Introduction: Navigating the Global Market for led strip lighting connectors

In the rapidly evolving LED lighting industry, led strip lighting connectors serve as the critical link between innovation and application, enabling seamless electrical connectivity and flexible installation. For international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe—including markets like Vietnam and Spain—understanding the nuances of these connectors is essential to ensure product reliability, efficiency, and compliance with local standards.

This comprehensive guide addresses the full spectrum of considerations necessary for confident sourcing decisions. It explores various types of connectors—from snap-on clips to solderless options—tailored to different LED strip specifications and environmental conditions. Delving into material quality and manufacturing processes, the guide highlights how rigorous quality control impacts durability and performance, reducing costly returns and enhancing end-user satisfaction.

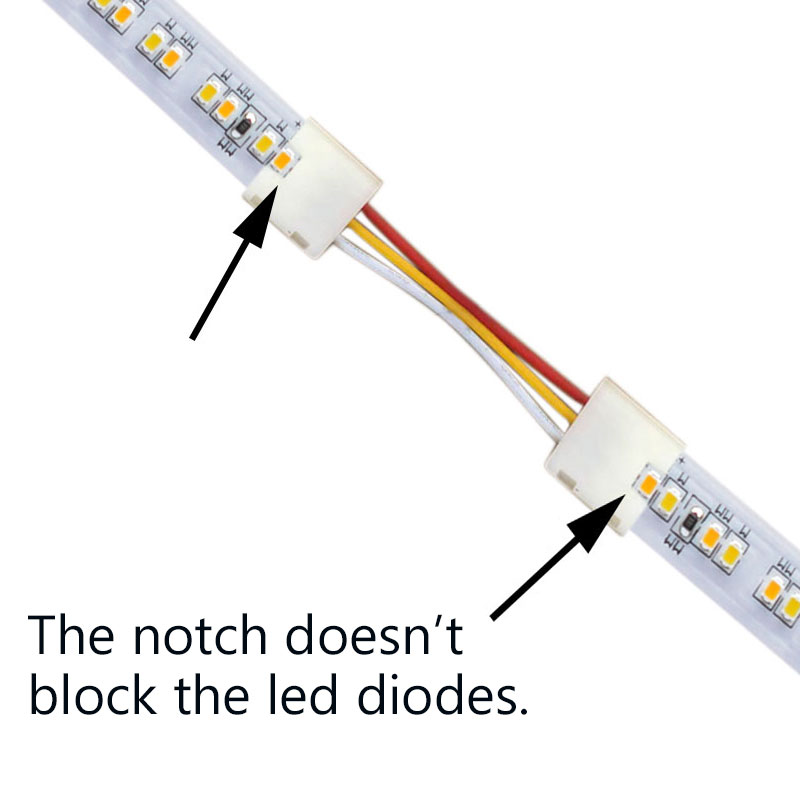

Illustrative Image (Source: Google Search)

Buyers will gain insights into selecting reputable suppliers and manufacturers, evaluating cost structures, and navigating complex global supply chains. The guide also examines market trends influencing pricing and availability, empowering buyers to anticipate shifts and secure competitive advantages. Additionally, an extensive FAQ section clarifies common technical and logistical questions, streamlining the procurement process.

By synthesizing technical knowledge with actionable market intelligence, this guide equips international B2B buyers to optimize their LED strip lighting connector sourcing strategies. Whether upgrading infrastructure or launching new product lines, readers will be better positioned to balance cost-efficiency, quality assurance, and regional market demands—ultimately driving sustainable business growth in a competitive global landscape.

Understanding led strip lighting connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clip-On Connectors | Tool-free snap-on design; compatible with standard LED strips | Quick installation in retail and hospitality | + Fast, no soldering; – Limited to specific strip widths |

| Soldered Connectors | Requires soldering wires to strip pads | Custom installations, permanent setups | + Secure, durable connection; – Time-consuming, needs skill |

| Magnetic Connectors | Magnetic coupling for easy disconnection | Modular lighting systems, exhibitions | + Reusable, flexible; – Higher cost, potential weak contact |

| Waterproof Connectors | Sealed and insulated for outdoor/IP65+ rated strips | Outdoor signage, architectural lighting | + Weatherproof, reliable; – Bulkier, higher unit cost |

| 4-Pin RGB Connectors | Supports RGB color channels with 4-pin interface | Color-changing LED strip projects | + Enables full RGB control; – Compatibility limited to RGB strips |

Clip-On Connectors

These connectors are designed for rapid, tool-free installation by clipping directly onto the LED strip’s copper pads. Ideal for large-scale retail or hospitality projects where installation speed is critical, they minimize labor costs and reduce downtime. However, buyers must ensure strip width compatibility, as these connectors fit standard sizes only. For B2B buyers in regions with variable labor costs such as Africa and South America, clip-on connectors offer a cost-effective and efficient solution.

Soldered Connectors

Soldered connections provide the most secure and durable link between LED strips and wiring. This method is preferred for custom or permanent installations where reliability is paramount, such as in industrial or architectural lighting. While soldering requires skilled labor and is more time-consuming, it offers flexibility across different strip sizes and configurations. B2B purchasers should factor in labor availability and training when opting for soldered connectors.

Magnetic Connectors

Magnetic connectors allow quick connection and disconnection, making them perfect for modular lighting setups like exhibitions or temporary installations. Their flexibility supports frequent reconfiguration, which is valuable for event organizers and showroom environments. The higher price point and potential for weaker electrical contact mean buyers must balance convenience against durability, especially in demanding environments like the Middle East.

Waterproof Connectors

Designed to maintain IP65 or higher ratings, waterproof connectors protect LED strip connections from moisture and dust, essential for outdoor or industrial applications. They tend to be bulkier and costlier but provide long-term reliability in harsh conditions such as outdoor signage or architectural facades. Buyers targeting markets with extreme weather conditions, such as parts of Europe and the Middle East, should prioritize waterproof connectors to reduce maintenance costs.

4-Pin RGB Connectors

Specifically engineered for RGB LED strips, these connectors support four-pin interfaces that control red, green, and blue channels for dynamic color lighting. They are crucial for projects requiring color customization, such as entertainment venues or decorative installations. Compatibility is limited to RGB strips, so buyers must ensure their LED products match connector specifications. This type is especially relevant for European and South American buyers engaged in creative and commercial lighting projects.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Key Industrial Applications of led strip lighting connectors

| Industry/Sector | Specific Application of led strip lighting connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Illuminated display cases and shelving with customizable LED strip lighting | Enhances product visibility and customer engagement, driving sales | Connector compatibility with various LED strip types, durability, and ease of installation for rapid store fit-outs |

| Hospitality & Leisure | Ambient and accent lighting in hotels, restaurants, and event venues | Creates inviting atmospheres, improving guest experience and brand image | Waterproof and heat-resistant connectors for humid or high-use environments, compliance with international safety standards |

| Automotive & Transportation | Interior and exterior vehicle lighting customization and repairs | Improves vehicle aesthetics and functionality, supporting aftermarket services | Connectors suited for vibration resistance, compact design, and compatibility with automotive-grade LED strips |

| Architecture & Construction | Architectural lighting for facades, walkways, and interior design projects | Adds aesthetic value and energy-efficient illumination to projects | Connectors with strong IP ratings for outdoor use, flexible installation options, and compliance with local electrical codes |

| Manufacturing & Industrial | Task and safety lighting in production lines and warehouses | Enhances worker safety and operational efficiency | Robust connectors resistant to dust, moisture, and mechanical stress; scalability for large installations |

In the retail and commercial sector, LED strip lighting connectors enable the integration of versatile lighting solutions into display cases and shelving. These connectors facilitate quick assembly and reconfiguration of LED strips, allowing businesses in markets like Spain or South Africa to adapt lighting setups to seasonal promotions or changing product lines. Buyers must prioritize connector compatibility with different strip widths and voltages, as well as connectors that support tool-free installation to reduce labor costs.

For hospitality and leisure, LED strip lighting connectors are essential for creating ambient and accent lighting in hotels, restaurants, and event venues. In regions such as the Middle East or Brazil, where humidity and temperature fluctuations can be significant, connectors need to be waterproof and heat-resistant to maintain performance and safety. International buyers should ensure connectors meet relevant certifications (e.g., IP65 or higher) and are easy to maintain for long-term use.

In the automotive and transportation industry, connectors are used extensively for customizing interior mood lighting and exterior accent lights. Businesses in countries like Vietnam or Germany benefit from connectors designed to withstand vibration and temperature extremes common in vehicles. Sourcing connectors that are compact yet robust ensures reliability and ease of installation during vehicle assembly or aftermarket upgrades.

Within architecture and construction, LED strip lighting connectors support the installation of architectural lighting on facades, walkways, and interiors. Buyers from Europe or African urban development projects require connectors with high ingress protection ratings (IP67 or above) to endure outdoor elements. Flexibility in connector design facilitates installation on complex surfaces, while compliance with local electrical standards ensures seamless project approvals.

Finally, the manufacturing and industrial sectors rely on LED strip lighting connectors for task lighting and safety illumination in production lines and warehouses. Connectors must be rugged, resistant to dust and moisture, and capable of handling large-scale deployments. International B2B buyers should evaluate the scalability and modularity of connectors to optimize lighting layouts that enhance worker safety and operational productivity.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for led strip lighting connectors

When selecting materials for LED strip lighting connectors, B2B buyers must evaluate performance, cost, manufacturing feasibility, and regional compliance standards to ensure optimal product reliability and market acceptance. Below is an in-depth analysis of four common materials used in LED strip lighting connectors, emphasizing their technical attributes and strategic considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a durable thermoplastic known for its high impact resistance, excellent dimensional stability, and good thermal resistance up to approximately 115°C. It offers moderate resistance to UV degradation and chemical exposure, making it suitable for indoor and some outdoor applications.

Pros & Cons:

– Pros: High mechanical strength, transparency (useful for visual inspection), and ease of injection molding for complex connector shapes. It also provides good electrical insulation.

– Cons: Polycarbonate can be prone to yellowing under prolonged UV exposure and may degrade in highly aggressive chemical environments. Its thermal limit restricts use in high-temperature applications.

Impact on Application:

Polycarbonate connectors are ideal for indoor LED strip lighting installations where moderate heat and environmental exposure are expected. They perform well in residential and commercial lighting but are less suited for harsh outdoor or industrial environments.

International B2B Considerations:

Buyers in regions with strong sunlight exposure (e.g., Middle East, parts of Africa) should verify UV-stabilized grades to enhance longevity. Compliance with international standards such as UL94 for flammability and IEC 60695 for electrical safety is common. European buyers often require RoHS compliance, which polycarbonate manufacturers typically meet.

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC is widely used for its excellent chemical resistance, flexibility, and flame retardancy. It withstands temperatures up to about 80°C and offers good electrical insulation properties.

Pros & Cons:

– Pros: Cost-effective, easy to process, and highly resistant to moisture and many chemicals. PVC connectors are flexible, which can simplify installation in tight spaces.

– Cons: Lower heat resistance limits use in high-temperature environments. PVC can release harmful fumes if burned, raising environmental and safety concerns.

Impact on Application:

PVC connectors are commonly used in budget-conscious projects and indoor applications where flexibility and chemical resistance are priorities. They are less suitable for outdoor or high-temperature industrial settings.

International B2B Considerations:

In South America and parts of Africa, PVC’s affordability and chemical resistance make it attractive. However, buyers should ensure compliance with local fire safety regulations and environmental standards, such as REACH in Europe, which restricts certain plasticizers in PVC. Middle Eastern markets may require connectors to meet ASTM or DIN standards for flame retardancy.

3. Polyamide (Nylon)

Key Properties:

Polyamide offers excellent mechanical strength, abrasion resistance, and thermal stability up to 150°C. It has good chemical resistance, especially to oils and greases, but can absorb moisture, which may affect dimensional stability.

Pros & Cons:

– Pros: High durability and heat resistance make nylon connectors suitable for demanding environments. It also resists wear and mechanical stress well.

– Cons: Moisture absorption can lead to swelling and dimensional changes, potentially affecting connector fit and reliability. Processing complexity and cost are higher compared to PVC and polycarbonate.

Impact on Application:

Nylon connectors are preferred in industrial LED lighting applications or outdoor installations requiring robust mechanical and thermal performance. They are well-suited for environments with exposure to oils or mechanical abrasion.

International B2B Considerations:

European buyers often favor polyamide for its durability and compliance with stringent industrial standards (e.g., DIN EN ISO 9001). In the Middle East and South America, nylon’s robustness justifies its higher cost for premium projects. Moisture considerations are critical in humid climates like Vietnam, requiring buyers to specify moisture-resistant grades or coatings.

4. Brass (with Nickel or Tin Plating)

Key Properties:

Brass is a metal alloy known for excellent electrical conductivity, corrosion resistance (especially when plated), and mechanical strength. Nickel or tin plating improves surface durability and oxidation resistance.

Pros & Cons:

– Pros: Superior conductivity ensures minimal power loss and reliable electrical connections. High mechanical strength and corrosion resistance extend connector lifespan.

– Cons: Higher material and manufacturing costs compared to plastics. Metal connectors are heavier and may require more complex assembly processes.

Impact on Application:

Brass connectors are ideal for high-performance LED strip lighting systems where electrical reliability and longevity are critical, such as architectural or commercial lighting. They perform well in humid or corrosive environments.

International B2B Considerations:

Buyers in coastal regions of Africa and South America benefit from brass connectors’ corrosion resistance. Compliance with ASTM B16 and EN standards for electrical components is often required in Europe and the Middle East. Cost sensitivity in emerging markets may limit brass use to premium product lines.

Summary Table

| Material | Typical Use Case for led strip lighting connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor residential and commercial lighting where impact resistance is needed | High impact strength and dimensional stability | Limited UV and high-temperature resistance | Medium |

| Polyvinyl Chloride (PVC) | Budget indoor applications requiring flexibility and chemical resistance | Cost-effective and chemically resistant | Lower heat tolerance and environmental concerns | Low |

| Polyamide (Nylon) | Industrial and outdoor LED lighting needing durability and heat resistance | Excellent mechanical and thermal properties | Moisture absorption affecting stability | High |

| Brass (Nickel/Tin Plated) | High-performance and corrosive environment LED lighting connectors | Superior electrical conductivity and corrosion resistance | Higher cost and manufacturing complexity | High |

This analysis equips international B2B buyers with actionable insights to select LED strip lighting connector materials aligned with their operational environments, compliance requirements, and budget constraints. Prioritizing material attributes relative to local climate, regulatory standards, and end-use applications will optimize product performance and market acceptance.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lighting connectors

The manufacturing and quality assurance of LED strip lighting connectors are critical factors that influence product reliability, safety, and performance. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding these processes can significantly improve supplier selection and risk mitigation. Below is a detailed overview of the typical manufacturing stages, quality control protocols, and actionable tips for verifying supplier quality.

Manufacturing Processes of LED Strip Lighting Connectors

The production of LED strip lighting connectors involves several key stages, each requiring precision and adherence to technical standards to ensure optimal electrical and mechanical performance.

1. Material Preparation

- Raw Materials: High-quality plastics (usually flame-retardant PC or ABS) for insulation housing and copper alloys (such as phosphor bronze or brass) for conductive parts are sourced.

- Material Inspection: Incoming raw materials undergo stringent incoming quality control (IQC) checks for chemical composition, mechanical properties, and surface finish to prevent defects downstream.

- Pre-treatment: Copper components may be electroplated (e.g., tin or nickel plating) to enhance corrosion resistance and conductivity.

2. Forming and Shaping

- Injection Molding: The plastic housing is created via injection molding, a precise process that shapes the connector casing according to design specifications. Temperature control and mold precision are critical to avoid warping or shrinkage.

- Stamping and Cutting: Metal contacts are produced using high-speed stamping machines that cut and form the conductive parts with exact dimensions to ensure proper electrical contact with LED strips.

- Bending/Forming: Contacts may undergo secondary forming processes to create the necessary geometry for insertion and locking mechanisms.

3. Assembly

- Component Integration: Metal contacts are inserted into the plastic housing, often using automated or semi-automated assembly lines to ensure consistent placement and pressure.

- Connection Features: Some connectors include features such as clips, locking tabs, or waterproof seals (e.g., silicone gaskets) which are added during assembly.

- Soldering or Welding: For certain connector types, soldering or ultrasonic welding may be used to secure internal components or wires.

4. Finishing and Packaging

- Surface Treatment: Final cleaning, deburring, or coating ensures smooth edges and prevents oxidation.

- Marking and Labeling: Connectors are labeled with batch numbers, certification marks, and technical specifications for traceability.

- Packaging: Products are packaged in moisture-proof, anti-static bags or boxes designed to protect during shipping and storage.

Quality Assurance and Control in LED Strip Connector Production

Robust quality assurance (QA) and quality control (QC) frameworks are essential to meet international market requirements and to maintain supplier credibility.

Relevant International and Industry Standards

- ISO 9001: This is the foundational quality management system standard that many reputable manufacturers adhere to, ensuring consistent process control and continual improvement.

- CE Marking: Required for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, critical for buyers concerned with environmental regulations.

- UL Certification: Common in North America and increasingly recognized globally, particularly for electrical safety.

- IP Ratings (e.g., IP20, IP65): Certify the connector’s resistance to dust and moisture, vital for outdoor or industrial applications.

- Other Regional Certifications: API or IEC standards may apply depending on the buyer’s region and application.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components to verify conformity before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing stages such as injection molding parameters, stamping accuracy, and assembly alignment.

- Final Quality Control (FQC): Comprehensive testing on finished connectors before shipment, including visual inspection, dimensional verification, and functional testing.

Common Testing Methods

- Dimensional Measurement: Using precision gauges or coordinate measuring machines (CMM) to ensure connector parts meet design tolerances.

- Electrical Testing: Verifying conductivity, insulation resistance, and voltage withstand capacity to prevent failures.

- Mechanical Testing: Checking tensile strength of contacts, insertion/removal force, and durability under repeated use.

- Environmental Testing: Simulating exposure to humidity, temperature extremes, and salt spray to assess corrosion resistance and sealing effectiveness.

- Safety Tests: Flammability and dielectric strength tests to comply with regulatory standards.

How B2B Buyers Can Verify Supplier Quality

For international buyers, especially those importing into diverse markets like Vietnam, Spain, or the Middle East, verifying the supplier’s quality assurance processes is crucial to avoid costly product failures or compliance issues.

Recommended Verification Practices

- Factory Audits: Conduct on-site or third-party audits focusing on process controls, equipment maintenance, workforce training, and documentation practices aligned with ISO 9001.

- Request Quality Documentation: Obtain certificates of conformity, test reports, and inspection records for each production batch.

- Third-Party Inspection: Engage independent inspection agencies to perform random sampling and testing before shipment, ensuring unbiased quality verification.

- Sample Testing: Request product samples for in-house or local laboratory testing to confirm performance claims.

- Supplier Capability Assessment: Evaluate the supplier’s ability to scale production without compromising quality, including backup plans for material sourcing.

Quality Assurance Nuances for Different Regions

B2B buyers should be aware of specific regional considerations that affect QC expectations and compliance:

- Africa & South America: Regulatory frameworks may be less stringent, so buyers should insist on international certifications (e.g., CE, RoHS) and rigorous testing to meet global standards.

- Middle East: Environmental conditions (high heat, dust) demand connectors with robust IP ratings and corrosion-resistant materials; verify environmental testing reports.

- Europe: Compliance with strict EU directives (REACH, RoHS) is mandatory; buyers should prioritize suppliers with CE marking and ISO 9001 certification.

- Vietnam and Southeast Asia: Rapidly growing markets with increasing quality demands; buyers should balance cost with quality by verifying supplier process controls and certifications.

Final Recommendations for Buyers

- Establish clear technical specifications upfront, including connector type, voltage rating, IP level, and certification requirements.

- Integrate quality assurance clauses in supplier contracts, specifying acceptance criteria and penalties for non-conformance.

- Use a layered approach to quality verification combining audits, documentation review, sample testing, and third-party inspection.

- Maintain ongoing communication with suppliers to monitor quality trends and address issues proactively.

By thoroughly understanding manufacturing processes and quality assurance frameworks, international B2B buyers can make informed decisions, secure reliable supply chains, and ensure that LED strip lighting connectors meet the demanding requirements of their markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lighting connectors Sourcing

Understanding Cost Components in LED Strip Lighting Connectors

When sourcing LED strip lighting connectors, international B2B buyers must first grasp the primary cost elements that influence pricing:

- Materials: The core raw materials—typically copper, plastics (like PVC or silicone), and metal alloys—form the bulk of the cost. Higher-grade or specialized materials for enhanced durability, waterproofing (e.g., IP65/IP67 ratings), or heat resistance will increase material expenses.

- Labor: Manufacturing labor costs vary significantly by country. Regions with lower labor costs, such as Vietnam, can offer competitive pricing compared to European or Middle Eastern manufacturers. However, labor quality impacts assembly precision and reliability.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Automated production lines tend to lower overhead per unit but may require larger minimum order quantities (MOQs).

- Tooling Costs: Initial setup costs for molds, stamping dies, or injection molding tools can be substantial. These are typically amortized over the production volume, so lower MOQs raise the per-unit tooling cost.

- Quality Control (QC): Stringent QC processes, including electrical testing and durability checks, add to the cost but reduce defects and returns, enhancing supplier reliability.

- Logistics and Shipping: Freight charges, customs duties, and import taxes are critical factors, especially for buyers in Africa, South America, and the Middle East where shipping routes and tariffs vary widely.

- Supplier Margin: Suppliers add their profit margin based on market positioning, brand reputation, and service levels.

Key Price Influencers to Consider

Several factors directly impact the final quoted price of LED strip lighting connectors:

- Order Volume & MOQ: Larger orders typically unlock volume discounts and reduce unit costs, making it essential to negotiate minimum quantities that align with budget and storage capacity.

- Specifications & Customization: Customized connectors—such as those with specific pin configurations, waterproof seals, or unique locking mechanisms—command higher prices due to tooling and design complexity.

- Material Quality & Certifications: Connectors with certifications like RoHS, CE, or UL often cost more but ensure compliance with international safety and environmental standards, critical for buyers targeting European and Middle Eastern markets.

- Supplier Location & Reputation: Established suppliers in China or Vietnam may offer lower prices but varying quality levels, whereas European suppliers generally have higher costs but stronger warranties and local support.

- Incoterms & Payment Terms: Shipping terms (e.g., FOB, CIF, DDP) affect who bears freight and customs risks/costs. Buyers should clarify these to avoid unexpected expenses.

Strategic Buyer Tips for Cost-Efficient Sourcing

For buyers from Africa, South America, the Middle East, and Europe aiming to optimize procurement of LED strip lighting connectors, the following strategies are recommended:

- Negotiate Beyond Price: Focus on total value including lead times, after-sales support, and warranty. Sometimes slightly higher prices yield better reliability and lower total cost of ownership (TCO).

- Factor in Total Cost of Ownership: Consider installation ease, connector lifespan, and compatibility with existing LED strips to avoid costly replacements or technical issues.

- Leverage Consolidated Shipping: Group orders with other components to reduce per-unit logistics expenses, especially for buyers in regions with higher import duties or complex customs processes.

- Request Samples and Certifications: Always verify product quality through samples and ensure certifications meet local regulations to minimize compliance risks.

- Understand Pricing Nuances by Region: For example, buyers in Spain (Europe) may benefit from local or regional suppliers to reduce shipping time and costs, while those in Africa or South America might prioritize suppliers offering DDP terms to simplify customs clearance.

- Use Flexible Payment Terms: Where possible, negotiate payment terms that minimize upfront capital outlay, such as letters of credit or partial payments tied to delivery milestones.

Disclaimer on Pricing

Prices for LED strip lighting connectors vary widely based on volume, customization, supplier, and market dynamics. The information provided here serves as a general guide to help buyers understand cost drivers and make informed decisions. It is advisable to request detailed quotations and perform comparative analyses tailored to specific sourcing scenarios.

Spotlight on Potential led strip lighting connectors Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip lighting connectors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lighting connectors

Critical Technical Properties for LED Strip Lighting Connectors

When sourcing LED strip lighting connectors internationally, understanding key technical specifications is essential to ensure compatibility, durability, and safety. Here are the most critical properties B2B buyers should prioritize:

-

Material Grade and Conductivity

Connectors are commonly made from copper alloys with tin or nickel plating for corrosion resistance and optimal electrical conductivity. Higher-grade materials reduce voltage drop and enhance longevity, especially important in humid or coastal markets across Africa and the Middle East. For buyers, specifying material quality upfront prevents premature failures and costly replacements. -

Voltage and Current Rating

Every connector is rated for maximum voltage and current it can safely handle, typically matching the LED strip’s specifications (e.g., 12V or 24V systems). Exceeding these ratings risks overheating and fire hazards. International buyers must verify these ratings align with their intended LED strip configurations to comply with local electrical standards and ensure reliable performance. -

Tolerance and Fit Precision

Connectors must maintain tight mechanical tolerances to ensure a secure fit with LED strips, preventing loose connections that cause flickering or power loss. Precision manufacturing is critical for automated installations common in European markets, where efficiency and quality standards are stringent. Buyers should request tolerance data and sample testing to confirm compatibility. -

Ingress Protection (IP) Rating

For outdoor or damp indoor applications, connectors require appropriate IP ratings (e.g., IP65 or higher) to resist dust and water ingress. This is particularly important for buyers in regions with high humidity or outdoor installations, such as parts of South America and the Middle East. Confirming IP compliance helps avoid warranty issues and product returns. -

Temperature Range and Thermal Stability

Connectors should withstand the operational temperature range of LED strips, often between -20°C to 60°C or higher. Thermal stability ensures connectors do not deform or degrade under continuous operation, which is crucial for installations in extreme climates like desert zones or cold European winters. -

Ease of Installation (Tool-Free vs. Soldered)

Many buyers prefer tool-free connectors for faster installation and reduced labor costs. However, soldered connectors may offer better electrical performance in high-demand applications. Understanding these trade-offs helps buyers specify connectors that align with their project timelines and workforce skills.

Key Industry and Trade Terms for LED Strip Lighting Connectors

Navigating international procurement requires familiarity with common trade and industry jargon. Here are essential terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce components or products that other companies rebrand and sell. Buyers seeking custom branding or specifications often engage with OEMs to develop unique LED strip connector solutions tailored to their markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. MOQs vary widely; smaller buyers in emerging markets like parts of Africa or South America should negotiate MOQs to avoid overstocking, while larger buyers benefit from volume discounts. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting pricing, lead times, and terms based on specified product requirements. A well-prepared RFQ that clearly states technical specs and quantities accelerates supplier response and reduces misunderstandings. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities and risks between buyers and sellers during shipment (e.g., FOB, CIF, DDP). Understanding Incoterms is critical for managing logistics costs and customs clearance efficiently, particularly for cross-continental shipments to Europe or the Middle East. -

RoHS Compliance (Restriction of Hazardous Substances)

Indicates that connectors meet environmental standards limiting hazardous materials like lead and mercury. European buyers especially prioritize RoHS compliance to meet regulatory demands and appeal to eco-conscious customers. -

Connector Type (e.g., 2-pin, 4-pin, RGB, RGBW)

Specifies the electrical and signal configuration of the connector corresponding to LED strip types. Accurate identification prevents compatibility issues; for example, RGB connectors differ from single-color strip connectors in pin count and wiring layout.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, mitigate risks, and establish efficient sourcing strategies for LED strip lighting connectors in diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lighting connectors Sector

Market Overview & Key Trends

The global market for LED strip lighting connectors is experiencing robust growth driven by escalating demand for energy-efficient lighting solutions across commercial, residential, and industrial sectors. Increasing urbanization and infrastructure development in emerging markets such as Africa, South America, and the Middle East are fueling demand for flexible and easy-to-install LED lighting systems, thereby driving the need for reliable connectors that ensure seamless electrical and mechanical integration.

Key market dynamics include a shift towards plug-and-play connector systems that minimize installation time and reduce labor costs. This trend is particularly advantageous for large-scale projects in regions like Vietnam and Spain, where rapid deployment and scalability are critical. Additionally, international buyers are prioritizing compatibility across different LED strip types (e.g., 12V, 24V, RGB, tunable white), which necessitates sourcing connectors that support versatile configurations.

From a sourcing perspective, the supply chain has become more globalized but also more complex, with manufacturers increasingly consolidating production in Asia, especially China and Southeast Asia. Buyers from Europe and the Middle East often seek suppliers with robust quality control and certifications to comply with stringent regional standards such as CE and RoHS. Meanwhile, African and South American buyers are focusing on cost-effective solutions without compromising reliability, often balancing local import tariffs and logistics considerations.

Technological advancements such as waterproof connectors (IP65 and above) and tool-free snap connectors are gaining traction, meeting the demand for outdoor and industrial applications. Furthermore, the integration of smart lighting controls is encouraging the development of connectors compatible with IoT-enabled LED strips, opening new opportunities for B2B buyers interested in smart building and energy management systems.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal factor in the procurement of LED strip lighting connectors as global buyers increasingly demand products that reduce environmental impact throughout their lifecycle. The manufacturing of connectors traditionally involves materials like plastics and metals, which can contribute to pollution and resource depletion if not responsibly sourced or recycled.

International B2B buyers, especially in Europe and the Middle East, are prioritizing suppliers who demonstrate transparent and ethical supply chains, ensuring compliance with environmental regulations and labor standards. Certifications such as ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) are becoming minimum requirements to verify sustainable practices.

Material innovation is also influencing purchasing decisions. Connectors made from recycled or bio-based plastics and those designed for easy disassembly and recyclability align with circular economy principles. Buyers from Africa and South America, where waste management infrastructure may be limited, benefit from sourcing connectors that reduce e-waste through durability and modularity, extending product lifespans.

Moreover, adopting suppliers with energy-efficient manufacturing processes helps reduce the carbon footprint associated with connector production. This is particularly relevant for multinational corporations operating in regions with strict carbon emissions targets. Ethical sourcing also encompasses fair labor practices, which are critical for buyers concerned with social responsibility in their supply chains.

Evolution of LED Strip Lighting Connectors

The evolution of LED strip lighting connectors reflects the broader advancements in LED technology and lighting design flexibility. Early connectors were predominantly solder-based, requiring skilled labor and time-consuming installation. The industry quickly transitioned to tool-free connectors, which simplified installation, reduced errors, and enabled quicker project turnaround.

Over time, connector designs have diversified to accommodate various strip widths, voltages, and environmental ratings. Waterproof connectors emerged in response to growing outdoor and industrial applications, while compact and low-profile connectors support slim-profile LED strips favored in architectural and retail lighting.

In recent years, the focus has shifted towards smart connectors capable of integrating with digital control systems, reflecting the LED sector’s move towards IoT and automation. This historical trajectory emphasizes increasing ease of use, adaptability, and integration, guiding B2B buyers to prioritize connectors that align with evolving technological and sustainability demands.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lighting connectors

-

How can I effectively vet LED strip lighting connector suppliers from different regions like Africa, South America, the Middle East, or Europe?

To vet suppliers internationally, start by verifying their business licenses and certifications relevant to electrical components. Request product samples and conduct quality testing to ensure compatibility and durability. Evaluate their production capacity and past client references, especially from your region. Utilize platforms with verified supplier ratings and consider factory audits, either in person or via third-party inspection services. Transparent communication about lead times, customization abilities, and after-sales support is crucial to assess reliability and alignment with your sourcing needs. -

What customization options are typically available for LED strip lighting connectors, and how can I ensure they meet my project specifications?

Most manufacturers offer customization in terms of connector types (e.g., 2-pin, 4-pin), waterproof ratings, cable lengths, and materials. To ensure compatibility, provide detailed technical specifications including voltage, current rating, and strip type. Request CAD drawings or prototypes for approval before mass production. Confirm that the supplier can accommodate any regional electrical standards or environmental conditions your market demands. Clear communication and a formal agreement on customization scope will prevent costly mismatches or delays. -

What are common minimum order quantities (MOQs) and lead times for LED strip lighting connectors, and how can I negotiate terms suitable for my market?

MOQs vary widely depending on manufacturer scale and customization level, typically ranging from 500 to 5,000 units. Lead times can range from 2 to 8 weeks. To negotiate better terms, consider consolidating orders or committing to long-term partnerships. Suppliers in regions like Vietnam or Spain might offer more flexible MOQs for repeat clients. Also, clarify payment terms upfront—partial upfront payments with balance on delivery are standard. Demonstrating your market potential and volume growth plans can help secure favorable MOQ and lead time arrangements. -

Which quality assurance certifications should I prioritize when sourcing LED strip lighting connectors internationally?

Look for certifications such as CE (Europe), RoHS (restriction of hazardous substances), UL or ETL (safety standards), and ISO 9001 (quality management systems). These ensure compliance with safety, environmental regulations, and consistent manufacturing quality. For buyers in Africa, South America, or the Middle East, checking for IEC standards compliance can be critical. Request copies of certificates and ensure they are current. Third-party lab test reports on electrical safety and material composition add confidence and support regulatory approvals in your target markets. -

What logistics considerations are important when importing LED strip lighting connectors from overseas suppliers?

Consider the total landed cost including shipping, customs duties, taxes, and handling fees. Choose reliable freight forwarders experienced with electronics to avoid delays or damage. Air freight is faster but costlier; sea freight is economical for large volumes but slower. Verify packaging quality to protect connectors from moisture and mechanical damage. Plan for customs clearance by understanding import regulations and required documentation in your country. Establish clear incoterms (e.g., FOB, CIF) with suppliers to define responsibilities and reduce disputes. -

How can I protect my business from disputes related to product quality or delivery issues with international suppliers?

Incorporate detailed product specifications, quality standards, delivery schedules, and penalties for non-compliance into your purchase agreements. Use letters of credit or escrow payment methods to mitigate financial risk. Conduct pre-shipment inspections or hire third-party quality control firms. Maintain thorough communication records and require traceability on batches. Establish clear dispute resolution mechanisms, such as arbitration clauses specifying neutral jurisdictions. Early engagement and transparency with suppliers often prevent conflicts and enable timely resolutions. -

Are there specific regional challenges I should anticipate when sourcing LED strip lighting connectors from countries like Vietnam or Spain?

Vietnam offers competitive pricing and growing manufacturing expertise but may have longer lead times due to production surges or port congestion. Language and cultural differences require clear, documented communications. Spain provides high-quality manufacturing and faster EU shipping but at higher costs. Understand local labor laws, export restrictions, and potential geopolitical impacts on supply chains. For both regions, consider time zone differences to optimize communication and stay updated on regional holidays that may affect production schedules. -

What payment methods are safest and most practical for international B2B transactions involving LED strip lighting connectors?

Common secure payment methods include letters of credit (L/C), telegraphic transfers (T/T), and escrow services. Letters of credit offer the highest security by tying payment to shipment and document verification but involve bank fees. T/T is faster and widely used but requires trust in the supplier. Escrow services protect both parties by holding funds until contract conditions are met. Negotiate partial upfront deposits to mitigate risk. Always confirm banking details independently to avoid fraud, especially when dealing with new suppliers from unfamiliar markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip lighting connectors

Strategic sourcing of LED strip lighting connectors is pivotal for international B2B buyers aiming to optimize cost-efficiency, product quality, and supply chain resilience. Key considerations include selecting connectors that align with technical specifications, ensuring compatibility with various LED strip types, and prioritizing suppliers with proven reliability and compliance with international standards. Buyers from Africa, South America, the Middle East, and Europe should leverage regional trade agreements and emerging market opportunities to negotiate favorable terms and reduce lead times.

Illustrative Image (Source: Google Search)

Effective sourcing strategies hinge on thorough supplier evaluation, emphasizing product certifications, customization capabilities, and after-sales support. Additionally, understanding logistics nuances and adopting flexible procurement models can mitigate risks associated with global disruptions. Integrating digital tools for supplier management and demand forecasting further enhances strategic decision-making.

Looking ahead, the LED strip lighting connector market is poised for innovation driven by smart lighting trends and sustainability demands. Buyers are encouraged to engage proactively with manufacturers offering advanced connector technologies and eco-friendly materials. By adopting a forward-thinking sourcing approach, international buyers can secure competitive advantages, foster long-term partnerships, and support evolving market needs.

Actionable insight: Begin by mapping your supply chain vulnerabilities and prioritize partnerships with suppliers who demonstrate agility and innovation. This strategic focus will empower businesses across diverse regions—from Vietnam to Spain—to thrive in the dynamic LED lighting ecosystem.