Introduction: Navigating the Global Market for motorcycle led strips

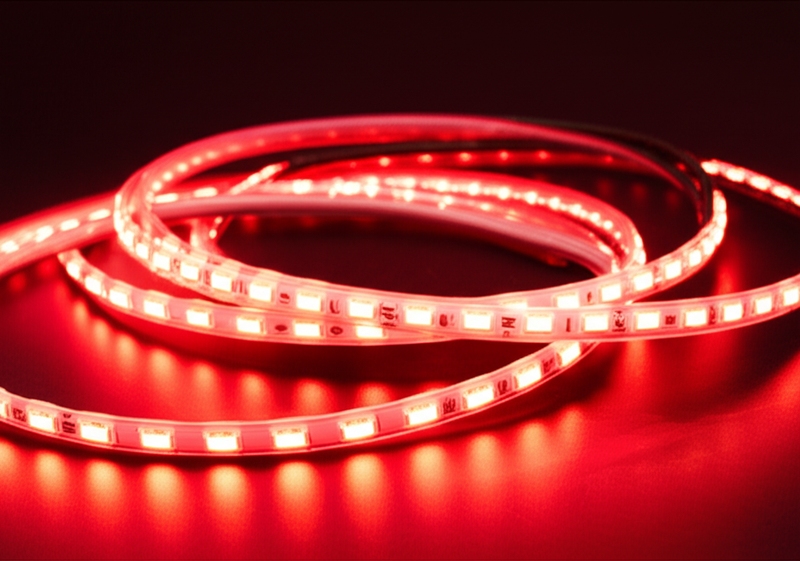

Motorcycle LED strips have rapidly evolved from niche accessories to essential components in the powersports industry, offering enhanced visibility, safety, and aesthetic appeal. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the complexities of sourcing high-quality motorcycle LED strips is critical. These products not only improve rider safety through superior illumination but also cater to customization trends that elevate brand value and consumer satisfaction.

This comprehensive guide delivers an authoritative roadmap to mastering the global motorcycle LED strip market. It covers the diverse types of LED strips, from flexible and rigid designs to color options and waterproof variants, enabling buyers to align product choices with regional preferences and regulatory requirements. Detailed insights into material selection and manufacturing processes highlight the importance of quality LED chips, PCB fabrication, and adhesive technologies—factors that directly impact durability, performance, and compliance.

Additionally, the guide explores quality control protocols, certifications, and supplier evaluation strategies, equipping buyers with tools to mitigate risks and ensure consistent product standards. Market dynamics, including cost structures and regional demand patterns, are analyzed to help businesses make competitive, cost-effective sourcing decisions. The inclusion of frequently asked questions further demystifies common challenges encountered by international buyers.

By leveraging this guide, B2B buyers from regions such as the UAE, Mexico, Brazil, South Africa, and beyond can confidently navigate supplier landscapes, optimize procurement strategies, and secure motorcycle LED strips that meet both functional and market expectations. This resource is designed to empower your business with actionable intelligence for successful global partnerships and sustainable growth in the motorcycle lighting sector.

Understanding motorcycle led strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible LED Strip | Bendable PCB, adhesive backing, customizable length | Custom motorcycle designs, accent lighting, aftermarket upgrades | + Easy installation and customization – May have lower durability in harsh conditions |

| Rigid LED Strip | Solid PCB, fixed length, high durability | Structural lighting, integrated OEM parts, high-impact environments | + High durability and stable light output – Limited flexibility for complex shapes |

| Waterproof LED Strip | Silicone or epoxy coating for water and dust resistance | Outdoor motorcycles, off-road bikes, regions with heavy rain | + Enhanced durability in wet conditions – Slightly higher cost and weight |

| RGB LED Strip | Multi-color LEDs with programmable lighting effects | Customization, branding, visual appeal, event motorcycles | + Versatile color options and effects – Requires controllers and more complex wiring |

| High-Intensity LED Strip | High lumen output, heat dissipation features | Safety lighting, headlight accents, urban and highway use | + Superior brightness and visibility – Higher power consumption and heat management needs |

Flexible LED Strip

Flexible LED strips are characterized by their bendable printed circuit boards and strong adhesive backing, allowing easy installation on curved or irregular motorcycle surfaces. They are ideal for aftermarket customizations and accent lighting, particularly popular in markets with diverse motorcycle styles like Africa and South America. B2B buyers should consider the quality of adhesive and LED chips to ensure longevity, especially in hot climates. Flexibility comes with a trade-off in durability, so sourcing from manufacturers with robust waterproofing options is recommended.

Rigid LED Strip

Rigid LED strips feature a solid, non-flexible PCB offering enhanced durability and stable light output. These strips are well-suited for OEM motorcycle parts where structural integrity is critical, such as headlight surrounds or frame lighting. Buyers targeting markets with high demand for durable, long-lasting components—like Europe and the Middle East—should prioritize suppliers with proven PCB quality and thermal management. The limitation is in their fixed shape, which requires precise measurement and design alignment.

Waterproof LED Strip

Designed with silicone or epoxy coatings, waterproof LED strips resist water, dust, and harsh environmental factors. This makes them essential for motorcycles used in off-road or tropical regions, including parts of the Middle East and Africa. For B2B buyers, evaluating waterproof ratings (e.g., IP67 or higher) and material resilience is critical for ensuring product reliability. These strips generally command a premium price but reduce returns and maintenance costs in challenging climates.

RGB LED Strip

RGB LED strips provide multi-color lighting with programmable effects, enhancing motorcycle aesthetics and brand differentiation. They require compatible controllers and wiring harnesses, making them suitable for high-end custom shops and event-focused motorcycle modifications, especially in affluent markets such as the UAE and Europe. Buyers should assess supplier capabilities in software integration and after-sales support. Complexity and higher costs are offset by the value-added appeal to end-users.

High-Intensity LED Strip

High-intensity LED strips deliver superior brightness with advanced heat dissipation designs, crucial for safety-oriented applications like daytime running lights or headlight accents. These are favored in urban and highway settings where visibility is paramount. B2B purchasers must focus on LED chip quality, thermal management, and compliance with regional lighting regulations. While power consumption is higher, the enhanced safety benefits justify the investment, especially for fleet operators and OEMs.

Related Video: Motorcycle Types for Beginners – How to Choose at RevZilla.com

Key Industrial Applications of motorcycle led strips

| Industry/Sector | Specific Application of Motorcycle LED Strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Accent and functional lighting for OEM motorcycle models | Enhances aesthetic appeal and safety, differentiates product lines | Compliance with regional safety standards (ECE, DOT), durability, and customization options |

| Motorcycle Customization | Aftermarket customization for personal and commercial motorcycles | Meets growing demand for personalization, increases aftermarket sales | Flexible designs, ease of installation, high-quality LEDs with long lifespan |

| Transportation & Delivery | Visibility enhancement on delivery motorcycles and scooters | Improves rider safety in low-light conditions, reduces accidents | Weatherproofing, high brightness, energy efficiency, and robust adhesive backing |

| Motorsports & Racing | Track and off-road motorcycle lighting for visibility and signaling | Supports safety and regulatory compliance during races | High-impact resistance, heat dissipation, and vibration-proof construction |

| Tourism & Rental Fleets | Decorative and functional lighting for rental motorcycles and tours | Enhances brand image, attracts tourists, improves night visibility | Cost-effective bulk sourcing, ease of maintenance, and aesthetic versatility |

Motorcycle LED strips find diverse applications across several key industries, each with unique demands and benefits for B2B buyers.

Motorcycle Manufacturing companies integrate LED strips as both functional and decorative elements on OEM models. These strips improve visibility and add modern styling cues that help differentiate brands in competitive markets like Europe and the Middle East. For international buyers, ensuring compliance with regional lighting regulations such as ECE (Europe) or DOT (USA) is critical. Durability against heat and vibration is also essential to maintain product longevity.

In the Motorcycle Customization sector, LED strips are popular aftermarket accessories. Custom shops and parts suppliers in regions such as South America and Africa capitalize on the rising consumer preference for personalized motorcycles. Buyers should prioritize flexibility in design and ease of installation to cater to a wide range of motorcycle models. High-quality LEDs with long lifespans reduce returns and boost customer satisfaction.

For Transportation & Delivery services relying on motorcycles or scooters, LED strips enhance rider visibility during night operations or poor weather. This application is particularly relevant in urban areas of the UAE and Mexico, where delivery fleets are expanding rapidly. Sourcing LED strips with robust weatherproofing, high brightness, and energy efficiency ensures safety without compromising operational costs.

In Motorsports & Racing, LED strips serve as critical safety and signaling devices during races and off-road events. Buyers in this niche must focus on products with high-impact resistance, excellent heat dissipation, and vibration-proof construction to withstand extreme conditions. Compliance with motorsport regulatory standards is also a key consideration for international teams and event organizers.

Lastly, Tourism & Rental Fleets use motorcycle LED strips to enhance both aesthetics and safety for rental bikes and guided tours. This is a growing market in tourist hotspots across Africa and Europe. Bulk sourcing cost-effective, easy-to-maintain LED strips that offer aesthetic versatility can significantly improve fleet branding and customer experience, driving higher rental turnover.

These applications highlight the strategic importance of selecting the right motorcycle LED strips tailored to specific industry needs, ensuring optimal performance, regulatory compliance, and business value for international B2B buyers.

Related Video: How to install LED lights on your motorcycle

Strategic Material Selection Guide for motorcycle led strips

When selecting materials for motorcycle LED strips, international B2B buyers must weigh factors such as durability, environmental resistance, manufacturing complexity, and compliance with regional standards. The choice of material directly affects product longevity, performance under harsh conditions, and suitability for various markets including Africa, South America, the Middle East, and Europe.

Polycarbonate (PC) Housing

Key Properties:

Polycarbonate offers excellent impact resistance, high temperature tolerance (up to 120°C), and superior UV stability, making it ideal for outdoor applications. It also exhibits good chemical resistance against oils and fuels commonly encountered in motorcycle environments.

Pros & Cons:

PC is highly durable and lightweight, providing robust protection for LED components against shocks and vibrations. Its transparency allows for efficient light transmission. However, it is more expensive than some plastics and requires precise molding techniques, increasing manufacturing complexity.

Impact on Application:

Polycarbonate is well-suited for motorcycle LED strips exposed to direct sunlight and varying weather conditions, including dusty or humid environments prevalent in regions like the Middle East and Africa. Its UV resistance ensures minimal yellowing over time, preserving light quality.

B2B Considerations:

Buyers in Europe and the UAE should ensure PC materials meet standards such as DIN EN ISO 4892 for weathering resistance. In South America and Africa, where cost sensitivity is higher, balancing PC’s benefits against price is critical. Compliance with RoHS and REACH regulations is often mandatory for European markets.

Flexible Printed Circuit Board (FPCB) Substrate

Key Properties:

FPCBs are made from polyimide or polyester films, offering excellent flexibility, heat resistance (up to 200°C for polyimide), and electrical insulation. This flexibility is crucial for conforming LED strips to curved motorcycle surfaces.

Pros & Cons:

FPCBs allow for versatile design and easy installation on irregular shapes, enhancing aesthetic integration. They provide reliable electrical performance and heat dissipation. The downside is higher cost and more delicate handling compared to rigid PCBs, potentially increasing production defects if not managed carefully.

Impact on Application:

Ideal for motorcycles with complex bodywork or custom designs common in European and Middle Eastern markets, where style and fit are prioritized. In regions with rough terrain like parts of Africa and South America, flexible circuits must be paired with robust protective coatings to withstand mechanical stress.

B2B Considerations:

International buyers should verify that FPCB suppliers comply with IPC standards (e.g., IPC-6013 for flexible circuits) and local certifications. For export to markets like Mexico and UAE, ensuring materials meet UL or CE certifications can facilitate smoother customs clearance and market acceptance.

Silicone-Based Adhesive Backing

Key Properties:

Silicone adhesives provide excellent thermal stability (-50°C to 250°C), strong adhesion on various substrates (metal, plastic, painted surfaces), and resistance to moisture and chemicals.

Pros & Cons:

Silicone backing ensures LED strips remain securely attached even under vibration and temperature fluctuations, critical for motorcycles operating in hot climates or humid coastal regions. It is more expensive than acrylic adhesives and may require longer curing times during manufacturing.

Impact on Application:

Highly beneficial for buyers targeting markets with extreme temperature variations such as the Middle East and parts of South America. Silicone adhesives also resist degradation from fuel and oils, common in motorcycle maintenance, enhancing product lifespan.

B2B Considerations:

Buyers should confirm adhesive certifications for automotive use (e.g., ASTM D3330 for peel adhesion) and compatibility with local environmental regulations. In Africa and Mexico, where aftermarket modifications are frequent, ease of installation and removal without residue can be a selling point.

Aluminum Alloy Heat Sink

Key Properties:

Aluminum alloys used in LED strips offer excellent thermal conductivity, corrosion resistance (especially anodized finishes), and mechanical strength. Operating temperature tolerance can exceed 150°C.

Pros & Cons:

Aluminum heat sinks effectively dissipate heat, prolonging LED lifespan and maintaining brightness. They add weight and cost but significantly improve reliability. Manufacturing involves extrusion or CNC machining, which can increase lead times and costs.

Impact on Application:

Crucial for high-performance motorcycle LED strips in markets demanding durability and long service life, such as Europe and the UAE. In humid or coastal regions of South America and Africa, anodized aluminum prevents corrosion, ensuring consistent performance.

B2B Considerations:

International buyers must ensure aluminum materials meet ASTM B221 or equivalent standards for alloy composition and mechanical properties. Surface treatments should comply with ISO 9227 for salt spray resistance to suit coastal environments.

| Material | Typical Use Case for motorcycle led strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Protective housing and lens covers for outdoor LED strips | High impact and UV resistance, lightweight | Higher cost and complex molding | High |

| Flexible PCB (FPCB) | Circuit substrate for curved or custom-shaped LED strips | Flexibility and heat resistance | Delicate handling, higher production defects | High |

| Silicone Adhesive | Mounting backing for secure adhesion under extreme conditions | Excellent thermal and chemical resistance | More expensive than acrylic adhesives | Medium |

| Aluminum Alloy | Heat sinks for thermal management in high-performance strips | Superior heat dissipation and corrosion resistance | Adds weight and manufacturing complexity | Medium |

This guide equips international B2B buyers with actionable insights to select materials that optimize performance, durability, and compliance for motorcycle LED strips tailored to diverse regional needs and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle led strips

Motorcycle LED strips are precision-engineered components designed to provide enhanced visibility, aesthetic appeal, and durability under diverse riding conditions. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding the detailed manufacturing and quality assurance (QA) processes is essential to ensure product reliability, compliance, and performance.

Illustrative Image (Source: Google Search)

Manufacturing Process Overview

The manufacturing of motorcycle LED strips typically involves four main stages: material preparation, forming, assembly, and finishing. Each stage incorporates specialized techniques to meet rigorous industry standards and operational demands.

1. Material Preparation

- LED Chips Selection: High-quality LED chips from reputable suppliers (e.g., Cree, Nichia) are chosen for optimal brightness, energy efficiency, and longevity. The choice of LED chips significantly affects the strip’s luminous efficacy and lifespan.

- PCB Fabrication: Flexible printed circuit boards (PCBs) are fabricated using materials such as polyimide or fiberglass epoxy resin. Flexibility is crucial for conforming to motorcycle contours. PCBs are engineered to optimize heat dissipation, which reduces LED degradation.

- Adhesive and Encapsulation Materials: Industrial-grade adhesives (typically 3M VHB tapes) are applied for secure mounting on varied surfaces. Silicone or epoxy coatings are prepared for waterproofing and UV resistance, critical for outdoor and rugged environments.

2. Forming

- PCB Patterning and Cutting: PCBs are patterned with conductive traces through photolithography and etching. Subsequently, they are cut into designated strip lengths or shapes compatible with motorcycle designs.

- LED Mounting: Automated pick-and-place machines accurately position LED chips onto PCB pads. This precision ensures consistent electrical contact and uniform light distribution.

- Soldering: Reflow soldering is employed to attach LED chips and other electronic components firmly to the PCB. This process uses controlled heat profiles to avoid component damage.

3. Assembly

- Wiring and Connectors: Flexible wires and waterproof connectors are integrated for seamless electrical connectivity and easy installation.

- Encapsulation: LED strips are coated or encased with silicone or epoxy to protect against moisture, dust, and mechanical impact. This step ensures compliance with IP65 or higher ingress protection ratings.

- Cut-to-Length Customization: Many manufacturers offer customization where LED strips are cut and prepped according to buyer specifications, facilitating integration into various motorcycle models.

4. Finishing

- Visual Inspection: Automated optical inspection (AOI) systems scan for solder joint quality, LED placement accuracy, and PCB defects.

- Functional Testing: Each strip undergoes electrical testing for continuity, brightness uniformity, and power consumption.

- Packaging: Final products are packaged with anti-static materials and shock-absorbent inserts to prevent damage during international shipping.

Quality Assurance and Control (QA/QC)

Robust QA/QC protocols are critical to ensure that motorcycle LED strips meet international safety, performance, and durability standards. B2B buyers should prioritize suppliers with comprehensive quality systems aligned with global certifications.

Key International and Industry Standards

- ISO 9001: This globally recognized quality management system standard ensures consistent production processes and continual improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, indicating compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances, essential for environmental sustainability and legal market access in Europe and beyond.

- IP Ratings (e.g., IP65, IP67): Define the level of protection against dust and water ingress, crucial for motorcycle applications.

- Other Certifications: Depending on the region, certifications such as ECE (Economic Commission for Europe) for automotive lighting, API standards for electrical components, or local regulatory approvals may apply.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials, including LED chips, PCB substrates, adhesives, and encapsulants. Suppliers should provide material certificates and batch test reports.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint integrity, LED alignment, and electrical testing after reflow soldering.

- Final Quality Control (FQC): Comprehensive testing of finished LED strips, including:

- Electrical Tests: Voltage, current, and power consumption measurements to ensure operational consistency.

- Optical Tests: Luminous intensity, color temperature, and uniformity assessments.

- Environmental Tests: Thermal cycling, vibration, and moisture resistance to simulate real-world motorcycle conditions.

- Visual Inspection: Checking for cosmetic defects and packaging integrity.

Common Testing Methods

- Automated Optical Inspection (AOI): Detects assembly defects such as misplaced LEDs or solder bridges.

- Electroluminescence Testing: Verifies LED functionality and uniformity.

- Thermal Imaging: Identifies hotspots to prevent premature failure.

- Environmental Stress Screening (ESS): Subjects products to extreme temperatures and humidity to ensure reliability.

- Ingress Protection (IP) Testing: Confirms resistance to dust and water penetration.

How B2B Buyers Can Verify Supplier QC

Ensuring supplier quality is vital, especially when sourcing motorcycle LED strips for international markets.

- Factory Audits: Conduct on-site or third-party audits to evaluate manufacturing capabilities, quality management systems, and compliance with standards like ISO 9001.

- Review Quality Documentation: Request and analyze IQC, IPQC, and FQC reports, including batch traceability and test result summaries.

- Third-Party Inspections: Employ independent inspection agencies to perform pre-shipment inspections, sample testing, and compliance verification.

- Sample Testing: Order product samples for in-house or accredited laboratory testing to confirm performance claims and certifications.

- Supplier Certifications: Verify authenticity of certifications such as CE, RoHS, and IP ratings through official registries or issuing bodies.

QC and Certification Nuances for International Buyers

International buyers face unique challenges and opportunities regarding QC and certification:

- Regional Regulatory Variations: For instance, the UAE requires adherence to Emirates Authority for Standardization and Metrology (ESMA) regulations, while Mexico enforces NOM standards for electrical safety. Understanding local requirements is critical.

- Certification Recognition: Some certifications accepted in Europe (e.g., CE) may not be sufficient alone for Middle Eastern or South American markets, necessitating supplementary approvals or local testing.

- Logistics and Packaging: Buyers should confirm that packaging protects against damage and environmental factors during long-distance transport, especially in climates with high humidity or temperature fluctuations.

- After-Sales Support: Robust warranty policies and technical support are essential to address quality issues arising post-import.

- Supplier Transparency: Preference should be given to manufacturers offering detailed process visibility, QC data access, and willingness to accommodate buyer-specific testing protocols.

Actionable Insights for International B2B Buyers

- Prioritize Suppliers with End-to-End Quality Control: Ensure manufacturers implement IQC, IPQC, and FQC stages with documented evidence.

- Demand Compliance Certificates Relevant to Your Market: Clarify which certifications are mandatory for your region and verify their authenticity.

- Invest in Third-Party Verification: Independent inspections reduce risks associated with overseas procurement.

- Request Customized Testing: If your market has particular environmental or regulatory demands, work with suppliers to tailor testing accordingly.

- Evaluate Packaging and Shipping Conditions: Confirm that the product packaging is suitable for your logistics chain to prevent damage.

- Establish Clear Quality Agreements: Define quality expectations, rejection criteria, and warranty terms upfront in contracts.

By thoroughly understanding the manufacturing and quality assurance processes, international B2B buyers can make informed decisions, mitigate risks, and secure high-performance motorcycle LED strips that meet stringent global standards and end-user expectations.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for motorcycle led strips Sourcing

Understanding the cost and pricing dynamics of motorcycle LED strips is essential for international B2B buyers aiming to optimize procurement strategies. The pricing framework is multifaceted, influenced by numerous components from raw materials to final delivery terms.

Key Cost Components in Motorcycle LED Strips

-

Materials: The primary cost driver includes LED chips, flexible or rigid PCBs, adhesives, and protective coatings. Premium LED chips from reputable suppliers enhance brightness and longevity but come at a higher price. PCB quality affects heat dissipation, directly influencing product lifespan and performance. Adhesive backing quality also impacts installation reliability and durability.

-

Labor: Skilled labor is required for precise assembly, soldering of LED chips, and quality inspections. Labor costs vary significantly depending on the manufacturing country and automation level.

-

Manufacturing Overhead: This covers utilities, factory maintenance, equipment depreciation, and indirect labor. Efficient factories with modern machinery often reduce overhead per unit.

-

Tooling: Initial setup costs for molds, dies, and specialized machinery are capital-intensive but amortized over large production runs. Custom designs or complex shapes increase tooling expenses.

-

Quality Control (QC): Rigorous testing, including stress and compliance checks, ensures product reliability and certification compliance. This step adds to costs but reduces returns and enhances brand reputation.

-

Logistics: Freight, customs duties, insurance, and warehousing contribute to final landed costs. International shipments, especially to regions like Africa, South America, or the Middle East, may incur higher logistics charges and longer lead times.

-

Profit Margin: Manufacturers and suppliers factor in margins based on market demand, competition, and value-added services such as OEM/ODM customization or after-sales support.

Influential Pricing Factors

-

Order Volume and MOQ: Larger orders typically attract volume discounts. Minimum order quantities (MOQs) set by suppliers can influence unit costs and inventory management for buyers.

-

Specifications and Customization: Custom LED color options, waterproofing levels, or unique shapes raise production complexity and cost. Buyers should balance bespoke requirements with budget constraints.

-

Material Quality and Certifications: Products certified with CE, RoHS, or UL often command premium pricing due to compliance costs and enhanced trustworthiness, which is crucial for regulated markets in Europe and the UAE.

-

Supplier Reputation and Location: Established suppliers with proven track records may price higher but offer reliability and better post-sale service. Proximity to buyers can reduce logistics costs and lead times.

-

Incoterms: Terms like FOB, CIF, or DDP define cost responsibility and risk allocation. Choosing appropriate Incoterms can optimize cash flow and reduce unexpected expenses.

Practical Buyer Tips for International Markets

-

Negotiate Beyond Unit Price: Engage suppliers on payment terms, warranty conditions, and bundled services to improve overall procurement value.

-

Evaluate Total Cost of Ownership (TCO): Consider not just purchase price but also shipping, customs clearance, installation, and potential after-sales support costs.

-

Leverage Volume Consolidation: Buyers from regions with smaller individual orders (e.g., African or South American distributors) can pool demand to meet MOQ thresholds and negotiate better pricing.

-

Assess Quality vs. Cost: Avoid sourcing solely on the lowest price. Inferior LED strips may lead to higher failure rates, increased warranty claims, and damaged brand reputation.

-

Understand Regional Compliance Needs: For European and UAE markets, insist on certified products to avoid import barriers and ensure customer safety.

-

Plan for Logistics Variability: Factor in potential delays and extra costs in regions with complex customs procedures or limited port infrastructure.

Indicative Pricing Disclaimer

Prices for motorcycle LED strips vary widely depending on order size, specifications, and supplier location. Typical FOB prices can range from USD 3 to USD 15 per unit, with custom or certified products at the higher end. Buyers should request detailed quotations and consider total landed costs before finalizing purchases.

By dissecting the cost structure and recognizing key pricing influencers, B2B buyers across Africa, South America, the Middle East, and Europe can make informed sourcing decisions that align with their operational and market requirements.

Spotlight on Potential motorcycle led strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘motorcycle led strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for motorcycle led strips

Critical Technical Properties of Motorcycle LED Strips

1. LED Chip Quality and Luminous Efficacy

The core component of motorcycle LED strips is the LED chip. High-grade chips offer superior brightness (measured in lumens) and energy efficiency, which translates to better visibility and lower power consumption. For B2B buyers, prioritizing premium chips ensures longer lifespan and reliability, reducing warranty claims and enhancing brand reputation in diverse markets including Africa, South America, and the Middle East.

2. Printed Circuit Board (PCB) Material and Type

The PCB serves as the base for mounting LED chips. Options typically include flexible or rigid PCBs made from materials such as FR4 or polyimide. Quality PCB materials provide excellent heat dissipation, preventing premature failure and flickering. Buyers should specify PCB type based on application needs—flexible PCBs are ideal for curved motorcycle parts, while rigid PCBs suit flat surfaces.

3. Ingress Protection (IP) Rating

Motorcycle LED strips must withstand harsh outdoor environments. The IP rating (e.g., IP67, IP68) indicates resistance to dust and water. Higher IP ratings mean better protection against rain, dust, and vibration—critical for regions with extreme weather or off-road riding conditions. Ensuring appropriate IP standards minimizes returns and enhances product durability.

4. Operating Voltage and Current Tolerance

Common operating voltages for motorcycle LED strips range between 12V and 24V DC. Precise voltage and current tolerance specifications guarantee consistent performance without overheating or dimming. Buyers should confirm these specs align with their motorcycle electrical systems to avoid compatibility issues and costly modifications.

5. Adhesive Backing Quality

The adhesive backing affects ease of installation and long-term adhesion under vibration and temperature changes. High-quality adhesives prevent peeling and ensure the strip remains securely attached even on curved or textured surfaces. This is vital for markets with varying climate conditions, ensuring customer satisfaction and reducing after-sales service costs.

6. Color Temperature and Customization Options

Color temperature (measured in Kelvins) influences the light’s appearance—from warm white (2700K) to cool white (6500K) or RGB options. Offering customizable color options can cater to different market preferences and regulatory requirements, giving buyers a competitive edge in tailoring products for regional tastes.

Key Trade Terminology for Motorcycle LED Strips

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strips designed to be branded and sold by another company. For buyers, working with OEM suppliers allows custom design and branding flexibility, essential for private labeling and regional differentiation.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and budget effectively, especially when entering new markets with uncertain demand.

RFQ (Request for Quotation)

A formal request sent to suppliers asking for pricing, lead times, and terms based on specific product requirements. RFQs enable buyers to compare offers and negotiate better terms, crucial for optimizing procurement costs.

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, EXW) that define responsibilities for shipping, insurance, and customs. Familiarity with Incoterms ensures clarity in logistics and cost allocation, reducing disputes in international transactions.

Lead Time

The total time from order placement to delivery. Accurate lead time information is critical for supply chain planning, especially for seasonal markets or regions with complex import procedures.

Certification Compliance

Common certifications include CE (Europe), RoHS (hazardous substances), and IP ratings. Compliance with these standards is often mandatory for market entry and helps assure buyers of product safety and quality.

By understanding these technical properties and trade terms, international B2B buyers can make informed procurement decisions that balance quality, cost, and market-specific requirements. This knowledge is especially valuable for businesses targeting diverse and dynamic regions such as Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the motorcycle led strips Sector

Market Overview & Key Trends

The global motorcycle LED strips market is experiencing robust growth driven by increasing demand for enhanced safety, aesthetic customization, and energy efficiency in motorcycles. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, this sector presents diverse opportunities influenced by regional mobility trends and regulatory frameworks.

Key Market Drivers:

- Rising Motorcycle Ownership: Regions such as Africa and South America are witnessing rapid urbanization and growing middle-class populations, fueling motorcycle sales. This increases demand for aftermarket accessories like LED strips for both functional and decorative purposes.

- Regulatory Push for Safety: Europe and the Middle East have progressively tightened vehicle lighting standards, encouraging manufacturers to adopt LED technology for better visibility and compliance.

- Technological Innovation: Advances in LED chip efficiency, flexible PCB materials, and smart lighting controls are enabling customizable, durable, and energy-saving LED strip solutions tailored to different motorcycle models and environments.

Emerging Sourcing Trends:

- OEM & ODM Partnerships: B2B buyers increasingly prefer manufacturers offering custom design services (OEM/ODM) to differentiate their product offerings with unique LED strip configurations, colors, and integration options.

- Regional Manufacturing Hubs: China remains a dominant supplier, but buyers in the UAE, Mexico, and Europe are exploring local or nearshore manufacturing to reduce lead times, logistics costs, and import duties.

- Digital Supply Chain Integration: Suppliers adopting digital platforms for real-time inventory, quality tracking, and order management help B2B buyers optimize procurement efficiency and transparency.

Market Dynamics for International Buyers:

- Quality and Certification Compliance: Buyers prioritize LED strips with certifications such as CE, RoHS, and UL to ensure safety and regulatory compliance across markets.

- Customization Demand: Markets like the Middle East and Europe show strong interest in high-end, customizable lighting solutions, while African and South American buyers often focus on cost-effective, durable options suitable for diverse road conditions.

- Aftermarket Growth vs. OEM Integration: While OEM adoption of LED strips is growing, aftermarket sales remain significant, allowing buyers to target both motorcycle manufacturers and accessory retailers.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are becoming increasingly critical in the motorcycle LED strips sector. International B2B buyers are urged to evaluate suppliers not only on product quality and cost but also on environmental and ethical performance.

Environmental Impact:

- Energy Efficiency: LED strips inherently consume less power than traditional lighting, reducing overall vehicle emissions indirectly by lowering fuel consumption. Selecting LED chips with higher luminous efficacy further enhances energy savings.

- Material Selection: Sustainable sourcing involves prioritizing LED chips and PCBs manufactured with minimal hazardous substances. Lead-free soldering and halogen-free materials are industry best practices to reduce environmental harm.

- Waste Management: Suppliers who implement recycling programs for electronic waste and packaging materials demonstrate responsible environmental stewardship.

Ethical Supply Chains:

- Labor Standards: Buyers should verify that their suppliers adhere to fair labor practices, including safe working conditions and reasonable wages, especially in regions with less stringent regulations.

- Transparency & Traceability: Demand for supply chain transparency is rising. Certifications like ISO 14001 (environmental management) and SA8000 (social accountability) provide assurance of ethical sourcing.

- Green Certifications: LED strip products carrying certifications such as RoHS (Restriction of Hazardous Substances), CE (Conformité Européenne), and Energy Star are preferable for buyers targeting environmentally conscious markets.

By integrating sustainability criteria into procurement strategies, B2B buyers can mitigate risks, meet regulatory requirements, and appeal to end customers increasingly valuing green products.

Brief Evolution of Motorcycle LED Strips

Motorcycle LED strips have evolved from simple aftermarket decorative accessories to essential lighting components with advanced functionalities. Initially popularized in the early 2000s for aesthetic enhancement, LED strips have since gained prominence due to their superior durability, low power consumption, and versatility.

The integration of flexible PCBs and high-efficiency LED chips has enabled manufacturers to design strips that conform to complex motorcycle contours, improving visibility and safety. Over time, the rise of smart lighting systems incorporating programmable colors and patterns has further expanded their appeal.

For B2B buyers, understanding this evolution highlights the importance of partnering with suppliers capable of delivering both innovative design and reliable performance to meet modern market expectations.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle led strips

-

How can I effectively vet suppliers of motorcycle LED strips for international B2B purchases?

To vet suppliers, request detailed company profiles, including manufacturing capabilities, certifications (such as CE, RoHS, UL), and client references. Verify their factory audits or third-party inspection reports to assess quality control standards. Ask for samples to evaluate product quality firsthand. Additionally, review their export experience, especially shipping to your region, and confirm compliance with local regulations. Using platforms with verified supplier credentials and conducting video factory tours can further reduce risk when sourcing from unfamiliar markets like Africa, South America, or the Middle East. -

Is customization of motorcycle LED strips available, and what are the typical options?

Yes, many manufacturers offer OEM/ODM customization services. Options commonly include LED color temperature, strip length, waterproof ratings (IP65, IP67, IP68), flexible vs. rigid PCB types, adhesive backing preferences, and connector types suitable for different motorcycle models. Some suppliers also provide private labeling and packaging customization. When negotiating, clarify minimum order quantities (MOQs) for custom products, lead times, and any additional tooling or design fees to ensure your specifications align with supplier capabilities and your market needs. -

What are typical minimum order quantities (MOQs) and lead times for motorcycle LED strip orders?

MOQs vary widely depending on supplier scale and customization level but typically range from 500 to 5,000 units for standard models. Customized orders may require higher MOQs or batch sizes due to tooling and material costs. Lead times generally span 4–8 weeks, with longer durations for bespoke designs or complex certifications. For international buyers in regions like Europe or the UAE, factor in additional time for shipping and customs clearance. Early communication about production schedules is critical to align expectations and avoid supply chain delays.

Illustrative Image (Source: Google Search)

-

Which payment terms are standard and safest for international B2B transactions involving motorcycle LED strips?

Common payment terms include a 30% deposit upfront with the balance paid before shipment or upon receipt of a clean bill of lading. Letters of credit (LC) and escrow services offer additional security, especially for larger orders or new suppliers. Pay attention to currency options and potential transfer fees, particularly when dealing with suppliers in Asia or Latin America. Establish clear payment milestones tied to production and quality inspections to minimize financial risk and maintain cash flow integrity. -

What quality assurance (QA) measures should I expect from reputable motorcycle LED strip manufacturers?

Top-tier manufacturers implement multiple QA steps: raw material inspection, in-process monitoring (e.g., soldering quality, LED chip placement), and final product testing including luminous efficacy, waterproofing, vibration resistance, and lifespan simulations. Certifications like CE, RoHS, and UL reflect adherence to international safety and environmental standards. Request detailed QA reports and certifications for each shipment. For buyers in regions with strict import regulations, confirming supplier compliance prior to order placement helps avoid customs rejections or costly returns. -

What certifications are essential for motorcycle LED strips to comply with international trade requirements?

Key certifications include CE (Europe), RoHS (restricted hazardous substances), UL (North America), and sometimes E-Mark for automotive lighting compliance in Europe. In the Middle East and Africa, conformity to IEC standards and local regulations may be required. Certifications ensure product safety, environmental compliance, and electrical compatibility. When sourcing from Asia or Latin America, verify that certificates are authentic and up-to-date. Insist on documentation during contract negotiation to streamline customs clearance and build trust with end customers. -

How should I plan logistics and shipping for motorcycle LED strip orders to regions like Africa, South America, or the Middle East?

Evaluate shipping options based on order size, cost, and urgency. Sea freight is cost-effective for bulk orders but requires longer lead times; air freight suits smaller, urgent shipments. Understand import duties, taxes, and customs clearance procedures specific to your country. Engage freight forwarders familiar with your region to manage documentation and reduce delays. Packaging should be robust to protect delicate LED components during transit. Consider insurance to mitigate risks of damage or loss, especially for high-value or customized products. -

What steps can I take to resolve disputes or quality issues with overseas motorcycle LED strip suppliers?

Maintain clear, documented communication throughout the transaction, including contracts specifying quality standards, delivery terms, and dispute resolution mechanisms. If issues arise, initiate prompt dialogue to negotiate returns, replacements, or refunds. Use third-party inspection and certification reports as objective evidence. For persistent problems, leverage trade platforms’ dispute resolution services or consider arbitration under international trade laws. Building long-term relationships with reliable suppliers and conducting periodic audits can minimize future conflicts and safeguard your supply chain integrity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for motorcycle led strips

Strategic sourcing of motorcycle LED strips demands a keen focus on quality, supplier reliability, and compliance with international standards. For B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing suppliers who demonstrate excellence in material sourcing—such as premium LED chips, robust PCBs, and durable adhesives—is essential to ensure product longevity and performance. Additionally, rigorous quality control and certification adherence mitigate risks associated with returns and regulatory barriers.

Key takeaways for buyers include:

- Assessing supplier capabilities in OEM/ODM design and customization to meet diverse market needs.

- Verifying compliance certifications (CE, RoHS, UL) to facilitate smooth import and distribution.

- Evaluating production processes for consistency and scalability, critical for sustaining competitive advantage.

- Considering logistical factors such as packaging quality and shipping reliability to protect product integrity.

Looking ahead, the motorcycle LED strip market is poised for growth driven by increasing demand for energy-efficient, customizable lighting solutions. International buyers who adopt strategic sourcing practices and build partnerships with innovative manufacturers will be well-positioned to capitalize on emerging trends and evolving regulatory landscapes. Embrace due diligence and proactive supplier engagement to secure high-value LED strip solutions that enhance your market offering and drive sustainable business growth.