purchase contract, including dispute resolution clauses specifying jurisdiction and arbitration processes. Maintain detailed records of communications, samples, and inspection reports. Engage third-party inspection agencies to certify product quality before shipment. If disputes arise, attempt mediation through trade chambers or industry associations. Legal recourse is often costly and time-consuming, so proactive communication and documented agreements are essential to minimize conflicts. -

Are there regional considerations (climate, regulations, electrical standards) that affect red LED strip light selection for markets like Saudi Arabia or Mexico?

Absolutely. For hot, arid regions like Saudi Arabia, select LED strips with high-temperature resistance and appropriate IP ratings (IP65 or above) for dust protection. In humid or tropical climates like parts of Mexico, waterproofing and corrosion-resistant materials are critical. Confirm that voltage and electrical standards (12V DC is standard) are compatible with local power supply systems and that products meet regional certification requirements. Tailoring specifications to local conditions ensures durability, compliance, and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for red led strip lights 12v

In sourcing red 12V LED strip lights for international markets, prioritizing quality, reliability, and compliance is essential. Buyers from Africa, South America, the Middle East, and Europe should focus on suppliers who provide robust technical support, adhere to international safety standards, and offer scalable solutions tailored to diverse climatic and installation conditions. Understanding critical factors such as power configuration, wire gauge selection, and waterproofing capabilities will enhance system longevity and reduce maintenance costs.

Strategic sourcing involves partnering with manufacturers and distributors who demonstrate transparency in product specifications, certifications, and supply chain traceability. Leveraging centralized parallel wiring designs and quality connection methods ensures consistent brightness and operational efficiency, particularly for large commercial or industrial projects. Moreover, considering local regulatory requirements and environmental factors will mitigate risks and optimize project outcomes.

Looking ahead, the demand for energy-efficient, customizable red LED strip lighting is set to grow across emerging and developed markets alike. International buyers are encouraged to engage proactively with trusted suppliers who innovate in durability and integration flexibility. By adopting a forward-thinking procurement strategy today, businesses can secure competitive advantage, drive sustainability goals, and meet evolving customer expectations in the dynamic global lighting landscape.