Introduction: Navigating the Global Market for outdoor led strip lights solar powered

The global demand for outdoor LED strip lights powered by solar energy is surging as businesses worldwide seek sustainable, cost-efficient lighting solutions that align with environmental commitments and operational efficiency. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, including emerging markets like South Africa and Vietnam, these solar-powered lighting systems represent not only a technological advancement but also a strategic investment in reducing energy costs and enhancing outdoor environments with versatile, durable illumination.

This comprehensive guide is designed to empower international buyers with deep insights into the various types of solar-powered outdoor LED strip lights, including critical distinctions in materials, waterproof ratings, and solar panel efficiencies. You will gain expert knowledge on manufacturing standards and quality control processes that ensure product reliability in diverse climatic conditions. Additionally, the guide provides actionable intelligence on identifying reputable suppliers and understanding cost structures, enabling you to optimize procurement strategies while mitigating risks associated with cross-border sourcing.

Beyond technical specifications and supplier evaluation, the guide explores current market trends and demand drivers specific to your region, helping you anticipate future needs and competitive advantages. To address common concerns, a detailed FAQ section clarifies practical issues from installation to maintenance.

By leveraging this resource, B2B buyers will be equipped to make informed sourcing decisions, tailor product selections to their unique market requirements, and confidently navigate the complexities of the global supply chain for outdoor solar LED strip lighting solutions. This is your essential toolkit for achieving sustainable growth and operational excellence in the evolving landscape of solar-powered outdoor illumination.

Understanding outdoor led strip lights solar powered Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Solar LED Strip Lights | Basic solar panel with integrated battery; flexible and waterproof strips; usually warm white or single color | Residential landscaping, small commercial outdoor areas | Pros: Cost-effective, easy installation, low maintenance. Cons: Limited brightness, shorter runtime in low sunlight regions. |

| Multicolor RGB Solar LED Strips | Multi-color LEDs with remote or app control; smart integration possible; moderate solar panel size | Hospitality venues, event spaces, retail storefronts | Pros: Customizable ambiance, enhanced aesthetics. Cons: Higher initial cost, complexity in control systems. |

| High-Efficiency Solar LED Strips | High-efficiency photovoltaic panels (>20% conversion); robust batteries; IP67+ waterproof rating | Industrial sites, large-scale outdoor lighting projects | Pros: Longer runtime, better performance in low light, durable. Cons: Higher price, more complex installation. |

| Battery-Operated Solar LED Strips | Solar charging with detachable or replaceable batteries; portable and modular design | Temporary installations, outdoor events, remote locations | Pros: Portability, ease of battery replacement. Cons: Limited continuous operation, battery lifecycle management needed. |

| Addressable Solar LED Strip Lights | Individually controllable LEDs for dynamic lighting effects; advanced controllers; solar-powered | Entertainment venues, architectural highlights, advertising | Pros: High customization, dynamic lighting effects. Cons: Higher technical complexity, requires skilled installation and maintenance. |

Standard Solar LED Strip Lights

These are the most common and cost-effective solar LED strips designed for basic outdoor illumination. Featuring flexible, waterproof strips paired with small to medium solar panels and integrated batteries, they are ideal for residential gardens and small commercial areas. For B2B buyers in regions with ample sunlight such as parts of Africa and South America, these strips offer a low-entry solution with minimal maintenance. When purchasing, consider the IP rating (IP65 or above) and battery capacity to ensure consistent performance.

Multicolor RGB Solar LED Strips

These strips incorporate RGB LEDs allowing for color variation and mood lighting, often controlled via remote or smartphone apps. They suit hospitality businesses, retail storefronts, and event venues looking to create a vibrant atmosphere. B2B buyers should evaluate control system compatibility (e.g., app or smart home integration) and solar panel size to support energy needs. These systems may require a slightly higher upfront investment but can boost customer engagement through dynamic lighting.

High-Efficiency Solar LED Strips

Equipped with advanced photovoltaic panels that exceed 20% conversion efficiency, these strips are designed for demanding environments like industrial sites or large-scale outdoor projects. Their robust construction and superior battery systems ensure reliable operation even in low sunlight conditions common in parts of Europe and the Middle East. Buyers should prioritize panel efficiency, battery quality, and IP67+ ratings for durability and longevity in harsh climates.

Battery-Operated Solar LED Strips

These variations feature detachable or replaceable batteries charged by solar panels, offering modularity and portability. They are well-suited for temporary setups such as outdoor events, exhibitions, or remote locations lacking reliable infrastructure. For B2B buyers, the ease of battery replacement and portability are key advantages, but attention must be paid to battery lifecycle costs and ensuring sufficient charging capacity for uninterrupted use.

Addressable Solar LED Strip Lights

Addressable strips allow individual LED control for dynamic and programmable lighting effects, powered by solar energy. These are ideal for entertainment venues, architectural features, and advertising displays where customized lighting sequences enhance visual appeal. B2B buyers should be prepared for more complex installation and maintenance, requiring technical expertise. The investment is justified by the ability to create unique, eye-catching lighting solutions that can differentiate commercial spaces.

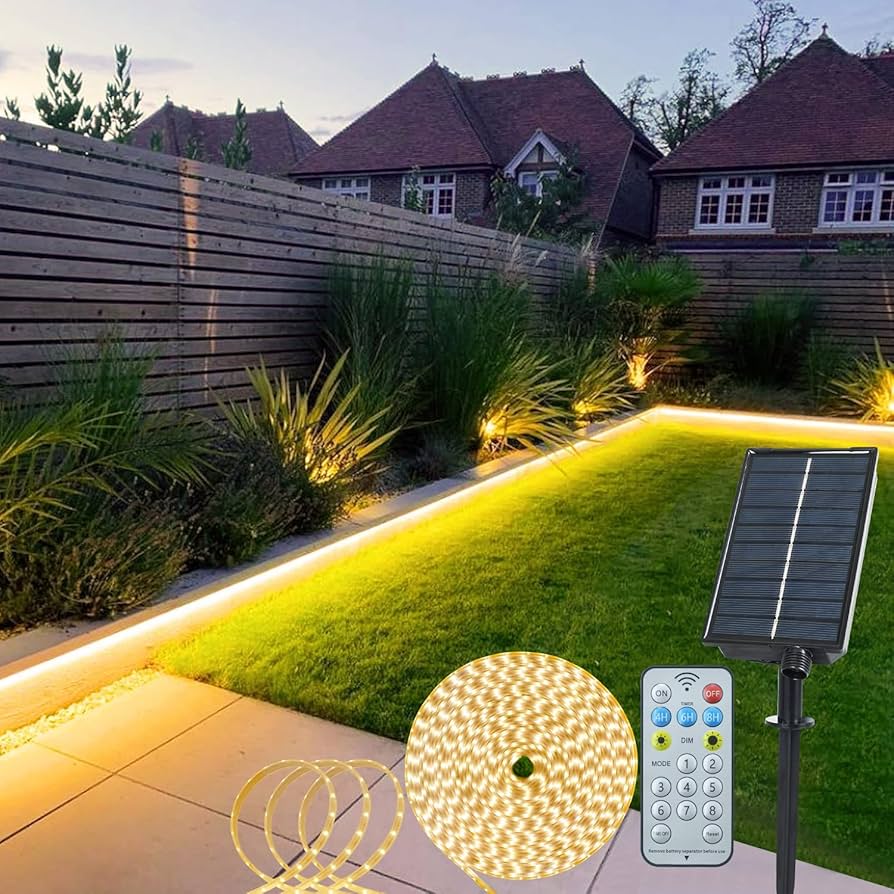

Related Video: Transform Your Outdoor Space: Solar Powered Strip Lights by Luhlee

Key Industrial Applications of outdoor led strip lights solar powered

| Industry/Sector | Specific Application of outdoor led strip lights solar powered | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Tourism | Landscape and pathway illumination for resorts and hotels | Enhances guest experience with eco-friendly, cost-effective lighting; reduces operational energy costs | High IP rating for weather resistance, aesthetic color options, reliable battery life for remote locations |

| Agriculture | Perimeter and greenhouse lighting for farms and agricultural facilities | Improves security and operational hours without increasing energy bills; supports sustainable farming practices | Durable materials to withstand dust and moisture; efficient solar panels for low sunlight regions |

| Retail & Commercial | Outdoor storefront and signage lighting | Attracts customers with vibrant, energy-saving illumination; lowers electricity expenses | Customizable lengths, color temperature options, ease of installation without electrical wiring |

| Urban Infrastructure | Public park, street, and walkway lighting | Provides safer, well-lit public spaces with sustainable power; reduces municipal energy consumption | Compliance with local safety standards, strong UV and weather resistance, scalable systems for large areas |

| Event Management | Temporary outdoor event and festival lighting | Offers flexible, wireless lighting solutions for diverse venues; reduces setup time and power dependency | Portability, remote control capability, quick installation and removal, robust battery capacity |

Hospitality & Tourism

Outdoor LED strip lights powered by solar energy are widely adopted in resorts and hotels to illuminate landscapes, walkways, and outdoor amenities. This application enhances the ambiance and safety for guests while significantly cutting down electricity costs, a crucial factor for large properties in regions like South Africa and the Middle East where energy costs can be high. Buyers should prioritize products with high ingress protection (IP65 or above) to withstand diverse weather conditions and opt for warm white or customizable color options to match the property’s aesthetic.

Agriculture

In agricultural settings, solar-powered LED strips provide essential lighting for perimeter security and greenhouse operations, enabling extended working hours and better surveillance without increasing energy expenses. This is especially valuable in rural areas across South America and Africa where grid access is limited or unreliable. International buyers need to ensure the products are rugged, dustproof, and moisture-resistant, with efficient solar panels capable of operating under variable sunlight conditions to guarantee continuous performance.

Retail & Commercial

Retail outlets and commercial buildings utilize solar LED strips to highlight storefronts and signage attractively while minimizing electricity usage. This application is particularly important in urban centers across Europe and emerging markets like Vietnam, where visual appeal directly impacts foot traffic and sales. Buyers should focus on flexible strip lengths, easy installation features that avoid complex wiring, and options for different color temperatures to suit branding requirements.

Urban Infrastructure

Municipalities and urban planners implement solar LED strip lighting in public parks, streets, and pedestrian walkways to improve safety and sustainability. This reduces the strain on public energy grids and supports green city initiatives prevalent in European and Middle Eastern cities. When sourcing for these projects, buyers must ensure compliance with local safety regulations, select products with high UV resistance, and consider scalability for covering extensive areas efficiently.

Event Management

Temporary outdoor events and festivals benefit from solar-powered LED strips as they provide wireless, flexible lighting solutions that can be rapidly deployed and removed. This is particularly advantageous in regions with limited access to power grids or where temporary setups are common, such as in parts of Africa and South America. Key considerations for buyers include portability, remote control functionality, robust battery life, and ease of installation to accommodate fast-paced event environments.

Related Video: Top 10 Best Outdoor Solar LED Lights

Strategic Material Selection Guide for outdoor led strip lights solar powered

When selecting materials for outdoor solar-powered LED strip lights, B2B buyers must weigh factors such as environmental durability, cost-efficiency, and compliance with regional standards. The material choice directly influences product longevity, installation ease, and maintenance needs, which are critical for markets in Africa, South America, the Middle East, and Europe, where climatic and regulatory conditions vary widely.

Polyvinyl Chloride (PVC)

Key Properties: PVC is widely used for LED strip light casings due to its excellent electrical insulation, moderate temperature resistance (typically -15°C to 60°C), and good resistance to moisture and UV radiation when properly formulated. It offers decent chemical resistance but can degrade under prolonged intense sunlight unless UV stabilizers are added.

Pros & Cons: PVC is cost-effective and easy to manufacture, allowing for flexible and lightweight designs. However, it can become brittle over time in harsh UV environments and may release harmful chemicals if burned, raising environmental concerns. Its moderate temperature tolerance limits use in extremely hot climates without additional stabilization.

Impact on Application: PVC is suitable for general outdoor use in temperate to warm climates but may require UV-resistant additives for regions like the Middle East and parts of Africa with intense sun exposure. It is compatible with standard waterproofing techniques and often meets ASTM and DIN standards for electrical insulation.

International Buyer Considerations: Buyers in Europe and South America should verify compliance with RoHS and REACH regulations, which restrict hazardous substances in PVC products. In African and Middle Eastern markets, preference for UV-stabilized PVC variants is advised to ensure durability. PVC’s affordability makes it attractive for large-scale projects with budget constraints.

Silicone Rubber

Key Properties: Silicone rubber excels in temperature resilience (-60°C to 230°C), outstanding UV and ozone resistance, and superior flexibility. It is highly resistant to water ingress and many chemicals, making it ideal for harsh outdoor environments.

Pros & Cons: Silicone offers exceptional durability and longevity, maintaining elasticity and clarity over time. However, it is more expensive than PVC and requires more complex manufacturing processes, which can increase lead times and costs.

Impact on Application: Silicone is ideal for LED strips in extreme climates, including the hot, arid regions of the Middle East and humid tropical zones in South America and Africa. Its waterproof and weatherproof characteristics support IP67 to IP68 ratings, crucial for reliable outdoor performance.

International Buyer Considerations: European buyers often favor silicone for premium outdoor lighting solutions due to stringent environmental standards and demand for long-lasting products. In emerging markets like Vietnam and South Africa, silicone’s higher cost may be justified by reduced maintenance and replacement frequency. Compliance with ASTM D2000 and ISO standards is common for silicone materials.

Polycarbonate (PC)

Key Properties: Polycarbonate is a strong, impact-resistant thermoplastic with high transparency and temperature tolerance (-40°C to 120°C). It resists UV degradation when treated with protective coatings and offers good dimensional stability.

Pros & Cons: PC is highly durable, providing excellent protection against physical damage and weathering. It is more expensive than PVC but less costly than silicone. The material can yellow over time without UV stabilizers and is less flexible, which may limit design versatility.

Impact on Application: PC is suitable for LED strip housings requiring robust protection against mechanical impact, such as in commercial or industrial outdoor settings. It performs well in European climates and can be adapted for use in sunny regions with appropriate UV coatings.

International Buyer Considerations: Buyers in Europe and the Middle East should ensure PC components meet EN 62262 (IK rating) for impact resistance and relevant UV standards. In South America and Africa, PC’s durability is beneficial for rugged environments but cost considerations may limit its use to premium products.

Thermoplastic Polyurethane (TPU)

Key Properties: TPU combines elasticity with high abrasion resistance, temperature tolerance (-40°C to 80°C), and excellent chemical resistance. It offers good UV resistance and flexibility, making it suitable for dynamic outdoor applications.

Pros & Cons: TPU is more flexible and durable than PVC, with better resistance to oils and solvents. However, it is generally more expensive and may require specialized processing equipment. Its temperature range is adequate for most outdoor conditions but less than silicone.

Impact on Application: TPU is effective for LED strips exposed to mechanical stress, such as in walkways or areas prone to physical contact. It performs well in moderate climates found in parts of Europe and South America and can be formulated for enhanced UV resistance.

International Buyer Considerations: For buyers in Africa and the Middle East, TPU’s abrasion resistance is advantageous for dusty or sandy environments. Compliance with ASTM D412 (tensile properties) and ISO 527 is typical. The material’s cost and processing complexity may restrict its use to mid- to high-end product lines.

| Material | Typical Use Case for outdoor led strip lights solar powered | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General outdoor lighting in temperate to warm climates | Cost-effective, easy to manufacture | UV degradation risk, moderate temperature range | Low |

| Silicone Rubber | Extreme climates with high UV exposure and moisture | Exceptional durability and temperature resistance | Higher cost and complex manufacturing | High |

| Polycarbonate (PC) | Industrial/commercial outdoor lighting needing impact resistance | Strong, impact-resistant, good transparency | Less flexible, potential yellowing without UV stabilizers | Medium |

| Thermoplastic Polyurethane (TPU) | Outdoor areas with mechanical stress and abrasion exposure | Flexible, abrasion and chemical resistant | Higher cost, limited temperature range compared to silicone | Medium |

This material selection guide empowers B2B buyers to make informed decisions tailored to their regional environmental challenges and regulatory frameworks, ensuring optimal performance and cost-efficiency for solar-powered outdoor LED strip lighting solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for outdoor led strip lights solar powered

Manufacturing and quality assurance of outdoor solar-powered LED strip lights involve intricate processes and rigorous standards to ensure product reliability, durability, and performance—critical factors for international B2B buyers sourcing for diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Manufacturing Process Overview

1. Material Preparation

- Substrate Selection: The base for LED strips typically involves flexible printed circuit boards (FPCBs) made of materials like polyimide or PET, chosen for flexibility and heat resistance.

- LED and Component Procurement: High-quality LEDs (SMD types like 3528, 5050) are sourced, alongside solar cells (monocrystalline or polycrystalline photovoltaic panels), rechargeable batteries (Li-ion or LiFePO4), charge controllers, resistors, and connectors.

- Protective Coatings and Encapsulation Materials: Weatherproofing compounds such as silicone or polyurethane gels are prepared to ensure IP65 or higher ingress protection.

2. Forming and Circuit Fabrication

- Circuit Printing: Copper traces are printed or etched onto the flexible substrate to form the electrical pathways.

- Solder Paste Application: Automated solder paste printers deposit solder on designated pads.

- Component Placement: Surface mount technology (SMT) machines place LEDs and other components precisely on the FPCBs.

- Reflow Soldering: The assembly passes through a reflow oven, melting solder paste to create electrical and mechanical bonds.

3. Assembly

- Solar Panel Integration: Photovoltaic panels are integrated with the LED strip assembly, ensuring efficient electrical connections to the battery and control circuitry.

- Battery and Controller Installation: Rechargeable battery packs and charge controllers are assembled into waterproof housings, often connected via custom wiring harnesses.

- Encapsulation and Sealing: To withstand outdoor elements, strips are coated or encapsulated with waterproof materials, followed by sealing processes to protect internal components from moisture, dust, and UV exposure.

- Connector and Mounting Hardware Attachment: Installation-friendly features like adhesive backing, mounting clips, or connectors for extension are added.

4. Finishing

- Visual Inspection: Final visual checks for solder joints, LED alignment, and surface defects.

- Labeling and Packaging: Products are labeled with certifications, batch numbers, and handling instructions, then packaged to prevent damage during shipment.

Quality Assurance Framework

For international B2B buyers, understanding the supplier’s quality control (QC) system is crucial to mitigate risks related to product failure and regulatory non-compliance.

Key International and Industry Standards

- ISO 9001: A globally recognized quality management system standard ensuring consistent production quality and continuous improvement.

- IEC 60598-1 & IEC 62257: Standards governing the safety and performance of LED lighting and solar power systems, respectively.

- CE Marking: Mandatory for the European market, indicating conformity with EU safety, health, and environmental protection requirements.

- RoHS Compliance: Restricts hazardous substances in electronic products, important for European and other regulated markets.

- IP Rating Standards (e.g., IP65, IP67, IP68): Certify the waterproof and dustproof capabilities essential for outdoor use.

- Other Region-Specific Certifications: For example, SABS certification in South Africa or INMETRO in Brazil may be required.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials and components (LEDs, solar panels, batteries) for compliance with specifications before production.

- In-Process Quality Control (IPQC): Monitoring during circuit assembly, soldering quality, and encapsulation processes to detect defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products including electrical performance, waterproof integrity, and physical durability.

Common Testing Methods

- Electrical Testing: Checking LED brightness, voltage, current, and battery charging/discharging cycles.

- Environmental Testing: Exposure to temperature extremes, humidity, UV radiation, and water immersion tests to validate IP ratings.

- Mechanical Testing: Flexibility tests for the strip, adhesion strength of coatings, and impact resistance.

- Functional Testing: Operation under simulated outdoor conditions, including solar charging efficiency and automatic on/off switching.

- Safety Tests: Ensuring no electrical hazards such as short circuits or overheating.

How B2B Buyers Can Verify Supplier Quality Control

- Factory Audits: Conduct or commission third-party audits evaluating manufacturing processes, equipment, employee training, and QC protocols.

- Review of QC Documentation: Request detailed QC reports, batch test results, and certification documents to verify compliance.

- Third-Party Testing: Utilize independent laboratories to validate product claims, particularly for certifications like CE or IP ratings.

- Sample Inspection: Obtain pre-shipment samples for in-house testing or local certification bodies.

- Supplier Quality Agreements: Establish contractual quality standards and penalties for non-compliance to ensure accountability.

QC and Certification Nuances for International Markets

-

Africa and Middle East: Buyers should prioritize products with robust waterproofing (IP67/IP68) due to diverse climates ranging from arid deserts to tropical regions. Local certification acceptance varies; partnering with suppliers familiar with regional standards (e.g., SABS for South Africa) can ease market entry.

-

South America: Given variable regulatory landscapes, B2B buyers should confirm compliance with local norms such as INMETRO in Brazil and seek suppliers with ISO 9001 and RoHS certifications to facilitate customs clearance and consumer trust.

-

Europe: The CE mark and RoHS compliance are non-negotiable. Buyers should also verify adherence to EU-specific energy efficiency directives and environmental regulations. Documentation transparency and traceability are critical here.

-

Cross-Regional Considerations: Shipping solar-powered LED strips internationally demands attention to packaging standards that prevent moisture ingress and electrostatic discharge. Moreover, battery certifications (UN38.3 for lithium-ion) are essential for air transport compliance.

By comprehensively understanding manufacturing stages, quality control practices, and certification requirements, B2B buyers across Africa, South America, the Middle East, and Europe can make informed procurement decisions. Prioritizing suppliers with transparent QC systems and relevant certifications reduces risk, ensures product longevity, and supports successful market deployment of outdoor solar-powered LED strip lights.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for outdoor led strip lights solar powered Sourcing

When sourcing solar-powered outdoor LED strip lights for international B2B procurement, understanding the comprehensive cost structure and pricing drivers is crucial for informed decision-making and negotiation success. This section breaks down key cost components, influential pricing factors, and offers practical buyer tips tailored to markets across Africa, South America, the Middle East, and Europe.

Key Cost Components in Solar-Powered LED Strip Lights

-

Materials

The largest cost driver includes photovoltaic solar panels, LED diodes, flexible circuit boards, rechargeable batteries, charge controllers, and weatherproof housing materials (e.g., silicone, rubber). High-grade components—especially solar cells with >20% efficiency and IP65+ rated waterproofing—raise upfront costs but improve durability and performance. -

Labor

Labor costs depend on the manufacturing location and complexity of assembly. Countries with advanced manufacturing infrastructure and skilled labor may have higher wages but offer better quality control and efficiency, which can reduce defect rates and rework costs. -

Manufacturing Overhead

This includes utilities, factory maintenance, equipment depreciation, and administrative expenses. Automation levels in production lines influence overhead; more automation reduces per-unit overhead but requires higher initial capital investment. -

Tooling and Setup Costs

Tooling involves molds, fixtures, and specialized equipment for producing flexible circuit boards and assembling solar modules. These are mostly fixed costs amortized over production volume. Custom designs or color configurations increase tooling expenses. -

Quality Control (QC)

Rigorous QC is essential due to outdoor exposure risks. Costs cover testing for waterproofing, electrical safety, battery reliability, and certifications (e.g., CE, RoHS, IEC standards). Higher QC standards reduce returns and warranty claims but add to unit costs. -

Logistics and Shipping

Solar LED strips are generally lightweight but may require careful packaging to avoid damage. Shipping costs depend on volume, weight, shipping mode (air/sea), and destination. For buyers in Africa, South America, and the Middle East, sea freight is common but slower, while Europe and Vietnam may benefit from faster land or air routes. -

Supplier Margin

Margins vary based on supplier reputation, brand positioning, and order size. Established brands with certified products typically command higher margins but offer better reliability and after-sales service.

Primary Price Influencers for B2B Buyers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders reduce per-unit costs through economies of scale. Many suppliers set MOQs between 500 to 5,000 units. Buyers can negotiate better pricing by consolidating orders or committing to long-term contracts.

-

Product Specifications and Customization: Custom lengths, color temperatures (warm white vs. RGB), and smart features (app control, voice integration) add complexity and cost. Modular designs with standard components are more cost-effective.

-

Materials Quality and Certifications: Higher efficiency solar panels and premium IP67/IP68 waterproof ratings increase costs but enhance product lifespan and market appeal. Certifications demanded by import regulations or end markets (e.g., CE for Europe) also impact price.

-

Supplier Location and Capacity: Suppliers in China and Southeast Asia typically offer competitive pricing due to mature supply chains. However, proximity to buyer markets (e.g., Europe or Middle East) can reduce logistics costs and lead times.

-

Incoterms and Payment Terms: Pricing varies with Incoterms chosen (EXW, FOB, CIF). Buyers should understand the implications on shipping, insurance, and customs duties. Favorable payment terms (e.g., letters of credit, partial upfront payments) can improve cash flow.

Strategic Buyer Tips for International Procurement

-

Negotiate Beyond Unit Price: Focus on total cost including shipping, customs, taxes, and warranty service. For African and South American buyers where import duties can be high, CIF or DDP terms may provide cost predictability.

-

Assess Total Cost of Ownership (TCO): Consider energy savings, maintenance costs, and product lifespan. Higher initial investment in quality solar LED strips often leads to lower TCO, especially in harsh climates typical of many African and Middle Eastern regions.

-

Leverage Volume and Long-Term Relationships: Consolidate multiple project needs to increase bargaining power. Establishing long-term supplier partnerships can unlock preferential pricing and priority production slots.

-

Validate Certifications and Quality: Request test reports and certifications upfront to avoid non-compliant shipments that can incur penalties or delays, particularly in Europe’s strict regulatory environment.

-

Understand Pricing Fluctuations: Raw material prices (e.g., silicon for solar cells) fluctuate with global supply-demand dynamics. Locking in prices through contracts or purchasing during low demand seasons can yield savings.

-

Local Regulatory and Environmental Incentives: Explore if target markets offer subsidies or tax breaks for solar-powered lighting, which can affect overall project economics and supplier selection.

Indicative Pricing Overview (Subject to Market Variability)

- Basic solar LED strip light kits typically start around $10–$20 per meter for standard IP65 waterproof models with moderate solar panel efficiency.

- Premium models featuring high-efficiency panels, IP68 rating, smart controls, and extended warranties can range from $25–$50 per meter or higher depending on features and volume.

- Custom orders and smaller MOQs usually carry a price premium of 10–30%.

By thoroughly analyzing these cost and pricing

Spotlight on Potential outdoor led strip lights solar powered Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘outdoor led strip lights solar powered’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for outdoor led strip lights solar powered

Key Technical Properties for Solar-Powered Outdoor LED Strip Lights

1. IP Rating (Ingress Protection)

The IP rating indicates the product’s resistance to dust and water ingress, crucial for outdoor durability. For solar LED strip lights, an IP rating of IP65 or higher is typically required to withstand rain, dust, and splashes common in outdoor environments. For buyers targeting regions with heavy rainfall or dust storms (e.g., parts of Africa or the Middle East), opting for IP67 or IP68 rated products ensures superior protection and longer product lifespan.

2. Solar Panel Efficiency (%)

Solar panel efficiency measures the percentage of sunlight converted into usable electrical energy. Panels with efficiencies above 20% are preferred for reliable performance in areas with variable sunlight, such as parts of Europe or South America. Higher efficiency panels reduce the physical footprint of solar arrays and improve energy harvesting, enabling longer lighting durations and better battery charging in low-light conditions.

3. Battery Capacity and Type

Battery capacity, usually measured in milliamp-hours (mAh) or watt-hours (Wh), determines how long the LED strips can operate after sunset. Lithium-ion or lithium-polymer batteries are standard for their high energy density and longer cycle life. For B2B buyers, selecting products with adequate battery capacity to cover typical night durations (8-12 hours) is essential for consistent illumination, especially in off-grid or remote locations.

4. LED Color Temperature and CRI (Color Rendering Index)

Color temperature, measured in Kelvins (K), affects the mood and application of the lighting. Warm white (2700K-3000K) creates cozy ambiance, ideal for hospitality or residential outdoor settings, while cooler white (4000K-6000K) suits commercial or security lighting. CRI indicates color accuracy under the light; a CRI above 80 is preferred for vibrant and natural color appearance, important in retail or public spaces.

5. Material Grade and Flexibility

The strip’s base material (often flexible PCB coated with silicone or rubber) affects durability and ease of installation. High-grade silicone coatings provide UV resistance and flexibility, essential for installation on curved or uneven surfaces. Buyers should ensure materials are UV-resistant, weatherproof, and flame-retardant to meet safety standards and reduce maintenance costs over time.

6. Power Consumption and Voltage

Power consumption (measured in watts per meter) affects energy efficiency and battery sizing. Lower wattage strips extend battery life but may reduce brightness. Most solar LED strips operate on 12V or 24V DC systems, which are safer and compatible with standard solar setups. Matching voltage specifications with solar panel output and battery voltage is critical to avoid system inefficiencies or damage.

Important Trade Terms in Solar-Powered Outdoor LED Strip Lighting

1. OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce products or components that other companies rebrand and sell. For international buyers, working with OEMs can offer customization options and cost advantages, especially when sourcing solar LED strips tailored to specific market needs or regulatory requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell in a single order. Understanding MOQ is critical for budget planning and inventory management. Smaller businesses or those testing new markets may seek suppliers with low MOQs, while larger buyers benefit from volume discounts at higher MOQs.

3. RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers asking for pricing, lead times, and terms for specified quantities and product specs. Precise RFQs help buyers compare offers effectively and negotiate better terms. Including detailed technical requirements and certification needs (like IP ratings or battery specs) in RFQs streamlines supplier responses.

4. Incoterms (International Commercial Terms)

Incoterms define responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free on Board), where the seller covers costs until goods are loaded on the transport vessel, and DDP (Delivered Duty Paid), where the seller handles all shipping and import duties. Understanding Incoterms helps buyers from diverse regions plan logistics, cost allocation, and risk management efficiently.

5. Lead Time

Lead time is the duration from placing an order to product delivery. In solar LED strip procurement, lead times can vary due to manufacturing complexity or shipping delays. Buyers should factor in lead times when planning project timelines, especially for large-scale or seasonal installations.

6. Certification and Compliance

Certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) verify product safety and environmental standards. Compliance with local regulations is mandatory for import and resale in many regions. Buyers should request certification documents upfront to avoid customs issues and ensure market acceptance.

These technical properties and trade terms form the foundation for informed decision-making in sourcing solar-powered outdoor LED strip lights. Understanding these aspects enables B2B buyers across Africa, South America, the Middle East, and Europe to select products that are reliable, compliant, and economically viable for their specific markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the outdoor led strip lights solar powered Sector

Market Overview & Key Trends

The global market for solar-powered outdoor LED strip lights is experiencing robust growth, driven by escalating demand for energy-efficient, sustainable lighting solutions across commercial, residential, and public infrastructure sectors. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, this market offers substantial opportunity as governments and enterprises increasingly prioritize renewable energy integration and cost-effective lighting alternatives.

Illustrative Image (Source: Google Search)

Key market drivers include rising electricity costs, expanding off-grid and rural electrification projects, and growing environmental regulations encouraging solar adoption. For example, countries such as South Africa and Vietnam emphasize solar-powered technologies to overcome grid unreliability and reduce carbon footprints. This trend is coupled with advances in LED and photovoltaic (PV) efficiency, enhancing the performance and appeal of solar LED strips.

In sourcing, B2B buyers are focusing on modular, IP65+ rated products that withstand diverse climatic conditions, from tropical humidity to desert heat. Integration with smart controls and IoT connectivity is an emerging trend, enabling remote management and energy optimization—features increasingly demanded by commercial clients and urban planners. Additionally, suppliers offering customizable lengths, color temperature options (warm white to RGB), and plug-and-play solar kits gain competitive advantage.

Market dynamics emphasize partnerships with manufacturers capable of delivering high-quality, durable, and certified products. Buyers from emerging markets seek flexible MOQ (Minimum Order Quantity) terms and localized support to navigate installation and maintenance challenges. Furthermore, supply chain resilience has become critical amid global disruptions, prompting buyers to diversify sourcing across Asia, Europe, and regional manufacturers to ensure steady inventory and cost control.

Sustainability & Ethical Sourcing in B2B

Sustainability is a core consideration for B2B buyers in the solar-powered outdoor LED strip lights sector. The environmental benefits stem from reduced reliance on fossil fuels and lower carbon emissions, as solar LED strips harness renewable energy and minimize electricity consumption. For buyers in environmentally sensitive regions or those aligned with ESG (Environmental, Social, Governance) mandates, solar LED strips represent a strategic investment in green infrastructure.

Ethical sourcing is equally important. Buyers should prioritize manufacturers adhering to responsible mining practices for rare earth elements used in LEDs and solar panels, avoiding suppliers linked to conflict minerals or exploitative labor. Transparent supply chains and certifications such as ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and CE marking provide assurance of compliance with international environmental and safety standards.

Material sustainability also plays a role. Opting for LED strips made with recyclable or biodegradable components, and solar panels with high conversion efficiency, reduces waste and maximizes lifecycle value. Additionally, selecting products with long operational lifespans and low maintenance requirements decreases environmental impact over time.

For B2B buyers, embedding sustainability criteria into procurement policies not only aligns with global climate goals but also enhances brand reputation, unlocks access to green financing, and meets the growing demand from end consumers for eco-friendly products.

Evolution of Solar-Powered Outdoor LED Strip Lights

The evolution of solar-powered outdoor LED strip lights reflects broader advances in LED technology and solar energy integration over the past decade. Initially, LED strip lights were primarily wired and dependent on grid electricity, limiting their outdoor deployment. The integration of compact, efficient solar panels and rechargeable lithium-ion batteries transformed these products into self-sufficient lighting solutions.

Early models were limited by low solar panel efficiency and shorter battery life, but improvements in photovoltaic cell technology and LED diode durability have significantly extended runtime and brightness levels. Waterproofing standards have evolved from basic splash resistance to IP65 and above, enabling reliable performance in harsh outdoor environments.

This evolution has expanded applications from decorative garden lighting to critical infrastructure such as pathway illumination, security lighting, and public space beautification—particularly in regions with limited grid access. Today’s solar LED strips combine smart control capabilities and diverse color options, meeting sophisticated aesthetic and functional requirements for B2B buyers worldwide.

By understanding these market dynamics, sourcing trends, and sustainability considerations, international B2B buyers can strategically select solar-powered outdoor LED strip light solutions that deliver performance, environmental benefits, and competitive advantage across diverse global markets.

Related Video: Govee Outdoor LED Strip Lights Waterproof | Review

Frequently Asked Questions (FAQs) for B2B Buyers of outdoor led strip lights solar powered

-

How can international B2B buyers verify the credibility and reliability of solar-powered outdoor LED strip light suppliers?

To ensure supplier credibility, buyers should conduct thorough due diligence, including checking business licenses, certifications (such as ISO, CE, RoHS), and customer references. Request detailed product datasheets and factory audit reports. Utilizing third-party inspection services or sourcing platforms with verified suppliers can add assurance. For buyers in regions like Africa or South America, verifying compliance with local import regulations and supplier experience with international shipping is critical to avoid delays and ensure product quality. -

Is customization available for solar LED strip lights, and how can buyers effectively communicate their specifications?

Most reputable manufacturers offer customization options such as length, LED color temperature, waterproof rating, and solar panel specifications. To facilitate smooth customization, buyers should provide detailed technical requirements, including IP ratings, expected operating conditions, and desired solar panel efficiency. Sharing CAD drawings or prototypes can help. Clear communication through email or video calls with suppliers’ technical teams ensures alignment and reduces costly revisions. -

What are typical minimum order quantities (MOQs) and lead times for solar-powered outdoor LED strip lights in international B2B trade?

MOQs generally range from 100 to 500 units depending on customization complexity and supplier scale. Lead times vary from 4 to 8 weeks, influenced by order size, customization, and current demand. Buyers should negotiate MOQs upfront and consider placing sample orders first. For markets with fluctuating demand like the Middle East or Europe, planning orders with buffer times and maintaining clear timelines with suppliers helps avoid supply chain disruptions. -

What payment terms are standard in B2B transactions for solar LED strip lights, and how can buyers minimize financial risks?

Common payment terms include 30% upfront deposit and 70% balance before shipment or via Letter of Credit (L/C) for large orders. Using escrow services or trade finance instruments can protect buyers. It is advisable to work with suppliers experienced in international trade and to confirm payment methods that comply with local banking regulations in buyer’s country, such as South Africa or Vietnam, to ensure smooth fund transfers. -

Which quality assurance (QA) certifications and testing standards should B2B buyers prioritize when sourcing solar-powered outdoor LED strip lights?

Buyers should prioritize products with certifications like CE (European Conformity), RoHS (Restriction of Hazardous Substances), FCC, and IEC standards for electrical safety. Additionally, IP65 or higher ratings confirm water and dust resistance essential for outdoor use. Requesting third-party lab test reports and factory QA protocols ensures the product meets international durability and performance benchmarks, crucial for maintaining reputation in competitive markets. -

What logistics considerations should international buyers keep in mind when importing solar LED strip lights?

Solar LED strip lights often come with solar panels and batteries, which may require special shipping considerations due to lithium battery regulations. Buyers should confirm if the supplier handles customs documentation, export licenses, and compliance with international shipping standards. Choosing reliable freight forwarders familiar with local import laws in regions like Europe or the Middle East reduces delays. Opting for consolidated shipments or sea freight can optimize costs but requires longer lead times. -

How can buyers effectively handle disputes or quality issues post-shipment with overseas suppliers?

Establishing clear contractual terms, including warranty periods and return policies, is vital. Buyers should conduct incoming inspections immediately upon receipt and document any defects with photos and reports. Utilizing third-party inspection companies and arbitration clauses in contracts helps resolve disputes. Maintaining open communication channels and building long-term supplier relationships encourages faster issue resolution and reduces business risks. -

Are there regional considerations for solar-powered LED strip lights that B2B buyers from Africa, South America, the Middle East, and Europe should be aware of?

Yes, regional climate conditions affect product selection; for example, higher IP ratings are essential in humid or rainy areas like parts of South America or Southeast Asia. Solar panel efficiency should be matched to local sunlight availability to ensure optimal performance. Additionally, compliance with regional electrical standards and import regulations is crucial. Buyers should also consider after-sales support availability and local service partners to ensure timely maintenance and warranty support.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for outdoor led strip lights solar powered

Strategic sourcing of solar-powered outdoor LED strip lights offers international B2B buyers a compelling opportunity to combine sustainability, cost efficiency, and technological innovation. Key considerations include prioritizing suppliers who provide high IP-rated, durable products with efficient photovoltaic panels to ensure reliable performance across diverse climates—from the sunny landscapes of South Africa and the Middle East to the variable weather in Europe and South America. Opting for flexible, easy-to-install systems with smart controls can significantly enhance value for commercial and residential projects alike.

For buyers in emerging and established markets, strategic sourcing means:

– Leveraging supplier expertise to customize solutions that meet local environmental conditions and regulatory standards.

– Evaluating total cost of ownership, including long-term energy savings and maintenance reduction.

– Building partnerships with manufacturers who invest in quality materials and innovative solar technologies, ensuring product longevity and scalability.

Looking ahead, the growing global emphasis on renewable energy and smart outdoor lighting solutions will continue to drive demand. Buyers who act decisively to integrate solar LED strip lighting into their portfolios will not only meet evolving market needs but also position themselves as leaders in sustainable infrastructure development. Embrace strategic sourcing now to unlock competitive advantages and contribute to greener, more energy-efficient outdoor environments worldwide.