Guide to Led Strip Remote Control

- Introduction: Navigating the Global Market for led strip remote control

- Understanding led strip remote control Types and Variations

- Key Industrial Applications of led strip remote control

- Strategic Material Selection Guide for led strip remote control

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip remote control

- Comprehensive Cost and Pricing Analysis for led strip remote control Sourcing

- Spotlight on Potential led strip remote control Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip remote control

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip remote control Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip remote control

- Strategic Sourcing Conclusion and Outlook for led strip remote control

Introduction: Navigating the Global Market for led strip remote control

The global demand for LED strip remote controls is surging as businesses across Africa, South America, the Middle East, and Europe seek versatile, energy-efficient lighting solutions that enhance user experience and operational flexibility. For international B2B buyers—from Kenya’s growing retail sector to the UK’s advanced smart home market—understanding the nuances of LED strip remote controls is crucial for sourcing products that meet diverse application needs and regional standards.

LED strip remote controls serve as the pivotal interface enabling precise manipulation of lighting color, brightness, and effects, transforming static LED strips into dynamic lighting systems. Their importance extends beyond convenience, directly impacting energy consumption, product lifespan, and user satisfaction. Choosing the right remote control technology—from infrared to RF or smart app integration—can differentiate suppliers and influence competitive positioning.

This comprehensive guide delves into every critical aspect of LED strip remote controls to empower informed procurement decisions. It covers:

- Types and technologies of remotes, including wireless and app-based solutions

- Material and manufacturing insights that affect durability and performance

- Quality control protocols and international compliance standards essential for reliable sourcing

- Supplier landscapes tailored to varied regional requirements and market maturity

- Cost analysis to balance budget with quality and innovation

- Frequently asked questions addressing common operational challenges and troubleshooting

By synthesizing manufacturing expertise, market trends, and buyer priorities, this guide equips B2B buyers with actionable knowledge to confidently navigate the global supply chain. Whether upgrading existing lighting systems or launching new projects, businesses can leverage this resource to secure high-quality LED strip remote controls that align with their technical specifications, budget constraints, and regional regulations—driving value and competitive advantage in today’s evolving lighting market.

Understanding led strip remote control Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Infrared (IR) Remote | Line-of-sight control, simple button interface | Retail lighting, hospitality, residential | Cost-effective and easy to use; limited range and requires direct line of sight |

| Radio Frequency (RF) Remote | Wireless control without line-of-sight, longer range | Large venue lighting, industrial installations | Flexible placement and extended range; higher cost and potential interference issues |

| Bluetooth Remote | Controlled via smartphone app or dedicated remote | Smart homes, offices, commercial showrooms | Offers advanced customization and integration; requires smartphone or compatible device |

| WiFi-Enabled Remote | Remote control via internet-connected devices and apps | Smart buildings, chain stores, remote management | Enables remote access and scheduling; depends on stable internet and higher initial investment |

| Wired Remote Control | Physical connection to LED strip controller, no wireless | Permanent installations, industrial automation | Reliable and interference-free; limited flexibility and installation complexity |

Infrared (IR) Remote

Infrared remotes are the most traditional and widely used type for LED strip control. They require a direct line of sight to the receiver and are generally easy to operate with straightforward button controls for power, color, brightness, and modes. For B2B buyers in retail or hospitality sectors, IR remotes offer a cost-effective solution for small to medium-sized installations. However, their limited range and the necessity of unobstructed signals may pose challenges in larger or more complex environments.

Radio Frequency (RF) Remote

RF remotes eliminate the line-of-sight limitation by using radio waves, enabling control through walls or furniture. This makes them ideal for larger venues or industrial settings where LED strips are installed in hard-to-reach places. While RF remotes provide flexibility and a longer range, B2B buyers should consider potential interference from other wireless devices and the generally higher cost compared to IR models. Ensuring compatibility with existing infrastructure is essential.

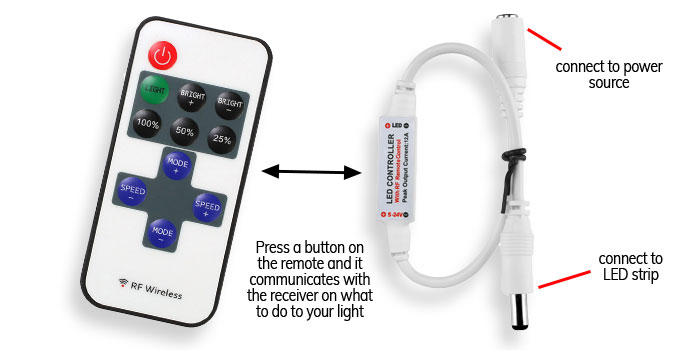

Illustrative Image (Source: Google Search)

Bluetooth Remote

Bluetooth-enabled remotes leverage smartphone apps or dedicated controllers, allowing users to customize colors, brightness, and lighting modes with greater precision. This type is especially suitable for smart homes, offices, and commercial showrooms seeking interactive lighting solutions. For international buyers, Bluetooth remotes offer ease of use without the need for internet access, but require compatible devices and proximity within Bluetooth range, which can be a limiting factor in large-scale deployments.

WiFi-Enabled Remote

WiFi LED strip remotes provide advanced control features through internet connectivity, including remote access, scheduling, and integration with smart home ecosystems like Amazon Alexa or Google Home. This option is highly attractive for smart buildings, chain stores, and facilities requiring centralized lighting management. B2B buyers must weigh the benefits of convenience and scalability against the need for stable internet infrastructure and potentially higher upfront costs.

Wired Remote Control

Wired remotes connect directly to the LED strip controller via cables, offering reliable and interference-free operation. They are favored in permanent installations and industrial automation where wireless signals may be unstable or undesirable. Although wired remotes provide consistent performance, they lack flexibility in placement and can complicate installation. Buyers should consider the trade-offs between reliability and adaptability depending on their project requirements and environment.

Related Video: How to Control your LED strips with Alexa and Google Home

Key Industrial Applications of led strip remote control

| Industry/Sector | Specific Application of led strip remote control | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Dynamic ambient lighting control in stores, hotels, and restaurants | Enhanced customer experience and brand differentiation | Compatibility with existing lighting systems, ease of integration, durability in commercial environments |

| Manufacturing & Warehousing | Adjustable task lighting for assembly lines and storage areas | Increased worker productivity and energy savings | Robust remote range, industrial-grade durability, and compliance with safety standards (CE, UL) |

| Real Estate & Property Development | Smart lighting for residential and commercial building projects | Attractive property showcasing and energy-efficient management | Scalability, multi-zone control capability, and compliance with regional electrical codes |

| Entertainment & Events | Remote-controlled stage and event lighting | Flexible and quick lighting changes to enhance event atmosphere | Compatibility with DMX controllers, wireless control reliability, and fast response time |

| Transportation & Infrastructure | Illuminated signage and safety lighting with remote adjustment | Improved visibility and safety with remote adaptability | Weather-resistant designs, long-range remote functionality, and ease of maintenance |

Retail & Hospitality

In retail stores, hotels, and restaurants, LED strip remote controls enable businesses to dynamically adjust lighting colors, brightness, and effects to match different times of day, promotions, or moods. This flexibility enhances the ambiance, attracting customers and encouraging longer visits. For B2B buyers in regions like Kenya or the UK, sourcing remote controls that integrate seamlessly with existing lighting infrastructure and withstand frequent use in commercial environments is crucial. Durability and user-friendly interfaces are key to ensuring operational efficiency and customer satisfaction.

Manufacturing & Warehousing

Manufacturers and warehouse operators benefit from LED strip remote controls by enabling precise control over task lighting. Adjustable brightness and color temperature help reduce eye strain and increase accuracy on assembly lines or inventory management. For buyers in Africa, South America, or the Middle East, prioritizing industrial-grade remote controls that offer extended wireless range and robust build quality is essential to withstand harsh environments and maintain consistent performance. Compliance with international safety standards ensures reliability and worker safety.

Real Estate & Property Development

Property developers and real estate firms use LED strip remote control systems to showcase residential and commercial properties with customizable lighting scenes. Buyers can highlight architectural features or create mood lighting to appeal to potential clients. International buyers must consider scalability to control multiple zones remotely and ensure compatibility with regional electrical codes. Energy-efficient models with remote scheduling capabilities also help reduce operational costs, a key selling point in markets like Europe and the Middle East.

Entertainment & Events

Event organizers and entertainment venues rely on remote-controlled LED strips for versatile stage lighting that can quickly adapt to different scenes or performances. The ability to switch colors, modes, and brightness remotely enhances audience engagement and production value. B2B buyers should look for systems compatible with DMX protocols and wireless controls that offer fast, reliable response times. This is particularly important for event companies operating across diverse regions, ensuring seamless setup and operation under tight schedules.

Transportation & Infrastructure

In transportation hubs and infrastructure projects, LED strip remote controls are used for illuminated signage and safety lighting that can be adjusted remotely to respond to changing conditions or schedules. This improves visibility and safety for passengers and workers. For international buyers, sourcing weather-resistant and long-range remote control solutions is vital to ensure functionality in outdoor or harsh environments. Easy maintenance and integration with existing control systems facilitate efficient operation across different locations.

Related Video: How To Use the LED Light Remote! – Explaining Every Button! [Tutorial]

Strategic Material Selection Guide for led strip remote control

When selecting materials for LED strip remote controls, international B2B buyers must consider factors that directly affect product performance, durability, and compliance with regional standards. The remote control casing and internal components are typically made from plastics, metals, or composite materials, each with distinct properties and implications for manufacturing and end-use. Below is an analysis of four common materials used in LED strip remote control manufacturing.

1. ABS Plastic (Acrylonitrile Butadiene Styrene)

Key Properties:

ABS is a thermoplastic polymer known for its good impact resistance, moderate heat resistance (typically up to 80-100°C), and excellent dimensional stability. It offers good electrical insulation and chemical resistance against mild acids and alkalis.

Pros & Cons:

ABS is cost-effective and easy to mold, making it ideal for high-volume manufacturing. It provides a smooth finish suitable for branding and labeling. However, it has moderate UV resistance, which can lead to discoloration or brittleness if exposed to prolonged sunlight without additives. It is less resistant to high temperatures compared to some engineering plastics.

Impact on Application:

ABS is widely used for remote control housings due to its balance of durability and cost. For indoor applications, it performs well, but for outdoor or high-temperature environments common in some African and Middle Eastern regions, UV-stabilized grades or coatings may be necessary.

Considerations for International Buyers:

ABS complies with many international standards including ASTM D4761 and ISO 180 for impact resistance. Buyers in Europe and the UK should verify RoHS and REACH compliance to meet environmental regulations. In South America and Africa, availability of UV-stabilized ABS variants is crucial for durability in sunny climates.

2. Polycarbonate (PC)

Key Properties:

Polycarbonate is a strong, transparent thermoplastic with high impact resistance and excellent heat resistance (up to 135°C). It offers superior dimensional stability and good electrical insulation properties.

Pros & Cons:

PC is more durable and heat-resistant than ABS, making it suitable for remote controls expected to endure rough handling or higher operating temperatures. However, PC is more expensive and can be more challenging to process due to higher melting points. It also has moderate chemical resistance, vulnerable to some solvents.

Impact on Application:

Ideal for premium remote controls requiring enhanced durability and clarity (for indicator windows or backlit buttons). Its toughness suits markets with demanding environmental conditions, including parts of Europe and the Middle East where product longevity is a key selling point.

Considerations for International Buyers:

Buyers should ensure PC materials meet UL 94 V-0 flammability standards and comply with ASTM D256 for impact resistance. European buyers often require compliance with EN 71 (toy safety) if products are marketed for family use. PC’s higher cost may affect pricing strategies in cost-sensitive markets like parts of Africa and South America.

3. Aluminum Alloy (e.g., 6063 or 5052 series)

Key Properties:

Aluminum alloys offer excellent corrosion resistance, good thermal conductivity, and moderate strength. They can withstand temperatures well above 150°C and have good electromagnetic interference (EMI) shielding properties.

Pros & Cons:

Using aluminum for remote control casings enhances durability and premium feel, while improving heat dissipation from internal electronics. Aluminum is lightweight but more expensive and requires more complex manufacturing processes such as extrusion or CNC machining. Surface finishing (anodizing or powder coating) is necessary to prevent oxidation and maintain aesthetics.

Impact on Application:

Aluminum is preferred in high-end or industrial LED strip remote controls where robustness and EMI shielding are critical. Its corrosion resistance makes it suitable for humid or coastal regions common in South America and parts of Africa.

Considerations for International Buyers:

Buyers should verify compliance with ASTM B221 for aluminum extrusions and consider local standards for corrosion resistance. In Europe and the UK, anodized aluminum must meet EN ISO 7599 for durability. The higher cost and manufacturing complexity may limit use to premium product lines.

4. Silicone Rubber (for Buttons and Seals)

Key Properties:

Silicone rubber is flexible, highly resistant to temperature extremes (-60°C to 230°C), UV radiation, and many chemicals. It provides excellent tactile feedback and water resistance.

Pros & Cons:

Silicone is ideal for remote control buttons and seals, offering durability and comfort. It is more expensive than standard rubber but provides superior longevity and environmental resistance. Manufacturing involves molding processes that can increase unit costs.

Impact on Application:

Silicone rubber enhances user experience and device lifespan, especially in harsh climates with dust, moisture, or temperature fluctuations. It is critical for markets with high humidity or outdoor use potential, such as in the Middle East and tropical regions of Africa.

Considerations for International Buyers:

Buyers should ensure silicone materials comply with ASTM D2000 for rubber properties and meet FDA or EU food-grade standards if relevant. Availability of high-quality silicone grades varies by region, so sourcing from reputable suppliers is essential to maintain consistency.

Summary Table

| Material | Typical Use Case for led strip remote control | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS Plastic | Remote control casing, general housing | Cost-effective, easy to mold, good impact resistance | Moderate UV resistance, limited high-temp tolerance | Low |

| Polycarbonate (PC) | Premium casing, indicator windows, backlit buttons | High impact and heat resistance, dimensional stability | Higher cost, more complex processing | Medium |

| Aluminum Alloy | Premium or industrial casing, EMI shielding | Excellent durability, corrosion resistance, heat dissipation | Higher cost, complex manufacturing, needs finishing | High |

| Silicone Rubber | Buttons, seals, flexible parts | Excellent temperature and chemical resistance, tactile feel | Higher cost, specialized molding required | Medium |

This guide equips international B2B buyers with critical insights to select appropriate materials based on their target markets’ environmental conditions, compliance requirements, and cost considerations. For buyers in Africa, South America, the Middle East, and Europe, understanding these material characteristics helps optimize product performance and customer satisfaction in diverse applications.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip remote control

Overview of Manufacturing Processes for LED Strip Remote Controls

The production of LED strip remote controls involves a series of carefully coordinated stages designed to ensure functionality, durability, and user-friendliness. For international B2B buyers, understanding these stages is crucial to assess supplier capabilities and product quality.

1. Material Preparation

This initial stage involves sourcing and verifying raw materials such as printed circuit boards (PCBs), electronic components (microcontrollers, infrared or RF modules), plastic housings, buttons, batteries, and infrared LEDs or RF transmitters. High-quality materials are essential for reliable signal transmission and long product life. Suppliers often procure components from certified vendors to meet international standards.

2. PCB Fabrication and Component Mounting

The heart of the remote control is the PCB, which is fabricated using multilayer copper boards designed for optimal electrical performance and heat dissipation. Surface Mount Technology (SMT) is commonly employed to place and solder components with precision. Automated pick-and-place machines ensure accurate positioning of microchips, resistors, capacitors, and transmitters. This stage demands strict control to avoid defects like solder bridges or cold joints.

3. Assembly

After PCB assembly, the board is integrated into the remote housing. This includes installing buttons, battery compartments, and protective covers. The assembly process can be automated or manual, depending on production scale. Key techniques include ultrasonic welding or snap-fitting plastic parts to ensure tight seals that prevent dust and moisture ingress, critical for product longevity in diverse environments.

4. Finishing and Packaging

Final steps involve printing button labels, applying coatings for durability, and packaging. Packaging is designed to protect the remote during international transit, often including anti-static bags and custom foam inserts. For B2B buyers, packaging quality reflects supplier professionalism and concern for product integrity during shipping.

Quality Control Frameworks and Checkpoints

Robust quality assurance is vital to meet the demanding requirements of international markets, especially for buyers in regions like Africa, South America, the Middle East, and Europe, where environmental and usage conditions vary widely.

International and Industry Standards

– ISO 9001: This global quality management standard ensures suppliers have systematic processes for consistent product quality and continuous improvement.

– CE Marking (Europe): Confirms compliance with EU safety, health, and environmental protection requirements.

– FCC Certification (USA): For products emitting radio frequencies, ensuring they do not cause harmful interference.

– RoHS Compliance: Restricts hazardous substances, critical for environmentally conscious markets like the UK and EU.

– API and Regional Standards: Some Middle Eastern and African markets may require compliance with local standards or additional certifications related to electromagnetic compatibility or safety.

Key Quality Control Checkpoints in Manufacturing

1. Incoming Quality Control (IQC)

Suppliers inspect raw materials and components upon receipt. For remote controls, this includes verifying PCB integrity, electronic components’ specifications, and plastic housing quality. Defective parts are rejected before entering production.

2. In-Process Quality Control (IPQC)

During assembly, IPQC monitors soldering quality, component placement accuracy, button functionality, and assembly integrity. Automated optical inspection (AOI) and manual checks are commonly used. Early detection of issues reduces waste and rework costs.

3. Final Quality Control (FQC)

Before packaging, finished remotes undergo comprehensive testing including:

– Functional Testing: Ensures all buttons respond correctly and the remote transmits signals consistently.

– Battery and Power Testing: Verifies battery compartment fit and power delivery.

– Durability Tests: Include drop tests, button lifespan cycles, and environmental resistance (humidity, temperature).

– Signal Range and Interference Testing: Confirms effective remote control operation within specified distances and in environments with potential RF interference.

Common Testing Methods for LED Strip Remote Controls

- Electrical Testing: Voltage, current, and signal integrity are measured to ensure stable operation.

- Environmental Stress Screening (ESS): Simulates harsh conditions (high/low temperature, humidity) to identify potential early failures.

- EMC Testing: Ensures the remote control does not emit or is not susceptible to electromagnetic interference, critical for compliance in Europe and other regulated markets.

- User Interface Testing: Checks for button responsiveness, tactile feedback, and ergonomic design.

How B2B Buyers Can Verify Supplier Quality Control

1. Factory Audits

International buyers should conduct or commission third-party factory audits to verify adherence to manufacturing standards and quality management systems like ISO 9001. Audits assess process controls, worker training, equipment maintenance, and QC documentation.

2. Review of Quality Reports

Request detailed inspection reports including IQC, IPQC, and FQC data. Look for consistency in defect rates, test results, and corrective actions taken by the supplier.

3. Third-Party Inspection and Testing

Independent labs can perform product testing for compliance certifications (CE, RoHS, FCC) and performance benchmarks. This is especially important for buyers importing into regulated markets such as the UK and EU.

4. Sample Testing and Pilot Runs

Ordering pre-production samples or small pilot batches allows buyers to conduct their own in-house testing or field trials under local conditions before large-scale orders.

Quality Assurance Nuances for Buyers in Africa, South America, the Middle East, and Europe

- Environmental Considerations: Regions like Africa and the Middle East experience high temperatures and dust exposure. Buyers should prioritize suppliers that conduct environmental stress testing to ensure remote controls withstand these conditions.

- Certification Requirements: European buyers must insist on CE and RoHS compliance to meet legal import requirements. Buyers in South America and Africa should verify if local regulations require additional certifications or approvals.

- Supply Chain Transparency: For buyers in emerging markets, transparency in component sourcing and manufacturing processes reduces risks of counterfeit parts and quality failures.

- After-Sales Support: Reliable after-sales service and warranty policies are critical, especially in regions where repair facilities are limited. Buyers should assess suppliers’ responsiveness and availability of spare parts.

- Customization Capability: Buyers may require remotes tailored to specific LED strip models or with localized features (e.g., specific languages on buttons). Selecting suppliers with flexible manufacturing and QC processes supports these needs.

Summary for International B2B Buyers

Understanding the detailed manufacturing processes and comprehensive quality assurance measures behind LED strip remote controls empowers buyers to make informed decisions. Key takeaways include:

- Evaluate suppliers’ material sourcing, PCB fabrication, assembly techniques, and packaging quality.

- Confirm adherence to international standards such as ISO 9001, CE, RoHS, and relevant regional certifications.

- Verify quality control checkpoints with evidence from IQC, IPQC, and FQC inspections, and insist on rigorous testing methods.

- Conduct factory audits and third-party inspections to validate supplier claims.

- Consider environmental and regulatory factors unique to your region to ensure product suitability and compliance.

- Prioritize suppliers offering strong after-sales support and customization options to meet your specific market demands.

By applying these insights, B2B buyers from Africa, South America, the Middle East, and Europe can confidently source LED strip remote controls that combine reliability, compliance, and performance, ensuring long-term satisfaction and business success.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip remote control Sourcing

Breakdown of Cost Components in LED Strip Remote Control Sourcing

Understanding the cost structure behind LED strip remote controls is crucial for international B2B buyers aiming to optimize procurement budgets while maintaining quality.

- Materials: The primary cost driver includes LED chips, PCBs, remote control components (IR or RF modules, microcontrollers), batteries, adhesives, and packaging materials. Premium LED chips and durable remote casings increase costs but improve longevity and performance.

- Labor: Labor costs vary significantly depending on manufacturing location. Countries with lower labor costs (e.g., parts of South America or Asia) may offer more competitive pricing but require careful vetting for quality consistency.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories employing automation reduce overhead, positively impacting unit pricing.

- Tooling: Initial tooling costs for molds, PCB assembly, and remote casing production can be substantial. These are often amortized over large order volumes, impacting pricing for smaller buyers.

- Quality Control (QC): Rigorous QC processes—such as functional testing of remotes, durability checks, and compliance certification (CE, RoHS)—add to costs but are essential to minimize returns and warranty claims.

- Logistics: Shipping, customs duties, and insurance costs vary by region. Buyers from Africa, the Middle East, and South America should factor in longer transit times and potentially higher freight charges.

- Margin: Supplier margin typically ranges from 10% to 30%, influenced by supplier reputation, exclusivity of design, and after-sales service offerings.

Key Price Influencers for LED Strip Remote Controls

Several factors impact the final purchase price and should be carefully considered during negotiations:

- Order Volume & Minimum Order Quantity (MOQ): Larger orders significantly reduce per-unit costs due to economies of scale. Many manufacturers set MOQs ranging from hundreds to thousands of units; buyers with smaller requirements may face higher prices.

- Specifications & Customization: Custom remote controls with unique branding, additional buttons, or smart features (e.g., WiFi or Bluetooth connectivity) increase costs. Standard models are more cost-effective but may lack differentiation.

- Material Quality & Certifications: Products with certified components (UL, CE, RoHS) command premium pricing but assure compliance with international safety and environmental standards, critical for European buyers and regulated markets.

- Supplier Factors: Established suppliers with proven quality and reliable lead times may price higher but reduce risk. New or lesser-known manufacturers may offer competitive prices but require thorough due diligence.

- Incoterms: Shipping terms (FOB, CIF, DDP) affect cost transparency and responsibility for logistics and customs clearance. Buyers should clarify terms to avoid hidden costs, especially important for importers in Africa and South America.

Practical Buyer Tips for Cost-Efficient Sourcing

- Negotiate on Volume & Payment Terms: Use forecasted purchase volumes to negotiate better unit prices and favorable payment terms such as letters of credit or deferred payments to ease cash flow.

- Prioritize Total Cost of Ownership (TCO): Consider factors beyond unit price—warranty, after-sales support, replacement parts availability, and potential import duties—to avoid costly surprises.

- Request Samples for Quality Validation: Before placing bulk orders, obtain samples to verify build quality, remote responsiveness, and compatibility with your LED strips.

- Leverage Supplier Audits & Certifications: For buyers in Kenya, the Middle East, or Europe, insist on supplier audits and certification documentation to ensure compliance with local import regulations and quality standards.

- Optimize Logistics: Consolidate shipments and choose reliable freight forwarders experienced with your region to reduce delays and extra charges.

- Understand Pricing Nuances: Be aware that remote controls bundled with LED strips often come at a lower incremental cost. However, standalone remote sourcing may attract higher per-unit prices due to lower volume.

Indicative Pricing Disclaimer

Prices for LED strip remote controls vary widely based on features, order size, and supplier location. As a rough benchmark, basic IR remote controls may cost between $1.50 to $3.00 per unit at volumes exceeding 1,000 pieces, whereas smart WiFi-enabled remotes can range from $5.00 to $10.00 or more. These figures are indicative and should be validated with direct supplier quotations.

By carefully analyzing these cost components and price influencers, international B2B buyers can strategically negotiate and source LED strip remote controls that balance cost, quality, and delivery reliability tailored to their regional market needs.

Spotlight on Potential led strip remote control Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip remote control’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip remote control

Critical Technical Properties of LED Strip Remote Controls

1. Signal Type and Range

LED strip remotes typically operate using Infrared (IR) or Radio Frequency (RF) signals. IR remotes require a clear line of sight and have shorter ranges (usually up to 8 meters), while RF remotes offer longer ranges (up to 30 meters or more) and can penetrate obstacles like walls. For B2B buyers, choosing the right signal type affects installation flexibility and user convenience, especially in commercial or large-scale projects.

2. Compatibility and Control Protocols

Compatibility with specific LED strip models and control protocols (e.g., PWM for dimming, RGB or RGBW color control) is crucial. Remote controls must support the LED strip’s voltage and chip type (commonly 12V or 24V, 5050 or 3528 LED chips). Ensuring compatibility reduces integration issues and returns, which is vital for buyers managing diverse inventory or custom solutions.

3. Battery Life and Power Source

Most remotes use standard coin-cell batteries (CR2025 or CR2032). Battery life impacts operational costs and customer satisfaction. For bulk buyers, understanding battery specifications and availability in local markets (Africa, South America, Middle East, Europe) ensures easy maintenance and after-sales support.

4. Build Quality and Material Grade

Durability of remote casings (typically ABS plastic) and quality of buttons (resistance to wear and tear) influence the lifespan of remote controls. High-grade materials prevent premature failures in harsh environments, especially in regions with high humidity or dust. This lowers replacement rates and operational disruptions for B2B clients.

5. Functionality and User Interface

Key functional features include on/off control, brightness adjustment, color modes (static, fade, jump), DIY custom modes, and speed control for effects. Intuitive button layout and clear labeling enhance user experience. For distributors and retailers, offering remotes with versatile functions can increase product appeal across different market segments.

6. Certification and Compliance

Look for remotes with CE, RoHS, or FCC certification to ensure safety, electromagnetic compatibility, and environmental compliance. For international buyers, compliance with local regulations is mandatory to avoid customs delays and legal issues, facilitating smoother market entry.

Common Trade Terminology for LED Strip Remote Control Procurement

OEM (Original Equipment Manufacturer)

Refers to products manufactured by one company but branded and sold by another. B2B buyers often request OEM services to customize remote controls with their brand, packaging, or specifications, enhancing market differentiation.

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and cash flow, particularly important for startups or businesses in emerging markets with limited upfront capital.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms for specific products. Effective RFQs lead to competitive pricing and clear contractual terms, essential for managing procurement costs and supplier relationships.

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities of buyers and sellers regarding shipping, insurance, and customs duties. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowing Incoterms helps buyers negotiate better deals and manage logistics effectively.

Lead Time

The total time from placing an order to receiving the goods. Accurate lead time information is critical for production planning, seasonal sales, or project deadlines, especially when importing from overseas manufacturers.

Batch Testing

A quality control process where a sample from a batch is tested to verify product standards before shipment. Buyers benefit from batch testing as it reduces the risk of defective products, ensuring consistency and reliability in their supply chain.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, optimize procurement strategies, and establish successful partnerships with LED strip remote control manufacturers and suppliers worldwide.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip remote control Sector

Market Overview & Key Trends

The global LED strip remote control market is rapidly expanding, driven by increasing demand for energy-efficient, customizable lighting solutions across commercial, residential, and industrial sectors. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are capitalizing on this growth as urbanization, smart infrastructure, and consumer preferences evolve. For example, countries such as Kenya and the UK are witnessing rising adoption of LED lighting systems integrated with remote control technology to enhance convenience, energy management, and ambiance control.

Key market drivers include advances in wireless communication protocols (e.g., RF, IR, WiFi, Bluetooth) embedded in remote controls, enabling seamless integration with smart home and building automation systems. The trend towards smart LED strip lights controlled via mobile apps or voice assistants is particularly strong in Europe and the Middle East, where IoT adoption is accelerating. Meanwhile, in Africa and South America, cost-effectiveness and ease of installation remain critical factors, pushing suppliers to offer versatile remote control solutions compatible with both traditional and smart LED strips.

From a sourcing perspective, B2B buyers are increasingly prioritizing suppliers who provide customization options—such as programmable DIY modes, multi-zone controls, and compatibility with various LED chip types—to cater to diverse market needs. The supply chain is also becoming more transparent, with buyers demanding adherence to international quality certifications (CE, RoHS, UL) and compliance with regional standards to ensure product safety and reliability. Additionally, geopolitical factors and shipping logistics impact sourcing strategies, prompting buyers to diversify supplier bases across Asia, Europe, and emerging manufacturing hubs to mitigate risks.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are gaining prominence in the LED strip remote control sector, as buyers seek to minimize environmental footprints while maintaining high performance. LED strips themselves contribute to energy savings, but the sourcing and production of remote controls and electronic components involve materials and processes with potential environmental impacts. Ethical supply chains that prioritize responsible mining of rare earth elements, reduction of hazardous substances, and waste management are becoming essential criteria for B2B partnerships.

Buyers from Europe and the Middle East, in particular, are driving demand for “green” certifications such as RoHS (Restriction of Hazardous Substances), WEEE (Waste Electrical and Electronic Equipment), and Energy Star compliance. These certifications ensure products limit the use of harmful chemicals like lead, mercury, and cadmium, and support recycling and end-of-life management. For buyers in Africa and South America, aligning with suppliers who demonstrate transparent sourcing policies and social responsibility—such as fair labor practices and community engagement—can enhance brand reputation and compliance with emerging regulatory frameworks.

Material innovation is also a key trend; manufacturers increasingly incorporate recyclable PCB materials, biodegradable adhesives, and energy-efficient LED chips to reduce lifecycle environmental impact. Sustainable packaging solutions, designed to protect products during transit while minimizing plastic use, are gaining traction. B2B buyers can leverage these sustainability factors not only to meet regulatory demands but also to differentiate their offerings in increasingly eco-conscious markets.

Evolution of LED Strip Remote Controls

The evolution of LED strip remote controls reflects broader advancements in lighting and smart technology. Initially, LED strips were controlled by simple infrared (IR) remotes with limited functionality and range, primarily offering on/off and basic color selection. Over time, remote controls have become more sophisticated, incorporating radio frequency (RF) technology to overcome line-of-sight limitations and expanding the feature set to include brightness adjustment, multiple preset modes, and customizable DIY color settings.

The latest generation integrates wireless connectivity such as WiFi and Bluetooth, enabling control through mobile apps and voice assistants like Amazon Alexa and Google Home. This shift has transformed LED strip lighting into a component of smart ecosystems, allowing for automation, scheduling, and synchronization with other smart devices. For B2B buyers, understanding this evolution is crucial for selecting products that not only meet current operational needs but also future-proof installations against rapid technological changes.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip remote control

-

How can I effectively vet suppliers of LED strip remote controls for international B2B purchases?

To vet suppliers, start by verifying their certifications such as CE, RoHS, and UL, which indicate compliance with international safety and environmental standards. Request detailed product datasheets and inquire about their manufacturing process, quality control measures, and after-sales support. Check references or reviews from other international buyers, especially in regions like Africa and the Middle East, to assess reliability. Conduct sample testing to evaluate product performance and durability before committing to large orders. A transparent supplier will willingly provide factory audits or third-party inspection reports. -

Is customization of LED strip remote controls feasible for bulk international orders?

Yes, many manufacturers offer customization options including branding (logo printing), firmware programming for specific control modes, and tailored remote designs to suit your market needs. Customization typically requires negotiation on minimum order quantities (MOQs) and lead times. For B2B buyers in diverse markets like South America or Europe, customization can help differentiate your product and meet regional preferences. Always clarify the extent of customization available upfront and request prototypes to approve before mass production. -

What are typical MOQ and lead times when sourcing LED strip remote controls from overseas suppliers?

MOQ can vary widely depending on the supplier and customization level, generally ranging from 500 to 5,000 units. Lead times typically span 4 to 12 weeks, influenced by order size, customization, and current factory workload. For buyers in regions with longer shipping times such as Africa or the Middle East, factor in additional transit time when planning inventory. Negotiate clear terms for lead times and confirm production schedules to avoid delays, especially during peak seasons or global supply chain disruptions. -

Which payment terms are common and safest for international B2B transactions involving LED strip remotes?

Common payment terms include 30% upfront deposit with balance paid before shipment or upon delivery, often via bank transfer (T/T). Letters of credit (L/C) provide additional security but may involve higher banking fees. For first-time transactions, consider using escrow services or platforms that hold payment until goods are verified. Always confirm payment methods with suppliers and avoid full prepayment without proven trust. Negotiate clear contract terms including penalties for delays or quality issues to protect your investment. -

What quality assurance measures should I expect from LED strip remote control suppliers?

Suppliers should implement rigorous quality control protocols such as functional testing of remotes, battery and range tests, and stress tests under different environmental conditions. Request documentation of quality checks, including batch testing results and compliance certificates. For international buyers, insist on certifications like CE (Europe), FCC (USA), and RoHS to ensure the product meets local regulatory standards. Conduct third-party inspections or lab testing for critical orders to mitigate risks of faulty or substandard products.

Illustrative Image (Source: Google Search)

-

How do certifications impact the import and resale of LED strip remote controls in different international markets?

Certifications like CE (Europe), RoHS (environmental compliance), and FCC (radio frequency compliance) are often mandatory for legal import and sale in many regions. Lack of proper certification can lead to customs clearance delays, fines, or product recalls. For buyers in Africa, South America, or the Middle East, verify if additional local certifications or approvals are required. Always request copies of valid certificates from your supplier and ensure they are up-to-date and relevant to your target market to facilitate smooth customs clearance and build buyer trust. -

What logistics considerations should B2B buyers keep in mind when importing LED strip remote controls?

Consider shipping methods (air vs. sea), lead times, customs clearance procedures, and import duties specific to your country. Packaging quality is critical to prevent damage during transit, especially for sensitive electronics like remotes. Work with freight forwarders experienced in handling electronics shipments and familiarize yourself with any hazardous material regulations related to batteries. For buyers in regions with complex customs processes, engaging a local customs broker can expedite clearance and reduce unexpected costs. -

How should disputes over product quality or delivery be handled in international B2B transactions?

Establish clear contractual terms including product specifications, delivery timelines, and dispute resolution mechanisms before placing orders. If quality issues arise, document them with photos and test reports and communicate promptly with the supplier. Many suppliers offer replacement or refund policies within a warranty period; ensure these terms are clearly understood. For unresolved disputes, consider mediation or arbitration through recognized international trade bodies. Maintaining professional communication and keeping detailed records can help resolve conflicts efficiently and protect your business interests.

Strategic Sourcing Conclusion and Outlook for led strip remote control

Strategic sourcing of LED strip remote controls demands a nuanced understanding of component quality, manufacturing precision, and evolving technology integration. For international B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing suppliers who excel in sourcing premium LED chips, reliable PCB fabrication, and durable adhesives is essential. This ensures end products that deliver consistent performance, longevity, and compliance with global standards—key factors that reduce warranty claims and elevate brand reputation.

Moreover, embracing innovations such as smart remote controls with app and voice integration positions businesses to meet growing market expectations for convenience and customization. Strategic partnerships with manufacturers who invest in rigorous quality control and certification compliance can unlock competitive advantages, particularly in regions where energy efficiency and product reliability are increasingly valued.

Looking ahead, buyers should proactively engage with suppliers offering scalable solutions tailored to regional market dynamics, including varied infrastructure and consumer preferences. By combining due diligence in material sourcing with a forward-thinking approach to technology adoption, businesses can confidently navigate the LED strip remote control market’s complexities and capitalize on emerging growth opportunities worldwide.

Take action now: evaluate your supply chain for quality and innovation readiness to secure durable, high-performance LED strip remote controls that resonate with your target markets.