Guide to Led Strip Power Source

- Introduction: Navigating the Global Market for led strip power source

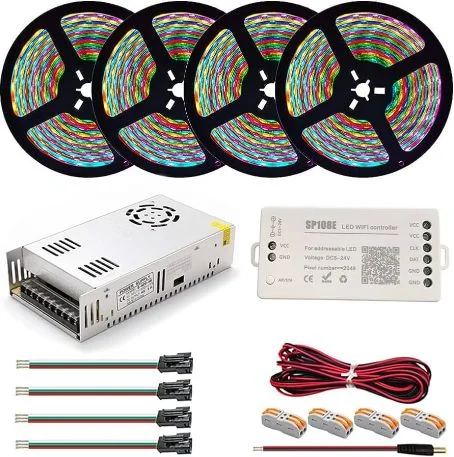

- Understanding led strip power source Types and Variations

- Key Industrial Applications of led strip power source

- Strategic Material Selection Guide for led strip power source

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip power source

- Comprehensive Cost and Pricing Analysis for led strip power source Sourcing

- Spotlight on Potential led strip power source Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip power source

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip power source Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip power source

- Strategic Sourcing Conclusion and Outlook for led strip power source

Introduction: Navigating the Global Market for led strip power source

The power source for LED strip lighting is a pivotal component that directly impacts performance, reliability, and energy efficiency. For international B2B buyers—especially those operating in emerging and diverse markets such as Africa, South America, the Middle East, and Europe—understanding the nuances of LED strip power sources is essential for making informed procurement decisions that align with local infrastructure, regulatory standards, and project requirements.

This comprehensive guide delves into every critical aspect of LED strip power sources, starting with the different types available, including constant voltage and constant current drivers, as well as their compatibility with various LED strip configurations. It further explores the materials and manufacturing processes that ensure durability and safety, emphasizing quality control measures and international certifications that safeguard against failures and compliance issues.

In addition to technical insights, the guide offers a detailed overview of the global supplier landscape, highlighting sourcing strategies tailored to regional market dynamics—helping buyers from Kenya, Brazil, the UAE, Italy, and beyond to navigate vendor reliability, cost structures, and shipping logistics effectively. Cost considerations and value optimization strategies are also covered, enabling businesses to balance upfront investment with long-term operational efficiency.

Finally, an extensive FAQ section addresses common concerns such as voltage compatibility, power capacity planning, and integration with smart lighting systems. By consolidating this critical knowledge, the guide empowers B2B buyers to confidently select LED strip power sources that meet their precise needs, ensuring successful installations that maximize both performance and return on investment across diverse international markets.

Understanding led strip power source Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Constant Voltage Power Supply | Provides fixed voltage output (commonly 12V or 24V) | Retail lighting, signage, architectural lighting | Pros: Easy to install, widely compatible; Cons: Limited to specific strip voltages, less efficient for long runs |

| Constant Current Power Supply | Delivers a fixed current, adjusting voltage as needed | Industrial lighting, high-power LED strips | Pros: Prevents LED burnout, better for high-power strips; Cons: More complex, costlier than constant voltage units |

| Battery-Powered Drivers | Portable power sources, often rechargeable lithium-ion batteries | Temporary displays, outdoor installations | Pros: Mobility and flexibility; Cons: Limited runtime, requires charging infrastructure |

| USB-Powered Adapters | Low voltage (5V) power source using USB ports | Consumer electronics, small-scale projects | Pros: Convenient, plug-and-play; Cons: Limited power output, not suitable for large or bright installations |

| Smart/IoT-Enabled Power Supplies | Integrated with wireless control and dimming capabilities | Smart buildings, advanced commercial lighting | Pros: Remote control, energy savings; Cons: Higher upfront cost, requires network setup |

Constant Voltage Power Supply

This is the most common type used for LED strips, providing a steady voltage (usually 12V or 24V). It suits a wide range of applications from retail displays to architectural lighting. Buyers should ensure the power supply matches the LED strip’s voltage rating to avoid damage. For large projects, selecting a high-quality constant voltage supply with adequate wattage is crucial to maintain consistent brightness and longevity.

Constant Current Power Supply

Designed for LED strips that require a fixed current rather than voltage, these power sources are ideal for high-power or industrial LED strips that demand precise current control to prevent overheating and extend lifespan. B2B buyers should consider these for projects involving high-density LEDs or custom installations where reliability and safety are paramount, despite the higher cost and complexity.

Battery-Powered Drivers

Battery-powered options provide the advantage of portability and ease of installation in locations without direct access to mains power. They are popular for temporary setups like events or outdoor signage. For international buyers in regions with unstable power grids, these units offer flexibility but require planning for battery replacement or recharging infrastructure.

USB-Powered Adapters

USB-powered LED strip power sources are perfect for small-scale or consumer-grade applications where convenience is key. They are easy to integrate with existing USB ports, making them attractive for tech retail environments or product displays. However, their limited power output restricts their use in larger commercial or industrial projects.

Smart/IoT-Enabled Power Supplies

These advanced power sources incorporate wireless connectivity and dimming controls, enabling integration with building management systems or smart home platforms. Ideal for modern commercial spaces and smart buildings, they offer energy efficiency and enhanced user control. Buyers should weigh the higher initial investment against long-term operational savings and the benefits of remote management.

Related Video: Ultra Thin LED Strip Power Supply

Key Industrial Applications of led strip power source

| Industry/Sector | Specific Application of led strip power source | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting in stores and showrooms | Enhanced customer experience, energy savings, and flexible lighting control | Compatibility with dimmers, stable voltage output, scalability for large installations |

| Hospitality & Events | Dynamic lighting systems for hotels, restaurants, and event venues | Creates immersive environments, reduces operational costs, and allows customization | Robustness for frequent use, ease of integration with smart controls, warranty support |

| Industrial & Manufacturing | Task and safety lighting in factories and assembly lines | Improves worker safety and productivity, reduces downtime due to lighting failure | High reliability, surge protection, compliance with industrial safety standards |

| Transportation & Infrastructure | Lighting for tunnels, stations, and public transport hubs | Energy-efficient, long-lasting lighting solutions that enhance safety and visibility | Waterproof and dustproof ratings, compliance with local regulations, durability under harsh conditions |

| Architectural & Urban Planning | Outdoor façade and landscape lighting powered by LED strips | Enhances aesthetic appeal, reduces energy consumption, supports sustainable urban development | Weatherproof power sources, UV resistance, compatibility with renewable energy sources |

LED strip power sources play a critical role in retail and commercial environments, powering ambient and accent lighting that enhances product displays and creates inviting atmospheres. For international buyers, especially in regions like Italy and Kenya, selecting power sources with stable voltage output and dimming compatibility is essential to ensure consistent lighting quality and energy efficiency. Scalability is also important for large retail chains or commercial complexes to maintain uniform lighting across multiple locations.

In hospitality and event sectors, LED strip power sources enable dynamic and customizable lighting schemes that can transform hotel lobbies, restaurants, and event spaces. Buyers from the Middle East and South America should prioritize power supplies that offer robust construction to withstand frequent on/off cycles and integration capabilities with smart lighting controls. Reliable warranty and after-sales support are vital to minimize downtime and maintenance costs in these high-use environments.

Industrial and manufacturing facilities rely on LED strip power sources for task and safety lighting that must operate continuously under demanding conditions. For buyers in Africa and Europe, ensuring the power source includes surge protection and meets industrial safety certifications is crucial to prevent failures and maintain worker safety. High reliability reduces costly downtime and supports compliance with workplace lighting standards.

Transportation infrastructure projects utilize LED strip power sources to illuminate tunnels, stations, and transport hubs with energy-efficient, long-lasting lighting. Buyers in diverse climates must seek power sources with high IP ratings for water and dust resistance and compliance with local safety regulations. Durability under harsh environmental conditions ensures sustained performance and reduces maintenance frequency.

In architectural and urban planning, LED strip power sources are essential for outdoor façade and landscape lighting that enhances city aesthetics while promoting sustainability. Buyers should focus on weatherproof and UV-resistant power supplies compatible with renewable energy systems to support eco-friendly initiatives. This is especially relevant for European and Middle Eastern markets where environmental standards are increasingly stringent.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip power source

When selecting materials for LED strip power sources, B2B buyers must consider factors such as electrical conductivity, thermal management, corrosion resistance, manufacturing complexity, and compliance with international standards. These elements directly influence product reliability, lifespan, and suitability across diverse environments found in Africa, South America, the Middle East, and Europe.

Copper

Key Properties: Copper is renowned for its excellent electrical conductivity and thermal performance, making it a prime choice for power source components such as wiring and connectors. It has good corrosion resistance but can oxidize over time if not properly treated or coated.

Pros & Cons: Copper’s superior conductivity ensures minimal power loss and efficient heat dissipation, enhancing LED strip longevity. However, it is relatively expensive compared to alternatives and can increase manufacturing costs. Its softness requires careful handling during assembly to avoid deformation.

Impact on Application: Copper is ideal for high-performance LED strip power sources where stable current delivery and heat management are critical, such as in commercial or industrial lighting installations. Its corrosion resistance can be enhanced with protective coatings, making it suitable for humid or coastal environments common in regions like Kenya or Brazil.

International B2B Considerations: Copper components often comply with ASTM B170 and EN 13601 standards, widely recognized in Europe and parts of the Middle East. Buyers should verify supplier certifications to ensure material purity and consistent electrical properties. In markets with cost sensitivity, such as some African countries, balancing copper’s benefits against budget constraints is crucial.

Aluminum

Key Properties: Aluminum offers good electrical conductivity (though less than copper) and excellent thermal conductivity. It is lightweight, corrosion-resistant, and has a high strength-to-weight ratio, making it suitable for heat sinks and enclosures in LED power sources.

Pros & Cons: Aluminum is more cost-effective than copper and easier to machine or extrude into complex shapes, facilitating innovative power source designs. However, its lower electrical conductivity requires design compensations, such as thicker conductors. It can oxidize but forms a protective oxide layer that prevents deeper corrosion.

Impact on Application: Aluminum is commonly used in LED strip power source housings and heat dissipation elements, especially where weight reduction is important, such as portable or architectural lighting. Its corrosion resistance suits outdoor and humid environments typical in South America and the Middle East.

International B2B Considerations: Aluminum materials often meet EN AW-6063 or ASTM B221 standards, ensuring quality and dimensional stability. European buyers, including Italy, frequently require compliance with RoHS and REACH regulations for aluminum components. For African markets, suppliers offering corrosion-resistant anodized finishes add value.

Polycarbonate (PC)

Key Properties: Polycarbonate is a durable thermoplastic with high impact resistance, excellent electrical insulation properties, and good thermal stability up to approximately 135°C. It is transparent, making it useful for protective covers or diffusers in LED power sources.

Pros & Cons: Polycarbonate offers lightweight, shatter-resistant protection for sensitive electrical components, enhancing product safety and longevity. It is cost-effective compared to metals but less effective in heat dissipation, necessitating careful thermal design. It can degrade under prolonged UV exposure unless UV-stabilized grades are used.

Impact on Application: PC is ideal for LED power source casings and protective covers, especially in applications requiring electrical insulation and impact resistance, such as residential or commercial lighting in Europe and the Middle East. Its UV resistance is critical for outdoor installations in sunny climates like those in Kenya or Brazil.

International B2B Considerations: Compliance with UL 94 flammability standards and ISO 9001 manufacturing quality certifications is important for PC components. Buyers in Europe and the Middle East often prioritize materials with documented UV resistance and fire safety ratings. African buyers should consider suppliers offering UV-stabilized PC to withstand intense sun exposure.

Stainless Steel

Key Properties: Stainless steel provides excellent mechanical strength, corrosion resistance, and durability. It has moderate electrical conductivity but is typically used for structural or protective elements rather than conductive parts in LED power sources.

Pros & Cons: Stainless steel’s robustness and resistance to harsh environmental conditions make it suitable for enclosures and mounting hardware. It is heavier and more expensive than aluminum or plastics, and its electrical conductivity is poor compared to copper or aluminum, limiting its use in conductive pathways.

Impact on Application: Stainless steel is favored in industrial or outdoor LED strip power source applications where mechanical protection and corrosion resistance are paramount, such as in coastal or desert environments prevalent in parts of the Middle East and South America.

International B2B Considerations: Materials often conform to ASTM A240 or EN 10088 standards, ensuring corrosion resistance and mechanical properties. European buyers expect compliance with REACH and RoHS for stainless steel components. African buyers should consider the availability of local fabrication services capable of handling stainless steel to reduce costs.

Summary Table

| Material | Typical Use Case for led strip power source | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Conductive wiring and connectors | Excellent electrical and thermal conductivity | Higher cost, softer material requiring careful handling | High |

| Aluminum | Heat sinks, enclosures, lightweight conductive parts | Lightweight, corrosion-resistant, cost-effective | Lower conductivity than copper, requires thicker conductors | Medium |

| Polycarbonate | Protective casings and diffusers | High impact resistance, electrical insulation, lightweight | Poor heat dissipation, UV degradation without stabilization | Low |

| Stainless Steel | Structural enclosures, mounting hardware | Superior corrosion resistance and strength | Heavy, expensive, poor electrical conductivity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip power source

The manufacturing of LED strip power sources is a sophisticated process that combines advanced materials, precise assembly techniques, and rigorous quality assurance protocols to ensure reliable, efficient, and durable products. For international B2B buyers—especially those from regions such as Africa, South America, the Middle East, and Europe—understanding these manufacturing and quality control (QC) processes is critical to making informed sourcing decisions that mitigate risks and optimize value.

Manufacturing Process of LED Strip Power Sources

The production of LED strip power sources typically involves four key stages: material preparation, forming, assembly, and finishing. Each stage utilizes specialized techniques designed to enhance product performance and longevity.

1. Material Preparation

- Component Sourcing: High-quality raw materials such as semiconductor chips, electronic components (capacitors, resistors, transformers), PCBs (printed circuit boards), and protective casings are sourced. Selecting reputable suppliers for these components is crucial, as the quality of input materials directly impacts efficiency and lifespan.

- Pre-Inspection: Incoming materials undergo initial quality checks, including visual inspection and electrical parameter verification, to ensure conformity with specifications.

2. Forming

- PCB Fabrication: The PCB serves as the foundational platform for the power source circuitry. Manufacturers employ techniques such as multilayer lamination and copper etching to create precise conductive pathways. For LED strip power sources, PCBs often require excellent thermal conductivity to dissipate heat effectively.

- Component Mounting: Surface-mount technology (SMT) is predominantly used to place components on the PCB with high accuracy and speed. Automated pick-and-place machines ensure consistent alignment and solder paste application.

3. Assembly

- Soldering: Reflow soldering solidifies the electrical connections, ensuring durability and conductivity. For power sources, wave soldering or selective soldering may also be used for through-hole components.

- Encapsulation and Protection: To protect sensitive electronics from moisture, dust, and mechanical stress, power sources are often encapsulated using silicone or epoxy resins. Protective housings, typically made from aluminum or high-grade plastic, are formed and integrated to enhance heat dissipation and physical robustness.

- Wiring and Connectors: Final wiring harnesses and connectors are attached, often customized to client specifications for compatibility with LED strips and control systems.

4. Finishing

- Labeling and Marking: Each unit is marked with product codes, batch numbers, and certification logos to enable traceability.

- Packaging: Units are carefully packed using anti-static materials and cushioning to prevent damage during transportation. Packaging is often customized for bulk shipments and may include branding elements.

Quality Assurance Framework for LED Strip Power Sources

Quality assurance in LED strip power source manufacturing is a multi-tiered process that integrates international standards compliance, systematic testing, and supplier verification mechanisms. This framework is essential for ensuring that power sources deliver consistent performance and meet safety requirements across diverse markets.

Key International and Industry Standards

- ISO 9001: This is the foundational quality management system standard that governs the entire manufacturing process. Suppliers certified with ISO 9001 demonstrate consistent process control, continual improvement, and customer focus.

- CE Marking: Essential for the European market, CE certification indicates conformity with EU safety, health, and environmental directives. It assures buyers that the power source meets electromagnetic compatibility and low-voltage requirements.

- UL (Underwriters Laboratories): Widely recognized in North America and increasingly accepted globally, UL certification verifies electrical safety and fire hazard prevention.

- RoHS Compliance: Restricts hazardous substances in electrical products, a critical requirement especially in European and some Middle Eastern markets.

- API and IEC Standards: Specific electrical performance and safety standards that apply depending on the region and application, such as IEC 61347 for lamp control gear.

Quality Control Checkpoints and Testing Methods

Quality control is embedded at every stage of the manufacturing process, typically divided into:

- Incoming Quality Control (IQC): Verification of raw materials and components against technical specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, component placement accuracy, and thermal management checks.

-

Final Quality Control (FQC): Comprehensive testing of finished power sources, including:

-

Electrical Testing: Verifying output voltage, current stability, efficiency, and ripple noise.

- Thermal Testing: Stress tests under elevated temperatures to evaluate heat dissipation and component resilience.

- Safety Testing: Dielectric strength, insulation resistance, and short-circuit protection tests to ensure compliance with safety standards.

- Environmental Testing: Exposure to humidity, vibration, and shock to simulate real-world operating conditions.

- Functional Testing: Load tests to confirm the power source’s ability to drive LED strips consistently.

How B2B Buyers Can Verify Supplier Quality Control

For buyers in Africa (e.g., Kenya), South America, the Middle East, and Europe (e.g., Italy), verifying supplier quality assurance processes is essential to avoid supply chain disruptions and ensure product reliability.

Illustrative Image (Source: Google Search)

- Factory Audits: Conduct on-site or virtual audits to assess manufacturing capabilities, QC procedures, and compliance with certifications like ISO 9001 and CE. Third-party audit firms can provide unbiased evaluations.

- Review of QC Documentation: Request detailed QC reports, including inspection records, test data, and certification copies. Consistent documentation is a hallmark of mature quality systems.

- Third-Party Inspection Services: Engage independent inspection agencies to perform random batch inspections or pre-shipment checks. This is especially useful when direct audits are impractical.

- Sample Testing: Obtain product samples for in-house or third-party lab testing to verify electrical performance, safety compliance, and durability claims.

- Supplier Quality Agreements (SQA): Establish contractual agreements that specify quality standards, inspection requirements, and penalties for non-compliance to ensure accountability.

QC and Certification Nuances for International Buyers

- Regulatory Variations: Different regions have specific compliance demands. For example, European buyers prioritize CE and RoHS, Middle Eastern markets may require SASO certification (Saudi Arabia), and South American buyers often look for INMETRO certification (Brazil). Understanding these nuances helps avoid customs clearance issues and product rejections.

- Climate Considerations: Buyers in tropical or desert climates (e.g., parts of Africa and the Middle East) should ensure power sources are tested for high temperature and humidity resilience.

- Voltage and Frequency Compatibility: Power sources must comply with regional electrical standards (e.g., 220-240V/50Hz in Europe and many African countries vs. 110-120V/60Hz in some South American regions).

- After-Sales Support and Warranty: Given the logistical challenges in certain regions, buyers should prioritize suppliers offering robust warranty terms and accessible customer support to minimize downtime and service costs.

Conclusion

For B2B buyers sourcing LED strip power sources internationally, gaining a thorough understanding of manufacturing stages and quality assurance protocols empowers smarter procurement decisions. By focusing on suppliers with transparent, certified quality management systems and rigorous testing regimes, buyers can secure power sources that meet both technical and regulatory requirements. Leveraging factory audits, sample testing, and third-party inspections further mitigates risks, ensuring that the LED lighting solutions they deploy are safe, efficient, and durable across diverse operational environments.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip power source Sourcing

Understanding the cost structure and pricing dynamics of LED strip power sources is essential for international B2B buyers seeking optimal value and reliability. These power sources, critical for efficient LED strip operation, encompass several cost elements and pricing influencers that vary by supplier, order scale, and customization requirements.

Key Cost Components

-

Materials: The core materials include electronic components such as transformers, capacitors, resistors, and circuit boards. High-quality components ensure better efficiency and durability but come at a premium. Sourcing from reputable suppliers impacts both cost and performance.

-

Labor: Skilled labor is required for assembly, soldering, and testing of power supplies. Labor costs differ significantly depending on the manufacturing location. For example, production in Asia may offer lower labor costs compared to Europe but may vary in terms of lead times and quality control.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production processes reduce overhead per unit, benefiting bulk buyers.

-

Tooling and Setup: Initial tooling costs for molds, assembly lines, or custom configurations are amortized over production volume. Buyers ordering customized power sources should anticipate higher upfront costs.

-

Quality Control (QC): Rigorous testing for electrical safety, voltage stability, and certification compliance (e.g., CE, UL) adds to cost but is crucial to avoid failures and returns.

-

Logistics: Freight, customs duties, and insurance affect landed cost. Shipping modes (air, sea, or land) impact both cost and delivery time, which is particularly relevant for buyers in Africa, South America, and the Middle East where logistics infrastructure varies.

-

Margin: Supplier profit margins depend on market positioning, competition, and order volume. Negotiation can influence margin, especially in large volume deals.

Influential Pricing Factors

-

Order Volume & MOQ: Larger orders typically attract volume discounts. Minimum order quantities (MOQs) vary by supplier and can affect unit pricing. Buyers from regions with smaller project sizes may need to consolidate orders or partner with distributors.

-

Specifications & Customization: Power sources with specific voltage, wattage, or waterproof ratings command higher prices. Custom branding, packaging, or unique connectors also increase cost.

-

Material Quality & Certifications: Certified products (CE, RoHS, UL) cost more but reduce compliance risks and ensure safety, a critical consideration for European buyers and regulated markets.

-

Supplier Reputation & Location: Established suppliers with proven quality records may charge a premium but reduce risk. Sourcing closer to the buyer’s region can reduce logistics costs and lead times.

-

Incoterms: The choice of delivery terms (e.g., FOB, CIF, DDP) affects who bears shipping and customs costs. Buyers should clarify terms to accurately assess total landed cost.

Strategic Buyer Recommendations

-

Negotiate Beyond Price: Engage suppliers on payment terms, lead times, and after-sales support. Longer payment cycles or flexible MOQs can optimize cash flow.

-

Assess Total Cost of Ownership (TCO): Factor in warranty, energy efficiency, replacement frequency, and compatibility with LED strips. Cheaper initial costs may lead to higher maintenance or failure rates.

-

Request Samples & Certifications: Especially important when sourcing from new suppliers or regions. Samples help verify quality and compatibility before bulk commitment.

-

Consolidate Shipments: For buyers in Africa, South America, or the Middle East, consolidating orders can reduce freight cost and customs complexity.

-

Understand Regional Import Regulations: Different countries have varying certification and documentation requirements. Working with suppliers familiar with these regulations can smooth customs clearance.

-

Leverage Local Distributors: In regions like Kenya or Italy, partnering with local distributors can reduce lead time and provide localized support, albeit sometimes at a higher unit cost.

Indicative Pricing Disclaimer

Prices for LED strip power sources can vary widely based on specifications, certifications, and order volumes. The figures provided by suppliers should be considered indicative. Buyers are encouraged to request detailed quotes including all ancillary costs to make fully informed procurement decisions.

By thoroughly analyzing these cost components and pricing influencers, international B2B buyers can optimize procurement strategies for LED strip power sources, ensuring cost-efficiency without compromising quality or compliance.

Spotlight on Potential led strip power source Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip power source’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip power source

Key Technical Properties of LED Strip Power Sources

Understanding the technical specifications of LED strip power sources is crucial for international B2B buyers to ensure product compatibility, safety, and long-term performance. Here are the most critical properties to consider:

-

Output Voltage (V):

LED strips require specific voltages, commonly 12V or 24V DC. The power source must match the strip’s voltage rating precisely to avoid damage or underperformance. For buyers in regions with varying electrical standards, verifying output voltage compatibility is essential to prevent costly returns or installation issues. -

Output Current (A) and Power Capacity (W):

The current rating indicates how much current the power supply can provide continuously. Power capacity, measured in watts, shows the maximum load it can support. Selecting a power source with adequate current and wattage ensures stable operation without overheating or voltage drops, particularly important for large or high-brightness LED installations. -

Efficiency (%):

Efficiency measures how well the power source converts input electricity into usable output power. Higher efficiency (typically above 85%) means less energy waste, reducing operational costs and heat generation. This is especially valuable for buyers aiming for energy-efficient solutions in commercial or industrial projects. -

Material Quality and Build:

Durable components such as high-grade capacitors and robust casing materials contribute to longer lifespan and resistance to environmental factors like humidity or dust. For buyers in diverse climates (e.g., humid regions in Africa or cold European markets), selecting power sources with appropriate ingress protection (IP ratings) and material standards is critical. -

Voltage Tolerance and Stability:

Voltage tolerance defines how much deviation from the nominal voltage the power source can handle without affecting LED performance. Stable output protects against flickering or premature LED failure, ensuring consistent lighting quality—an important consideration for retail or hospitality applications. -

Safety Certifications (CE, UL, RoHS):

Certified power sources comply with international safety and environmental standards, reducing liability risks and easing customs clearance. Buyers should prioritize suppliers offering certified products, especially when importing into regions with strict regulatory requirements such as the EU or Middle East.

Common Trade Terminology for LED Strip Power Source Procurement

Familiarity with industry jargon and trade terms will streamline communication and negotiation with suppliers, helping buyers secure the best deals and avoid misunderstandings.

-

OEM (Original Equipment Manufacturer):

Refers to manufacturers that produce components or products for other companies to brand and sell. Buyers seeking customized LED strip power sources or private-label products often engage OEMs to tailor specifications or packaging to their market needs. -

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers balance inventory costs with project demands, especially for SMEs or regional distributors in emerging markets where cash flow and storage may be limited. -

RFQ (Request for Quotation):

A formal inquiry sent to suppliers requesting price and availability information based on detailed product requirements. Crafting clear RFQs with technical specs and quantities accelerates supplier response times and improves quotation accuracy. -

Incoterms (International Commercial Terms):

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs between buyers and sellers. Knowing Incoterms enables buyers to manage logistics effectively and budget for total landed costs, crucial for cross-border transactions. -

Lead Time:

The period between placing an order and receiving the goods. Accurate lead time estimates are vital for project planning and supply chain management, helping buyers avoid delays in installation or production schedules. -

Warranty and After-Sales Support:

Guarantees provided by the supplier covering product defects or failures within a specified period. Buyers should evaluate warranty terms and support services to minimize risks and ensure long-term reliability of LED strip power sources.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, negotiate better contracts, and ensure smooth procurement of LED strip power sources tailored to their regional and project-specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip power source Sector

Market Overview & Key Trends

The global LED strip power source market is experiencing robust growth driven by expanding applications in commercial, residential, and industrial lighting sectors. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial to sourcing effectively. In emerging markets such as Kenya and parts of South America, rising urbanization and infrastructure development are fueling demand for energy-efficient lighting solutions. Meanwhile, European countries like Italy prioritize high-quality, compliant power sources due to stringent safety and energy regulations.

Key market drivers include:

- Energy Efficiency Demands: LED strip power sources offer superior energy savings compared to traditional lighting power supplies, aligning with global efforts to reduce carbon footprints.

- Technological Advancements: Modern power sources feature smart controls, dimmability, and enhanced thermal management, enabling integration with IoT and smart building systems.

- Customization & Scalability: Suppliers increasingly provide tailored voltage and wattage options to suit diverse LED strip configurations, essential for large-scale projects or unique installations.

- Supply Chain Localization: Buyers in Africa and the Middle East benefit from emerging regional manufacturing hubs, reducing lead times and import costs.

- Price Sensitivity & Quality Balance: While cost remains a critical factor, there is growing recognition of the risks associated with low-quality power sources, such as premature failure and safety hazards.

Sourcing trends for international B2B buyers:

- Preference for suppliers offering CE, UL, and RoHS certifications to ensure compliance and reliability.

- Increasing demand for modular and waterproof power supplies to accommodate outdoor or industrial environments.

- Growing interest in suppliers with transparent supply chains and traceability, mitigating risks related to counterfeit or substandard components.

Sustainability & Ethical Sourcing in B2B

Sustainability is rapidly becoming a core consideration in the procurement of LED strip power sources. Energy-efficient power supplies not only reduce operational costs but also contribute to corporate social responsibility goals. For buyers in all regions—especially Europe, where green regulations are stringent—selecting power sources with eco-friendly certifications is vital.

Environmental impact considerations:

- Material Selection: Power sources incorporating lead-free solder, halogen-free components, and recyclable materials reduce toxic waste.

- Energy Efficiency Certifications: Look for products meeting ENERGY STAR or equivalent standards, which guarantee minimal energy loss and heat generation.

- End-of-Life Management: Suppliers offering take-back programs or designing for easy disassembly support circular economy principles.

Ethical supply chain importance:

- Ensuring suppliers adhere to fair labor practices and avoid conflict minerals enhances brand reputation and compliance with international trade laws.

- Transparent sourcing of components, especially semiconductor chips and transformers, reduces risks of supply disruption and reputational damage.

Green certifications to prioritize:

- RoHS (Restriction of Hazardous Substances): Limits harmful materials in electronic components.

- CE Marking: Confirms compliance with EU safety, health, and environmental requirements.

- UL Certification: Verifies product safety and performance standards.

- ISO 14001: Indicates supplier commitment to environmental management systems.

For international buyers, partnering with suppliers who demonstrate sustainability leadership can unlock access to premium markets and long-term procurement stability.

Brief Evolution of LED Strip Power Sources

The evolution of LED strip power sources parallels the advancement of LED lighting technology itself. Early LED strips relied on simple, often inefficient power supplies that limited performance and lifespan. Over time, innovations in switching power supplies and driver circuitry enabled more compact, efficient, and reliable power sources tailored specifically for LED strips.

Modern LED strip power sources now integrate advanced features such as constant current regulation, overvoltage protection, and compatibility with dimming controls. These developments have expanded the applications of LED strips from decorative lighting to critical commercial and industrial uses, influencing purchasing decisions in B2B markets worldwide.

This evolution underscores the importance for buyers to stay informed about technological improvements to optimize lighting performance, reduce maintenance costs, and comply with evolving regulatory standards.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of led strip power source

-

How can I effectively vet suppliers of LED strip power sources for international B2B purchases?

Start by verifying the supplier’s business licenses, certifications, and compliance with international standards such as CE, RoHS, or UL. Request client references or case studies, particularly from your region (e.g., Africa or Europe), to assess reliability and product performance. Evaluate communication responsiveness and after-sales support. Consider visiting manufacturing facilities or conducting third-party audits if feasible. Checking for long-term warranties and return policies also helps ensure supplier credibility and product quality. -

What customization options are typically available for LED strip power sources in bulk orders?

Many suppliers offer customization such as voltage ratings, wattage output, connector types, cable lengths, and housing materials to meet specific project requirements. Custom branding on packaging or the power source casing may also be available. It’s important to clearly specify your technical needs and intended application upfront. Discussing these details early in the sourcing process helps avoid delays and ensures the product fits your installation environment and regulatory requirements in your target markets. -

What are common minimum order quantities (MOQs) and lead times for LED strip power sources in international trade?

MOQs vary widely depending on the supplier and customization level, typically ranging from 100 to 1,000 units per SKU. Lead times can span from 2 to 8 weeks, influenced by production schedules, customization complexity, and shipping logistics. Bulk orders usually benefit from better pricing and priority production. To optimize supply chain efficiency, align your order volumes and timelines with project milestones and negotiate flexible MOQs when possible, especially for trial runs or phased rollouts. -

Which payment terms and methods are most secure and practical for international B2B transactions?

Common payment methods include Letters of Credit (LC), Telegraphic Transfers (T/T), and Escrow services. LCs provide strong security but can be complex and costly, while T/T is faster but requires trust. For new suppliers, consider partial upfront deposits combined with balance payments upon shipment or inspection. Always clarify payment milestones in contracts and confirm currency exchange rates to avoid surprises. Using reputable trade platforms or banks with international experience can further safeguard your transactions. -

What quality assurance (QA) and certifications should I require for LED strip power sources?

Insist on suppliers providing documentation for internationally recognized certifications such as CE (European conformity), RoHS (restriction of hazardous substances), UL (Underwriters Laboratories), and ISO 9001 quality management. Request test reports for electrical safety, thermal performance, and electromagnetic compatibility (EMC). Regular batch testing and factory audits help maintain consistent quality. These certifications ensure compliance with import regulations in regions like Europe or the Middle East and reduce risks of product recalls or customs delays. -

How can I optimize logistics and shipping for bulk LED strip power source orders to regions like Africa or South America?

Work closely with suppliers to consolidate shipments and choose cost-effective freight options such as sea freight for large volumes or express air freight for urgent deliveries. Verify that packaging is robust and moisture-resistant to prevent damage during long transit. Understand import duties, taxes, and clearance procedures specific to your country to avoid unexpected costs. Partnering with experienced freight forwarders familiar with your destination can streamline customs clearance and last-mile delivery. -

What steps should I take if there is a dispute or product quality issue with my LED strip power source supplier?

First, document all discrepancies clearly with photos and detailed descriptions. Communicate promptly and professionally with the supplier to seek amicable resolution such as replacements, refunds, or discounts. Refer to your purchase contract’s dispute resolution clauses, which may include mediation or arbitration. In cases involving international trade, leverage trade insurance and engage legal counsel familiar with cross-border commerce. Maintaining thorough records and clear communication channels helps resolve disputes efficiently and preserves business relationships. -

Are there regional considerations I should be aware of when sourcing LED strip power sources for markets like Kenya or Italy?

Yes, regional power standards (e.g., voltage and frequency), climate conditions (humidity, temperature), and regulatory requirements vary significantly. For example, Kenya may require robust waterproofing and surge protection due to environmental factors, while Italy emphasizes strict CE compliance and energy efficiency labeling. Understanding local certification requirements, import restrictions, and consumer preferences is critical. Collaborating with suppliers experienced in your target market’s standards ensures smoother approvals and better product acceptance.

Strategic Sourcing Conclusion and Outlook for led strip power source

Strategic sourcing of LED strip power sources is pivotal for businesses aiming to optimize cost-efficiency, reliability, and product performance in their lighting solutions. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding supplier credibility, material quality, and compliance certifications is essential to securing power sources that ensure longevity and compatibility with diverse LED strip configurations.

Key takeaways for buyers include:

- Prioritizing suppliers with robust quality control processes and certifications (e.g., CE, RoHS) to mitigate risks associated with substandard components.

- Evaluating power source specifications carefully to match voltage, current, and environmental requirements of your projects, whether indoor or outdoor.

- Leveraging bulk purchasing and supplier relationships to negotiate better pricing, customization options, and reliable logistics support.

- Requesting product samples and technical documentation before committing to large orders to validate performance and integration ease.

Looking ahead, as LED technology advances with smarter, more energy-efficient power solutions, buyers who adopt strategic sourcing practices will gain competitive advantages in cost, innovation, and sustainability. Companies in emerging markets such as Kenya or established hubs like Italy are encouraged to cultivate partnerships with forward-thinking manufacturers to access the latest power source innovations that meet regional market demands and environmental standards.

Illustrative Image (Source: Google Search)

Act now to build resilient supply chains and future-proof your LED lighting projects by engaging trusted global suppliers who prioritize quality, compliance, and adaptability.