Introduction: Navigating the Global Market for led strip light repair

The global demand for LED strip lights continues to surge, driven by their versatility, energy efficiency, and aesthetic appeal across commercial, industrial, and residential applications. For international B2B buyers, especially those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, ensuring the longevity and performance of these lighting solutions hinges critically on effective LED strip light repair strategies. Repair not only extends product lifecycle but also safeguards investments against costly replacements and operational downtime.

This comprehensive guide is meticulously crafted to equip buyers with the knowledge needed to confidently navigate the complexities of the LED strip light repair market. It covers essential topics including the various types of LED strips, key materials and components involved, and the manufacturing and quality control standards that underpin product reliability. Additionally, it delves into identifying trustworthy suppliers, understanding repair cost structures, and analyzing regional market trends that influence sourcing decisions.

By consolidating expert insights and practical advice, this guide empowers procurement managers, distributors, and contractors to make informed, strategic choices that align with their operational goals and regional market conditions. Whether you are sourcing for large-scale infrastructure projects in the UK, retail fit-outs in Kenya, or industrial applications in Brazil or the UAE, the actionable intelligence provided here will help you build resilient supply chains, optimize repair processes, and maximize return on investment.

In an increasingly competitive global landscape, mastering LED strip light repair is no longer optional—it is a crucial differentiator for businesses committed to sustainable growth and customer satisfaction.

Understanding led strip light repair Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Soldering-Based Repair | Manual re-soldering of broken or damaged solder joints | Manufacturing defects, on-site quick fixes | + Cost-effective for small repairs – Requires skilled labor |

| Connector Replacement | Swapping out faulty connectors without rewiring the strip | Modular installations, easy maintenance | + Minimal downtime – Limited to connector-related failures |

| PCB Trace Repair | Repairing or bridging damaged PCB traces on the strip | High-end or custom LED strips | + Restores full functionality – Technically complex |

| Adhesive and Waterproof Seal Repair | Fixing or replacing strip adhesives and waterproof coatings | Outdoor or industrial LED strip applications | + Extends lifespan in harsh environments – May require special materials |

| Component-Level Replacement | Replacing individual LEDs or resistors on the strip | Precision lighting setups, customizable designs | + Targeted repair reduces waste – Needs specialized tools and parts |

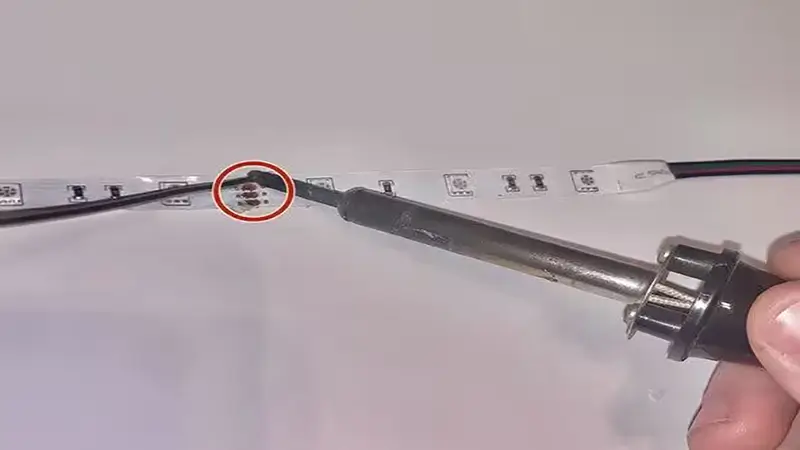

Soldering-Based Repair

This traditional repair method involves manually re-soldering broken joints or replacing damaged wiring on LED strips. It is highly suitable for manufacturers and contractors who require quick, cost-effective fixes, especially during installation or quality control. For B2B buyers, sourcing repair kits and ensuring access to skilled technicians are critical factors. While economical for small-scale repairs, soldering demands precision to avoid further damage, making training and quality control essential.

Connector Replacement

Replacing faulty connectors is a straightforward repair type, ideal for modular LED strip installations where connectors are the most common failure points. This approach minimizes downtime and is preferred in commercial and retail lighting projects where rapid maintenance is crucial. Buyers should evaluate connector compatibility with existing strips and confirm availability of replacement parts. However, this method is limited to connector issues and won’t resolve internal strip faults.

PCB Trace Repair

Repairing damaged printed circuit board (PCB) traces on LED strips is a specialized process often required for high-end or custom strips used in architectural or theatrical lighting. This repair restores electrical pathways, enabling full functionality without replacing the entire strip. B2B buyers should consider suppliers who provide technical support and certified technicians capable of precise PCB work. The complexity and cost can be higher, but it significantly extends product life.

Adhesive and Waterproof Seal Repair

LED strips designed for outdoor or industrial use often feature waterproof coatings and adhesives that may degrade over time. Repairing or replacing these seals is crucial to maintaining durability against moisture and environmental stress. Buyers in sectors like agriculture, construction, and outdoor advertising must prioritize suppliers offering specialized waterproof repair materials. While this extends lifespan, it requires careful material matching to ensure effectiveness.

Component-Level Replacement

This repair type focuses on swapping individual LEDs, resistors, or small components rather than entire sections. It’s particularly valuable in precision lighting applications such as display manufacturing or customizable lighting solutions. For B2B buyers, access to compatible spare parts and advanced repair tools is vital. Although this method reduces waste and cost, it demands technical expertise and precise component sourcing to ensure seamless integration.

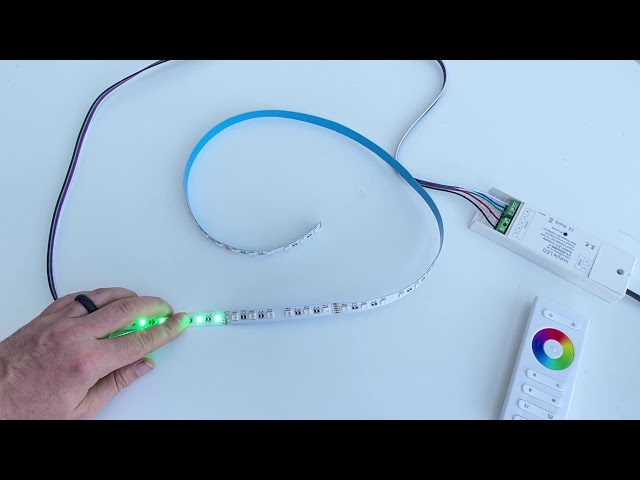

Related Video: How to repair LED tube light | Easy method

Key Industrial Applications of led strip light repair

| Industry/Sector | Specific Application of led strip light repair | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Repairing LED strip lighting in display cases and storefront signage | Maintains consistent, attractive lighting that enhances product visibility and customer experience, reducing downtime and replacement costs | Require durable, easy-to-install repair kits compatible with various LED strip types; ensure supplier offers quick delivery and local support for timely repairs |

| Hospitality & Leisure | Maintenance of ambient and accent lighting in hotels, restaurants, and entertainment venues | Preserves ambiance and guest satisfaction while minimizing operational disruptions and costly full replacements | Prioritize suppliers with expertise in waterproof and flexible LED strip repair solutions; certifications for safety and quality are critical |

| Manufacturing & Warehousing | Repair of LED strip lights used in assembly lines and storage areas for safety and operational efficiency | Ensures continuous illumination critical for worker safety and productivity, reducing accident risks and downtime | Focus on robust repair components able to withstand industrial environments; sourcing partners must provide technical support and bulk supply options |

| Transportation & Infrastructure | Repairing LED strips in public transit stations, airports, and tunnels | Keeps critical lighting systems operational, enhancing public safety and compliance with regulatory standards | Select suppliers with proven track records in supplying repair parts that meet international safety certifications and can handle high-volume orders |

| Residential & Property Management | Fixing LED strip lighting in residential complexes and commercial properties | Improves tenant satisfaction and property value by ensuring well-maintained, energy-efficient lighting | Look for repair solutions compatible with diverse LED strip models; suppliers should offer customization and local after-sales service |

LED strip light repair plays a pivotal role across several industries by extending the lifespan of lighting installations and reducing operational costs. In the retail and commercial sector, LED strips illuminate product displays and storefronts. Repairing these strips quickly prevents lighting inconsistencies that could detract from merchandise appeal. International buyers, especially in fast-growing markets like Kenya and Brazil, should source repair kits that are adaptable to different LED specifications and supported by reliable logistics to avoid sales disruptions.

In hospitality and leisure, ambient lighting creates the desired atmosphere in hotels and restaurants. LED strip repair services enable venues to maintain their lighting aesthetics without expensive full replacements. Buyers from Europe and the Middle East must prioritize waterproof and flexible repair solutions certified for safety, ensuring repairs withstand humid or high-traffic environments.

For manufacturing and warehousing, LED strips are essential for illuminating workspaces and storage areas. Timely repairs help maintain safety standards and operational efficiency. B2B buyers in industrial hubs across South America and Africa should seek suppliers offering durable repair components designed for harsh conditions, along with technical support to facilitate on-site fixes.

In transportation and infrastructure, LED strip lighting is vital in public transit areas and tunnels to ensure safety and regulatory compliance. Repairing these strips promptly prevents hazards and service interruptions. Buyers from regions like the UK and UAE need sourcing partners who provide repair parts meeting international certifications and can fulfill large orders with consistent quality.

Lastly, in residential and property management, maintaining LED strip lighting enhances tenant satisfaction and the overall value of properties. Repair solutions must be compatible with a variety of LED strip models common in different markets. International buyers should look for suppliers offering customization options and responsive local after-sales service to address diverse installation environments efficiently.

Strategic Material Selection Guide for led strip light repair

When selecting materials for LED strip light repair, international B2B buyers must consider a range of factors including durability, environmental resistance, compliance with regional standards, and cost-effectiveness. The choice of material directly impacts the longevity and performance of the repair, especially in diverse climates and regulatory environments found across Africa, South America, the Middle East, and Europe.

1. Polyvinyl Chloride (PVC) Insulation

Key Properties: PVC is widely used as an insulating and protective coating for LED strip lights due to its excellent electrical insulation, moderate temperature resistance (typically up to 105°C), and good chemical resistance. It offers reasonable flexibility and is resistant to abrasion and moisture.

Pros & Cons: PVC is cost-effective and easy to work with, making it a popular choice for repairs. However, it has limited heat resistance compared to other materials and can degrade under prolonged UV exposure, which is a consideration for outdoor applications. Manufacturing complexity is low, facilitating quick repairs and replacements.

Impact on Application: PVC insulation is suitable for indoor and sheltered outdoor LED strip light repairs but less ideal for harsh environments with high UV exposure or extreme temperatures. Its moisture resistance makes it compatible with humid climates common in parts of Africa and South America.

International Considerations: PVC materials generally comply with international standards such as ASTM D1784 and EN 50525 for electrical insulation. Buyers from Europe and the UK will find PVC widely accepted, but in regions like the Middle East and Africa, verifying compliance with local electrical safety regulations is essential. PVC’s flame retardant grades are preferred to meet stricter fire safety codes.

2. Silicone Rubber

Key Properties: Silicone rubber is prized for its exceptional temperature tolerance (-60°C to 230°C), flexibility, and excellent resistance to UV radiation, ozone, and moisture. It maintains elasticity over time and offers superior dielectric properties.

Pros & Cons: Silicone rubber is highly durable and ideal for waterproof LED strip light repairs, especially in outdoor or industrial settings. The downside is its higher cost and slightly more complex manufacturing and application processes compared to PVC. It may require specialized adhesives or curing methods.

Impact on Application: Its resilience makes silicone rubber perfect for LED strip lights exposed to harsh weather conditions, such as the intense sun in the Middle East or humid tropical climates in South America and Africa. It ensures long-lasting repairs without cracking or yellowing.

International Considerations: Silicone rubber products often meet ISO 10993 and UL 94 standards for safety and biocompatibility, which are critical for buyers in Europe and the UK. For African and South American markets, sourcing silicone materials certified for electrical insulation and UV resistance ensures compliance with growing regional standards.

3. Polyurethane (PU) Coatings

Key Properties: Polyurethane coatings provide excellent abrasion resistance, flexibility, and chemical resistance. They offer moderate temperature resistance (typically up to 120°C) and good adhesion to various substrates, making them suitable for protective layers in LED strip repairs.

Pros & Cons: PU coatings are durable and provide a high-gloss finish that can enhance the aesthetics of repaired LED strips. However, they are more expensive than PVC and require precise application techniques to avoid defects. PU is less flexible than silicone but more so than rigid plastics.

Impact on Application: PU coatings are well-suited for LED strip lights in commercial or decorative indoor environments where mechanical wear is a concern. Their chemical resistance also benefits installations in industrial zones common in Europe and South America.

International Considerations: PU materials must comply with standards such as DIN 53 361 for abrasion resistance and ASTM D412 for tensile strength. European buyers often demand REACH compliance, while African and Middle Eastern buyers should ensure PU coatings meet local environmental and safety regulations.

4. Copper Foil and Conductive Adhesives

Key Properties: Copper foil is commonly used for repairing damaged circuit traces on LED strips due to its excellent electrical conductivity and thermal management capabilities. Conductive adhesives complement copper foil by providing flexible bonding without soldering.

Pros & Cons: Copper foil repairs restore electrical pathways effectively and are relatively low-cost. However, copper is prone to oxidation and corrosion if not properly sealed, which can compromise repair longevity. Conductive adhesives offer convenience but may have lower conductivity and durability compared to solder.

Impact on Application: Copper foil is essential for electrical repairs on LED strips, especially in environments where soldering is impractical. In humid or corrosive environments (e.g., coastal regions in Africa or the Middle East), protective coatings over copper are vital.

International Considerations: Copper materials should meet ASTM B152 for purity and thickness. Conductive adhesives must comply with IEC 61340 for electrostatic discharge protection and have certifications like UL for safety. Buyers in Europe and the UK often require RoHS compliance to avoid hazardous substances, while African and South American markets focus on durability under varied environmental conditions.

| Material | Typical Use Case for led strip light repair | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC Insulation | Insulating and protective coating for indoor LED strips | Cost-effective, good moisture resistance | Limited heat and UV resistance | Low |

| Silicone Rubber | Waterproof and outdoor LED strip repairs | High temperature and UV resistance | Higher cost, requires specialized application | High |

| Polyurethane (PU) | Protective coating for abrasion and chemical resistance | Durable with good aesthetics | More expensive, less flexible than silicone | Medium |

| Copper Foil & Conductive Adhesives | Electrical trace repair and bonding on LED circuits | Excellent conductivity and thermal management | Prone to corrosion if unprotected, adhesive durability varies | Low to Medium |

This material selection guide equips international B2B buyers with the knowledge to make informed decisions tailored to their regional needs and application environments, ensuring durable and compliant LED strip light repairs.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip light repair

The manufacturing and quality assurance processes for LED strip light repair components are critical factors that international B2B buyers must understand to ensure product reliability, safety, and long-term supply stability. Buyers from Africa, South America, the Middle East, and Europe, including markets like the UK and Kenya, should focus on key manufacturing stages, rigorous quality control (QC) protocols, and compliance with relevant international standards. This knowledge equips buyers to evaluate suppliers thoroughly and mitigate risks in their supply chains.

Core Manufacturing Processes for LED Strip Light Repair Components

LED strip light repair typically involves manufacturing replacement parts such as flexible PCBs, LEDs, connectors, and adhesives that enable restoration or enhancement of existing strips. The manufacturing process generally includes the following main stages:

-

Material Preparation

– Substrate Selection: Flexible printed circuit boards (PCBs) form the base of LED strips. Common substrates include polyimide or PET film, chosen for flexibility and heat resistance.

– LED Chip Sourcing: High-quality LED chips with specific color temperatures and brightness levels are procured from trusted semiconductor manufacturers.

– Adhesives and Protective Coatings: Pressure-sensitive adhesives for mounting and silicone or epoxy coatings for waterproofing are prepared. -

Forming

– Circuit Patterning: Copper circuits are etched or printed onto the flexible substrate using photolithography or screen printing techniques.

– Component Placement: Automated pick-and-place machines position LED chips, resistors, and other components precisely on the PCB.

– Soldering: Reflow soldering or wave soldering ensures solid electrical connections between components and the PCB.

Illustrative Image (Source: Google Search)

-

Assembly

– Cutting and Shaping: LED strips are cut into standard or custom lengths with clean edges to facilitate repairs.

– Connector Attachment: End connectors or solder pads are added to enable seamless integration with existing LED strips.

– Encapsulation: Protective layers such as silicone gels or epoxy resins are applied for waterproofing and durability. -

Finishing

– Testing Preparations: Strips are trimmed, cleaned, and prepared for quality control testing.

– Packaging: After passing QC, strips are carefully packaged with anti-static materials and moisture-proof seals to preserve quality during shipping.

Quality Assurance Framework and Checkpoints

Robust quality control underpins the reliability of LED strip light repair parts. Buyers should seek suppliers adhering to internationally recognized standards and following a multi-tiered QC system:

- Relevant International Standards

- ISO 9001: This certification ensures the manufacturer maintains a comprehensive quality management system covering all stages from design to delivery.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection requirements.

- RoHS Compliance: Restricts hazardous substances in electronic components, crucial for environmentally conscious buyers.

- UL Certification: Recognized globally, especially in North America and Europe, for electrical safety.

-

API or IEC Standards: In some cases, compliance with industry-specific or regional standards (e.g., IEC 60598 for luminaires) may be relevant.

-

QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components, such as PCB substrate thickness, LED chip specifications, and adhesive quality.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint integrity, component placement accuracy, and circuit continuity.

-

Final Quality Control (FQC): Comprehensive functional tests on completed strips, covering brightness uniformity, color temperature consistency, waterproof integrity, and adhesion strength.

-

Common Testing Methods

- Electrical Testing: Voltage and current measurements to verify LED function and safety.

- Optical Testing: Luminous intensity and color rendering index (CRI) assessments to ensure lighting quality.

- Environmental Testing: Thermal cycling, humidity resistance, and UV exposure tests simulate real-world conditions.

- Mechanical Testing: Flexibility and tensile strength tests verify durability during installation and repair.

Verifying Supplier Quality Controls: Practical Steps for B2B Buyers

International buyers should adopt a proactive approach to verify suppliers’ QC claims and manufacturing capabilities:

- Factory Audits

- Arrange on-site or virtual audits to inspect manufacturing facilities, production lines, and QC labs.

- Evaluate supplier adherence to documented processes and certification validity.

-

Assess equipment modernization and employee training programs.

-

Request Quality Documentation

- Obtain ISO 9001 certificates, CE declarations, test reports, and material safety data sheets (MSDS).

- Review batch-level inspection reports and failure rate statistics.

-

Confirm RoHS and other regulatory compliance certificates.

-

Third-Party Inspections

- Engage independent inspection agencies to conduct pre-shipment inspections, sample testing, and process audits.

-

These inspections add credibility and reduce risks of receiving substandard or counterfeit components.

-

Sample Testing

- Request product samples for in-house or third-party laboratory testing.

- Conduct accelerated aging tests and compatibility checks with existing LED strips.

Quality Control and Certification Nuances for Different Global Markets

International buyers must consider regional regulatory nuances and logistics challenges:

- Africa & Middle East

- Emphasize suppliers with robust waterproofing and thermal management due to harsh environmental conditions.

- Confirm certifications accepted by local authorities, as some countries may require additional approvals or customs documentation.

-

Prioritize manufacturers experienced in export logistics and able to provide clear lead times.

-

South America

- Look for suppliers familiar with import regulations and local electrical standards (e.g., INMETRO certification in Brazil).

-

Consider suppliers offering support for after-sales service and warranty claims within the region.

-

Europe (Including UK)

- CE marking and RoHS compliance are essential.

- Suppliers should provide detailed technical files and maintain transparent quality records to meet stringent EU regulations.

- Sustainability and environmental impact are increasingly important; verify supplier commitments to eco-friendly manufacturing.

Conclusion: Strategic Considerations for B2B Buyers

Understanding the detailed manufacturing processes and quality assurance mechanisms for LED strip light repair components empowers B2B buyers to make informed supplier selections. Prioritize manufacturers with:

- Proven experience and certifications aligned with target markets.

- Transparent QC systems featuring multiple inspection stages and comprehensive testing.

- Willingness to support audits, provide detailed documentation, and accommodate third-party inspections.

This diligence mitigates supply chain risks, ensures product performance, and builds a foundation for long-term partnerships across diverse international markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip light repair Sourcing

Understanding the cost and pricing dynamics in sourcing LED strip light repair services or components is crucial for international B2B buyers aiming to optimize expenses while ensuring quality and reliability. The pricing structure is multifaceted, influenced by several components that contribute to the final quotation you receive from suppliers.

Key Cost Components in LED Strip Light Repair

-

Materials: This includes the cost of replacement LEDs, flexible PCBs, solder, connectors, adhesives, and any protective coatings. High-quality materials compliant with certifications (e.g., RoHS, CE) generally command higher prices but reduce failure rates and warranty claims.

-

Labor: Skilled technicians are required for precise repair work such as re-soldering, component replacement, and testing. Labor costs vary significantly by region; for example, labor in Europe and the Middle East tends to be costlier than in parts of Africa or South America.

-

Manufacturing Overhead: This covers utilities, equipment depreciation, and facility maintenance necessary to support repair operations. Efficient facilities with modern equipment may have higher overheads but deliver faster turnaround and consistent quality.

-

Tooling and Equipment: Specialized tools for diagnosing and repairing LED strips, including microscopes, reflow ovens, and testing rigs, contribute to fixed and variable costs.

-

Quality Control (QC): Rigorous testing to ensure repaired strips meet brightness, color consistency, and durability standards adds to the cost but protects your investment against premature failures.

-

Logistics: Freight charges, customs duties, insurance, and handling fees form a significant portion of landed costs, especially when sourcing internationally. Shipping modes (air vs. sea), Incoterms, and destination country infrastructure also impact these costs.

-

Supplier Margin: The supplier’s markup reflects their profit margin and risk buffer. Established suppliers with strong reputations may charge a premium but offer better reliability and support.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes typically reduce unit costs due to economies of scale. However, MOQ requirements might be challenging for smaller businesses or trial orders, particularly in emerging markets.

-

Product Specifications and Customization: Repairs involving specialized LED types, waterproofing, or integration with control systems often increase costs due to complexity and additional materials.

-

Material Quality and Certifications: Products meeting international safety and environmental standards generally cost more but are essential for compliance in regions like the EU and UK.

-

Supplier Experience and Capacity: Established suppliers with advanced production capabilities may offer better pricing tiers and flexible payment terms, reducing total cost of ownership.

-

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) directly affects logistics costs and risk distribution. Favoring terms that align with your import capabilities can optimize expenses.

Strategic Buyer Tips for International B2B Sourcing

-

Negotiate Beyond Price: Engage suppliers in discussions about lead times, warranty terms, after-sales support, and bundled services. These can add value beyond the initial quote.

-

Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also repair turnaround time, defect rates, shipping reliability, and potential customs delays. For buyers in Africa, South America, and the Middle East, where logistics can be complex, TCO analysis is critical.

-

Leverage Sampling and Pilot Orders: Testing samples and placing small initial orders help validate quality and supplier responsiveness before committing to large volumes.

-

Understand Pricing Nuances by Region: For example, buyers in Kenya or South America should factor in import taxes and local regulations, which may significantly impact landed costs compared to European buyers.

-

Build Long-Term Relationships: Suppliers often provide better pricing and priority service to repeat customers. Establishing trust and consistent communication can unlock preferential terms.

-

Use Incoterms Wisely: For buyers unfamiliar with international shipping complexities, opting for Delivered Duty Paid (DDP) can simplify import but may increase upfront costs. Conversely, FOB or Ex-Works can reduce prices but require more logistics management.

Indicative Pricing Disclaimer

Prices for LED strip light repair services vary widely based on the factors above and market conditions. It is essential to request detailed quotations and clarify inclusions such as testing, warranties, and shipping. Always treat initial prices as indicative and subject to negotiation and verification.

By carefully analyzing these cost components and pricing influencers, international B2B buyers can make informed sourcing decisions that balance cost-efficiency with product quality and supply chain reliability, ensuring sustainable business growth across diverse markets.

Spotlight on Potential led strip light repair Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip light repair’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip light repair

Understanding the critical technical properties and trade terminology related to LED strip light repair empowers international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—to make informed purchasing and partnership decisions. Below is an expert overview tailored for non-technical decision-makers seeking clarity and actionable insights.

Key Technical Properties for LED Strip Light Repair

-

Material Grade (Copper & PCB Quality)

The base material of LED strips, particularly the copper thickness and PCB (Printed Circuit Board) quality, directly affects durability and heat dissipation. Higher-grade materials prevent premature failures and enable longer lifespan, crucial for repair scenarios where reliability is paramount. For B2B buyers, prioritizing suppliers that specify copper thickness (e.g., 2oz or above) ensures better product longevity. -

Voltage and Current Tolerance

LED strips typically operate on 12V or 24V DC systems. Knowing the voltage rating and current tolerance is vital during repair to avoid electrical mismatches that can cause strip damage or failure. Buyers should confirm that replacement parts or repair components match these electrical specs to maintain system integrity and safety. -

IP Rating (Ingress Protection)

The IP rating classifies the strip’s resistance to dust and water (e.g., IP20 for indoor use, IP65/IP67 for waterproofing). For repair projects, selecting components with the correct IP rating ensures restored strips meet the original environmental protection, critical for outdoor or humid environments common in many global markets. -

Color Temperature and CRI (Color Rendering Index)

Matching the color temperature (measured in Kelvin, e.g., 3000K warm white, 6000K cool white) and CRI ensures consistent lighting quality post-repair. This is particularly important for retail, hospitality, and architectural projects where lighting ambiance affects customer experience. B2B buyers should request detailed specs to avoid mismatched light outputs.

-

Adhesive Quality and Flexibility

The adhesive backing and strip flexibility influence installation and repair ease. Strong adhesives reduce rework, especially in regions with temperature fluctuations or humid climates. Flexible strips accommodate curved surfaces and reduce breakage risk during repairs, enhancing operational efficiency. -

Dimmability and Control Compatibility

Compatibility with dimmers and smart controllers (e.g., PWM dimming) is critical for modern lighting systems. Repair components must support these features to preserve functionality. Buyers should verify that repaired strips can integrate seamlessly with existing control systems to avoid costly replacements.

Common Trade Terminology in LED Strip Light Repair

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce LED strips or components sold under another company’s brand. For B2B buyers, working with OEMs can offer customization options and cost advantages but requires thorough vetting to ensure quality consistency. -

MOQ (Minimum Order Quantity)

The smallest order size a supplier accepts. Understanding MOQ is essential for buyers balancing inventory costs and repair needs, especially in emerging markets where demand volumes may fluctuate. -

RFQ (Request for Quotation)

A formal process where buyers ask suppliers for pricing and terms on specific repair parts or LED strips. Clear RFQs with detailed technical specs help secure accurate bids and streamline procurement. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs. Knowing Incoterms enables buyers to negotiate better logistics and control costs, vital for cross-continental supply chains. -

Binning

The sorting of LEDs by brightness and color consistency during manufacturing. For repairs, sourcing components with proper binning ensures uniform light quality and prevents visible inconsistencies post-fix. -

IP Rating (Ingress Protection)

Though technical, this term frequently appears in trade documents. Buyers should understand IP ratings to specify appropriate protection levels for their applications and repair parts.

By mastering these technical properties and trade terms, B2B buyers can confidently evaluate suppliers, negotiate contracts, and ensure repaired LED strip lights meet performance expectations across diverse markets. This knowledge supports sustainable procurement strategies and strengthens supply chain reliability in competitive international environments.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip light repair Sector

Market Overview & Key Trends

The global LED strip light repair sector is evolving rapidly, driven by increasing adoption of LED lighting in commercial, industrial, and residential applications. For international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, understanding market dynamics is crucial to sourcing reliable repair components and services. The demand for LED strip light repairs is fueled by the growing emphasis on extending product lifecycles and reducing operational downtime, which makes repair services and spare parts a strategic investment.

Key trends shaping the sector include the rise of modular LED strip designs that simplify repair processes and improve compatibility across different brands. Technological advancements like improved flexible PCBs, enhanced adhesive materials, and better heat dissipation mechanisms are also influencing sourcing decisions. Buyers from emerging markets such as Kenya and Brazil are increasingly seeking suppliers who can offer customizable repair solutions tailored to local environmental conditions and usage patterns.

Additionally, supply chain agility has become paramount amid global disruptions. Buyers prioritize manufacturers and repair service providers with transparent lead times and robust logistical capabilities. Digital platforms facilitating direct communication and real-time tracking of repair orders are gaining traction, enhancing trust and operational efficiency.

The sector is also seeing a surge in demand for integrated repair kits that include diagnostic tools, replacement LEDs, and connectors, enabling faster onsite repairs. This trend supports B2B buyers aiming to minimize downtime in industries like retail, hospitality, and infrastructure development.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone for international buyers in the LED strip light repair market. Repairing LED strips rather than replacing entire units reduces electronic waste and conserves resources, aligning with global circular economy principles. Buyers from Europe and progressive markets in the Middle East increasingly demand suppliers who demonstrate commitment to environmental stewardship.

Ethical sourcing plays a pivotal role in ensuring that repair components are manufactured under fair labor conditions and comply with environmental regulations. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 (Environmental Management Systems) are key indicators of responsible supply chains. These certifications help B2B buyers mitigate risks associated with non-compliance and support corporate sustainability goals.

The use of green materials—such as lead-free solder, recyclable PCBs, and non-toxic adhesives—in repair parts is gaining momentum. Suppliers offering repair components with verified low carbon footprints and minimal hazardous waste generation appeal strongly to buyers in environmentally regulated markets like the UK and the European Union.

Illustrative Image (Source: Google Search)

For buyers in Africa and South America, partnering with suppliers who prioritize sustainability also aligns with growing local regulations and consumer awareness. Transparent reporting on sustainability metrics and ethical labor practices can differentiate suppliers in these regions and foster long-term partnerships.

Brief Evolution & Historical Context

The LED strip light repair sector has matured alongside advancements in LED technology over the past two decades. Initially, LED strips were relatively simple and inexpensive, often discarded rather than repaired. However, as LED lighting became more complex and integral to energy-efficient infrastructure, the economics of repair shifted significantly.

In the early 2010s, the introduction of standardized LED strip formats and improved manufacturing quality paved the way for more reliable repairs. The growing awareness of electronic waste and sustainability further accelerated the development of dedicated repair services and aftermarket parts suppliers.

Today, the sector is characterized by a collaborative ecosystem where manufacturers, repair specialists, and B2B buyers work closely to optimize product lifespans. This evolution reflects a broader industry trend towards sustainability, cost-efficiency, and technological innovation—making LED strip light repair an essential component of modern lighting supply chains worldwide.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of led strip light repair

-

How can I effectively vet LED strip light repair suppliers for international B2B sourcing?

To vet suppliers, start by verifying their business licenses and certifications such as ISO, CE, or RoHS that confirm compliance with international quality standards. Check their track record through reviews on B2B platforms like Alibaba or Made-in-China, and request references from existing clients, particularly those in your region. Assess their communication responsiveness and transparency during initial inquiries. Finally, request product samples for independent quality testing to ensure their repair components meet your durability and performance requirements before committing to large orders. -

Is customization available for LED strip light repair parts, and how should I approach it?

Many manufacturers offer customization services, including specific strip lengths, LED density, color temperatures, and waterproofing options. When negotiating, clearly outline your technical specifications and intended applications to ensure feasibility. Confirm the supplier’s R&D and prototyping capabilities to support tailored solutions. Also, discuss minimum order quantities (MOQs) for customized products, as these may differ from standard offerings. Establish clear agreements on intellectual property rights and confidentiality to protect your designs in international trade. -

What should I know about MOQs, lead times, and payment terms when ordering repair components internationally?

MOQ requirements can vary widely; some suppliers may set higher thresholds for custom repair parts. Negotiate MOQs that fit your initial demand to minimize inventory risks. Lead times typically range from 2 to 8 weeks depending on customization and order size—always confirm these upfront and build buffer time for shipping delays. Regarding payments, international buyers often use letters of credit, T/T (telegraphic transfer), or escrow services to mitigate risk. Insist on clear payment milestones aligned with production stages to protect your investment. -

How can I ensure the quality assurance and certifications of LED strip light repair parts meet international standards?

Request comprehensive QA documentation including test reports for electrical safety, waterproofing, and longevity from your supplier. Ensure the products carry recognized certifications such as CE for Europe, UL for North America (if applicable), and RoHS compliance to avoid hazardous materials. For African, Middle Eastern, and South American markets, verify if additional local certifications or approvals are necessary. Consider third-party inspections or audits during production and prior to shipment to maintain quality consistency across batches. -

What logistics considerations are critical when importing LED strip light repair supplies from Asia or Europe?

Choose suppliers experienced with international freight and customs processes to avoid delays. Clarify Incoterms (e.g., FOB, CIF) to understand your responsibilities and costs. For African and South American buyers, consider the reliability of regional ports and inland transportation infrastructure, as these impact delivery speed and cost. Consolidate shipments when possible to reduce freight expenses and customs clearance complexity. Also, confirm packaging standards to protect delicate LED components during transit in varying climates. -

How do I handle disputes or quality issues with overseas LED strip light repair suppliers?

Establish clear contractual terms including warranty periods, return policies, and dispute resolution mechanisms before placing orders. Use internationally recognized arbitration forums or specify governing law in contracts to protect your interests. Document all communications and retain evidence such as photos of defects and test results. Promptly report issues to suppliers and negotiate remediation such as replacement shipments or refunds. Building long-term relationships based on trust and transparency often reduces the frequency and severity of disputes. -

Can suppliers support after-sales service and technical support for LED strip light repairs internationally?

Reliable suppliers offer after-sales support including troubleshooting guides, replacement parts, and technical assistance. Confirm the availability of multilingual support to bridge language barriers, especially important for buyers in Africa, the Middle East, and South America. Check if they provide training materials or remote support for your technical teams. Strong after-sales service reduces downtime and enhances your ability to maintain client satisfaction, making it a crucial factor when selecting a repair parts supplier. -

What payment safeguards can B2B buyers use to minimize financial risk in international LED strip light repair transactions?

Utilize secure payment methods such as letters of credit or escrow accounts managed by trusted third parties, which release funds only upon meeting agreed conditions. Negotiate payment terms that include partial upfront deposits with balance payments after product inspection or delivery. Avoid full prepayments unless you have a longstanding relationship. Additionally, consider trade credit insurance to protect against supplier default or shipment non-delivery, particularly when dealing with new or unverified suppliers in emerging markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip light repair

Choosing the right partners and adopting a strategic sourcing approach are paramount for businesses involved in LED strip light repair. Across diverse markets—from the bustling commercial hubs in Europe and the UK to the rapidly growing infrastructure sectors in Africa, South America, and the Middle East—success hinges on securing suppliers who offer consistent product quality, reliable lead times, and responsive after-sales support. Prioritizing manufacturers with proven experience, robust certifications, and transparent communication ensures minimized downtime and elevated customer satisfaction.

For B2B buyers, the repair segment demands not only quality components but also access to customized solutions and scalable supply chains that can adapt to evolving project demands. Testing samples, verifying production capabilities, and establishing trial partnerships reduce risk and lay the foundation for long-term collaboration. Moreover, understanding regional logistics and regulatory environments empowers buyers to optimize costs and compliance.

Looking ahead, the LED strip light repair market is set to grow with increasing adoption of energy-efficient lighting solutions worldwide. International buyers are encouraged to leverage strategic sourcing as a competitive advantage—investing in strong supplier relationships and continuous quality assurance. By doing so, businesses can future-proof their operations, enhance sustainability, and capitalize on emerging opportunities in global lighting markets. Take proactive steps today to build resilient supply chains that meet tomorrow’s LED repair challenges with confidence and agility.