Introduction: Navigating the Global Market for philips hue led strip lighting

Philips Hue LED strip lighting represents a transformative innovation in smart lighting solutions, offering unparalleled flexibility, energy efficiency, and seamless integration with modern digital ecosystems. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of Philips Hue LED strips is critical to capitalizing on growing market demands in commercial, hospitality, retail, and residential sectors.

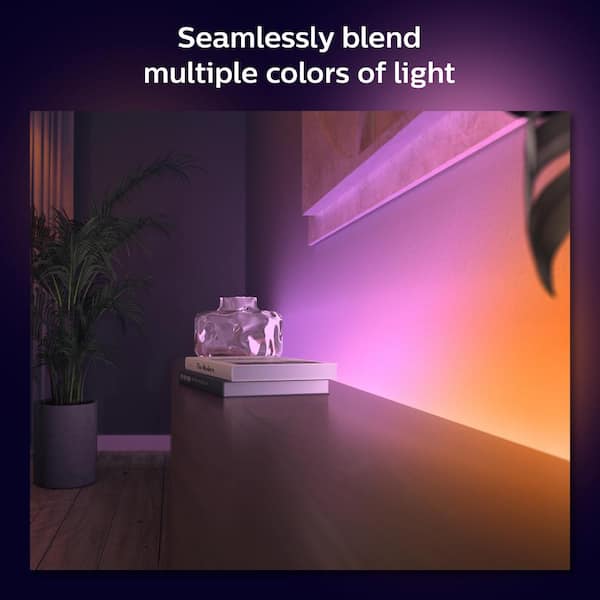

These advanced LED strips combine customizable color palettes, intuitive control systems, and high-quality materials that meet stringent manufacturing and quality control standards. Their adaptability to diverse applications—ranging from ambient lighting in upscale hotels to dynamic accent lighting in retail environments—makes them an essential product for businesses aiming to enhance customer experiences and operational efficiency.

This comprehensive guide equips buyers with actionable insights across key areas including:

- Types and variations of Philips Hue LED strip lighting tailored for indoor, outdoor, and specialty uses

- Material composition and manufacturing quality controls ensuring durability and performance

- Supplier selection criteria to identify reputable manufacturers and distributors with global reach

- Cost structures and pricing models relevant to different regions and order volumes

- Market trends and demand forecasts to optimize sourcing strategies and inventory planning

- Frequently asked questions addressing technical, logistical, and compliance concerns

By providing a holistic view of the Philips Hue LED strip lighting market, this guide empowers B2B buyers in emerging and established markets alike to make informed, strategic sourcing decisions that align with their business objectives and regional market dynamics.

Understanding philips hue led strip lighting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solo Lightstrip | Flexible, standard RGBW LED strip; up to 10 meters length; tunable white and color | Retail displays, office ambiance, hospitality lighting | + Versatile and easy to install – Limited dynamic effects compared to Gradient |

| Gradient Lightstrip | Multi-zone color control with smooth gradient transitions; designed for immersive effects | High-end retail, entertainment venues, experiential marketing | + Rich color gradients enhance ambiance – Higher cost and requires advanced control |

| Outdoor Lightstrip | Weather-resistant with IP67 rating; designed for exterior use; RGBW color and white tunability | Outdoor signage, architectural lighting, hospitality exteriors | + Durable for harsh environments – Installation complexity and cost higher due to weatherproofing |

| TV Lightstrip | Designed to sync with TV content; dynamic color matching; shorter lengths | Retail electronics displays, entertainment venues, digital signage | + Enhances viewer experience with content sync – Limited length and application scope |

| String Lights | Decorative LED string with multiple bulbs; RGBW color control; flexible layout | Event decoration, retail promotions, hospitality settings | + Easy to customize layout – Less brightness compared to strip lights |

Solo Lightstrip

The Solo Lightstrip is a flexible LED strip offering tunable white and full RGB colors, ideal for general lighting and ambient effects. Its ease of installation and scalability up to 10 meters make it a practical choice for offices, retail spaces, and hospitality environments seeking customizable yet straightforward lighting solutions. B2B buyers should consider compatibility with existing Hue ecosystems and the need for uniform lighting without complex gradient effects.

Gradient Lightstrip

Gradient Lightstrips provide advanced multi-zone color control enabling smooth color transitions and immersive lighting experiences. This makes them perfect for premium retail environments, experiential marketing setups, and entertainment venues where visual impact is critical. Buyers should assess the higher investment cost and ensure they have compatible control systems to leverage the full potential of gradient effects.

Outdoor Lightstrip

Specifically engineered for exterior environments, the Outdoor Lightstrip features IP67 weatherproofing and robust construction to withstand rain, dust, and temperature variations. It is suited for architectural lighting, outdoor signage, and hospitality facades. International buyers from regions with diverse climates, such as Africa and the Middle East, will benefit from its durability but must plan for more complex installation and higher upfront costs.

TV Lightstrip

Designed to synchronize dynamically with on-screen content, the TV Lightstrip enhances viewer engagement by projecting ambient colors that match the display. This type is ideal for electronics retailers, entertainment venues, and digital signage applications. While it offers a unique selling point, its limited length and niche use case mean buyers should evaluate the return on investment carefully in relation to their target market.

String Lights

Philips Hue String Lights offer a decorative, flexible lighting solution with RGBW color control, suitable for event decoration, temporary retail promotions, or hospitality settings requiring customizable ambiance. Their modular design allows for creative layouts but they generally provide less brightness than continuous strip lights. Buyers should consider their specific aesthetic goals and whether string lights complement or replace other lighting elements.

Related Video: Philips Hue LED Strip Light Plus Unboxing and Setup

Key Industrial Applications of philips hue led strip lighting

| Industry/Sector | Specific Application of Philips Hue LED Strip Lighting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Ambient and accent lighting in stores, hotels, and restaurants | Enhances customer experience and brand ambiance, increases dwell time | Durability for high-traffic areas, ease of installation, compatibility with smart controls, energy efficiency |

| Corporate Offices | Dynamic workspace lighting for meeting rooms and collaborative areas | Boosts employee productivity and well-being through customizable lighting | Integration with existing smart building systems, scalability, local support and warranty services |

| Entertainment Venues | Mood and stage lighting in theaters, clubs, and event spaces | Creates immersive environments, flexible scene setting for events | High color accuracy, reliable wireless control, robust construction for frequent use |

| Architectural & Interior Design | Highlighting architectural features and creating layered lighting effects | Adds aesthetic value, supports design innovation, and client satisfaction | Customizable color gradients, long strip lengths, IP rating for indoor/outdoor versatility |

| Healthcare Facilities | Circadian lighting and wayfinding in hospitals and clinics | Improves patient comfort, supports staff alertness, and aids navigation | Compliance with health and safety standards, flicker-free operation, easy maintenance |

Philips Hue LED strip lighting finds versatile industrial applications that cater to the unique needs of various sectors worldwide, including regions such as Africa, South America, the Middle East, and Europe.

Retail & Hospitality: In retail stores, hotels, and restaurants, Philips Hue LED strips are used to create ambient and accent lighting that enhances the customer experience and reinforces brand identity. These strips solve the problem of static, uninspiring lighting by offering dynamic color and brightness control, which can be adjusted to different times of day or promotional events. For B2B buyers in markets like Kenya or Brazil, sourcing considerations include ensuring the strips are robust enough to withstand busy environments and compatible with local smart systems for seamless integration.

Corporate Offices: Philips Hue strips are increasingly adopted in corporate environments to foster dynamic workspaces. Adjustable lighting in meeting rooms and collaborative spaces can improve employee productivity and well-being by mimicking natural light patterns. International buyers should prioritize compatibility with existing building automation systems and opt for scalable solutions that can grow with the office infrastructure. Reliable local service and warranties are also crucial for maintaining operational continuity.

Entertainment Venues: Theaters, clubs, and event spaces utilize Philips Hue LED strips to create immersive atmospheres through vibrant, customizable lighting scenes. These strips address the need for flexible and high-quality lighting that can be quickly adapted for various performances or events. Buyers in regions with high humidity or dust, such as parts of the Middle East or South America, should consider strips with appropriate ingress protection and durable wireless control options.

Architectural & Interior Design: Philips Hue LED strips are pivotal in highlighting architectural elements and enabling layered lighting designs that elevate interior aesthetics. This application supports design innovation by allowing precise control over color gradients and lighting intensity. International B2B buyers must evaluate strip length options and IP ratings, especially if installations span indoor and outdoor environments, common in European and coastal African markets.

Healthcare Facilities: In hospitals and clinics, Philips Hue LED strips contribute to circadian lighting systems that promote patient comfort and staff alertness. They also assist in wayfinding by illuminating corridors and critical areas subtly. For healthcare buyers, compliance with health and safety standards and flicker-free operation are mandatory. Maintenance ease is another key factor, given the critical nature of healthcare environments and the need to minimize downtime.

These applications demonstrate Philips Hue LED strip lighting’s adaptability across industries, offering international buyers tailored solutions that address both functional and aesthetic business needs.

Strategic Material Selection Guide for philips hue led strip lighting

When selecting materials for Philips Hue LED strip lighting, international B2B buyers must consider factors such as durability, environmental resistance, manufacturing complexity, and compliance with regional standards. The choice of materials directly impacts the product’s performance, longevity, and suitability for diverse applications across Africa, South America, the Middle East, and Europe.

Flexible PCB Substrate (Polyimide or PET)

Key Properties: Flexible printed circuit boards (PCBs) made from polyimide or polyethylene terephthalate (PET) substrates are the backbone of LED strips. These materials offer excellent thermal stability (up to 200°C for polyimide), electrical insulation, and flexibility. Polyimide is more heat resistant and chemically stable compared to PET, which is more cost-effective but less durable under high temperatures.

Pros & Cons: Polyimide substrates provide superior durability and thermal resistance, making them ideal for high-performance lighting applications. However, they come at a higher cost and require more complex manufacturing processes. PET substrates reduce costs and simplify manufacturing but may degrade faster in harsh environments.

Impact on Application: For installations in hot climates like the Middle East or parts of Africa, polyimide substrates ensure longer lifespan and consistent performance. In more temperate regions such as Europe, PET substrates may suffice for indoor applications, balancing cost and performance.

International Considerations: Buyers in regions with stringent electrical and fire safety standards (e.g., Europe’s CE marking, RoHS compliance) should prioritize polyimide-based PCBs to meet regulatory requirements. In emerging markets, cost sensitivity may favor PET substrates, but buyers must assess environmental exposure risks carefully.

Silicone or Polyurethane Coating (Encapsulation)

Key Properties: Silicone and polyurethane coatings protect LED strips from moisture, dust, and mechanical damage. Silicone offers excellent UV resistance, flexibility, and temperature tolerance (-40°C to 200°C), while polyurethane provides strong abrasion resistance but lower UV stability.

Pros & Cons: Silicone encapsulation is ideal for outdoor and humid environments due to its waterproof and UV-resistant nature. Polyurethane coatings are more economical and provide good mechanical protection but may yellow or degrade under prolonged sun exposure.

Impact on Application: For outdoor or semi-outdoor installations common in South America and coastal regions of Africa, silicone coatings extend product life significantly. Indoor or controlled environments in Europe or the Middle East can benefit from polyurethane coatings for cost savings without compromising durability.

International Considerations: Compliance with international standards like ASTM D2247 (humidity resistance) and DIN EN 60598 (safety of luminaires) is critical. Buyers should verify that coatings meet these standards, especially for export or large-scale commercial projects.

Copper Conductors (Flexible Copper Foil)

Key Properties: Copper is the standard conductor material in LED strips due to its excellent electrical conductivity and thermal management. Flexible copper foils used in PCBs typically have a thickness ranging from 35 to 70 microns, balancing conductivity and flexibility.

Pros & Cons: Copper ensures minimal voltage drop and efficient heat dissipation, enhancing LED performance and lifespan. However, copper is susceptible to oxidation and corrosion if not properly protected, which can degrade electrical connections over time.

Impact on Application: In humid or corrosive environments such as tropical regions in South America or coastal Middle East areas, copper conductors require protective coatings or plating (e.g., tin or gold) to prevent corrosion. In dry, indoor environments, standard copper foils perform reliably without additional treatment.

International Considerations: Buyers must consider local environmental conditions and ensure that copper conductors comply with IEC or JIS standards for electrical safety and corrosion resistance. Regions with high humidity or salt exposure should prioritize corrosion-resistant finishes.

Adhesive Backing (Acrylic or Silicone-based)

Key Properties: The adhesive backing secures the LED strip to various surfaces. Acrylic adhesives offer strong bonding, good temperature resistance (-40°C to 120°C), and water resistance. Silicone adhesives provide superior heat and UV resistance but at a higher cost.

Pros & Cons: Acrylic adhesives are cost-effective and suitable for most indoor applications. Silicone adhesives excel in outdoor or high-temperature environments but increase overall product cost and may complicate manufacturing.

Impact on Application: For installations in hot or outdoor environments like the Middle East or parts of Africa, silicone adhesives prevent detachment due to heat or UV exposure. In indoor or less demanding environments common in Europe and South America, acrylic adhesives provide sufficient performance at a lower price point.

International Considerations: Adhesive materials should comply with standards such as ASTM D3330 (peel adhesion) and ISO 9001 for quality assurance. Buyers should request certifications to ensure adhesive reliability, particularly for large-scale or critical installations.

| Material | Typical Use Case for Philips Hue LED Strip Lighting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible PCB Substrate (Polyimide/PET) | Base substrate for LED mounting and circuitry | High thermal stability and flexibility (polyimide) | Higher cost and manufacturing complexity (polyimide) | Medium to High |

| Silicone or Polyurethane Coating | Protective encapsulation against moisture and UV | Excellent waterproofing and UV resistance (silicone) | Polyurethane less UV stable, silicone more expensive | Medium to High |

| Copper Conductors (Flexible Copper Foil) | Electrical conduction and heat dissipation | Superior electrical conductivity and thermal management | Susceptible to corrosion without protective coating | Medium |

| Adhesive Backing (Acrylic/Silicone) | Surface mounting of LED strips | Strong adhesion with temperature and water resistance | Silicone adhesive costlier and more complex to apply | Low to Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for philips hue led strip lighting

Manufacturing Process of Philips Hue LED Strip Lighting

Philips Hue LED strip lighting represents a sophisticated blend of advanced materials and precision engineering. Understanding its manufacturing process equips international B2B buyers with the insights necessary for assessing product quality and supplier reliability.

1. Material Preparation

– Substrate Fabrication: The process starts with the preparation of flexible printed circuit boards (FPCBs) made from high-quality polyimide or polyester films. These substrates must ensure excellent flexibility and thermal stability.

– LED Chip Procurement: Philips Hue utilizes premium semiconductor LED chips sourced from reputable manufacturers, chosen for their color accuracy, brightness, and energy efficiency.

– Component Sourcing: Other components such as resistors, connectors, and IC chips for smart control are procured under stringent specifications to guarantee compatibility and durability.

2. Forming and Patterning

– Circuit Printing: Using precision photolithography and etching, copper circuits are printed onto the FPCB with micron-level accuracy to ensure consistent electrical conductivity.

– Solder Mask Application: A protective solder mask is applied to prevent short circuits and protect the circuitry from environmental damage.

– Surface Mount Technology (SMT): LED chips and other electronic components are mounted on the PCB through automated SMT lines, ensuring rapid placement with minimal error. This stage demands exact alignment to maintain light uniformity.

3. Assembly

– Component Integration: The LED strips incorporate smart modules that enable wireless control and color adjustment. These modules are integrated and soldered with precision.

– Encapsulation: To protect the delicate electronics, the strips are coated with silicone or epoxy resin, providing waterproofing and mechanical protection without compromising flexibility.

– Connector Attachment: Standardized connectors are attached to enable easy installation and expansion. Philips ensures these connectors comply with international compatibility standards.

4. Finishing and Packaging

– Cutting and Testing: LED strips are cut to standard lengths or customized sizes. Each piece undergoes functional testing before packaging.

– Labeling and Documentation: Packaging includes clear labeling with certifications, serial numbers, and installation instructions tailored for different regional markets.

– Sustainable Packaging: Philips emphasizes eco-friendly packaging materials in line with global sustainability goals.

Quality Assurance and Control Protocols

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding Philips Hue’s rigorous Quality Control (QC) framework is critical to ensuring product reliability and regulatory compliance.

International and Industry Standards

– ISO 9001: Philips Hue LED strip manufacturing adheres to ISO 9001 quality management systems, ensuring consistent processes and continuous improvement.

– CE Marking: Compliance with CE standards guarantees conformity with European health, safety, and environmental protection requirements. This is essential for buyers in Europe and countries recognizing CE as a benchmark.

– RoHS Compliance: Restriction of hazardous substances is strictly observed, minimizing environmental and health risks, a key consideration in global markets.

– IEC and UL Standards: For electrical safety and performance, Philips Hue lighting conforms to IEC and UL standards, relevant for many countries’ import regulations.

– Wireless Communication Certifications: Smart features comply with Bluetooth SIG and Zigbee Alliance standards, ensuring interoperability and security.

Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials and components undergo thorough inspection for dimensional accuracy, material properties, and functional integrity before entering production. This prevents defective inputs from affecting final quality.

– In-Process Quality Control (IPQC): During assembly, continuous monitoring through automated optical inspection (AOI) and manual checks ensures soldering quality, component placement accuracy, and electrical continuity. Defects are identified and rectified in real time.

– Final Quality Control (FQC): Completed LED strips undergo comprehensive testing including:

– Electrical Testing: Voltage, current, and power consumption verification to meet design specs.

– Photometric Testing: Measurement of brightness, color temperature, and uniformity using spectroradiometers.

– Environmental Testing: Resistance to humidity, temperature fluctuations, and mechanical stress is evaluated to certify durability.

– Waterproof Testing: For outdoor variants, IP65 or higher ratings are validated through immersion or spray tests.

– Smart Functionality Testing: Wireless connectivity, app control, and color change responsiveness are validated.

Verifying Supplier Quality Control for International B2B Buyers

To mitigate risks associated with product quality and compliance, B2B buyers should adopt a proactive approach to supplier evaluation.

1. Supplier Audits

– Conduct on-site audits or remote assessments focusing on manufacturing processes, QC systems, and compliance documentation. Audits should verify adherence to ISO 9001 and relevant industry certifications.

– Request process flow charts and evidence of continuous improvement initiatives such as Six Sigma or Lean Manufacturing.

2. Review of Quality Documentation

– Insist on receiving detailed QC reports including IQC, IPQC, and FQC results for each batch. These reports should detail test methodologies, acceptance criteria, and non-conformance resolutions.

– Obtain copies of third-party certification reports (e.g., SGS, TÜV) to validate claims related to safety and environmental standards.

3. Third-Party Inspection Services

– Employ independent inspection agencies for pre-shipment inspections focusing on visual defects, electrical performance, and packaging integrity. This is particularly valuable for buyers in regions with limited local testing infrastructure.

– Consider laboratory testing in accredited facilities to verify photometric and electrical parameters against contractual specifications.

QC and Certification Nuances for Buyers in Africa, South America, the Middle East, and Europe

International buyers must navigate distinct regulatory environments and market expectations:

-

Africa (e.g., Kenya):

Local regulatory bodies may require certification from regional authorities such as KEBS (Kenya Bureau of Standards). Buyers should confirm Philips Hue products meet these local standards in addition to international ones. Consider logistics and after-sales support availability. -

South America:

Certification requirements often include INMETRO (Brazil) or SEC (Chile). Buyers should ensure the supplier can provide documentation for these local certifications and that products comply with regional electrical standards and voltage variations. -

Middle East:

Compliance with GSO (Gulf Standards Organization) and SASO (Saudi Standards) is often mandatory. Philips Hue’s CE and IEC certifications help streamline approvals, but buyers should verify local mark acceptance and compatibility with regional electrical codes. -

Europe:

The CE mark is mandatory, alongside RoHS and WEEE compliance. Buyers benefit from Philips Hue’s established presence and transparent QC documentation. Emphasis should be placed on supply chain traceability and environmental compliance, increasingly important in European tenders.

Key Takeaways for B2B Buyers

- Understand the full manufacturing lifecycle to assess potential risks and quality assurance points.

- Demand comprehensive QC documentation and certifications aligned with your local market requirements.

- Leverage third-party inspections and audits to independently verify supplier claims.

- Be aware of regional regulatory nuances affecting product acceptance and certification validity.

- Engage suppliers with transparent processes and sustainability commitments to align with global and local procurement policies.

By applying these insights, international B2B buyers can confidently source Philips Hue LED strip lighting solutions that meet the highest standards of quality, safety, and performance tailored to their regional market demands.

Comprehensive Cost and Pricing Analysis for philips hue led strip lighting Sourcing

Breakdown of Cost Components in Philips Hue LED Strip Lighting

When sourcing Philips Hue LED strip lighting for B2B purposes, understanding the underlying cost components is essential for effective procurement and negotiation:

- Materials: High-quality LEDs, flexible PCBs, silicone or plastic diffusers, and electronic components such as controllers and power adapters form the bulk of material costs. Philips Hue’s commitment to premium materials, including certified and sustainable components, influences pricing.

- Labor: Skilled labor involved in assembly, testing, and packaging impacts the overall cost. Labor costs vary by manufacturing location but are generally optimized for large-scale production.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor related to production management.

- Tooling: Initial setup costs for molds, assembly lines, and automated machinery are amortized over production volume but can be significant for customized or low-volume orders.

- Quality Control (QC): Philips Hue products undergo rigorous QC processes to meet international certifications such as CE, RoHS, and energy efficiency standards, which add to cost but ensure reliability and compliance.

- Logistics: Shipping, customs clearance, warehousing, and last-mile delivery contribute to landed costs. Logistics expenses vary widely based on origin, destination, and transportation mode.

- Margin: Philips Hue’s pricing includes brand premium and distributor margins, reflecting product innovation, warranty, and after-sales support.

Key Price Influencers for International B2B Buyers

Pricing for Philips Hue LED strip lighting is influenced by several factors critical to international buyers, especially from Africa, South America, the Middle East, and Europe:

- Order Volume / Minimum Order Quantity (MOQ): Larger orders typically unlock better unit pricing. Buyers should assess their demand forecasts and negotiate MOQs aligned with their supply chain capacity.

- Product Specifications and Customization: Customized lengths, color gradients, or integration with smart home systems can raise costs. Standardized products generally offer better pricing leverage.

- Material Quality and Certifications: Philips Hue’s adherence to stringent quality and environmental certifications may result in higher upfront costs but reduce risks and warranty claims.

- Supplier and Distribution Channels: Direct sourcing from authorized Philips Hue distributors or regional partners may offer better pricing versus third-party resellers, though availability varies by region.

- Incoterms: Shipping terms such as FOB, CIF, or DDP significantly affect the buyer’s cost exposure. Buyers should carefully evaluate the most cost-effective and risk-mitigated terms based on their import capabilities.

Strategic Buyer Tips for Cost-Efficient Sourcing

For B2B buyers in emerging and mature markets alike, optimizing procurement of Philips Hue LED strip lighting involves several best practices:

- Negotiate Based on Total Cost of Ownership (TCO): Consider not only unit price but also warranty, energy savings, installation costs, and lifecycle durability. Philips Hue’s smart lighting solutions often justify higher initial prices through long-term operational savings.

- Leverage Volume Consolidation: Pooling orders with other buyers or across multiple projects can enhance bargaining power and reduce per-unit costs.

- Understand Regional Pricing Nuances: Import duties, VAT, and local distribution markups vary widely. Engage local experts or consultants to map the full landed cost, especially in markets like Kenya or Brazil.

- Prioritize Certified Suppliers: Ensure suppliers are authorized Philips Hue distributors to avoid counterfeit products which can result in costly failures or warranty voidance.

- Optimize Logistics and Payment Terms: Negotiate favorable Incoterms to reduce customs delays and extra charges. For example, DDP terms may simplify import for buyers with less developed customs infrastructure.

- Plan for After-Sales Support: Factor in costs and availability of technical support and spare parts, which Philips Hue typically provides through official channels, enhancing reliability.

Disclaimer on Pricing Information

Prices for Philips Hue LED strip lighting are indicative and subject to change based on market conditions, currency fluctuations, and supplier negotiations. Buyers should request formal quotations from authorized distributors tailored to their order size, specifications, and delivery location to obtain accurate cost information.

By carefully analyzing cost drivers and engaging in strategic sourcing, international B2B buyers can maximize value while ensuring access to Philips Hue’s premium smart lighting technology across diverse global markets.

Spotlight on Potential philips hue led strip lighting Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘philips hue led strip lighting’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for philips hue led strip lighting

Critical Technical Properties of Philips Hue LED Strip Lighting

-

Color Temperature Range and Color Rendering Index (CRI)

Philips Hue LED strips offer a wide color temperature range (typically 2000K to 6500K) and a high CRI (above 80), which measures the ability to render colors accurately. For B2B buyers, especially in retail, hospitality, or office environments, this ensures lighting enhances visual appeal and user experience, critical for customer satisfaction and workplace productivity. -

Connectivity Protocols (Zigbee and Bluetooth)

These strips support Zigbee mesh networking and Bluetooth for smart control integration. Understanding connectivity is vital for buyers planning large-scale installations or integration with building management systems. Zigbee allows scalable, reliable networks ideal for commercial projects, while Bluetooth suits smaller or standalone setups. -

Material Grade and IP Rating

Philips Hue strips use high-quality flexible PCB materials with protective silicone coatings. Indoor strips typically have an IP20 rating, whereas outdoor variants offer IP67 or higher for water and dust resistance. Selecting the correct IP rating ensures durability and compliance with local environmental conditions, reducing maintenance costs and warranty claims. -

Luminous Flux and Power Consumption

The luminous flux (brightness) of Philips Hue strips ranges around 1600 lumens for standard lengths, with power consumption optimized for energy efficiency (about 20W per 2 meters). Buyers should evaluate lumen output relative to power use to balance lighting needs with operational cost-efficiency, a key consideration in markets with variable electricity costs. -

Dimming and Color Gradient Capability

Advanced models feature smooth dimming and multi-zone color gradients, allowing dynamic lighting effects. This technical property is crucial for clients in experiential retail, entertainment, or hospitality sectors seeking to create immersive environments and differentiate their offerings. -

Cut and Extension Flexibility

Philips Hue strips can be cut at designated points and extended with compatible connectors, offering installation versatility. For B2B buyers managing complex architectural lighting projects, this flexibility facilitates customization, reduces waste, and streamlines inventory management.

Key Trade Terminology for B2B Buyers

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce products or components used in another company’s final product. For Philips Hue LED strips, understanding OEM relationships can help buyers negotiate private labeling or bespoke product configurations tailored to local market needs. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. Philips Hue products may have MOQs set by distributors or regional partners. Knowing MOQ helps buyers in emerging markets like Kenya or Brazil plan procurement budgets and inventory levels efficiently. -

RFQ (Request for Quotation)

A formal process where buyers solicit price and delivery terms from suppliers. When sourcing Philips Hue LED strips, issuing a clear RFQ specifying technical specs, certification requirements, and delivery timelines enables competitive pricing and reliable supply. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs. Common Incoterms include FOB (Free on Board) and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers from Africa, the Middle East, or Europe manage logistics risks and calculate landed costs accurately. -

Lead Time

The period between order placement and delivery. For Philips Hue lighting projects, lead time impacts project schedules and cash flow management. Buyers should clarify lead times upfront, especially for large or customized orders. -

Warranty and Certification

Warranty terms define after-sales support, while certifications (e.g., CE, RoHS, UL) ensure compliance with regional safety and environmental standards. Buyers must verify these to mitigate legal risks and ensure product acceptance in their local markets.

By grasping these technical specifications and trade terms, international B2B buyers can make informed purchasing decisions, optimize supply chain management, and align Philips Hue LED strip lighting solutions with their market demands and operational requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the philips hue led strip lighting Sector

Market Overview & Key Trends

The global market for Philips Hue LED strip lighting is driven by rising demand for smart, energy-efficient lighting solutions across commercial and residential sectors. Increasing urbanization, the proliferation of IoT-enabled smart home systems, and growing consumer awareness about ambiance and convenience are key factors fueling adoption. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, these trends translate into expanding opportunities to supply smart lighting solutions that integrate seamlessly with home automation and building management systems.

Emerging technologies like wireless connectivity improvements (e.g., Zigbee, Bluetooth Mesh), enhanced color rendering, and extended product lifespan are reshaping sourcing priorities. Buyers are prioritizing suppliers who offer scalable, customizable Philips Hue LED strips, including gradient and outdoor variants, to meet diverse market needs. Additionally, bundled solutions combining LED strips with smart controls, sensors, and security devices are gaining traction, reflecting demand for comprehensive smart ecosystem offerings.

Market dynamics in developing regions like Kenya and Vietnam highlight increasing interest from commercial real estate developers, hospitality, and retail sectors seeking differentiated lighting experiences to attract customers and reduce operational costs. However, challenges such as import regulations, infrastructure variability, and after-sales service capabilities require strategic sourcing partnerships. Collaborating with established Philips Hue distributors and authorized resellers ensures product authenticity, warranty support, and localized technical assistance—critical factors for sustainable market penetration.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central criterion for B2B buyers of Philips Hue LED strip lighting, driven by environmental regulations and corporate social responsibility commitments worldwide. Philips Hue products are designed to minimize energy consumption and reduce carbon footprints, leveraging LED technology’s inherent efficiency advantages over traditional lighting. Buyers are increasingly evaluating suppliers based on the lifecycle environmental impact of lighting solutions, including raw material sourcing, manufacturing processes, packaging, and end-of-life recyclability.

Illustrative Image (Source: Google Search)

Ethical sourcing practices are paramount, especially for buyers in Europe and the Middle East, where regulatory frameworks mandate transparent supply chains free from conflict minerals and labor abuses. Philips Hue’s adherence to international standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) ensures compliance with stringent environmental and health safety requirements. Furthermore, certifications like ENERGY STAR and the EU Ecolabel serve as important benchmarks for verifying product sustainability credentials.

Incorporating Philips Hue LED strip lighting into B2B procurement portfolios supports buyers’ green building certifications (e.g., LEED, BREEAM) by contributing to energy savings and reduced environmental impact. Prioritizing suppliers with clear commitments to circular economy principles—such as take-back programs and recyclable packaging—aligns with evolving corporate sustainability goals. For markets in Africa and South America, where infrastructure and waste management systems may be developing, sourcing from responsible manufacturers helps mitigate ecological risks and enhance brand reputation.

Evolution of Philips Hue LED Strip Lighting

Philips Hue LED strip lighting has evolved significantly since its introduction, reflecting broader advances in smart lighting technology. Initially launched as simple white light strips, the product line expanded to include full-color, tunable white, and gradient lightstrips, enabling dynamic lighting effects and personalized ambiance. Integration with the Philips Hue Bridge and compatibility with major smart home platforms (Google Assistant, Amazon Alexa, Apple HomeKit) have enhanced user control and interoperability.

For B2B buyers, this evolution means access to versatile lighting solutions adaptable to diverse applications—from hospitality and retail displays to corporate environments and outdoor settings. The modular design and extendable lengths of Philips Hue strips provide flexibility in installation and design customization. Continuous improvements in energy efficiency, color accuracy, and connectivity ensure that Philips Hue LED strips remain at the forefront of the smart lighting market, offering long-term value and innovation potential for international business buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of philips hue led strip lighting

-

How can I effectively vet Philips Hue LED strip lighting suppliers for international B2B purchasing?

When vetting suppliers, prioritize those with verified certifications like ISO 9001 and compliance with international safety standards (e.g., CE, RoHS). Review their export history, especially to regions like Africa, South America, the Middle East, and Europe, to ensure experience with cross-border logistics and customs. Request samples to assess product quality and compatibility with Philips Hue systems. Additionally, evaluate their financial stability, communication responsiveness, and after-sales support capabilities. Engaging with suppliers who have established partnerships with Philips or are authorized distributors can further reduce risk. -

Is customization available for Philips Hue LED strip lighting, and what should B2B buyers consider?

Yes, many suppliers offer customization such as length adjustments, connector types, and packaging tailored for specific markets. B2B buyers should clarify compatibility with Philips Hue Bridge and ecosystem to avoid integration issues. It’s crucial to confirm the supplier’s capability for consistent color accuracy and firmware updates in customized units. Understand lead times for custom orders and ensure that any modifications comply with regional electrical and safety regulations. Custom branding or private labeling options may also be available to enhance market differentiation. -

What are typical minimum order quantities (MOQs) and lead times for Philips Hue LED strip lighting in international B2B deals?

MOQs vary widely depending on the supplier and customization level but commonly range from 100 to 500 units for standard products. Lead times typically span 4 to 8 weeks, influenced by product complexity, customization, and shipping method. Buyers from regions like Kenya, Brazil, or the UAE should factor in additional time for customs clearance and local certification where required. Early communication with suppliers to negotiate MOQs and confirm realistic lead times is essential for aligning inventory planning and market launch strategies. -

Which payment terms and methods are advisable for international B2B purchases of Philips Hue LED strip lighting?

Secure payment methods such as Letters of Credit (LC) or escrow services provide protection against fraud and ensure supplier accountability. For trusted suppliers, negotiated terms like 30% upfront and 70% upon shipment or delivery can balance risk and cash flow. International buyers should consider currency exchange risks and transaction fees, opting for stable currencies or forward contracts when possible. Establish clear payment schedules and document all terms in contracts to avoid disputes. Utilizing platforms with trade assurance can also enhance transaction security. -

What quality assurance processes should I expect from Philips Hue LED strip lighting suppliers?

Reputable suppliers implement rigorous QA processes including in-line inspections, functional testing, and aging tests to guarantee product performance and longevity. Request detailed QA reports and certifications demonstrating compliance with international standards such as IEC, UL, or local equivalents. For Philips Hue products, firmware stability and interoperability tests with the Hue Bridge are critical. Insist on pre-shipment inspections by third-party agencies to verify order accuracy and quality before shipment, which mitigates risks of receiving defective or non-compliant goods. -

What certifications and compliance standards are essential for Philips Hue LED strip lighting in international markets?

Philips Hue LED strips must comply with regional electrical safety and environmental standards such as CE (Europe), FCC (USA), RoHS (restricting hazardous substances), and potentially local certifications like SONCAP for Nigeria or INMETRO for Brazil. Compliance ensures market access and avoids regulatory penalties. Buyers should request certificates of conformity and test reports from suppliers. For outdoor or specialized applications, IP ratings and warranty terms should be verified. Ensuring these certifications upfront facilitates smoother customs clearance and enhances buyer confidence. -

How should international B2B buyers manage logistics and shipping for Philips Hue LED strip lighting?

Select suppliers with experience in exporting to your region and who can provide DDP (Delivered Duty Paid) or FOB (Free On Board) terms depending on your logistics capabilities. Consider the product’s fragility and packaging to minimize damage during transit. Air freight offers faster delivery but higher costs, suitable for urgent restocking, while sea freight is economical for bulk orders with longer lead times. Plan for customs duties, taxes, and local import regulations, engaging with trusted freight forwarders and customs brokers familiar with your country’s requirements to avoid delays. -

What steps can B2B buyers take to resolve disputes or quality issues with Philips Hue LED strip lighting suppliers?

Establish clear contractual terms covering quality standards, delivery schedules, and penalties for non-compliance. In case of disputes, initiate resolution through direct supplier communication emphasizing documented evidence such as inspection reports and shipment records. Utilize mediation or arbitration clauses in contracts to avoid lengthy litigation. For recurring issues, consider appointing third-party inspection agencies or quality auditors. Maintaining strong supplier relationships and transparency can facilitate amicable solutions, while having backup suppliers reduces dependency risk.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for philips hue led strip lighting

Philips Hue LED strip lighting represents a compelling opportunity for international B2B buyers seeking to enhance their product offerings with cutting-edge smart lighting solutions. Key strategic sourcing considerations include evaluating product compatibility with diverse smart home ecosystems, assessing supply chain resilience, and prioritizing sustainable, energy-efficient technologies that align with global environmental standards. For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics and leveraging Philips’ global distribution network can optimize procurement efficiency and reduce lead times.

Strategic sourcing of Philips Hue LED strips unlocks several advantages:

- Access to premium, customizable lighting products that support IoT integration and enhance user experience

- Opportunities to bundle with complementary smart home devices for value-added propositions

- Alignment with sustainability goals through Philips’ commitment to eco-friendly manufacturing and energy savings

- Robust after-sales support and scalability for expanding smart lighting projects

Looking ahead, the demand for intelligent, adaptive lighting solutions is expected to grow rapidly across emerging and mature markets alike. International buyers are encouraged to engage proactively with Philips Hue’s authorized distributors and explore tailored partnership models that maximize local market penetration. By adopting a strategic sourcing approach focused on innovation, quality, and sustainability, businesses can confidently position themselves at the forefront of the evolving smart lighting landscape.