Introduction: Navigating the Global Market for led strip light wiring diagram

Understanding the intricacies of LED strip light wiring diagrams is paramount for international B2B buyers aiming to source high-quality lighting solutions that meet diverse project requirements. Accurate wiring diagrams not only ensure correct installation but also optimize performance, safety, and longevity of LED strip systems. For markets across Africa, South America, the Middle East, and Europe—including industrial hubs like Poland and France—mastering these technical blueprints is essential to mitigating risks associated with product incompatibility and faulty connections.

This comprehensive guide delivers an authoritative roadmap through the complex landscape of LED strip light wiring. It covers a wide array of critical topics: from the various wiring configurations tailored to different LED types and voltages, to the selection of premium materials that guarantee durability and efficiency. Buyers will gain in-depth knowledge on manufacturing processes and quality control standards that influence product reliability. Additionally, the guide offers strategic insights into evaluating suppliers, analyzing cost structures, and understanding market dynamics specific to global sourcing.

By integrating practical wiring knowledge with broader procurement considerations, this resource empowers businesses to make informed decisions that align with their operational goals and regulatory environments. Whether managing large-scale commercial installations or intricate architectural lighting projects, buyers will acquire the tools needed to streamline sourcing workflows, enhance supplier negotiations, and ultimately secure LED strip light solutions that deliver optimal value and innovation in a competitive global marketplace.

Understanding led strip light wiring diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color Wiring Diagram | Simple two-wire connection (positive and negative) | Basic architectural lighting, retail stores | + Cost-effective, easy installation – No color control options |

| RGB Wiring Diagram | Four-wire setup (common positive + R, G, B negative wires) | Hospitality, event venues, advertising | + Dynamic color control – Requires compatible controllers |

| RGBW Wiring Diagram | Five-wire configuration (adds white LED channel) | High-end residential, museums, galleries | + Enhanced color accuracy and white tones – More complex wiring |

| Addressable LED Wiring Diagram | Data line plus power and ground for individually controlled LEDs | Interactive displays, smart lighting systems | + Pixel-level control, customizable effects – Higher cost, complex installation |

| Waterproof Wiring Diagram | Similar wiring to above types but with sealed connectors and insulation | Outdoor, industrial, landscape lighting | + Weather-resistant, durable – Slightly higher cost, limited flexibility |

Single-Color Wiring Diagram

This wiring type is the most straightforward, involving just two wires for power delivery. It suits projects requiring consistent lighting without color changes, such as retail shelves, office illumination, or corridor lighting. For B2B buyers in regions with budget constraints or projects emphasizing simplicity, this type offers a reliable and low-cost solution. Buyers should verify voltage compatibility and power supply specifications to ensure seamless integration.

RGB Wiring Diagram

RGB wiring incorporates an additional control line for red, green, and blue LEDs, enabling a spectrum of colors through mixing. This setup is prevalent in hospitality venues, event spaces, and advertising where dynamic color effects are essential. B2B buyers should consider the necessity of compatible controllers and the potential complexity in installation and maintenance. Ensuring supplier support for controller integration is critical for smooth deployment.

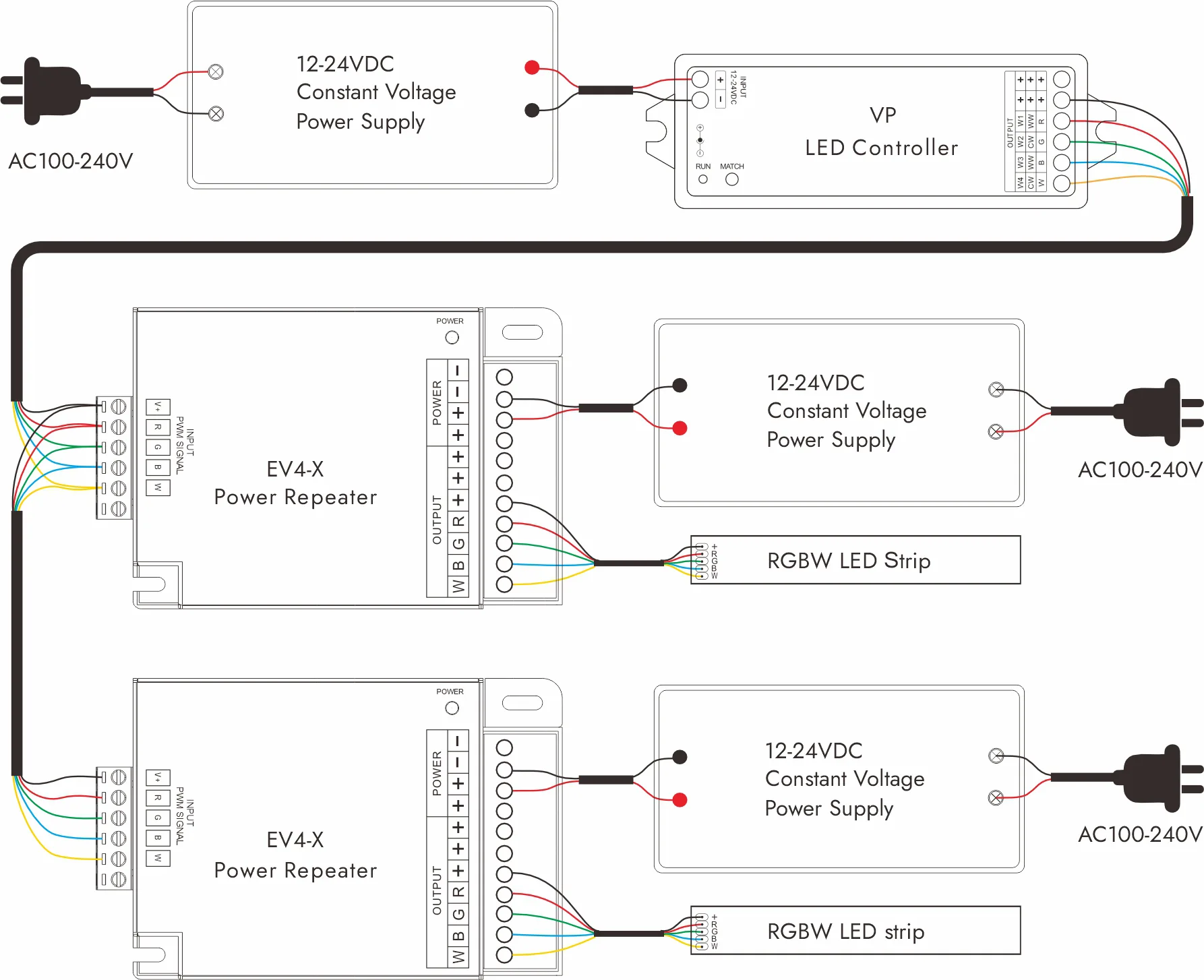

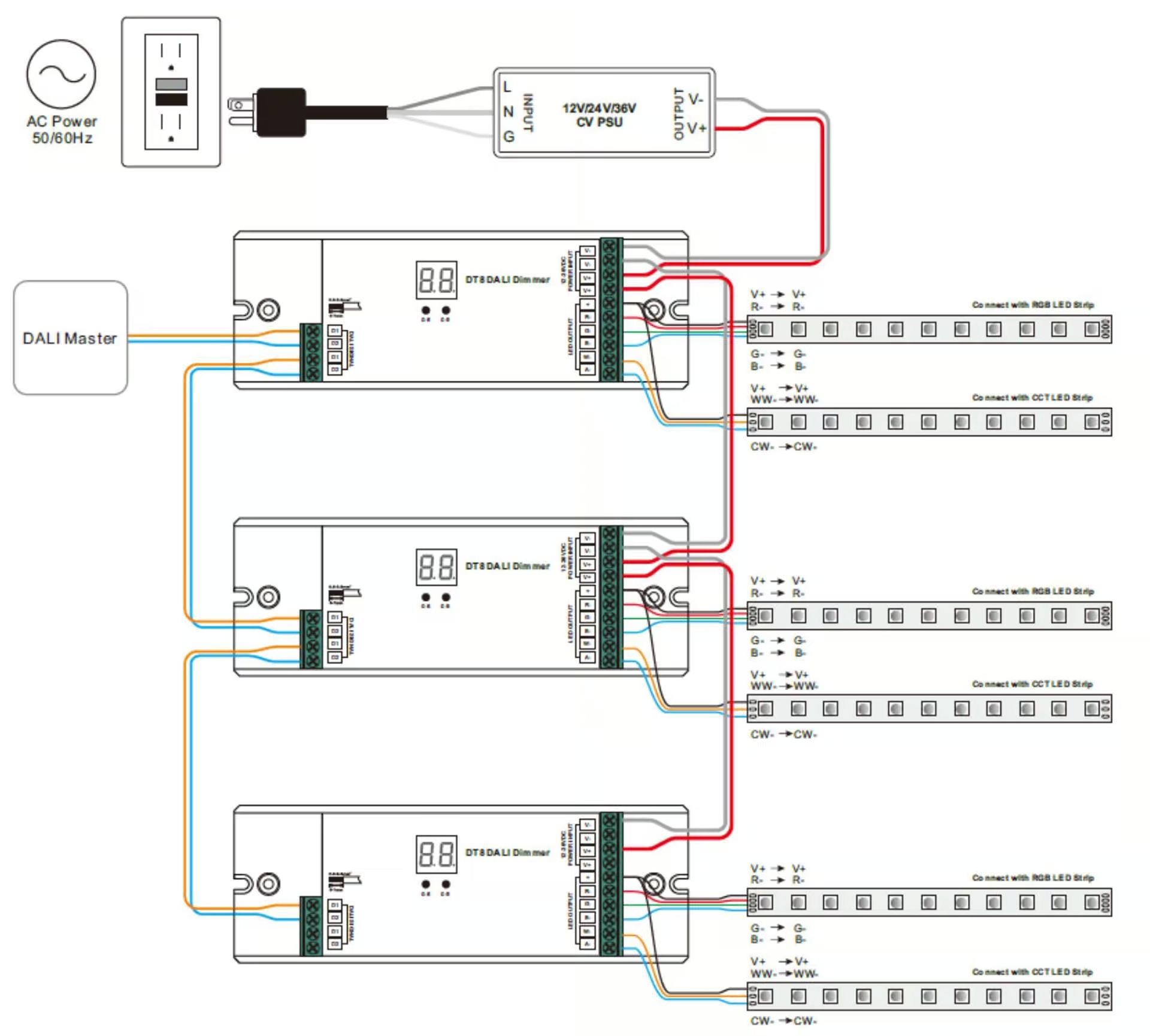

RGBW Wiring Diagram

By adding a dedicated white LED channel, RGBW wiring diagrams provide superior white light quality alongside full RGB color mixing. This configuration is ideal for premium applications such as museums or high-end residential projects where accurate color rendering and white tones are important. Buyers must evaluate the increased wiring complexity and potential cost implications but benefit from enhanced lighting versatility.

Addressable LED Wiring Diagram

Addressable LED strips use a data line in addition to power and ground, allowing individual LEDs to be controlled independently. This type is suited for interactive displays, smart lighting, and customized visual effects, making it attractive for technologically advanced projects. B2B buyers should prepare for higher costs, more complex wiring, and the need for advanced controllers and software. Supplier expertise in programming and technical support is a key consideration.

Waterproof Wiring Diagram

Waterproof wiring diagrams adapt any of the above types with sealed connectors and protective insulation to withstand moisture and harsh environments. This is crucial for outdoor lighting, industrial applications, and landscaping projects across diverse climates in Africa, South America, the Middle East, and Europe. Buyers should prioritize IP ratings and ensure compatibility with existing lighting systems to maximize durability and reduce maintenance costs.

Related Video: A Useful Guide about How to Install, Cut and Connect RGB LED Strip Light

Key Industrial Applications of led strip light wiring diagram

| Industry/Sector | Specific Application of led strip light wiring diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Retail | Storefront and in-store LED lighting installations | Enhances product visibility and creates immersive shopping experiences | Compatibility with existing electrical infrastructure; ease of installation and scalability |

| Hospitality & Tourism | Ambient and accent lighting in hotels, restaurants, and resorts | Improves guest experience and ambiance; energy-efficient lighting solutions | Compliance with regional safety standards; flexible wiring options for diverse layouts |

| Industrial Manufacturing | Task and safety lighting on production floors and assembly lines | Increases operational safety and productivity with clear visibility | Durability under harsh conditions; robust wiring diagrams to minimize downtime |

| Architectural & Urban Design | Façade and landscape lighting for buildings and public spaces | Elevates aesthetic appeal and brand presence; supports smart lighting control | Weatherproof wiring solutions; integration with smart control systems |

| Transportation & Infrastructure | Interior and exterior lighting in airports, train stations, and tunnels | Enhances safety, navigation, and energy efficiency in transit hubs | High reliability wiring diagrams; adherence to international electrical codes |

In Commercial Retail, LED strip light wiring diagrams are crucial for designing and implementing lighting systems that highlight merchandise and guide customer flow effectively. These diagrams assist electrical engineers and installers in configuring power supplies and controllers to achieve uniform illumination and color effects. For B2B buyers in Africa, South America, and Europe, sourcing wiring diagrams that accommodate local voltage standards and allow modular expansion is essential to future-proof retail spaces and reduce installation complexity.

Within the Hospitality & Tourism sector, wiring diagrams for LED strip lights enable seamless integration of lighting that adjusts to ambiance needs, such as dimming or color changes for different times of day or events. Accurate wiring layouts ensure that lighting controllers and power units are correctly connected, minimizing maintenance issues. Buyers in the Middle East and Europe should prioritize diagrams that support energy-efficient drivers and comply with regional electrical safety regulations to optimize operational costs and guest satisfaction.

In Industrial Manufacturing, LED strip light wiring diagrams support the installation of task lighting that enhances visibility on assembly lines and safety lighting in hazardous zones. These diagrams provide detailed guidance to ensure wiring robustness and correct power distribution, which is critical to minimizing downtime and electrical faults. International buyers must consider diagrams designed for high durability and compliance with industrial standards, especially in regions with challenging environmental conditions like parts of Africa and South America.

For Architectural & Urban Design, wiring diagrams facilitate the complex installation of LED strips on building façades and urban landscapes, often requiring integration with smart lighting control systems. These diagrams help planners and contractors understand wiring routes, power load balancing, and controller placement to deliver dynamic lighting effects that enhance urban aesthetics. Buyers in Europe and the Middle East should seek diagrams that support waterproof connectors and are compatible with IoT-based lighting management platforms for long-term scalability.

In Transportation & Infrastructure, LED strip light wiring diagrams are fundamental for ensuring safe and energy-efficient lighting in transit hubs and tunnels. Detailed wiring instructions help engineers implement reliable lighting circuits that meet stringent safety codes and facilitate maintenance. For B2B buyers in international markets, sourcing wiring diagrams that comply with global and local electrical standards and offer clear fault diagnosis paths is critical to sustaining uninterrupted operations and passenger safety.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for led strip light wiring diagram

When selecting materials for LED strip light wiring diagrams, it is crucial to evaluate the properties that directly affect performance, durability, and compliance with international standards. This ensures that the wiring system supports the LED strips’ operational requirements and withstands environmental and electrical stresses typical in diverse markets such as Africa, South America, the Middle East, and Europe.

Copper Conductors

Key Properties: Copper is the industry standard for electrical wiring due to its excellent electrical conductivity, high thermal resistance, and good mechanical strength. It typically withstands temperatures up to 105°C and offers superior corrosion resistance when properly insulated.

Pros & Cons: Copper wiring is highly durable and efficient, reducing energy loss and heat buildup. However, it is more expensive than alternatives like aluminum and requires careful handling to avoid mechanical damage. Manufacturing complexity is moderate, with well-established global supply chains.

Impact on Application: Copper wiring is ideal for LED strip installations requiring stable current flow and minimal voltage drop, especially in long runs or high-power configurations. Its corrosion resistance makes it suitable for humid or coastal environments common in Middle Eastern and African regions.

B2B Considerations: Buyers from Europe (e.g., Poland, France) will benefit from copper wiring’s compliance with stringent standards such as IEC and DIN, ensuring safety and reliability. In South America and Africa, where supply chain variability can affect quality, sourcing certified copper wiring with clear compliance documentation is critical to avoid failures.

PVC Insulation

Key Properties: Polyvinyl chloride (PVC) insulation is widely used due to its flame-retardant properties, flexibility, and resistance to moisture and chemicals. It typically supports temperature ratings up to 70°C or 90°C depending on formulation.

Pros & Cons: PVC insulation is cost-effective and easy to manufacture, providing good protection for wiring in indoor and dry environments. However, it can degrade under prolonged UV exposure or extreme heat, limiting outdoor applications unless specially treated.

Impact on Application: PVC-insulated wiring suits LED strip installations in commercial indoor settings or controlled environments. It is less suitable for outdoor or industrial applications where temperature and UV resistance are critical.

B2B Considerations: For buyers in the Middle East and Africa, where high temperatures and sunlight exposure are common, PVC wiring should be carefully evaluated for UV resistance or replaced with more robust alternatives. European buyers benefit from PVC materials that meet RoHS and REACH regulations, ensuring environmental compliance.

Silicone Rubber Insulation

Key Properties: Silicone rubber offers excellent thermal stability, withstanding temperatures from -60°C up to 200°C. It is highly flexible, resistant to moisture, UV radiation, and various chemicals, making it ideal for harsh environments.

Pros & Cons: Silicone-insulated wiring provides superior durability and flexibility, especially in dynamic or outdoor installations. The downside is a higher cost and more complex manufacturing process compared to PVC.

Impact on Application: This insulation is preferred for LED strip wiring in outdoor, industrial, or automotive applications where exposure to extreme temperatures and environmental factors is expected. Its flexibility also facilitates installation in tight or curved spaces.

B2B Considerations: Buyers in Africa and South America, where climate conditions vary widely, will find silicone insulation advantageous for outdoor LED lighting projects. Compliance with ASTM and IEC standards is common, and European buyers appreciate its alignment with eco-friendly material mandates.

Tinned Copper Conductors

Key Properties: Tinned copper wires are copper conductors coated with a thin layer of tin to enhance corrosion resistance, especially in marine or humid environments. They maintain copper’s conductivity while extending lifespan under corrosive conditions.

Pros & Cons: The tin coating significantly improves durability in harsh environments but adds to the cost and slightly reduces conductivity compared to bare copper. Manufacturing is moderately complex due to the tinning process.

Impact on Application: Tinned copper wiring is ideal for LED strip installations in coastal areas, outdoor signage, or industrial settings prone to moisture and salt exposure. It ensures long-term reliability where standard copper might corrode.

B2B Considerations: For Middle Eastern and African markets with coastal installations, tinned copper wiring is a strategic choice to reduce maintenance and replacement costs. European buyers benefit from its compliance with IEC and EN standards, supporting high-quality, durable installations.

| Material | Typical Use Case for led strip light wiring diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Conductors | General wiring for indoor/outdoor LED strip installations | Excellent conductivity and corrosion resistance | Higher cost and moderate manufacturing complexity | High |

| PVC Insulation | Indoor LED strip wiring in commercial and residential environments | Cost-effective and flame-retardant | Limited UV and heat resistance | Low |

| Silicone Rubber Insulation | Outdoor/industrial LED strip wiring requiring high flexibility | Superior thermal stability and environmental resistance | Higher cost and complex manufacturing | High |

| Tinned Copper Conductors | Coastal and humid environment LED strip wiring | Enhanced corrosion resistance in harsh conditions | Slightly reduced conductivity and higher cost | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip light wiring diagram

Manufacturing and quality assurance of LED strip light wiring diagrams involve precise, multi-stage processes designed to ensure product reliability, safety, and performance. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding these processes and quality control (QC) measures is critical to sourcing LED strip lighting solutions that meet regional and international standards.

Core Manufacturing Processes for LED Strip Light Wiring Diagrams

The production of LED strip light wiring diagrams typically accompanies or integrates with the manufacturing of the LED strips themselves, focusing on electrical layout, connection integrity, and user-friendly design. Key manufacturing stages include:

-

Material Preparation

– Substrate Selection: Flexible printed circuit boards (FPCBs) are prepared, usually made from polyimide or PET materials, chosen for durability and heat resistance.

– Component Procurement: High-quality LEDs, resistors, connectors, and wiring materials are sourced, emphasizing consistency and compliance with electrical ratings. -

Circuit Forming and Patterning

– Copper Tracing: Copper layers are etched or printed onto the substrate to form precise wiring paths according to the wiring diagram specifications.

– Solder Mask Application: A protective solder mask is applied to isolate circuits and prevent short circuits, ensuring long-term reliability. -

Component Assembly

– Surface Mount Technology (SMT): LEDs and other components are placed on the substrate using automated pick-and-place machines, followed by soldering via reflow ovens to secure electrical connections.

– Connector Integration: Wiring connectors and terminals are attached, enabling easy installation and modularity. -

Finishing and Protective Coating

– Encapsulation: To protect wiring and LEDs from environmental factors, silicone or epoxy coatings are applied, especially for waterproof models.

– Cutting and Packaging: The strips are cut to standard or customized lengths, and wiring diagrams (printed or digital) are prepared to guide installation.

Quality Assurance Frameworks and International Standards

For B2B buyers, the assurance of product quality and compliance with international standards is paramount. Leading manufacturers implement stringent QC systems based on recognized frameworks:

- ISO 9001 Certification: Demonstrates the manufacturer’s commitment to quality management systems, ensuring consistent production processes and continuous improvement.

- CE Marking: Indicates conformity with European safety, health, and environmental protection standards, essential for buyers in the EU and associated markets such as Poland and France.

- RoHS Compliance: Restricts hazardous substances in electrical products, critical for environmental regulations in Europe and increasingly adopted worldwide.

- UL and ETL Listings: North American safety certifications that may be relevant for buyers sourcing for global markets requiring these approvals.

- IP Ratings (Ingress Protection): Defines protection levels against dust and water, crucial for outdoor or industrial applications, often detailed in product specifications.

Key Quality Control Checkpoints

Quality control in LED strip light wiring diagram production is typically segmented into stages to catch defects early and ensure final product integrity:

-

Incoming Quality Control (IQC):

Verifies raw materials and components upon arrival, checking for dimensional accuracy, electrical properties, and supplier certifications to prevent defective inputs. -

In-Process Quality Control (IPQC):

Conducted during production, focusing on solder joint quality, wiring continuity, and adherence to wiring diagram specifications. Automated optical inspection (AOI) systems and manual checks are commonly used. -

Final Quality Control (FQC):

Includes comprehensive testing of completed LED strips and wiring assemblies for functionality, durability, and safety. This often involves electrical load testing, insulation resistance testing, and visual inspections.

Common Testing Methods for Wiring Diagrams and LED Strips

- Continuity and Short-Circuit Testing: Ensures wiring paths are correctly connected without unintended shorts, critical for safety and performance.

- Voltage and Current Load Testing: Confirms the wiring can handle specified electrical loads without overheating or failure.

- Environmental Stress Testing: Simulates exposure to humidity, temperature fluctuations, and mechanical stress to assess long-term reliability.

- EMC (Electromagnetic Compatibility) Testing: Checks for electromagnetic interference, particularly important for installations near sensitive equipment.

How B2B Buyers Can Verify Supplier Quality Control

To confidently source LED strip light wiring diagrams and associated products, buyers should proactively verify supplier QC capabilities:

- Factory Audits: On-site or third-party audits review manufacturing processes, equipment, personnel qualifications, and QC documentation. This is especially recommended for buyers in regions with complex import regulations or quality concerns.

- Review of QC Reports and Certificates: Request detailed inspection reports, test data, and certification copies (e.g., ISO 9001, CE, RoHS) to validate compliance claims.

- Third-Party Testing and Inspection: Engage independent labs or inspection agencies to conduct product sampling and verification, providing unbiased quality assurance.

- Supplier Quality Agreements: Formal contracts outlining QC expectations, defect rates, and remedial actions help align both parties on quality standards.

Quality Control Considerations for Diverse International Markets

B2B buyers across Africa, South America, the Middle East, and Europe face unique challenges and opportunities in sourcing:

- Regulatory Variations: Europe’s stringent CE and RoHS requirements mandate rigorous supplier compliance, while some African and South American markets may emphasize durability and cost-efficiency due to harsher environments and budget constraints.

- Environmental Conditions: Buyers from the Middle East should prioritize waterproofing and heat resistance in wiring diagrams and LED strips, given extreme temperatures and dust exposure.

- Documentation and Traceability: European buyers often require detailed technical files and traceability for customs clearance and product liability, underscoring the need for transparent QC records.

- Language and Technical Support: Suppliers offering wiring diagrams with clear, multilingual instructions and responsive technical support facilitate smoother installations and reduce operational risks for international clients.

By understanding the comprehensive manufacturing stages and stringent quality assurance measures behind LED strip light wiring diagrams, international B2B buyers can make informed decisions that align with their operational demands and regulatory environments. Prioritizing suppliers with robust QC systems, verified certifications, and transparent processes will mitigate risks and enhance the value of procurement investments across diverse global markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip light wiring diagram Sourcing

When sourcing LED strip light wiring diagrams—a critical component for installation, maintenance, and customization—understanding the cost and pricing structure is essential for international B2B buyers. This analysis breaks down key cost elements, pricing drivers, and practical buyer strategies tailored to markets in Africa, South America, the Middle East, and Europe, including countries like Poland and France.

Core Cost Components in LED Strip Light Wiring Diagram Sourcing

-

Materials

The primary costs stem from the quality and type of materials used in the wiring diagram documentation and associated components (e.g., connectors, cables). Higher-grade materials that ensure durability, electrical safety, and compatibility with specific LED strips typically command premium prices. -

Labor and Manufacturing Overhead

Skilled labor is required to design, draft, and test wiring diagrams, especially for customized or complex LED strip lighting systems. Overhead costs include factory utilities, equipment depreciation, and indirect labor, which vary by region and supplier capacity. -

Tooling and Design Development

For custom wiring diagrams or proprietary configurations, tooling and initial design setup costs can be significant. These are often amortized over large order volumes but can impact pricing for smaller or bespoke orders. -

Quality Control (QC) and Certification

Rigorous QC processes to verify wiring accuracy, safety compliance, and adherence to international standards add to the cost base. Certifications such as CE for Europe or local electrical safety marks influence pricing and buyer confidence. -

Logistics and Shipping

Shipping costs for physical documentation or associated wiring components depend on the supplier’s location, chosen Incoterms, and delivery speed. Buyers from Africa and South America should anticipate higher freight costs and potential customs duties compared to European buyers. -

Supplier Margin

Margins vary based on supplier reputation, exclusivity of design, and volume commitments. Established manufacturers with strong compliance and support services may price higher but offer better long-term value.

Key Pricing Influencers to Consider

-

Order Volume and Minimum Order Quantity (MOQ)

Bulk purchases typically reduce unit costs. Buyers from emerging markets should negotiate MOQs aligned with their demand forecasts to optimize pricing without overstocking. -

Specification Complexity and Customization

Standard wiring diagrams for common LED strip models cost less than fully customized, application-specific diagrams that require additional engineering. -

Material and Component Quality

Diagrams incorporating wiring for premium LED strips or waterproof, high-voltage configurations may increase costs due to specialized components. -

Quality Certifications and Compliance

Products meeting international safety and quality standards command higher prices but reduce risk and potential rework costs. -

Supplier Location and Experience

Suppliers closer to the buyer’s region or with proven expertise in the LED lighting industry often offer better pricing structures and faster turnaround times. -

Incoterms and Payment Terms

Understanding shipping terms (e.g., FOB, CIF, DDP) impacts landed cost calculations. Favorable payment terms can improve cash flow and price negotiations.

Practical Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO):

Focus beyond unit price to include installation ease, warranty support, and after-sales service embedded in the wiring diagram package. -

Leverage Volume Discounts and Long-Term Contracts:

For buyers in regions like Africa or South America, committing to longer-term partnerships can unlock better pricing and priority production slots. -

Assess Quality vs. Cost Trade-offs:

In markets with variable infrastructure, such as parts of the Middle East or Africa, prioritizing certified, robust wiring diagrams reduces costly failures. -

Factor in Logistics and Customs:

Buyers in Europe (e.g., Poland, France) benefit from streamlined customs processes but should still consider transit times and packaging to avoid damage. -

Request Samples and Pilot Runs:

Before large orders, validate wiring diagram accuracy and compatibility through pilot projects to avoid costly revisions. -

Understand Local Regulations:

Compliance with electrical and safety codes in target markets influences design requirements and cost.

Indicative Pricing Disclaimer

Pricing for LED strip light wiring diagrams varies widely based on customization level, order volume, and supplier capabilities. The figures should be considered indicative. Buyers are advised to request detailed quotations and factor in all associated costs, including shipping, taxes, and potential currency fluctuations, to make fully informed procurement decisions.

By dissecting cost drivers and pricing influencers, B2B buyers can strategically navigate supplier negotiations and optimize sourcing decisions for LED strip light wiring diagrams, ensuring cost-effective, reliable lighting solutions tailored to their regional and application-specific needs.

Spotlight on Potential led strip light wiring diagram Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip light wiring diagram’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip light wiring diagram

Critical Technical Properties for LED Strip Light Wiring Diagrams

When sourcing LED strip lights and their wiring diagrams, understanding the technical specifications is crucial for ensuring product compatibility, performance, and long-term reliability. Here are key properties that international B2B buyers should prioritize:

-

Voltage Rating (e.g., 5V, 12V, 24V)

This specifies the operating voltage of the LED strip and its wiring system. Selecting the correct voltage is vital to avoid underperformance or damage. For example, 12V and 24V strips are common for commercial and architectural projects, offering longer runs and reduced voltage drop. Buyers should confirm that power supplies and wiring diagrams match the voltage rating to ensure safety and efficiency. -

Material Grade and PCB Quality

The printed circuit board (PCB) material, often flexible copper-clad laminate, affects durability and heat dissipation. High-quality PCBs reduce the risk of circuit failure and improve lifespan, especially in demanding environments like outdoor or industrial installations. B2B buyers should request material certifications or test reports to verify compliance with international standards. -

IP Rating (Ingress Protection)

Indicates the level of protection against dust and moisture. For wiring diagrams, understanding the IP rating guides the selection of appropriate connectors and protective casing. For instance, IP65 or higher is essential for outdoor or humid environments common in regions like the Middle East or coastal Africa. -

Tolerance Levels and Current Capacity

Tolerance refers to the allowable variation in electrical parameters such as current and resistance. Proper tolerance ensures consistent light output and prevents overheating. Wiring diagrams should specify maximum current loads per segment to help buyers plan safe installations and avoid product failures. -

Connector Types and Polarity Markings

Clear identification of connectors (e.g., solder pads, quick connectors) and polarity is critical for correct wiring. Miswiring can cause LED damage or system failure. Buyers should look for wiring diagrams that include detailed connector specifications and polarity indicators, facilitating faster installation and reducing labor costs. -

Thermal Management Specifications

Effective heat dissipation methods, such as aluminum backplates or heat sinks, are often included in wiring plans. Proper thermal management enhances LED longevity and performance, which is especially important for high-intensity or continuous-use applications in industrial or commercial settings.

Essential Trade Terminology for International B2B Buyers

Navigating the LED strip light market requires familiarity with common trade terms that impact procurement, negotiation, and logistics. Here are key terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strip lights or components that can be branded and customized by buyers. OEM partnerships allow businesses in Europe, South America, and beyond to source tailored products with specific wiring configurations and branding, often at competitive prices. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. MOQ affects pricing, inventory management, and supply chain planning. Buyers from emerging markets like Africa or the Middle East should negotiate MOQs that align with project scale to optimize cash flow and storage. -

RFQ (Request for Quotation)

A formal process where buyers request detailed price and specification information from suppliers. RFQs are essential for comparing offers on LED strip light wiring diagrams and components, enabling B2B buyers to make informed sourcing decisions based on cost, quality, and delivery terms. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers from different continents manage import costs and risks effectively. -

Lead Time

The duration from order placement to product delivery. Accurate lead time estimates are critical for project scheduling, especially for large-scale installations in regions with complex logistics like South America or remote areas in Africa. -

Certification Standards (e.g., CE, RoHS, UL)

Compliance certifications ensure that LED strip lights and wiring comply with safety, environmental, and quality regulations. Buyers should verify certifications to meet regional import requirements and guarantee product safety and market acceptance.

By mastering these technical properties and trade terms, international B2B buyers can streamline their procurement processes, mitigate risks, and secure LED strip light solutions that meet both performance and regulatory demands across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip light wiring diagram Sector

Market Overview & Key Trends

The global market for LED strip light wiring diagrams is experiencing robust growth driven by the widespread adoption of LED lighting technologies across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Poland and France—are increasingly seeking detailed and reliable wiring diagrams to support complex lighting installations that demand precision and scalability. This growth is fueled by rising demand for energy-efficient lighting solutions, smart home integration, and customizable lighting effects.

Key market dynamics include the integration of advanced digital control systems such as SPI (Serial Peripheral Interface) and PWM (Pulse Width Modulation) for precise color and brightness management. This has made wiring diagrams more complex but also more critical for ensuring seamless system performance. B2B buyers are prioritizing suppliers that provide comprehensive technical documentation and modular wiring solutions to reduce installation time and maintenance costs.

Emerging sourcing trends emphasize the need for compatibility with multiple voltage levels (5V, 12V, 24V) and the inclusion of waterproof connectors for outdoor applications, reflecting the diversification of end-use environments. Additionally, the rise of IoT-enabled lighting systems is pushing demand for wiring diagrams that integrate with wireless controllers and DMX protocols, particularly in the event and architectural lighting markets.

For international buyers, particularly those in emerging markets, partnering with suppliers that offer localized technical support and customization services is becoming a competitive advantage. This is especially relevant in Africa and the Middle East, where infrastructure and regulatory standards vary widely. European buyers often focus on compliance with stringent electrical safety standards and certifications, requiring suppliers to provide detailed wiring schematics aligned with local codes.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly shaping procurement decisions in the LED strip light wiring diagram sector. Buyers are more aware of the environmental impact of their supply chains and demand wiring solutions that minimize waste and enable energy-efficient operation of LED systems. Ethical sourcing of materials such as copper for wiring and lead-free solder in connectors is becoming a baseline expectation, aligning with global regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Green certifications, including ISO 14001 for environmental management and compliance with ENERGY STAR standards, serve as important indicators of supplier commitment to sustainability. Buyers from Europe and South America often require documentation verifying the use of recyclable materials and adherence to circular economy principles in the production of wiring components.

In addition to environmental concerns, ethical labor practices are a critical factor. Buyers are increasingly scrutinizing supplier transparency regarding working conditions and fair wages, especially when sourcing from regions with less regulatory oversight. This is vital for maintaining corporate social responsibility (CSR) standards and protecting brand reputation in international markets.

Illustrative Image (Source: Google Search)

Sourcing wiring diagrams from suppliers who implement eco-friendly packaging, reduce hazardous chemical use, and provide clear lifecycle assessments can reduce operational risks and enhance long-term value. For B2B buyers, embedding sustainability criteria into supplier evaluation processes is now a key strategy to future-proof their procurement activities and meet the growing expectations of end customers.

Brief Evolution and Historical Context

The evolution of LED strip light wiring diagrams parallels the rapid technological advancements in LED lighting over the past two decades. Initially, wiring diagrams were straightforward, reflecting simple single-color LED strips operating at fixed voltages. As LED technology advanced to include RGB and RGBW variants with dynamic color control, wiring diagrams grew increasingly complex, incorporating multiple signal lines, power feeds, and control interfaces.

The introduction of digital addressable LEDs and smart controllers further transformed wiring schematics, requiring detailed guidance on data signal routing, amplifier placement, and power management to prevent voltage drop and signal degradation. This complexity has made professional-grade wiring diagrams indispensable for B2B buyers aiming for flawless installation and system scalability.

Historically, the shift from analog to digital control systems in LED strips has driven the demand for more sophisticated wiring documentation, making it a critical factor in supplier selection and project success. Understanding this evolution helps buyers appreciate the technical nuances and supplier capabilities necessary to meet modern lighting demands efficiently.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of led strip light wiring diagram

-

How can I effectively vet suppliers of LED strip light wiring diagrams for international B2B purchases?

Start by verifying the supplier’s certifications, such as ISO quality management and compliance with international electrical standards (e.g., CE, RoHS). Request detailed product datasheets and sample wiring diagrams to assess technical accuracy. Evaluate their experience with export markets relevant to your region (Africa, South America, Middle East, Europe). Check references or reviews from other B2B clients. Consider suppliers offering technical support and customization options, as these are indicators of reliability and expertise. Conduct virtual or on-site audits if possible to confirm manufacturing capabilities and quality control processes. -

What customization options are typically available for LED strip light wiring diagrams?

Suppliers often provide tailored wiring diagrams to match specific voltage requirements (5V, 12V, 24V), LED types (SMD, RGB, RGBW), and control systems (PWM, DMX, SPI). Custom diagrams may include integration with smart controllers, power supply configurations, and connectors suitable for local standards. For international buyers, ensuring diagrams incorporate regional electrical codes and wiring color conventions is critical. Request suppliers to provide CAD or vector files for easier integration into your project documentation. Customization reduces installation errors and enhances system compatibility. -

What are common minimum order quantities (MOQs) and lead times for wiring diagrams in bulk LED strip light orders?

MOQs for wiring diagrams themselves are usually low or negotiable, but they are tied to the associated LED strip light product orders. Typical LED strip light MOQs range from 500 to 1,000 meters per model, depending on supplier scale and product complexity. Lead times vary from 2 to 6 weeks, influenced by customization, order size, and shipping method. For buyers in Africa or South America, factor in additional transit time and customs clearance. Negotiate clear terms upfront and request detailed production schedules to align with your project timelines. -

Which payment terms are standard and safest when sourcing LED strip light wiring diagrams internationally?

Common payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), and increasingly, secure online platforms offering escrow services. For new suppliers, consider partial upfront payment (30%) and balance after delivery or inspection. Large B2B buyers in Europe or the Middle East often negotiate net 30 to net 60 payment terms to optimize cash flow. Always verify supplier banking details to avoid fraud and use contracts specifying payment schedules, penalties for delays, and quality assurances to protect your interests. -

What quality assurance measures and certifications should I look for related to LED strip light wiring diagrams?

Quality assurance encompasses verification that wiring diagrams comply with international electrical safety standards and accurately represent the product’s wiring. Look for suppliers whose diagrams are validated by certified electrical engineers and accompanied by product certifications like CE, UL, or IEC. Suppliers should have documented quality control processes including prototype testing, EMC (electromagnetic compatibility) testing, and factory inspections. For critical projects, request third-party testing reports and confirm that wiring diagrams are updated to reflect any design changes during production. -

How should I handle logistics and shipping challenges when importing LED strip light wiring diagrams and related products?

Wiring diagrams are typically digital files, so logistics mainly concern the physical LED strip lights and accessories. Choose suppliers experienced with international shipping and customs procedures for your region. Opt for freight forwarders familiar with your destination’s import regulations to minimize delays. For Africa and South America, sea freight is cost-effective but slower; air freight is faster but more expensive. Verify packaging standards to prevent damage during transit. Ensure your supplier provides tracking information and assist with customs documentation to streamline clearance. -

What steps can be taken to resolve disputes related to wiring diagram inaccuracies or product mismatches?

Establish clear contract terms detailing product specifications, diagram accuracy requirements, and acceptance criteria. Maintain thorough communication records and request formal approvals of wiring diagrams before production. If discrepancies arise, promptly notify the supplier with documented evidence (photos, test reports). Use third-party technical experts for unbiased evaluation if needed. Many suppliers offer warranty or replacement policies for faulty products. Consider arbitration clauses specifying jurisdiction or international trade bodies (e.g., ICC) to handle unresolved disputes efficiently.

- Are there regional considerations I should be aware of when sourcing LED strip light wiring diagrams for markets like Poland, France, or the Middle East?

Yes, regional electrical codes and standards vary—European markets (Poland, France) require compliance with CE marking, RoHS, and often EN standards. Middle Eastern countries may have specific voltage levels and certifications (e.g., SASO in Saudi Arabia). Wiring color codes and connector types also differ regionally. Engage suppliers who demonstrate familiarity with your target market’s regulatory environment and can customize wiring diagrams accordingly. Understanding local installation practices and climate conditions (humidity, temperature) will also impact wiring design and product durability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip light wiring diagram

Strategic Sourcing: Key Takeaways and Future Directions for LED Strip Light Wiring Diagrams

For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe (including markets like Poland and France), mastering the intricacies of LED strip light wiring diagrams is essential to sourcing success. A clear understanding of wiring configurations ensures compatibility, safety, and optimal performance—critical factors that directly impact installation efficiency and end-user satisfaction.

Strategic sourcing in this domain demands:

- Thorough supplier vetting to confirm technical expertise and adherence to international wiring standards.

- Prioritizing quality control processes that verify wiring integrity and product durability.

- Customizing solutions to meet region-specific voltage requirements and environmental conditions.

- Leveraging detailed wiring diagrams as a communication tool with manufacturers to minimize errors and reduce lead times.

Looking ahead, the increasing adoption of smart lighting systems and integration with IoT technologies will elevate the complexity of wiring setups. Buyers who proactively engage with suppliers offering advanced, modular wiring solutions will gain a competitive edge. Furthermore, embracing sustainability in sourcing—such as selecting energy-efficient components and recyclable materials—will align with global regulatory trends and buyer expectations.

Actionable advice: International buyers should cultivate strategic partnerships with manufacturers who provide comprehensive wiring documentation and support. This approach not only mitigates risks but also accelerates deployment and innovation in LED lighting projects worldwide.