Guide to Led Strips For Outdoors

- Introduction: Navigating the Global Market for led strips for outdoors

- Understanding led strips for outdoors Types and Variations

- Key Industrial Applications of led strips for outdoors

- Strategic Material Selection Guide for led strips for outdoors

- In-depth Look: Manufacturing Processes and Quality Assurance for led strips for outdoors

- Manufacturing Processes for Outdoor LED Strips

- Quality Assurance and Control (QC) in Outdoor LED Strip Production

- Comprehensive Cost and Pricing Analysis for led strips for outdoors Sourcing

- Spotlight on Potential led strips for outdoors Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strips for outdoors

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strips for outdoors Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strips for outdoors

- Strategic Sourcing Conclusion and Outlook for led strips for outdoors

Introduction: Navigating the Global Market for led strips for outdoors

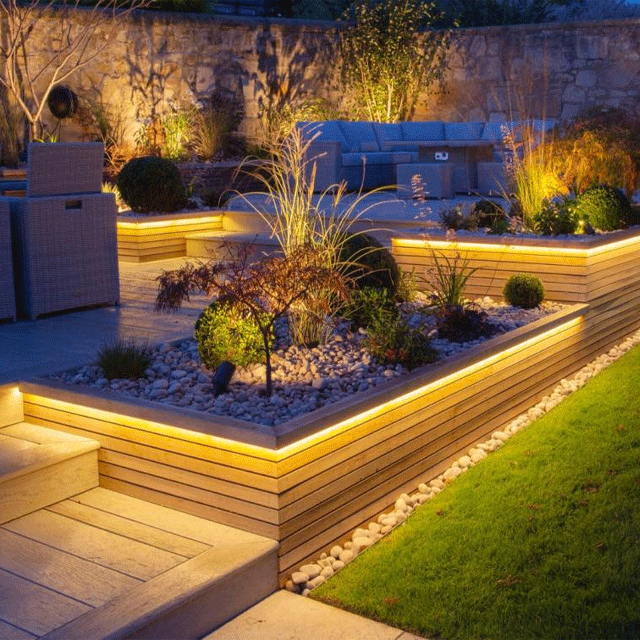

In today’s rapidly evolving global marketplace, outdoor LED strip lighting stands out as a transformative solution for businesses seeking energy-efficient, durable, and versatile illumination. For B2B buyers across Africa, South America, the Middle East, and Europe—including dynamic markets like Thailand and Colombia—the ability to source high-quality LED strips tailored for outdoor environments is critical to meeting diverse commercial, industrial, and architectural needs. These lighting systems not only enhance aesthetic appeal but also improve safety, reduce energy costs, and support sustainable business operations.

This comprehensive guide is designed to empower international buyers with deep insights into the outdoor LED strip market. It covers essential topics such as the various types of LED strips available, key materials and waterproofing standards, manufacturing processes, quality control benchmarks, and how to evaluate and select reliable suppliers. Additionally, it breaks down cost structures and market trends to help businesses optimize their investment and forecast demand accurately.

By navigating through this guide, buyers will gain practical knowledge on how to identify products that combine longevity, performance, and customization—factors that are particularly crucial when sourcing for challenging outdoor conditions. Whether outfitting retail exteriors, industrial facilities, hospitality venues, or public spaces, this resource equips procurement professionals with the tools to make informed, strategic decisions that align with their operational goals and regional market requirements.

Unlock the potential of outdoor LED strip lighting with confidence and precision—your gateway to innovative, cost-effective, and scalable illumination solutions worldwide.

Understanding led strips for outdoors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof LED Strips | High IP rating (IP65 to IP68), sealed with silicone or epoxy | Outdoor signage, architectural lighting, landscaping | Pros: Durable in harsh weather, versatile; Cons: Slightly higher cost, requires proper installation |

| RGB & RGBW LED Strips | Multi-color LEDs with color-changing capability, often remote-controlled | Hospitality, retail facades, event venues | Pros: Dynamic lighting, customizable ambiance; Cons: More complex control systems, higher power consumption |

| High Brightness LED Strips | Enhanced lumen output, often with wider LED spacing or high-power LEDs | Industrial outdoor areas, security lighting | Pros: Strong illumination for safety and visibility; Cons: Higher energy use, may require heat dissipation measures |

| Flexible LED Neon Strips | Silicone-encased flexible strips mimicking neon lighting | Outdoor advertising, decorative outlines | Pros: Aesthetic appeal, flexible design; Cons: More expensive than standard strips, less bright than traditional neon |

| Solar-Powered LED Strips | Integrated solar panel and battery for off-grid outdoor use | Remote locations, garden lighting, street furniture | Pros: Energy independent, eco-friendly; Cons: Dependent on sunlight, limited brightness and runtime |

Waterproof LED Strips

These strips come with a high Ingress Protection (IP) rating, typically IP65 to IP68, making them resistant to water, dust, and harsh weather conditions. They are encased in silicone or epoxy to protect the LEDs and circuitry. Ideal for outdoor signage, garden lighting, and architectural features, waterproof strips ensure longevity and reliability. For B2B buyers, it’s critical to verify the IP rating matches the environmental conditions and to ensure proper installation to maintain waterproof integrity.

RGB & RGBW LED Strips

Featuring multi-color LEDs capable of producing millions of colors, these strips are popular in hospitality, retail, and event settings where dynamic lighting enhances customer experience. RGBW adds a dedicated white LED for better color rendering and brightness. Buyers should consider the complexity of control systems and power requirements, as well as ensuring compatibility with existing smart lighting infrastructure to maximize flexibility and energy efficiency.

High Brightness LED Strips

Designed for environments requiring strong illumination, these strips use high-power LEDs or wider LED spacing to boost brightness. Common in industrial outdoor areas and security lighting, they improve visibility and safety. Buyers must weigh the increased energy consumption and possible need for heat dissipation solutions against the benefits of enhanced illumination, especially in large-scale or high-demand installations.

Flexible LED Neon Strips

These strips mimic the look of traditional neon lights but offer greater flexibility and durability. Encased in silicone, they are weather-resistant and ideal for outdoor advertising and decorative outlines. While more expensive than standard LED strips, their aesthetic appeal and design versatility make them attractive for premium branding projects. B2B buyers should assess the cost-to-impact ratio and ensure supplier quality for consistent color and brightness.

Solar-Powered LED Strips

Equipped with integrated solar panels and rechargeable batteries, these strips are perfect for off-grid applications such as remote signage, garden lighting, and street furniture in regions with inconsistent power infrastructure. They offer energy independence and eco-friendliness but have limitations in brightness and operational hours due to solar reliance. Buyers in Africa, South America, and the Middle East should evaluate local sunlight availability and maintenance logistics before procurement.

Related Video: Introduction to Fire Behavior Fuel Models

Key Industrial Applications of led strips for outdoors

| Industry/Sector | Specific Application of led strips for outdoors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Tourism | Outdoor ambiance lighting for hotels, resorts, and restaurants | Enhances guest experience and brand image with dynamic, weather-resistant lighting | Waterproof rating (IP65+), color customization, energy efficiency, durability |

| Retail & Commercial | Exterior storefront and signage illumination | Increases visibility and attractiveness to customers, driving foot traffic | Brightness levels, UV resistance, ease of installation, long lifespan |

| Urban Infrastructure | Street furniture and public space lighting | Improves safety and aesthetics in public areas while reducing energy costs | Compliance with local regulations, vandal-proof design, energy efficiency |

| Industrial Facilities | Perimeter and safety zone lighting | Enhances security and operational safety in harsh outdoor environments | High IP rating, robust materials, compatibility with industrial power sources |

| Event Management | Temporary outdoor event lighting and decorative installations | Flexible, easy-to-install lighting solutions that support brand activation and event themes | Portability, quick installation, customizable colors and effects |

Hospitality & Tourism

Outdoor LED strips are extensively used in hotels, resorts, and restaurants to create inviting and memorable atmospheres. These strips illuminate patios, walkways, pools, and building facades, enabling businesses to enhance guest experience with vibrant, customizable lighting effects. For B2B buyers in regions like Africa and South America, sourcing waterproof and UV-resistant LED strips is critical due to tropical climates and intense sun exposure. Energy efficiency and long lifespan are also key to reducing operational costs in these often energy-sensitive markets.

Retail & Commercial

Retailers leverage outdoor LED strips for storefront lighting, window displays, and signage backlighting to boost visibility and attract customers. In competitive markets across the Middle East and Europe, high-brightness and color-stable LED strips help stores stand out during day and night. International buyers should prioritize products with strong UV protection and durable casings to withstand diverse weather conditions, from intense sun to rain, ensuring consistent performance and minimal maintenance.

Urban Infrastructure

City planners and municipalities use outdoor LED strips to light street furniture, benches, bus stops, and public squares. This lighting improves public safety and urban aesthetics while lowering energy consumption compared to conventional lighting. Buyers from emerging urban centers in Africa and South America must ensure compliance with local electrical standards and focus on vandal-resistant designs to maintain longevity in public spaces. Energy-efficient options also align with sustainability goals increasingly prioritized worldwide.

Industrial Facilities

Outdoor LED strips serve a vital role in illuminating perimeters, loading docks, and hazardous zones in factories, warehouses, and oil & gas sites. They enhance security and operational safety by providing reliable lighting under harsh conditions such as dust, moisture, and temperature extremes. For buyers in the Middle East or Europe, sourcing LED strips with high IP ratings and robust industrial-grade materials is essential. Compatibility with existing power infrastructure and certifications for industrial use should also be carefully evaluated.

Event Management

The event industry benefits from flexible, portable outdoor LED strips for lighting stages, tents, and decorative installations at festivals, exhibitions, and corporate events. Their quick installation and color customization allow event organizers to tailor lighting effects to branding and themes, enhancing attendee engagement. Buyers in diverse markets like Thailand or Colombia should focus on products that combine ease of transport with weatherproofing and remote control capabilities to maximize operational efficiency and visual impact.

Related Video: Watch This Before Using LED Strips!

Strategic Material Selection Guide for led strips for outdoors

When selecting materials for LED strips designed for outdoor use, international B2B buyers must carefully consider the environmental conditions, durability requirements, and regulatory standards specific to their regions. The choice of material directly impacts the product’s lifespan, performance under harsh weather, and compliance with international norms, which vary across Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in outdoor LED strip manufacturing, focusing on their properties, advantages, limitations, and regional considerations.

1. Silicone Rubber (Encapsulation and Coating)

Key Properties:

Silicone rubber is highly flexible, UV-resistant, and maintains elasticity over a wide temperature range (-60°C to 230°C). It offers excellent waterproofing (commonly IP67 to IP68 ratings) and strong resistance to ozone, salt spray, and environmental pollutants.

Pros & Cons:

– Pros: Exceptional weatherproofing and durability against UV degradation and extreme temperatures. It also provides good electrical insulation and flexibility for curved or irregular surfaces.

– Cons: Higher material and processing costs compared to simpler plastics; manufacturing complexity increases due to curing processes. Silicone coatings can be less abrasion-resistant than harder plastics.

Impact on Application:

Ideal for outdoor LED strips in coastal or desert regions where UV exposure and salt corrosion are severe, such as parts of the Middle East and coastal Africa. Its flexibility suits architectural lighting requiring bends and curves.

Regional Considerations:

Buyers in Europe and South America should ensure compliance with RoHS and REACH regulations concerning chemical safety. In Africa and the Middle East, silicone’s resistance to sand and heat makes it a preferred choice. ASTM D2000 standards for rubber materials are commonly referenced internationally.

2. Polyurethane (PU) Coating

Key Properties:

Polyurethane coatings provide robust mechanical protection, good chemical resistance, and moderate UV stability. They typically withstand temperatures from -40°C to 90°C and offer waterproofing up to IP65 to IP67.

Pros & Cons:

– Pros: Cost-effective compared to silicone, excellent abrasion resistance, and good adhesion to flexible PCBs.

– Cons: Less UV resistant than silicone, leading to potential yellowing or degradation over prolonged sun exposure. Moderate flexibility but can become brittle in very cold climates.

Impact on Application:

Suitable for outdoor LED strips in temperate climates or shaded areas where UV exposure is limited. Commonly used in commercial outdoor signage and retail lighting in Europe and parts of South America.

Regional Considerations:

European buyers should verify compliance with EN ISO 2812 for paint and coating durability. In regions like Thailand and Colombia, where humidity is high, polyurethane’s moisture resistance is beneficial but may require additional UV stabilizers for longevity.

3. Polyvinyl Chloride (PVC) Housing

Key Properties:

PVC is a rigid or flexible plastic widely used for LED strip housing and insulation. It offers moderate UV resistance and chemical resistance, with temperature tolerance generally between -20°C and 60°C.

Pros & Cons:

– Pros: Low cost, easy to manufacture, and widely available. Good electrical insulation properties and flame retardancy can be enhanced with additives.

– Cons: Limited temperature range and UV resistance, leading to brittleness and cracking under prolonged outdoor exposure unless specially treated. Environmental concerns over plasticizers and chlorine content.

Impact on Application:

Best suited for budget-sensitive projects in mild climates or where LED strips are protected by additional fixtures. Common in indoor-outdoor transitional spaces or temporary outdoor installations.

Regional Considerations:

Buyers in Europe must consider stringent environmental regulations (e.g., REACH) limiting certain plasticizers. In Africa and South America, cost advantages are significant, but buyers should assess local climate impact on PVC longevity.

4. Aluminum Alloy (Rigid Backing and Heat Dissipation)

Key Properties:

Aluminum alloys are used primarily for the backing or mounting channels of outdoor LED strips. They offer excellent thermal conductivity, corrosion resistance (especially anodized finishes), and mechanical strength. Temperature tolerance ranges from -40°C to 150°C.

Pros & Cons:

– Pros: Enhances heat dissipation, prolonging LED lifespan. Provides structural rigidity and excellent corrosion resistance with anodizing or powder coating.

– Cons: Adds weight and cost; requires precise manufacturing processes. Not flexible, limiting use to straight or gently curved installations.

Impact on Application:

Ideal for high-performance outdoor LED installations requiring robust heat management, such as stadium lighting, large-scale architectural facades, and industrial facilities in hot climates like the Middle East and parts of Africa.

Regional Considerations:

International standards such as ASTM B221 (aluminum extrusion) and DIN EN 573 (aluminum alloys) are relevant. European buyers often require compliance with RoHS and WEEE directives for electronic components. Aluminum’s recyclability is a plus in environmentally conscious markets.

Summary Table

| Material | Typical Use Case for led strips for outdoors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Flexible, waterproof LED strips for harsh UV and salt exposure | Superior UV and temperature resistance; high flexibility | Higher cost and manufacturing complexity | High |

| Polyurethane (PU) | Protective coating for outdoor retail and commercial lighting | Good abrasion resistance; cost-effective | Moderate UV resistance; can yellow over time | Medium |

| Polyvinyl Chloride (PVC) | Budget LED strip housings in mild outdoor environments | Low cost; easy to produce | Limited UV and temperature tolerance; brittle | Low |

| Aluminum Alloy | Rigid backing and heat dissipation for industrial/architectural lighting | Excellent heat dissipation and corrosion resistance | Not flexible; higher cost and weight | Medium to High |

This guide empowers international B2B buyers to align material selection with environmental challenges, regulatory frameworks, and project budgets, ensuring optimal performance and compliance for outdoor LED strip applications worldwide.

In-depth Look: Manufacturing Processes and Quality Assurance for led strips for outdoors

Manufacturing Processes for Outdoor LED Strips

Producing high-quality LED strips suitable for outdoor applications involves a carefully controlled series of manufacturing stages. Each phase ensures the product meets durability, performance, and safety requirements essential for harsh environmental conditions.

1. Material Preparation

- Selection of Components: The process begins with sourcing premium materials including flexible printed circuit boards (PCBs), high-efficiency LEDs (commonly SMD types like 3528, 5050), resistors, and waterproof encapsulation materials such as silicone or epoxy resin.

- Waterproofing Materials: For outdoor LED strips, materials must meet specific IP ratings (IP65, IP67, or IP68) to withstand moisture, dust, and temperature fluctuations.

- Raw Material Inspection: Incoming quality control (IQC) validates that all raw components comply with specifications, focusing on PCB flexibility, LED brightness and color consistency, and waterproof compound quality.

2. Forming and Circuit Assembly

- PCB Fabrication: Flexible PCBs are manufactured with copper traces designed to ensure consistent current flow and heat dissipation. High-quality copper thickness and substrate flexibility are critical for outdoor resilience.

- LED Mounting: LEDs and other components are surface-mounted onto the PCB using automated pick-and-place machines followed by soldering, typically via reflow soldering for precise and reliable connections.

- Waterproof Coating Application: After assembly, strips are coated with waterproof layers—silicone tubes or liquid coatings—curing to form a protective barrier without compromising flexibility.

- Cutting and Connector Attachment: The strips are cut into standard or customized lengths, and connectors or cables are attached, ensuring secure electrical connections and ease of installation.

3. Finishing Processes

- Encapsulation and Sealing: Additional sealing methods, including end caps and sealing adhesives, are applied to enhance water resistance, especially at connection points.

- Packaging: LED strips are carefully packaged to prevent damage during shipping, often including anti-static bags and moisture-proof wrapping, essential for maintaining product integrity in long international transit.

Quality Assurance and Control (QC) in Outdoor LED Strip Production

Maintaining stringent quality control throughout production is vital for ensuring product reliability, safety, and regulatory compliance. For international B2B buyers, understanding these processes and standards helps in evaluating suppliers effectively.

Key International and Industry Standards

- ISO 9001: This is the global benchmark for quality management systems. Suppliers adhering to ISO 9001 demonstrate consistent manufacturing processes and a commitment to continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, CE certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electronic products, critical for buyers in Europe and increasingly required worldwide.

- IP Ratings (Ingress Protection): IP65, IP67, and IP68 ratings indicate the level of waterproofing and dust resistance, essential for outdoor LED strips.

- UL Certification: Particularly important for North American markets, UL marks ensure electrical safety and performance.

- Other Regional Certifications: Depending on the target market, certifications such as BIS (India), SAA (Australia), or local Middle Eastern standards may apply.

QC Checkpoints During Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials and components before production. This includes LED binning to ensure uniform brightness and color temperature.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, such as solder joint inspection, LED placement accuracy, and waterproof coating uniformity.

- Final Quality Control (FQC): Comprehensive testing of finished LED strips, including visual inspections, electrical tests, and waterproof integrity verification.

Common Testing Methods

- Electrical Testing: Measures voltage, current, and power consumption to confirm compliance with specifications and detect defective units.

- Light Output and Color Consistency: Spectrophotometers assess brightness and color temperature to ensure uniformity across batches.

- Waterproof Testing: Methods like water immersion, spray testing, and humidity exposure simulate outdoor conditions to validate IP ratings.

- Thermal Testing: Evaluates heat dissipation and operating temperature ranges to prevent premature failure.

- Mechanical Flexibility Testing: Ensures that the LED strips maintain performance after bending or twisting, crucial for installation on irregular outdoor surfaces.

- Aging Tests: Long-duration operation under controlled conditions checks for degradation in brightness or color shift.

How B2B Buyers Can Verify Supplier QC

- Supplier Audits: On-site factory audits allow buyers to evaluate manufacturing processes, worker training, and QC protocols firsthand. For international buyers, third-party audit firms can perform inspections if travel is impractical.

- Review of QC Documentation: Request detailed quality reports including IQC, IPQC, and FQC records, test certificates, and batch traceability documentation.

- Third-Party Testing and Certification: Independent labs can verify compliance with international standards, providing unbiased test reports. This is particularly important for buyers in Africa, South America, the Middle East, and Europe, where import regulations may require recognized certifications.

- Sample Evaluation: Prior to large orders, buyers should obtain product samples for in-house testing under their specific environmental and operational conditions.

- Warranty and After-Sales Support: Confirm the supplier’s warranty terms and availability of technical support, which reflect confidence in product quality and responsiveness to issues.

QC and Certification Nuances for International B2B Buyers

- Regional Regulatory Variations: Buyers from regions such as Africa, South America, and the Middle East should verify that products meet both international standards and any additional local regulations. For example, some countries require product registration or additional safety markings.

- Shipping and Handling Considerations: Extended transit times and varying climates mean packaging and waterproofing must be robust to prevent damage before installation.

- Language and Documentation: Ensure all QC documentation, certificates, and user manuals are available in the buyer’s preferred language to avoid misunderstandings.

- Customs and Import Compliance: Proper certification expedites customs clearance. Buyers should confirm that suppliers provide all necessary paperwork, including CE, RoHS, and test reports.

- Supplier Stability and Transparency: In emerging markets like Thailand or Colombia, choosing suppliers with transparent QC processes and stable production capabilities reduces risk in long-term supply agreements.

For international B2B buyers targeting outdoor LED strips, a clear understanding of manufacturing processes and rigorous quality assurance is essential. Prioritizing suppliers who implement robust QC systems and hold internationally recognized certifications will ensure product durability, regulatory compliance, and ultimately, customer satisfaction in diverse and challenging outdoor environments.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strips for outdoors Sourcing

Understanding the cost and pricing dynamics of outdoor LED strips is essential for international B2B buyers aiming to optimize procurement strategies and ensure cost-effective investments. This analysis breaks down the primary cost components, key price influencers, and practical buyer insights tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Outdoor LED Strip Manufacturing

-

Materials: The core cost driver, encompassing LED chips (SMD types such as 2835, 5050), flexible PCB substrates, waterproof coatings (usually silicone or epoxy for IP65/IP67 ratings), connectors, and protective housings. High-quality raw materials increase durability and performance, especially critical for outdoor use where weather resistance is mandatory.

-

Labor: Assembly labor costs vary significantly depending on the manufacturing location. Countries with advanced automation may have lower labor costs relative to manual assembly hubs. Labor also includes quality inspection and packaging operations.

-

Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with streamlined workflows and modern machinery can reduce overhead, impacting final pricing.

-

Tooling and Setup: Initial costs for producing molds, stencils, and assembly jigs. These are amortized over production volumes but can increase unit costs for small orders or customized designs.

-

Quality Control (QC): Testing for brightness, waterproofing, voltage stability, and longevity adds to costs but ensures product reliability, a non-negotiable for outdoor applications.

-

Logistics and Shipping: Freight costs depend on shipping modes (air, sea, road), distance, and packaging. For international buyers, customs duties, taxes, and local handling fees also contribute to total landed cost.

-

Supplier Margin: Reflects the profit markup by manufacturers or distributors. Margins vary by supplier reputation, product exclusivity, and market demand.

Influencers on Pricing for Outdoor LED Strips

-

Order Volume and Minimum Order Quantity (MOQ): Higher volumes typically unlock lower per-unit prices due to economies of scale. Buyers from emerging markets such as Colombia or South Africa should negotiate MOQs that align with their project scale to avoid excess inventory costs.

-

Product Specifications and Customization: Features like waterproof ratings (IP65, IP67, IP68), RGB or tunable white LEDs, dimming capabilities, and custom lengths or packaging increase complexity and cost. Custom branding or packaging further elevates pricing.

-

Material Quality and Certifications: Compliance with international standards (CE, RoHS, UL) assures safety and durability but may increase costs. Buyers prioritizing certified products gain long-term reliability, particularly important for outdoor installations exposed to harsh environments.

-

Supplier Reliability and Location: Established suppliers with proven track records may price higher but offer better quality assurance and after-sales support. Proximity affects shipping time and costs; sourcing closer to the buyer’s region (e.g., European buyers sourcing from EU-based suppliers) can reduce delivery times and tariffs.

-

Incoterms and Payment Terms: Terms such as FOB, CIF, or DDP influence who bears shipping and customs costs. Buyers must understand these terms to accurately calculate landed costs and negotiate favorable payment schedules to optimize cash flow.

Strategic Tips for International B2B Buyers

-

Negotiate Beyond Price: Engage suppliers on MOQ flexibility, payment terms, warranty coverage, and after-sales service. Bundling orders or committing to repeat purchases can improve bargaining power.

-

Focus on Total Cost of Ownership (TCO): Factor in installation, maintenance, energy consumption, and product lifespan. Higher upfront costs for premium, energy-efficient LED strips often yield savings over time.

-

Request Samples and Pilot Runs: Validate product quality and compatibility with your project requirements before large-scale procurement, reducing the risk of costly returns or failures.

-

Leverage Consolidated Shipping: For buyers in regions with high import duties or complex customs, consolidating shipments reduces per-unit logistics costs and simplifies clearance.

-

Understand Regional Market Nuances: For example, African buyers should consider suppliers who provide robust waterproofing due to tropical climates; Middle Eastern buyers might prioritize UV resistance. European buyers often require compliance with stringent environmental regulations.

-

Monitor Currency Fluctuations and Tariffs: International buyers should hedge against exchange rate volatility and stay updated on trade policies affecting import costs.

Indicative Pricing Disclaimer

Prices for outdoor LED strips vary widely based on quality, specifications, order volume, and supplier location. Typical wholesale prices can range from approximately $1.50 to $5.00 per meter for standard IP65 waterproof LED strips, with custom or high-spec models commanding higher rates. Buyers should treat these figures as indicative and conduct thorough supplier quotations to obtain accurate pricing tailored to their needs.

By understanding the layered cost components and actively managing price influencers, international B2B buyers can secure competitively priced, high-quality outdoor LED strips that meet their performance and budgetary requirements. Strategic sourcing combined with informed negotiation will enhance procurement outcomes across diverse global markets.

Spotlight on Potential led strips for outdoors Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strips for outdoors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strips for outdoors

Key Technical Properties for Outdoor LED Strips

When sourcing LED strips for outdoor use, understanding the critical technical properties ensures product durability, performance, and suitability for your project’s environment. Here are the essential specifications to consider:

-

IP Rating (Ingress Protection)

This rating indicates the LED strip’s resistance to dust and water. Outdoor LED strips typically require a minimum of IP65, which protects against water jets and dust ingress. Higher ratings like IP67 or IP68 provide even greater water resistance, suitable for immersion or heavy rain exposure. For B2B buyers, selecting the correct IP rating is crucial to guarantee longevity and reduce maintenance costs in harsh weather conditions. -

Material Quality and Coating

Outdoor LED strips use materials like flexible PCBs coated with silicone or epoxy resin to protect LEDs and circuits from moisture and UV damage. High-grade materials prevent corrosion and color fading over time. For businesses, investing in premium materials ensures consistent product quality, reduces returns, and supports brand reputation. -

Voltage and Power Consumption

Common outdoor LED strips operate at 12V or 24V DC, with power consumption measured in watts per meter (W/m). Lower voltage strips (12V) are easier to install but may have voltage drop over longer runs, while 24V strips handle longer distances better. Understanding voltage and power helps B2B buyers plan efficient power supplies and avoid performance issues. -

Color Temperature and Color Rendering Index (CRI)

Color temperature (measured in Kelvin) defines the light tone, from warm white (2700K) to cool white (6500K), or RGB for color-changing options. CRI indicates how accurately colors appear under the light; values above 80 are preferred for natural color rendering. Choosing the right color temperature and CRI enhances outdoor ambiance and visual appeal, important in hospitality, retail, and architectural projects. -

Durability and Operating Temperature Range

Outdoor LED strips must withstand temperature fluctuations, typically ranging from -20°C to 50°C or more. Durable construction ensures consistent performance despite heat, cold, or humidity. B2B buyers should verify operating ranges to match local climates, preventing premature failures and ensuring customer satisfaction.

Common Trade Terminology in LED Strip Procurement

Understanding industry jargon streamlines communication and negotiation with suppliers, reducing risks and improving procurement outcomes:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who manufacture LED strips that can be branded and customized by the purchasing company. OEM partnerships enable businesses to offer unique products under their own brand, enhancing market differentiation and customer loyalty. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQ affects pricing, inventory planning, and cash flow. B2B buyers from emerging markets or smaller enterprises should negotiate MOQs to balance cost savings with manageable stock levels. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms based on specified product requirements. RFQs are essential for comparing multiple vendors and securing competitive deals in international trade. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyers and sellers during shipping (e.g., FOB, CIF, EXW). Understanding Incoterms helps B2B buyers from Africa, South America, the Middle East, and Europe clarify logistics, avoid hidden costs, and plan deliveries efficiently. -

IP Rating (Ingress Protection)

Although a technical spec, it is also a key trade term used to specify the environmental protection level of the LED strips. Clarity on IP ratings in contracts ensures both parties agree on product suitability for outdoor conditions. -

Lead Time

The period between placing an order and receiving the goods. Lead times can vary significantly based on supplier location, customization, and shipping method. Accurate lead time expectations are critical for project scheduling and inventory management.

By prioritizing these technical properties and mastering key trade terms, international B2B buyers can confidently source outdoor LED strips that meet performance standards, comply with local environmental demands, and optimize procurement processes. This knowledge fosters stronger supplier relationships and ensures successful project outcomes across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strips for outdoors Sector

Market Overview & Key Trends

The global market for outdoor LED strips is experiencing robust growth driven by rising demand for energy-efficient, durable, and customizable lighting solutions. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, this sector presents significant opportunities fueled by increasing urbanization, infrastructure development, and a growing emphasis on aesthetic yet functional outdoor lighting for commercial, industrial, and public spaces. Countries like Thailand and Colombia are investing heavily in upgrading public lighting and commercial venues, boosting demand for high-quality, weather-resistant LED strip products.

Key market dynamics include a shift towards smart LED strips that integrate IoT capabilities—enabling remote control, scheduling, and dynamic color adjustments. This trend aligns with growing preferences for automation and energy management in commercial properties and public infrastructure. Additionally, waterproof and high-IP-rated LED strips are increasingly critical for outdoor environments exposed to harsh weather conditions, prompting suppliers to innovate with improved sealing and durable materials.

From a sourcing perspective, international buyers benefit from the expanding network of manufacturers and wholesale suppliers offering customization options such as tailored lengths, color temperatures, and packaging. This is especially valuable for large-scale projects requiring consistent quality and branding alignment. Buyers should also be aware of evolving supply chain considerations, including lead times and shipping logistics, which are influenced by global trade dynamics and regional import regulations.

Moreover, competitive pricing pressures and the availability of advanced technologies, like tunable white and RGB color-changing LED strips, allow buyers to differentiate their offerings in retail, hospitality, and urban development projects. The emphasis on energy efficiency remains a critical driver, as businesses seek to reduce operational costs and comply with increasingly stringent energy regulations.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a decisive factor for B2B buyers in the outdoor LED strip market. The environmental impact of lighting solutions is scrutinized, with LED strips favored for their low power consumption and extended lifespan, which significantly reduce carbon footprints compared to traditional lighting. However, sustainability extends beyond energy efficiency to include the materials used, manufacturing processes, and end-of-life recyclability.

Ethical sourcing is gaining prominence as buyers demand transparency and accountability from suppliers. This includes ensuring that components such as semiconductors, circuit boards, and packaging materials are procured from conflict-free zones and produced under fair labor conditions. Certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) serve as important benchmarks for compliance with environmental and safety standards, reducing harmful substances in LED strips.

Green certifications, including Energy Star and TÜV Rheinland, further validate product sustainability claims and are often prerequisites for public and large commercial tenders, especially in Europe and the Middle East. Buyers should prioritize suppliers who implement eco-friendly manufacturing practices, such as waste minimization, use of recyclable or biodegradable packaging, and energy-efficient production lines.

Moreover, the rise of circular economy principles encourages B2B buyers to collaborate with suppliers offering take-back programs or modular LED strip designs that facilitate easy repair or component replacement, prolonging product life and reducing electronic waste. Adopting these sustainability criteria not only supports corporate social responsibility goals but also enhances brand reputation and meets the growing expectations of environmentally conscious end-users.

Evolution of Outdoor LED Strip Technology

Outdoor LED strip lighting has evolved significantly over the past two decades. Initially, LED strips were simple, low-intensity light sources primarily used indoors. Advances in LED chip technology and materials science have transformed these strips into high-output, weatherproof lighting solutions suitable for diverse outdoor applications.

The introduction of waterproofing standards (IP65 and above) marked a turning point, enabling LED strips to withstand rain, dust, and extreme temperatures. This expanded their use into outdoor architectural lighting, landscape illumination, and public safety lighting. Concurrently, the integration of smart controls and color-changing capabilities allowed businesses to create dynamic lighting environments that adapt to time of day, events, or customer preferences.

For B2B buyers, this evolution means access to versatile, durable, and energy-efficient products that can be customized to specific project requirements. The shift from static to smart lighting solutions has also opened new avenues for energy savings and operational control, reinforcing the role of outdoor LED strips as a cornerstone in modern commercial and urban lighting strategies.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strips for outdoors

-

How can I effectively vet suppliers of outdoor LED strips for international B2B purchases?

Vet suppliers by verifying their business licenses, certifications (such as ISO or CE), and customer references, especially from your region (Africa, South America, Middle East, Europe). Request product samples to evaluate quality and durability under outdoor conditions. Assess their communication responsiveness and after-sales support. Use third-party inspection services or request factory audit reports to confirm manufacturing capabilities. Prioritize suppliers with transparent supply chains and proven export experience to your target markets, ensuring smoother transactions and compliance with local regulations. -

What customization options are typically available for outdoor LED strips in bulk orders?

Many suppliers offer customization such as waterproof ratings (IP65, IP67, IP68), color temperature variations, RGB or tunable white options, lengths, and packaging tailored to your branding. Custom PCB designs and connectors can also be arranged for specialized installations. When negotiating, clarify minimum order quantities (MOQs) for custom specs and confirm lead times. Customization enhances product suitability for specific climates or applications, which is crucial for diverse markets like humid tropical regions or desert environments.

-

What are common MOQ and lead times for international bulk orders of outdoor LED strips?

MOQs vary widely but typically range from 500 to 5,000 meters depending on customization level. Standard products often have lower MOQs. Lead times usually span 3 to 8 weeks, influenced by order complexity and supplier location. For international buyers, factor in additional time for customs clearance and shipping. Early communication with suppliers about your order schedule and flexibility can help optimize production and delivery timelines, avoiding project delays. -

Which payment terms and methods are safest and most common for international B2B LED strip transactions?

Common payment methods include wire transfers (T/T), Letter of Credit (L/C), and increasingly, escrow services. Many reputable suppliers request a 30%-50% deposit upfront with balance paid upon shipment or receipt. For new suppliers, L/C or escrow reduce risk by ensuring payment only after meeting contract terms. Negotiate clear payment milestones and confirm currency exchange implications, especially when dealing with emerging market currencies. Always document payment terms in contracts to safeguard your transaction. -

What quality assurance measures and certifications should I look for in outdoor LED strips?

Ensure LED strips have IP ratings suitable for outdoor use (minimum IP65 for splash resistance, IP67/IP68 for immersion). Look for certifications such as CE, RoHS, UL, or ETL, which indicate compliance with international safety and environmental standards. Ask suppliers about their internal quality control protocols, including testing for brightness consistency, waterproof sealing, and longevity (e.g., 50,000+ hours). Request batch test reports and consider third-party lab testing for critical projects to guarantee product reliability. -

How can I optimize logistics and shipping when ordering outdoor LED strips internationally?

Consolidate shipments to reduce per-unit freight costs and leverage bulk shipping discounts. Choose suppliers with experience exporting to your region and who can handle customs documentation accurately. Consider freight forwarders or third-party logistics providers familiar with local import regulations. Air freight suits urgent orders but is costlier; sea freight is economical for large volumes but slower. Verify packaging robustness to protect strips during transit, especially for long journeys to regions with challenging infrastructure.

Illustrative Image (Source: Google Search)

-

What steps should I take if I encounter disputes or quality issues with my LED strip supplier?

First, document all issues with photos, videos, and detailed descriptions. Refer to your purchase contract’s warranty and return policies. Communicate promptly and professionally with the supplier to seek resolution, such as replacement, refund, or discount. If unresolved, use mediation or arbitration clauses if included in your contract. For high-value disputes, consider legal counsel familiar with international trade law. Maintaining clear records and contracts upfront helps protect your interests in such cases. -

Are there specific considerations for sourcing outdoor LED strips from suppliers in Asia for markets in Africa, South America, or the Middle East?

Yes, consider longer shipping times and customs clearance complexity when importing from Asia. Ensure suppliers understand your local electrical standards and voltage requirements to avoid compatibility issues. Factor in climate differences; for example, high humidity in tropical regions demands higher waterproof ratings. Currency fluctuations and import duties can affect final costs—work with suppliers who provide transparent pricing including shipping and taxes. Building strong supplier relationships and understanding local market needs improve procurement success across diverse regions.

Strategic Sourcing Conclusion and Outlook for led strips for outdoors

Key Takeaways for B2B Buyers

Outdoor LED strip lights represent a transformative solution in energy-efficient, durable, and customizable lighting. For international buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding product specifications such as waterproof ratings, voltage requirements, and color options is essential. Strategic sourcing from reputable suppliers ensures access to the latest technologies, including smart controls and tunable lighting, while enabling bulk cost advantages and tailored customization to meet diverse project needs.

The Value of Strategic Sourcing

Successful procurement hinges on partnering with reliable manufacturers who offer warranties, competitive pricing, and flexible shipping options. For large-scale or specialized outdoor installations, consolidating orders through trusted wholesale channels not only reduces costs but also guarantees consistency and compliance with local standards. Requesting samples and verifying supplier credentials are crucial steps to mitigate risk and secure high-quality products that withstand harsh environmental conditions.

Illustrative Image (Source: Google Search)

Looking Ahead

As LED technology evolves, international B2B buyers are encouraged to leverage strategic sourcing to capitalize on innovations such as IoT-enabled lighting and enhanced energy management systems. By doing so, businesses across emerging and established markets—from Colombia to Thailand—can future-proof their outdoor lighting solutions, optimize operational efficiency, and elevate their competitive edge. Start building strong supplier relationships today to unlock long-term value and sustainable growth in your outdoor LED strip lighting projects.