Introduction: Navigating the Global Market for marine led light strips

Marine LED light strips have emerged as indispensable components in the maritime industry, transforming vessel aesthetics, safety, and operational efficiency. For international B2B buyers—especially from dynamic markets across Africa, South America, the Middle East, and Europe—understanding the complexities of sourcing these specialized lighting solutions is critical to maintaining a competitive edge. Marine environments demand lighting products that are not only visually appealing but also engineered to withstand harsh conditions such as saltwater exposure, humidity, and vibration.

This comprehensive guide is designed to empower procurement professionals and business leaders with a deep dive into the marine LED light strip market. It covers essential topics including the various types of marine-grade LED strips, materials and manufacturing standards that ensure durability and compliance, and rigorous quality control processes that guarantee long-term performance. Buyers will gain insights into selecting reliable suppliers, navigating cost structures, and analyzing market trends relevant to their regional contexts—from Italy’s sophisticated maritime sector to Colombia’s expanding coastal industries.

Additionally, this guide addresses frequently asked questions that clarify technical specifications, installation considerations, and customization options, helping businesses tailor solutions to unique project requirements. By consolidating critical knowledge and actionable strategies, the guide supports informed decision-making, reduces procurement risks, and enhances value for companies aiming to source marine LED light strips at scale. Whether upgrading fleets, outfitting commercial vessels, or developing marine infrastructure, international buyers will find this resource essential for navigating the global market with confidence and precision.

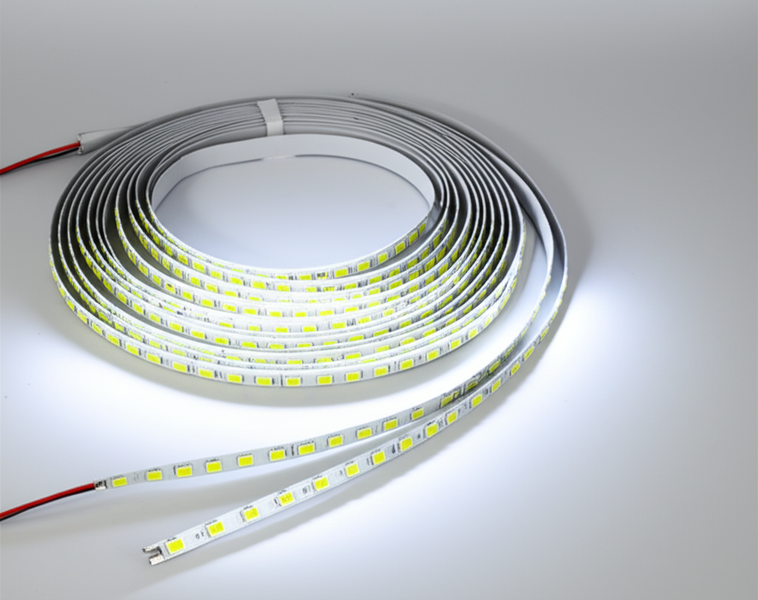

Illustrative Image (Source: Google Search)

Understanding marine led light strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof LED Strips | IP65 to IP68 rated for water resistance, flexible design | Marine vessel interiors, decks, underwater lighting | Pros: Durable in wet environments, versatile installation Cons: Higher cost due to sealing, requires certified suppliers |

| RGB Color-Changing Strips | Multi-color LEDs with controller compatibility | Ambiance lighting in yachts, commercial boats | Pros: Customizable lighting effects, enhances aesthetic appeal Cons: Complexity in installation, potential higher inventory costs |

| High Lumen Output Strips | High brightness LEDs, often with enhanced heat dissipation | Task lighting, navigation aids, commercial marine use | Pros: Superior illumination, energy-efficient Cons: May require specialized power supplies, increased upfront cost |

| Flexible & Cuttable Strips | Easily cut to size, bendable for curved surfaces | Custom installations in boat cabins, signage | Pros: Adaptable to various shapes, reduces waste Cons: Requires precise measurement, risk of damage if mishandled |

| UV-Resistant LED Strips | Coated with UV-resistant materials for sun exposure | Exterior decks, fishing boats, outdoor marine environments | Pros: Long-lasting color and performance under sun Cons: Limited color options, slightly higher price point |

Waterproof LED Strips are essential for marine environments where exposure to water and moisture is constant. These strips typically have IP65 to IP68 ratings, ensuring protection against splashes and submersion. For B2B buyers in Africa, South America, the Middle East, and Europe, sourcing certified waterproof LED strips is critical for compliance with marine safety standards. These strips are ideal for both interior and exterior applications on vessels, offering durability and reliability. When purchasing, consider supplier certifications and warranty terms due to the demanding conditions.

RGB Color-Changing Strips offer dynamic lighting solutions with the ability to switch between multiple colors via controllers. This type is popular in luxury yachts and commercial boats aiming to create customizable ambiance lighting. International buyers should evaluate the compatibility of controllers and power supplies with local standards and ensure suppliers provide technical support for installation. While RGB strips add aesthetic value, they may involve more complex logistics and inventory management.

High Lumen Output Strips are designed for applications requiring bright, focused illumination such as navigation lighting and work areas on boats. These strips often incorporate advanced heat dissipation technologies to maintain performance. For B2B buyers, especially those supplying commercial marine projects, these strips deliver energy efficiency and compliance with marine lighting regulations. However, they may need specific power configurations, so sourcing from knowledgeable manufacturers with customization options is advisable.

Flexible & Cuttable Strips provide adaptability for installations in curved or irregular surfaces common in marine vessels. Their cuttable nature minimizes waste and allows precise fitting, which is beneficial for custom boat interiors and signage. Buyers should ensure that suppliers offer clear guidelines on cutting and installation to avoid damage. This type is well-suited for markets requiring tailored lighting solutions, but requires technical expertise during installation.

UV-Resistant LED Strips are coated to withstand prolonged exposure to sunlight without degradation, making them ideal for outdoor marine applications such as decks and fishing boats. These strips maintain color fidelity and performance despite harsh UV conditions. For international buyers in sunny regions, prioritizing UV resistance can extend product lifespan and reduce maintenance costs. The trade-off may be a higher price and fewer color options, so evaluating supplier material specifications is essential.

Related Video: How to install Underwater LED Boat Lights | TH Marine.

Key Industrial Applications of marine led light strips

| Industry/Sector | Specific Application of marine led light strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Shipbuilding | Underwater and deck lighting for vessels | Enhances safety and aesthetics, reduces maintenance costs | Waterproof rating (IP68), corrosion resistance, flexible sizing |

| Offshore Oil & Gas | Illumination of offshore platforms and walkways | Improves operational safety and energy efficiency | High durability, explosion-proof options, long lifespan |

| Hospitality & Tourism | Ambient lighting in yachts, cruise ships, and waterfront resorts | Creates premium guest experiences and reduces energy consumption | Custom color options, dimmability, compliance with maritime standards |

| Fishing Industry | Boat and net illumination for night fishing | Increases catch efficiency and safety during night operations | High brightness, waterproof and saltwater resistant, easy installation |

| Aquaculture | Tank and facility lighting for fish farms | Promotes healthy aquatic life and operational monitoring | Non-toxic materials, adjustable light spectrum, waterproof design |

Marine & Shipbuilding: In this sector, marine LED light strips are primarily used for underwater lighting and deck illumination on vessels. These strips provide enhanced visibility for crew safety during night operations and docking, while also improving the vessel’s aesthetic appeal. For international buyers, especially from coastal countries in Africa and South America, sourcing strips with high waterproof ratings (IP68) and excellent corrosion resistance is critical due to harsh marine environments. Flexible sizing options allow for custom installations on a variety of vessel types, from fishing boats to luxury yachts.

Offshore Oil & Gas: Offshore platforms require robust lighting solutions to ensure worker safety and operational efficiency in challenging conditions. Marine LED strips are deployed along walkways, staircases, and critical equipment areas to provide reliable illumination with minimal energy consumption. Buyers from the Middle East and Europe must prioritize sourcing explosion-proof and highly durable LED strips capable of withstanding extreme weather and chemical exposure. Long operational lifespan and easy maintenance are key factors to reduce downtime and operational costs.

Hospitality & Tourism: The luxury yacht, cruise ship, and waterfront resort industries leverage marine LED light strips to create ambient and mood lighting that enhances guest experiences. These strips are used for interior accents, exterior deck lighting, and underwater illumination to add a premium feel while reducing energy usage. For buyers in Italy and other European markets, customization in color and dimming capabilities is essential to match branding and design aesthetics. Compliance with maritime safety and environmental standards is also a crucial sourcing consideration.

Fishing Industry: Night fishing operations benefit significantly from marine LED light strips that illuminate decks and fishing nets. This lighting improves visibility, safety, and catch efficiency during nocturnal activities. Buyers in regions like Colombia and coastal African nations should focus on high-brightness LED strips with strong waterproof and saltwater resistance. Ease of installation and durability against rough handling and marine conditions are important to ensure long-term performance and value.

Aquaculture: Fish farms and aquaculture facilities use marine LED light strips to provide controlled lighting environments that support aquatic health and operational monitoring. Adjustable light spectrums can simulate natural conditions to promote fish growth and wellbeing. International buyers must seek non-toxic, waterproof strips that can withstand humid and corrosive environments. Flexibility in installation and the ability to integrate with automated monitoring systems are additional benefits that enhance operational efficiency.

Related Video: LED – Light Emitting Diode | Basics, Characteristics, Working & Applications | LED Vs PN Diode

Strategic Material Selection Guide for marine led light strips

Analysis of Common Materials for Marine LED Light Strips

1. Silicone

Key Properties: Silicone is highly flexible, with excellent thermal stability (operating temperatures typically from -60°C to 230°C). It offers outstanding resistance to UV radiation, saltwater corrosion, and extreme weather conditions, making it ideal for marine environments. Silicone also provides good electrical insulation and moisture resistance.

Pros & Cons: Silicone’s durability against harsh marine conditions and flexibility make it a top choice for marine LED strips. It is resistant to cracking and yellowing over time, preserving light quality. However, silicone is relatively costly compared to other materials and can be more complex to manufacture, requiring precise molding and curing processes.

Impact on Application: Silicone’s water and salt resistance make it suitable for exposed outdoor and underwater lighting applications on boats and docks. Its flexibility allows installation on curved surfaces, common in marine vessels.

International B2B Considerations: Buyers from Africa, South America, the Middle East, and Europe should note that silicone materials often comply with ASTM D2000 and ISO 10993 standards, ensuring quality and safety. European buyers, especially in Italy, may require compliance with REACH regulations for chemical safety. In regions with intense UV exposure like the Middle East, silicone’s UV resistance is a critical advantage.

2. Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic with moderate flexibility and good resistance to moisture and chemicals. It operates effectively within a temperature range of approximately -15°C to 60°C. PVC is less resistant to UV degradation and saltwater corrosion compared to silicone.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it attractive for large-scale production. However, it has lower durability in harsh marine environments and tends to become brittle or discolored over time when exposed to UV and saltwater.

Impact on Application: PVC is best suited for indoor marine applications or sheltered outdoor areas where exposure to direct sunlight and saltwater is limited. It is commonly used in budget-conscious projects or where replacement cycles are short.

International B2B Considerations: PVC materials generally meet ASTM D1784 and DIN 53438 standards. Buyers in South America and Africa should verify local chemical regulations and environmental restrictions, as PVC disposal and recycling can be problematic. European buyers must consider RoHS compliance and potential restrictions on phthalates used as plasticizers in PVC.

3. Polycarbonate (PC)

Key Properties: Polycarbonate is a rigid, impact-resistant plastic with excellent clarity and high heat resistance (up to 135°C). It offers good resistance to saltwater and UV rays but can be prone to scratching and chemical attack from certain solvents.

Pros & Cons: PC provides superior mechanical strength and optical clarity, ideal for high-visibility marine LED strips. It is more expensive than PVC but generally less costly than high-grade silicone. The manufacturing process is more complex, often involving injection molding.

Impact on Application: Polycarbonate is suitable for protective housings or covers for LED strips in marine applications requiring high durability and transparency, such as navigation lights or cabin lighting.

International B2B Considerations: PC complies with ASTM D3935 and ISO 178 standards. Buyers in Europe and the Middle East should ensure compliance with local fire safety and chemical regulations. PC’s recyclability is a plus for environmentally conscious buyers in all regions, including Italy and Colombia.

4. Thermoplastic Polyurethane (TPU)

Key Properties: TPU combines elasticity with toughness, offering excellent abrasion resistance, flexibility, and chemical resistance. It operates in a temperature range of approximately -40°C to 80°C and resists saltwater and UV exposure well.

Pros & Cons: TPU provides a balance between flexibility and durability, making it ideal for marine LED strips that require frequent bending or movement. It is more expensive than PVC but generally less costly than silicone. Manufacturing TPU strips can be more challenging due to its elastic nature.

Impact on Application: TPU is well-suited for flexible LED strip applications on yachts, inflatable boats, or areas prone to mechanical stress. Its abrasion resistance extends product life in high-traffic marine environments.

International B2B Considerations: TPU materials often meet ASTM D412 and DIN 53504 standards. Buyers in Africa and South America should consider TPU for applications requiring durability in tropical climates. European buyers should verify compliance with REACH and RoHS directives, especially for products destined for consumer markets.

Summary Table of Materials for Marine LED Light Strips

| Material | Typical Use Case for marine led light strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Outdoor and underwater flexible LED strips | Excellent UV and saltwater resistance; high flexibility | Higher cost and complex manufacturing | High |

| PVC | Indoor or sheltered marine lighting | Cost-effective and easy to produce | Poor UV and saltwater durability; brittle over time | Low |

| Polycarbonate | Protective covers and rigid housings for LED strips | High impact resistance and optical clarity | Susceptible to scratching and chemical attack | Medium |

| TPU | Flexible, abrasion-resistant LED strips on moving parts | Balanced flexibility and toughness | More expensive than PVC; manufacturing complexity | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for marine led light strips

The manufacturing and quality assurance of marine LED light strips involve precise processes and rigorous testing to ensure durability, safety, and performance in harsh marine environments. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these aspects is critical for selecting reliable suppliers and ensuring compliance with regional and global standards.

Illustrative Image (Source: Google Search)

Manufacturing Processes of Marine LED Light Strips

1. Material Preparation

The process begins with sourcing high-quality raw materials suited for marine conditions. This includes:

- Flexible PCB substrates: Typically made from waterproof, corrosion-resistant materials like polyimide or polyester.

- LED chips: High-efficiency, low-heat LEDs with marine-grade encapsulation.

- Encapsulation materials: Silicone or epoxy resins that provide waterproofing and UV resistance.

- Connectors and wiring: Marine-grade copper wires with corrosion-resistant coatings.

Material inspection at this stage ensures components meet specified technical and environmental durability criteria.

2. Forming and Circuit Fabrication

Next, the flexible printed circuit boards (FPCBs) are fabricated:

- Circuit etching or printing: Copper traces are precisely formed on flexible substrates using photolithography or screen printing.

- Solder mask application: Protective layers are applied to prevent short circuits and corrosion.

- Cutting and shaping: The strips are cut to standard or custom lengths, with perforations for easy installation.

Advanced machinery ensures tight tolerances and consistent electrical pathways critical for marine reliability.

3. LED Mounting and Assembly

LED chips and other components are mounted on the FPCBs through:

- Surface Mount Technology (SMT): Automated pick-and-place machines position LEDs and resistors with high accuracy.

- Soldering: Reflow soldering secures components, ensuring strong electrical connections.

- Encapsulation: LEDs and circuits are coated with waterproof sealants like silicone gels or epoxy to protect against moisture and saltwater.

- Connector attachment: Robust, waterproof connectors are affixed to facilitate secure electrical connections.

Assembly lines often incorporate cleanroom environments to reduce contamination, enhancing product longevity.

4. Finishing and Packaging

Final steps include:

- Protective casing: Some marine LED strips are enclosed in UV-resistant, impact-resistant housings.

- Labeling and branding: Includes batch numbers, compliance marks, and installation instructions.

- Custom packaging: Designed to protect products during shipping and storage, often tailored to client requirements for bulk orders.

Packaging quality is crucial for preventing damage during international transit.

Quality Assurance and Control (QA/QC) Measures

Effective QA/QC is essential to guarantee marine LED strips perform reliably in demanding conditions such as saltwater exposure, vibration, and temperature fluctuations.

Relevant International and Industry Standards

- ISO 9001: Ensures manufacturers implement robust quality management systems covering all production stages.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards, vital for EU market access.

- Ingress Protection (IP) Ratings: IP65, IP67, or IP68 ratings certify waterproofing levels critical for marine applications.

- RoHS Compliance: Restricts hazardous substances, important for environmental and health safety.

- Marine-specific standards: Some buyers may require compliance with standards like API (American Petroleum Institute) for offshore marine applications or DNV GL certifications for marine equipment.

Buyers should verify that suppliers provide documentation proving adherence to these standards.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected for defects, correct specifications, and certifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly to detect soldering defects, LED placement accuracy, and waterproof sealing integrity.

- Final Quality Control (FQC): Comprehensive testing of finished products, including visual inspections, functional tests, and performance validation.

Common Testing Methods for Marine LED Strips

- Waterproof Testing: Submersion or spray tests simulate marine exposure to verify IP ratings.

- Thermal Cycling: Products undergo repeated heating and cooling to assess durability against temperature changes.

- Salt Spray Test: Accelerated corrosion testing to confirm resistance to saltwater environments.

- Electrical Safety Testing: Checks for insulation resistance, voltage stability, and absence of short circuits.

- Lumen and Color Consistency Testing: Ensures uniform brightness and color temperature across batches.

- Vibration and Shock Testing: Simulates marine vessel movements to assess mechanical robustness.

How B2B Buyers Can Verify Supplier Quality Control

- Request Quality Certifications and Test Reports: Ensure suppliers provide up-to-date ISO 9001 certificates, CE declarations, IP test results, and any relevant marine certifications.

- Supplier Audits: Conduct on-site or third-party audits to evaluate manufacturing processes, quality management systems, and worker training.

- Third-Party Inspections: Engage independent inspection agencies to perform batch inspections, functional testing, and packaging verification before shipment.

- Sample Evaluation: Order pre-production samples or small pilot batches to test in your local marine conditions.

- Review Traceability Systems: Verify that the supplier maintains detailed production records and batch traceability, which is crucial for warranty claims and quality investigations.

QC and Certification Nuances for International Buyers

- Africa & South America: Consider local import regulations and certification acceptance. CE and RoHS marks are often preferred, but buyers should confirm compatibility with local marine safety authorities. Language and documentation translation may be necessary.

- Middle East: Buyers should verify compliance with Gulf Cooperation Council (GCC) standards and look for suppliers experienced with high-temperature and saline environments common in the region.

- Europe (e.g., Italy): Strict adherence to EU directives and environmental regulations is mandatory. Suppliers should demonstrate thorough CE compliance and maintain transparent quality records.

- Customs and Shipping Considerations: Packaging must meet international shipping standards, and suppliers should support export documentation (e.g., Certificates of Origin, Test Reports) to facilitate smooth customs clearance.

Final Recommendations for B2B Buyers

- Prioritize suppliers with proven marine LED strip experience and comprehensive quality systems.

- Insist on clear, verifiable certifications and independent test reports.

- Use audits and third-party inspections as standard due diligence to reduce risk.

- Factor in environmental and regulatory requirements specific to your region.

- Consider customization and packaging options that support your installation and resale needs.

By thoroughly understanding manufacturing processes and quality assurance practices, international B2B buyers can secure marine LED light strips that deliver long-term performance and compliance, ensuring successful project outcomes and satisfied end customers.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for marine led light strips Sourcing

Cost Components in Marine LED Light Strips Sourcing

When sourcing marine LED light strips, understanding the underlying cost components is crucial for effective budgeting and negotiation. The primary elements influencing the final price include:

- Materials: High-quality LEDs, flexible PCB substrates, waterproof coatings (such as silicone or epoxy), and corrosion-resistant connectors are essential for marine-grade durability. Premium materials typically increase costs but ensure longevity and compliance with marine standards.

- Labor: Skilled labor is required for assembly, soldering, and quality checks. Labor costs vary significantly by manufacturing location, impacting overall pricing.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and administrative expenses, which are factored into the product cost.

- Tooling: Custom molds and dies for specific strip designs or connectors add upfront investment, often amortized over large production runs.

- Quality Control (QC): Rigorous testing for waterproofing, voltage stability, and marine certification compliance (e.g., IP68 ratings) adds to production costs but is vital for reliability.

- Logistics: Freight charges, customs duties, and insurance for international shipping—especially for fragile electronic goods—must be included in total sourcing costs.

- Margin: Supplier profit margins vary depending on market positioning, order volume, and competitive landscape.

Key Price Influencers in the Marine LED Strip Market

Several factors influence pricing beyond raw costs, shaping supplier quotations and buyer negotiations:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower unit costs due to economies of scale. Buyers from emerging markets like Africa or South America should consolidate orders where possible to reduce per-unit expenses.

- Specifications and Customization: Custom lengths, color temperatures, RGB capabilities, or unique waterproofing standards raise costs. Tailored packaging or branding may also add premiums.

- Material Grade and Certifications: Marine-grade materials and certifications (such as CE, RoHS, or UL marine listings) command higher prices but offer assurance of durability and compliance.

- Supplier Location and Reputation: Established suppliers with proven track records may charge premium prices but reduce risk. Conversely, emerging suppliers from Asia or Eastern Europe might offer competitive rates with variable quality.

- Incoterms and Shipping Terms: The chosen Incoterms (e.g., FOB, CIF, DDP) significantly affect landed costs. Buyers should evaluate total landed cost rather than just factory price, especially for shipments to regions with complex customs like the Middle East or Europe.

Practical Buyer Tips for International B2B Procurement

For buyers from Africa, South America, the Middle East, and Europe, navigating cost and pricing nuances requires strategic approaches:

- Negotiate Beyond Price: Engage suppliers on payment terms, warranty periods, volume discounts, and bundled shipping to optimize total cost of ownership (TCO).

- Factor in Total Cost of Ownership: Consider installation costs, potential maintenance, and energy efficiency benefits. Higher upfront costs may be justified by longer lifespan and lower energy consumption in marine environments.

- Request Samples and Pilot Runs: Validate product quality and compatibility before committing to large volumes, especially when dealing with new suppliers or unfamiliar markets.

- Leverage Local Partners or Distributors: In markets like Italy or Colombia, working with local agents can reduce logistics complexity and provide better after-sales support.

- Understand Currency and Tax Implications: Fluctuating exchange rates, import duties, and VAT can impact final costs. Planning purchases during favorable currency conditions or utilizing trade agreements can improve pricing.

- Consider Lead Times and Shipping Options: Longer lead times might reduce unit costs but delay projects. Balance cost savings against project timelines to avoid costly delays.

Indicative Pricing Disclaimer

Prices for marine LED light strips vary widely based on specifications, supplier, and order volume. Typical FOB prices can range from $3 to $15 per meter, depending on quality and features. Buyers should treat these figures as indicative and conduct thorough supplier comparisons to obtain accurate quotes tailored to their specific requirements.

By carefully analyzing these cost components and price influencers, international B2B buyers can make informed decisions, optimize procurement strategies, and secure competitive pricing for marine LED light strips that meet both quality and budget expectations.

Spotlight on Potential marine led light strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘marine led light strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for marine led light strips

Critical Technical Properties of Marine LED Light Strips

1. IP Rating (Ingress Protection)

The IP rating indicates the level of protection the LED strip has against dust and water. Marine environments are harsh, with exposure to saltwater, humidity, and spray, so an IP65 rating or higher (commonly IP67 or IP68) is essential. For B2B buyers, selecting strips with appropriate IP ratings ensures longevity and reduces maintenance costs, especially for vessels or installations exposed to direct water contact.

2. Material Grade and Corrosion Resistance

Marine LED strips often feature components made from high-grade, corrosion-resistant materials such as marine-grade silicone or PVC coatings and stainless steel connectors. This prevents degradation caused by saltwater and UV exposure. Prioritizing these materials is vital for buyers in coastal or tropical regions like Africa, the Middle East, and South America, where corrosion risks are elevated.

3. Operating Voltage and Power Consumption

Typical marine LED strips operate at 12V or 24V DC to integrate seamlessly with boat electrical systems. Power consumption, measured in watts per meter, affects energy efficiency and battery life on marine vessels. Understanding these specs helps buyers optimize energy use and ensure compatibility with onboard power supplies.

4. Lumens Output and Color Temperature

Lumens measure brightness, and color temperature (in Kelvins) defines the light’s hue (warm to cool). Marine applications often require bright, cool white LEDs (around 5000K–6500K) for visibility and safety, or customizable RGB options for ambiance. Accurate specification helps buyers meet functional and aesthetic requirements.

5. Flexibility and Cut-Ability

Marine LED strips should be flexible enough to fit curved surfaces and allow cutting at designated points without damaging the circuit. This flexibility reduces installation complexity and waste, which is a crucial consideration for large projects or custom designs in diverse markets.

6. Lifespan and Warranty

A long operational life (typically 30,000 to 50,000 hours) ensures lower replacement frequency and cost savings. Reliable warranties from suppliers protect buyers against premature failures, a key factor when sourcing from international manufacturers.

Key Trade Terminology for Marine LED Light Strip Buyers

OEM (Original Equipment Manufacturer)

Refers to products made by one company but branded and sold by another. For B2B buyers, OEM agreements enable customization and private labeling, helping businesses in Europe or South America establish unique offerings without investing in production facilities.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ is crucial for budgeting and inventory planning, especially for startups or distributors in emerging markets like Africa or the Middle East where capital and storage space may be limited.

RFQ (Request for Quotation)

A formal document or inquiry sent to suppliers to obtain pricing, lead times, and terms for specific products. Using RFQs allows buyers to compare offers transparently and negotiate better terms, essential for managing costs in large-scale marine projects.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller (e.g., FOB, CIF, DDP). Knowing Incoterms helps B2B buyers from different continents clarify logistics, reduce disputes, and control landed costs.

IP Rating (Ingress Protection)

While also a technical property, IP rating is frequently used as a trade term to specify product suitability for marine conditions. Buyers should explicitly confirm this rating in contracts to ensure compliance with environmental requirements.

Lead Time

The period between order placement and product delivery. Understanding supplier lead times is vital for project scheduling and avoiding costly delays, especially for international shipments to ports in Italy, Colombia, or Dubai.

By mastering these technical properties and trade terms, international B2B buyers can make informed procurement decisions that optimize product performance, cost-efficiency, and supply chain reliability in the marine LED lighting sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the marine led light strips Sector

Market Overview & Key Trends

The marine LED light strips market is experiencing robust growth driven by increasing demand for energy-efficient, durable, and customizable lighting solutions in the maritime and recreational boating sectors. Globally, this growth is propelled by rising investments in luxury yachts, commercial vessels, and offshore infrastructure, alongside a growing trend for enhanced onboard aesthetics and safety. For B2B buyers in Africa, South America, the Middle East, and Europe—regions with expanding maritime activities and recreational boating cultures—this presents significant opportunities to source advanced lighting technologies that meet stringent marine standards.

Key market dynamics include a strong shift towards waterproof and corrosion-resistant LED strips, designed to withstand harsh marine environments. Suppliers are innovating with flexible form factors and IP68-rated products that ensure longevity and reliability in saltwater conditions. Additionally, smart LED technologies integrating app control, dimming capabilities, and color customization are gaining traction, especially in European markets like Italy where design and user experience are paramount.

From a sourcing perspective, buyers increasingly prioritize suppliers offering customization options for length, color temperature, and packaging to align with specific vessel designs or branding. Bulk purchasing remains prevalent for large-scale projects, such as outfitting commercial fleets or marina developments, with suppliers providing competitive pricing tiers and streamlined logistics. In regions like Colombia and parts of the Middle East, emerging marine tourism and coastal development projects are driving demand for cost-effective yet high-quality lighting solutions.

Furthermore, international trade conditions, including import tariffs and shipping logistics, influence procurement strategies. Buyers benefit from partnering with suppliers who can offer direct-from-manufacturer shipping and local warehousing options to reduce lead times and costs. Staying abreast of evolving marine certification standards, such as UL and CE marks, is critical for compliance and market acceptance in diverse regulatory environments.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration for B2B buyers in the marine LED light strip sector, reflecting broader global trends towards environmental responsibility. The marine industry’s unique environmental challenges—such as marine pollution and energy consumption—make sourcing eco-friendly lighting solutions a strategic priority. LED technology inherently offers energy efficiency, consuming significantly less power than traditional lighting, thereby reducing carbon footprints for vessels and offshore installations.

Ethical sourcing extends beyond environmental impact, encompassing responsible supply chain management and social compliance. Buyers are increasingly scrutinizing suppliers for adherence to fair labor practices and the use of conflict-free raw materials, especially in regions where supply chains may intersect with sensitive geopolitical areas. Certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are essential indicators of product safety and sustainability compliance.

Marine LED strips utilizing recyclable materials and low-toxicity components further appeal to buyers committed to green procurement policies. Some advanced manufacturers are adopting eco-design principles, minimizing packaging waste and optimizing product lifespan through modular designs that facilitate repair and upgrade rather than replacement. For B2B buyers in Europe, especially Italy, and environmentally conscious markets in South America, these sustainability credentials can be decisive factors in supplier selection.

Engaging with suppliers who demonstrate transparency in their environmental impact assessments and who participate in initiatives like the Global Reporting Initiative (GRI) or carbon neutrality programs strengthens buyer confidence and supports corporate sustainability goals. Ultimately, prioritizing sustainable marine LED lighting solutions not only aligns with global regulatory trends but also enhances brand reputation and long-term cost efficiency.

Brief Evolution and Industry Context

The marine LED light strip sector has evolved significantly over the past two decades, transitioning from basic, low-durability lighting to sophisticated, marine-grade illumination solutions. Early marine lighting relied heavily on incandescent or halogen bulbs, which were energy-intensive and prone to damage in marine environments. The advent of LED technology introduced a paradigm shift, offering enhanced energy efficiency, longer lifespan, and superior resistance to vibration and moisture.

Initially, marine LED strips were simple single-color lights used primarily for functional illumination. Over time, innovation led to the development of multi-color RGB LED strips, programmable lighting effects, and integration with vessel control systems. This evolution has enabled marine LED strips to serve both aesthetic and safety functions, from underwater accent lighting to deck illumination and navigation aids.

For B2B buyers, understanding this evolution underscores the importance of sourcing from suppliers who invest in continuous product development and compliance with maritime safety standards. The sector’s trajectory highlights a clear trend towards customization, durability, and smart technology integration, all of which are critical for meeting the complex demands of modern marine applications.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of marine led light strips

-

How can I effectively vet suppliers of marine LED light strips for international B2B purchases?

Thorough supplier vetting is crucial to ensure product quality and reliability. Start by verifying the supplier’s business registration, years in operation, and reputation through industry references or trade platforms like Alibaba or Global Sources. Request detailed product specifications, certifications (e.g., IP68 for waterproofing, marine-grade standards), and samples to evaluate quality firsthand. Assess their after-sales support and warranty policies. Additionally, check for compliance with international shipping and export regulations, especially if importing to regions like Africa, South America, or Europe. Engaging in video calls or factory visits (virtual or in-person) can further confirm legitimacy. -

What customization options are typically available for marine LED light strips, and how should I approach these requests?

Customization is common in marine LED strip supply, including options for length, color temperature, waterproofing level, and packaging branding. Many suppliers offer custom cutting and specific IP ratings suitable for harsh marine environments. When requesting customization, provide clear technical requirements and intended applications to avoid miscommunication. It’s advisable to negotiate minimum order quantities (MOQs) for custom runs upfront, as these are often higher than standard products. Confirm lead times and ensure prototypes or samples are approved before full production to minimize costly errors. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders of marine LED strips?

MOQs vary widely depending on supplier capacity and customization but typically range from 100 to 500 meters per order for standard strips. Lead times can span from 2 to 6 weeks, influenced by order size, customization, and shipping method. Payment terms often include a 30-50% deposit upfront with balance on delivery or letter of credit arrangements for large orders. For buyers in Africa, South America, the Middle East, and Europe, negotiating flexible payment options and staggered shipments can reduce risk and improve cash flow. -

Which quality assurance certifications should international buyers look for when sourcing marine LED light strips?

Key certifications include IP68 or higher for waterproof and dustproof assurance, CE marking for compliance with European safety standards, RoHS for hazardous substances, and UL or ETL for electrical safety. For marine applications, certifications from recognized maritime authorities or compliance with ISO 9001 quality management systems strengthen supplier credibility. Buyers should request test reports or certification copies and consider third-party inspections to verify compliance before finalizing large orders. -

How can I optimize logistics and shipping for marine LED light strips across continents like Africa, South America, and Europe?

Choosing suppliers with experience in international shipping is essential. Opt for consolidated shipments to reduce freight costs and customs complexities. Understand import duties, VAT, and marine product-specific regulations in your country to avoid delays. Use reliable freight forwarders familiar with your region and consider Incoterms carefully—preferably FOB or CIF to clarify responsibility. Track shipments actively and prepare for potential customs documentation requirements, including certificates of origin and conformity. Building strong communication channels with suppliers and logistics partners ensures timely delivery. -

What steps can I take to mitigate risks related to product disputes or defects in international marine LED light strip orders?

Mitigation begins with clear contracts outlining product specifications, quality standards, delivery timelines, and dispute resolution mechanisms. Insist on pre-shipment quality inspections or third-party audits. Keep detailed records of communications and product samples. Establish warranty terms specifying remedies for defective goods, including replacements or refunds. In case of disputes, leverage trade insurance, involve mediation services, or use international arbitration clauses. Promptly reporting defects with photographic evidence facilitates faster resolution and maintains supplier relationships. -

Are there specific considerations for sourcing marine LED strips in regions with harsh environments like the Middle East or coastal Africa?

Yes, environmental factors such as high salinity, extreme temperatures, and UV exposure necessitate selecting LED strips with superior waterproofing (IP68+), corrosion-resistant materials, and UV-stable coatings. Confirm that suppliers use marine-grade silicone or polyurethane coatings and robust connectors. Additionally, verify performance longevity under local climate conditions through testing data or references. For regions with intermittent power supply, consider LED strips with built-in surge protection or voltage regulation. Tailoring products to local conditions reduces maintenance costs and extends service life. -

How can international B2B buyers leverage bulk purchasing of marine LED light strips to maximize cost efficiency?

Bulk buying significantly reduces per-unit costs and shipping fees. To maximize savings, consolidate orders across multiple projects or business units. Negotiate volume discounts and flexible payment terms with suppliers. Explore options for standardized product runs to avoid customization surcharges. Consider long-term partnerships with manufacturers for preferential pricing and priority production slots. Additionally, coordinate logistics to optimize container usage and minimize customs fees. Bulk procurement also allows access to newer technologies or exclusive product lines, providing competitive advantages in your regional markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for marine led light strips

In conclusion, sourcing marine LED light strips strategically is essential for international B2B buyers aiming to optimize cost-efficiency, product quality, and supply chain reliability. Key takeaways include prioritizing suppliers with proven marine-grade certifications, ensuring waterproof and corrosion-resistant features, and leveraging bulk purchasing to benefit from competitive pricing and customization options. Buyers from Africa, South America, the Middle East, and Europe should also consider logistics factors such as shipping times, import regulations, and supplier support to minimize delays and maintain project timelines.

Strategic sourcing enables businesses to:

- Secure durable, high-performance LED strips tailored for harsh marine environments

- Access the latest innovations in LED technology to differentiate their offerings

- Scale procurement efficiently for diverse applications, from commercial vessels to luxury yachts

- Build strong supplier relationships that facilitate ongoing technical support and warranty coverage

Looking ahead, the marine LED lighting market continues to evolve with advances in energy efficiency, smart controls, and sustainable materials. International buyers are encouraged to engage proactively with reputable manufacturers and distributors who prioritize innovation and compliance with global maritime standards. By adopting a forward-thinking sourcing approach, businesses in regions such as Italy, Colombia, and beyond can confidently enhance their product portfolios, meet growing demand, and drive sustainable growth in the marine sector.