Introduction: Navigating the Global Market for led strip light holder

The global demand for LED strip light holders continues to surge as businesses across industries seek versatile, durable, and efficient lighting solutions. For international B2B buyers—especially those operating in dynamic markets like Africa, South America, the Middle East, and Europe—understanding the critical role of LED strip light holders is essential. These components not only secure and protect LED strips but also influence installation ease, longevity, and overall lighting performance.

This comprehensive guide offers an authoritative roadmap to mastering the complexities of sourcing LED strip light holders. It covers a wide spectrum of topics including the various types and designs tailored for different applications, the materials best suited for durability and environmental resistance, and key manufacturing and quality control standards that ensure product reliability. Furthermore, the guide explores how to identify reputable suppliers and manufacturers, evaluate cost structures, and navigate regional market trends that impact supply chain decisions.

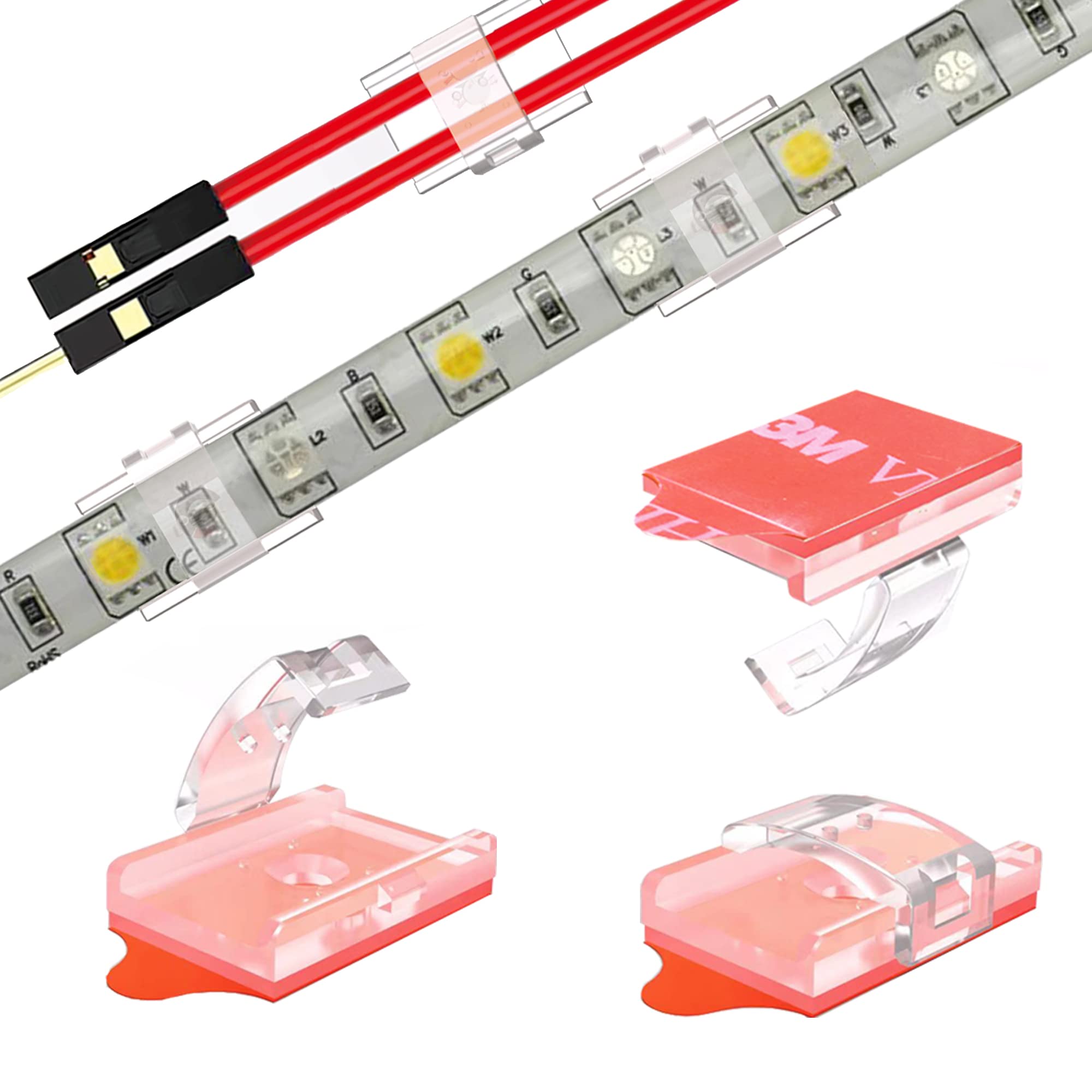

Illustrative Image (Source: Google Search)

Designed with a solution-oriented approach, this resource empowers buyers from diverse regions—whether a distributor in Spain, a contractor in Brazil, or an importer in the UAE—to make informed, strategic procurement choices. By leveraging insights into product specifications, certification requirements, and supplier vetting processes, international buyers can build resilient supply chains that support scalable growth and competitive advantage.

Ultimately, this guide equips B2B professionals with the knowledge to source LED strip light holders that meet stringent quality benchmarks while optimizing cost-efficiency and delivery reliability in a globally interconnected marketplace.

Understanding led strip light holder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Channel Holders | Durable aluminum construction, often with diffusers, heat dissipation properties | Commercial lighting, retail displays, architectural lighting | Pros: Excellent heat management, professional finish, protects LED strips. Cons: Higher cost, requires precise measurements for installation. |

| Plastic Clip Holders | Lightweight plastic clips, easy snap-in installation, flexible sizing options | Residential projects, temporary setups, basic commercial uses | Pros: Cost-effective, easy to install/remove, versatile. Cons: Less durable, limited heat dissipation, may degrade under UV exposure. |

| Magnetic Holders | Magnetic backing for quick attachment and repositioning, reusable | Exhibition stands, temporary installations, event lighting | Pros: Fast installation, reusable, no surface damage. Cons: Limited to metal surfaces, weaker hold on rough or non-metallic surfaces. |

| Adhesive Mount Holders | Holders with built-in adhesive pads, simple mounting on various surfaces | DIY projects, automotive lighting, small-scale commercial use | Pros: Easy to mount, no drilling required, flexible placement. Cons: Adhesive may weaken over time, less suitable for heavy or outdoor use. |

| Corner and Flexible Holders | Designed for LED strips in corners or curved surfaces, flexible materials | Cove lighting, architectural details, curved furniture lighting | Pros: Enables creative installations, flexible fit. Cons: May require custom sizing, sometimes less robust. |

Aluminum Channel Holders

Aluminum channel holders are the premium choice for B2B buyers seeking durability and professional aesthetics. Their metal construction provides superior heat dissipation, extending LED strip lifespan—crucial for commercial and architectural projects. Many come with diffusers that soften light and protect LEDs from dust and physical damage. Buyers should consider precise measurements and installation complexity, as these holders often require mounting hardware. Their higher upfront cost is offset by longevity and enhanced lighting quality, making them ideal for long-term, high-end applications in markets like Europe and the Middle East.

Plastic Clip Holders

Plastic clip holders offer a budget-friendly and versatile solution for various lighting needs. Their snap-in design allows quick installation and removal, suitable for projects with frequent changes or temporary setups. While they lack the heat dissipation benefits of aluminum, they work well in low-heat environments such as residential or small commercial spaces. For B2B buyers in regions like South America and Africa, plastic clips provide an economical option, but durability and UV resistance should be evaluated for outdoor or high-humidity conditions.

Magnetic Holders

Magnetic holders are ideal for businesses requiring flexible, non-permanent LED strip installations. Their magnetic backing enables quick repositioning without damaging surfaces, an advantage for event organizers or exhibition stand builders. However, magnetic holders are limited to metal surfaces and may not hold well on textured or non-metallic materials. Buyers should assess the typical installation environments and surface compatibility before committing, particularly in markets with diverse infrastructure like Africa and parts of South America.

Adhesive Mount Holders

Adhesive mount holders simplify the installation process by eliminating the need for screws or brackets. They are well-suited for lightweight LED strips in DIY projects, automotive lighting, or small commercial applications. The quality of adhesive varies, so buyers must ensure it can withstand environmental factors such as heat, humidity, and dust—especially important in tropical regions like Brazil or the Middle East. While convenient, adhesive holders may require replacement over time due to adhesive degradation.

Corner and Flexible Holders

Corner and flexible holders cater to LED strip installations on non-linear surfaces, such as coves, arches, or curved furniture. These holders allow creative lighting designs and are essential for architectural and interior design projects. Their flexibility can sometimes compromise robustness, so buyers should verify material quality and compatibility with LED strip dimensions. For B2B buyers targeting sophisticated markets in Europe or upscale commercial developments, these holders enable innovative lighting solutions but may involve higher customization costs.

Related Video: THE SECRET OF GREAT LED STRIP LIGHT INSTALLS – COB

Key Industrial Applications of led strip light holder

| Industry/Sector | Specific Application of led strip light holder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Display lighting for shelves, showcases, and signage | Enhances product visibility, attracts customers, and improves ambiance | Durable materials, easy installation, compatibility with various LED strips, and aesthetic design |

| Automotive | Interior ambient lighting and dashboard illumination | Improves vehicle interior aesthetics and driver experience | Heat resistance, vibration durability, and precise fit for automotive interiors |

| Hospitality & Tourism | Accent lighting in hotels, restaurants, and event spaces | Creates mood lighting, enhances guest experience, and supports branding | Waterproofing, flexible mounting options, and compliance with local electrical standards |

| Industrial & Manufacturing | Task lighting in workstations and machinery panels | Increases worker productivity and safety with focused illumination | Robust build quality, resistance to dust and moisture, and long lifespan |

| Architecture & Interior Design | Cove and under-cabinet lighting in residential and commercial projects | Adds design value, energy efficiency, and customizable lighting effects | Low-profile design, ease of integration, and high-quality finish |

Retail & Commercial Lighting

In retail environments across Africa, South America, the Middle East, and Europe, led strip light holders are essential for mounting LED strips in display cases, shelves, and signage. They provide a secure and visually appealing way to highlight products, boosting customer engagement and sales. Buyers should prioritize holders made from durable, lightweight materials with versatile mounting options to accommodate different shelf types and retail layouts. Compatibility with varying LED strip widths and easy replacement features are critical for efficient store maintenance.

Automotive Interior Lighting

For automotive manufacturers and aftermarket suppliers, led strip light holders are used to secure ambient lighting strips inside vehicles, including dashboards, door panels, and footwells. These holders must withstand heat, vibration, and tight installation spaces, especially in markets like Europe and the Middle East where automotive standards are stringent. International buyers should seek holders with high thermal resistance and precise dimensions to ensure safety and durability without compromising vehicle aesthetics.

Hospitality & Tourism Sector

Hotels, restaurants, and event venues utilize led strip light holders to install accent lighting that sets the ambiance and enhances brand identity. In humid or outdoor environments common in parts of Africa and South America, holders with waterproof and corrosion-resistant features are essential. Flexible mounting options allow for creative lighting designs on walls, ceilings, and furniture. Compliance with local electrical codes and easy integration with smart lighting systems are important considerations for buyers.

Industrial & Manufacturing Applications

In industrial settings, led strip light holders support task lighting on assembly lines, machinery panels, and inspection stations, improving visibility and worker safety. Holders must be rugged, dustproof, and moisture-resistant to endure harsh environments found in manufacturing plants across diverse regions. Long lifespan and secure mounting reduce downtime and maintenance costs. Buyers should verify certifications and quality standards to meet industry-specific requirements.

Architecture & Interior Design

Architects and interior designers use led strip light holders for cove lighting, under-cabinet illumination, and decorative accents in both residential and commercial projects. Low-profile holders that blend seamlessly with surfaces are preferred in European and Middle Eastern markets where aesthetics and energy efficiency are prioritized. Buyers should look for holders that support easy installation, customization options, and compatibility with dimmable LED strips to achieve desired lighting effects and client satisfaction.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Strategic Material Selection Guide for led strip light holder

Aluminum

Key Properties: Aluminum is lightweight with excellent thermal conductivity and corrosion resistance. It typically withstands temperatures up to 150°C and offers good structural strength while being resistant to rust and many chemicals.

Pros & Cons: Aluminum holders provide superior heat dissipation, which is crucial for LED longevity and performance. They are durable and relatively easy to manufacture with extrusion or CNC machining. However, aluminum can be more expensive than plastic alternatives and may require anodizing or powder coating for enhanced corrosion resistance in harsh environments.

Impact on Application: Aluminum holders are ideal for applications requiring efficient heat management, such as commercial lighting or outdoor installations. Their corrosion resistance suits humid or coastal regions, making them a strong choice for buyers in Africa and the Middle East where environmental conditions can be challenging.

B2B Buyer Considerations: European buyers, especially in Spain, often require compliance with standards like DIN EN 573 for aluminum alloys and RoHS directives for material safety. South American buyers, including Brazil, should verify ASTM B221 compliance for extrusion quality. Aluminum’s recyclability aligns well with sustainability goals prevalent in these regions.

Polycarbonate (PC)

Key Properties: Polycarbonate is a robust thermoplastic known for high impact resistance, transparency, and temperature tolerance up to around 135°C. It offers excellent electrical insulation and UV resistance when treated.

Pros & Cons: PC holders are lightweight, cost-effective, and easy to mold into complex shapes, enabling versatile design options. They resist shattering and provide good protection against mechanical stress. However, polycarbonate may yellow over time under intense UV exposure unless stabilized, and it has lower thermal conductivity compared to metals, which can affect heat dissipation.

Impact on Application: Polycarbonate is suitable for indoor LED strip light holders and environments where impact resistance is critical, such as retail or residential applications. Its electrical insulation properties are advantageous in sensitive electronic environments.

B2B Buyer Considerations: Buyers in Africa and South America benefit from PC’s affordability and ease of sourcing. Compliance with international standards like ISO 178 (flexural properties) and UL 94 (flammability) is common. Middle Eastern markets may require UV-stabilized variants due to strong sunlight exposure, while European buyers prioritize REACH compliance and eco-friendly certifications.

Stainless Steel

Key Properties: Stainless steel offers exceptional strength, corrosion resistance, and can tolerate temperatures well above 300°C. It is highly resistant to chemical exposure and mechanical wear.

Pros & Cons: Stainless steel holders provide unmatched durability and are ideal for harsh industrial or outdoor environments. They resist deformation and maintain structural integrity over time. However, stainless steel is heavier and more costly than aluminum or plastics, and manufacturing complexity (cutting, welding) can increase lead times and costs.

Impact on Application: Best suited for heavy-duty applications such as industrial lighting, outdoor architectural lighting, or marine environments. Its corrosion resistance is particularly valuable in coastal or chemically aggressive settings common in some African and Middle Eastern regions.

B2B Buyer Considerations: European buyers expect compliance with EN 10088 standards for stainless steel grades and surface finish. South American buyers should verify ASTM A240 for stainless steel quality. The higher cost and weight may limit use in some markets, but durability often justifies the investment for long-term projects.

PVC (Polyvinyl Chloride)

Key Properties: PVC is a widely used plastic with good chemical resistance, moderate temperature tolerance (up to 60-80°C), and excellent electrical insulation. It is easy to extrude and shape.

Pros & Cons: PVC holders are very cost-effective and offer good resistance to moisture and many chemicals. They are lightweight and simple to produce in large volumes. However, PVC has lower heat resistance and mechanical strength compared to PC or metals, which may limit its use in high-temperature or heavy-duty applications.

Impact on Application: PVC is commonly used in budget-sensitive projects or indoor environments where heat generation is minimal. It is suitable for residential or commercial lighting where exposure to harsh conditions is limited.

B2B Buyer Considerations: Buyers in emerging markets like parts of Africa and South America often prefer PVC for its low cost and availability. Compliance with ASTM D1784 or ISO 2409 for material quality is important. European buyers may have reservations due to environmental concerns and prefer alternatives with better sustainability profiles.

Summary Table

| Material | Typical Use Case for led strip light holder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Commercial/outdoor lighting requiring heat dissipation | Excellent thermal conductivity and corrosion resistance | Higher cost and manufacturing complexity | Medium |

| Polycarbonate | Indoor lighting with impact resistance and design flexibility | High impact resistance and electrical insulation | Lower heat dissipation, potential UV yellowing | Medium |

| Stainless Steel | Industrial, marine, and harsh outdoor environments | Superior strength and corrosion resistance | Heavy, costly, complex manufacturing | High |

| PVC | Budget indoor lighting with low heat requirements | Low cost and chemical resistance | Limited heat tolerance and mechanical strength | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip light holder

Manufacturing and quality assurance of LED strip light holders involve precise processes and stringent standards to ensure product reliability and performance. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding these aspects is critical for selecting dependable suppliers and maintaining supply chain integrity.

Typical Manufacturing Process of LED Strip Light Holders

The manufacturing workflow for LED strip light holders generally consists of four main stages: material preparation, forming, assembly, and finishing. Each stage utilizes specialized techniques to meet design specifications and durability requirements.

1. Material Preparation

- Raw Materials: Most LED strip light holders are made from aluminum alloys or high-grade plastics such as polycarbonate or ABS. Aluminum is favored for its excellent heat dissipation and structural strength.

- Procurement: High-quality raw materials should comply with environmental and safety regulations like RoHS (Restriction of Hazardous Substances).

- Inspection: Incoming materials undergo initial quality checks (IQC) for dimensional accuracy, chemical composition, and surface quality.

2. Forming

- Extrusion (for aluminum holders): Aluminum profiles are extruded to create the base channel of the holder. This process ensures consistent cross-sectional dimensions and structural integrity.

- Injection Molding (for plastic holders): Plastic holders are formed by injecting molten plastic into molds, allowing complex shapes and features like clips or mounting holes.

- Precision Cutting: Profiles or molded parts are cut to required lengths with CNC machines or automated cutters to ensure uniformity.

3. Assembly

- Component Integration: This stage involves assembling parts such as end caps, clips, diffusers, or mounting brackets. Automated or semi-automated assembly lines improve consistency.

- Adhesive Application: For some holders, adhesives or thermal tapes are applied to facilitate mounting LED strips.

- Electrical Considerations: While the holder itself is mechanical, compatibility with LED strip connectors is verified.

4. Finishing

- Surface Treatment: Aluminum holders often receive anodizing or powder coating to enhance corrosion resistance and aesthetic appeal. Plastic holders may undergo polishing or UV stabilization.

- Quality Marking: Product codes, certification marks, and branding are applied.

- Packaging: Final products are packaged with protective materials to prevent damage during shipping.

Quality Assurance and Control Checkpoints

Robust quality control (QC) is essential throughout the manufacturing process to meet international standards and buyer expectations. The QC framework includes several key checkpoints:

Incoming Quality Control (IQC)

- Verifies raw material quality before production.

- Checks for compliance with chemical and physical specifications.

- Rejects substandard batches to prevent downstream defects.

In-Process Quality Control (IPQC)

- Monitors critical parameters during extrusion or molding, such as dimensional tolerances and surface finish.

- Inspects assembly accuracy, fit, and function of components.

- Employs statistical process control (SPC) to identify trends and prevent defects.

Final Quality Control (FQC)

- Conducts comprehensive inspection of finished holders.

- Tests physical properties: strength, flexibility, and heat resistance.

- Verifies surface treatments and coatings for uniformity and adhesion.

- Confirms packaging integrity and labeling accuracy.

Relevant International Standards and Certifications

B2B buyers should prioritize manufacturers compliant with globally recognized quality standards to ensure product safety, performance, and regulatory acceptance.

- ISO 9001: The benchmark for quality management systems, ensuring consistent production processes and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating conformity with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts use of hazardous substances in electrical and electronic equipment, critical for environmental sustainability.

- UL Certification: Important for North American markets, certifying electrical safety.

- IP Ratings (Ingress Protection): Indicates dust and water resistance, essential for holders used in outdoor or humid environments.

- REACH Compliance: Addresses chemical safety within the EU, relevant for buyers in Europe and increasingly recognized worldwide.

Common Testing Methods for LED Strip Light Holders

- Dimensional Inspection: Using calipers, micrometers, or coordinate measuring machines (CMM) to ensure adherence to design specifications.

- Mechanical Strength Testing: Includes bending, impact resistance, and load-bearing tests to assess durability.

- Thermal Conductivity Testing: Particularly for aluminum holders to verify efficient heat dissipation.

- Adhesion Tests: For coatings and surface treatments to confirm resistance to peeling or corrosion.

- Environmental Testing: Simulates exposure to UV light, humidity, and temperature fluctuations to predict long-term performance.

- Compatibility Checks: Ensures holders fit various LED strip widths and connector types.

How B2B Buyers Can Verify Supplier Quality Control

International buyers should adopt a multi-pronged approach to validate supplier QC capabilities:

- Factory Audits: Conduct on-site or virtual audits focusing on production processes, QC protocols, and workforce training.

- Review of Quality Documentation: Request ISO certificates, inspection reports, test data, and corrective action records.

- Third-Party Inspections: Engage independent inspection agencies to perform pre-shipment inspections and random sample testing.

- Sample Testing: Obtain and evaluate product samples in local laboratories for compliance with specifications and standards.

- Supplier References and Track Record: Check for feedback from existing clients in similar markets or industries.

Quality Assurance Considerations for Buyers by Region

- Africa: Emphasize suppliers with certifications recognized by local regulatory bodies and global standards to avoid import issues. Focus on durability and environmental resilience due to varied climates.

- South America (e.g., Brazil): Compliance with INMETRO (Brazilian National Institute of Metrology) and Mercosur technical regulations is critical. Buyers should verify supplier familiarity with local certification processes.

- Middle East: Products must often meet GCC (Gulf Cooperation Council) standards and be suitable for high-temperature environments. Robust packaging and logistics planning are vital due to import complexities.

- Europe (e.g., Spain): Strict adherence to CE marking, RoHS, and REACH is mandatory. Buyers benefit from suppliers with transparent quality management systems and traceability.

In summary, international B2B buyers sourcing LED strip light holders should prioritize manufacturers with well-defined manufacturing processes, rigorous quality control checkpoints, and certifications aligned with their regional requirements. Conducting thorough due diligence through audits, sample testing, and third-party inspections will mitigate risks and ensure a reliable supply of high-quality holders tailored to diverse market needs.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip light holder Sourcing

Understanding the cost and pricing dynamics of sourcing LED strip light holders is critical for international B2B buyers aiming to optimize procurement budgets while ensuring product quality and supply reliability. The pricing structure is multi-faceted, driven by several cost components and market influencers that vary by region and supplier.

Key Cost Components in LED Strip Light Holder Pricing

-

Materials: The primary cost driver includes aluminum, plastic polymers (like PVC or PC), and sometimes silicone for waterproof variants. Material quality affects durability and heat dissipation capabilities, which in turn influence pricing. Premium or eco-friendly materials command higher prices.

-

Labor: Manufacturing labor costs depend on the country of origin and the complexity of the holder design. Countries with higher wage levels naturally reflect this in pricing, while automation in factories can reduce labor costs.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and indirect labor. Efficient factories with optimized processes usually have lower overheads, helping reduce final prices.

-

Tooling and Molds: Initial setup costs for custom holders or unique profiles can be significant. Tooling amortization is often spread across order volumes, making smaller MOQ orders more expensive per unit.

-

Quality Control (QC): Rigorous QC processes, including dimensional checks, material testing, and functionality tests, add to cost but are essential for reliable products, especially for buyers in regulated markets like the EU.

-

Logistics and Shipping: Freight charges, customs duties, taxes, and insurance vary considerably by destination. For buyers in Africa, South America, the Middle East, and Europe, port proximity and transport infrastructure impact landed costs.

-

Supplier Margin: The profit margin applied by the manufacturer or distributor varies with brand positioning, negotiation leverage, and relationship length.

Influencing Factors on Pricing

-

Order Volume and MOQ: Larger volumes typically yield lower unit prices due to economies of scale. Buyers from emerging markets like Brazil or South Africa should consolidate orders to negotiate better pricing.

-

Specifications and Customization: Customized holders with specific dimensions, finishes, or integrated features raise costs. Standardized designs are more cost-effective.

-

Material Quality and Certifications: Products compliant with international standards (e.g., RoHS, CE) may cost more but reduce risk of rejection or penalties in markets like Europe.

-

Supplier Experience and Reliability: Established suppliers with proven track records often price higher but provide consistent quality and fewer supply chain disruptions.

-

Incoterms and Payment Terms: Terms like FOB, CIF, or DDP affect pricing transparency and risk allocation. Buyers should evaluate total landed cost rather than just FOB prices.

Practical Tips for B2B Buyers Across Regions

-

Negotiate Beyond Price: Emphasize total value including quality assurance, delivery timelines, and after-sales service. Long-term partnerships often unlock better terms.

-

Assess Total Cost of Ownership (TCO): Factor in potential costs from defects, returns, and delayed shipments, which can be more expensive than upfront savings.

-

Leverage Regional Trade Agreements: For European buyers, sourcing from suppliers within trade blocs can reduce tariffs and customs delays.

-

Request Detailed Quotes: Ask suppliers to break down costs by component to identify areas for negotiation or cost optimization.

-

Pilot Orders and Samples: Especially important for buyers in Africa and South America to validate quality before scaling.

-

Consider Currency Fluctuations: Hedging or fixed-price contracts can protect against exchange rate volatility impacting final costs.

Indicative Pricing Disclaimer

Prices for LED strip light holders vary widely based on design complexity, material choice, order volume, and supplier location. Indicative unit costs typically range from $0.10 to $1.50 USD for standard holders in bulk quantities. Buyers should treat these figures as rough benchmarks and conduct direct supplier inquiries for accurate quotations tailored to their specific requirements.

By understanding these cost drivers and pricing influences, international B2B buyers can make informed sourcing decisions that balance cost-efficiency with quality and supply chain resilience, ensuring sustainable business growth across diverse markets.

Spotlight on Potential led strip light holder Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip light holder’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip light holder

When sourcing LED strip light holders, understanding their critical technical properties and common trade terminology is essential for making informed purchasing decisions. This knowledge helps international B2B buyers—especially from Africa, South America, the Middle East, and Europe—ensure product quality, compatibility, and smooth procurement processes.

Key Technical Properties of LED Strip Light Holders

-

Material Grade

LED strip light holders are commonly made from aluminum or high-quality plastic (such as polycarbonate). Aluminum holders provide excellent heat dissipation, improving the lifespan and performance of LED strips, which is crucial in warm climates like parts of Africa and the Middle East. Plastic holders offer lightweight and corrosion-resistant options suited for indoor environments. Specifying the correct material grade ensures durability and compliance with environmental conditions. -

Dimensional Tolerance

This refers to the allowable variation in the holder’s physical dimensions during manufacturing. Tight tolerances are vital for ensuring a secure fit with LED strips, preventing movement or damage during installation. For buyers, understanding tolerance levels helps avoid compatibility issues with LED strips sourced from different manufacturers, reducing returns and installation delays. -

Heat Dissipation Efficiency

Effective heat dissipation prevents LED strip overheating, which can cause premature failure. Aluminum holders with anodized surfaces typically offer better thermal management. For large-scale projects in hot climates, selecting holders with verified heat dissipation ratings can significantly enhance system reliability and reduce maintenance costs. -

IP (Ingress Protection) Rating

This rating defines the holder’s resistance to dust and water ingress. Common ratings for holders range from IP20 (indoor use, no water protection) to IP65 or higher (waterproof, suitable for outdoor or humid environments). Buyers targeting outdoor or industrial applications should prioritize higher IP-rated holders to meet safety standards and ensure longevity. -

Mounting Style and Compatibility

Holders come in various mounting options—clip-in, screw-mounted, or adhesive-backed. Selecting the appropriate mounting style based on installation environment and surface type is critical. Compatibility with standard LED strip widths (e.g., 8mm, 10mm, 12mm) should also be confirmed to avoid fitment issues. -

Surface Finish and Corrosion Resistance

For projects in coastal or humid regions (like parts of South America and Europe), corrosion resistance is essential. Anodized aluminum or UV-stabilized plastics prevent degradation and maintain aesthetic appeal over time. Buyers should verify finish specifications aligned with local environmental challenges.

Common Trade Terminology for LED Strip Light Holder Procurement

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing holders that can be branded or customized for another company. OEM partnerships are valuable for buyers seeking private labeling or tailored designs, facilitating brand differentiation in competitive markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory and budget effectively, especially important for small to medium enterprises in emerging markets where cash flow and storage may be limited. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms. Mastering RFQs enables buyers to compare offers transparently and negotiate better deals, critical in international trade with varying cost structures. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, EXW) defining responsibilities for shipping, insurance, and customs between buyer and seller. Familiarity with Incoterms protects buyers from unexpected costs and clarifies logistics roles, streamlining cross-border transactions. -

Lead Time

The duration from order placement to delivery. Knowing lead times allows buyers to schedule projects accurately and avoid costly delays, particularly important when coordinating multiple suppliers or meeting tight deadlines. -

Certification Standards

Terms like CE, RoHS, UL indicate compliance with safety, environmental, or quality standards. Buyers should insist on certified holders to ensure legal market access and reduce risks associated with substandard products.

By focusing on these technical properties and trade terms, international B2B buyers can enhance supplier evaluation, optimize purchasing strategies, and secure LED strip light holders that meet both performance expectations and commercial requirements. This approach supports scalable, reliable supply chains across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip light holder Sector

Market Overview & Key Trends

The global market for LED strip light holders is expanding rapidly, driven by the increasing adoption of LED lighting technology across commercial, industrial, and residential sectors. International B2B buyers, especially from emerging regions like Africa, South America, and the Middle East, alongside mature markets in Europe (notably Spain), are witnessing growing demand due to urbanization, infrastructure development, and energy efficiency mandates.

Key market drivers include the shift towards smart lighting systems, where LED strip holders must accommodate integrated sensors, controllers, and flexible mounting options. Buyers prioritize holders that ensure secure installation, heat dissipation, and compatibility with various LED strip models. For Africa and South America, affordability combined with durable, weather-resistant materials is critical, addressing both indoor and outdoor applications in diverse climates.

Emerging sourcing trends emphasize customization and modularity. Suppliers increasingly offer holders with adjustable clips, magnetic mounts, and multi-angle designs that facilitate versatile installations. Additionally, digital sourcing platforms and direct manufacturer partnerships are gaining traction, enabling buyers to negotiate better pricing and reduce lead times. European buyers, particularly in Spain, demand compliance with stringent quality and safety standards such as CE and RoHS certifications.

Illustrative Image (Source: Google Search)

Logistics and supply chain resilience remain focal points due to past disruptions. Buyers from the Middle East and South America are actively seeking suppliers with transparent production capabilities and reliable delivery schedules. This has prompted manufacturers to enhance communication channels and provide real-time order tracking, ensuring consistent supply and minimizing project delays.

Sustainability & Ethical Sourcing in B2B

Sustainability is an increasingly decisive factor for B2B buyers in the LED strip light holder sector. The environmental impact of manufacturing and materials selection is scrutinized closely, especially by European and Middle Eastern companies adhering to green building certifications like LEED and BREEAM. Buyers now demand holders manufactured from recyclable or biodegradable plastics, low-VOC coatings, and lead-free metals to reduce carbon footprints and comply with international environmental regulations.

Ethical sourcing is integral to building a responsible supply chain. Buyers from all regions are prioritizing manufacturers with transparent labor practices, fair wages, and safe working conditions. Certifications such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) are becoming baseline requirements in supplier evaluations.

Moreover, energy-efficient production processes and waste reduction initiatives influence supplier selection. Some manufacturers invest in renewable energy sources for their factories and adopt circular economy principles, such as reclaiming scrap materials for reuse. For buyers in Africa and South America, partnerships with suppliers who demonstrate sustainability credentials can also support corporate social responsibility goals and improve brand reputation.

In summary, sustainability in the LED strip light holder market extends beyond product specifications to encompass the entire lifecycle—from raw material sourcing to end-of-life disposal—making it a critical consideration for long-term B2B partnerships.

Brief Evolution and Industry Context

The LED strip light holder has evolved significantly from simple plastic clips to sophisticated mounting solutions tailored for various environments and technical requirements. Initially, holders were basic fixtures designed to secure LED strips on flat surfaces. However, as LED technology advanced and diversified, holders adapted to accommodate different strip widths, waterproofing needs, and heat dissipation challenges.

The rise of smart lighting and IoT integration further accelerated innovation, with holders now supporting embedded sensors and easy reconfiguration. This evolution reflects broader market trends emphasizing flexibility, durability, and energy efficiency. For B2B buyers, understanding this progression helps in selecting holders that are future-proof and compatible with evolving LED technologies, ensuring better ROI and reduced operational headaches.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip light holder

-

How can I effectively vet LED strip light holder suppliers from diverse regions like Africa, South America, the Middle East, and Europe?

To vet suppliers efficiently, focus on verifying their industry certifications such as ISO, CE, RoHS, or UL, which ensure compliance with international quality and safety standards. Request detailed company profiles and check their years of experience in LED accessories manufacturing. Evaluate customer reviews and testimonials on reputable B2B platforms. Additionally, ask for references and case studies demonstrating successful international trade partnerships. Consider suppliers who actively participate in regional trade shows or have local distribution centers to ease logistics and communication. -

What customization options are typically available for LED strip light holders, and how should I negotiate these with manufacturers?

Most reputable manufacturers offer customization in materials (e.g., aluminum, plastic), sizes, mounting styles, and finishes to fit different LED strip widths and environments. Discuss your specific technical requirements upfront, including durability for outdoor or industrial use. Negotiate customization costs early and request prototypes or samples to validate design and function. Ensure the supplier can support ongoing R&D and modifications as your product line evolves. Clear communication about batch consistency in customized orders is essential to avoid quality discrepancies. -

What are the typical minimum order quantities (MOQs) and lead times for LED strip light holders, and how flexible are suppliers in different markets?

MOQs vary widely depending on supplier scale and region but often range from a few hundred to several thousand units. Lead times typically span 3 to 8 weeks, influenced by order size, customization complexity, and shipping logistics. Suppliers in Europe may offer shorter lead times but higher costs, while manufacturers in Asia or South America might require larger MOQs with longer waits. Negotiate MOQs and lead times during initial discussions, and consider building trial orders to test supplier responsiveness before committing to large volumes. -

Which quality assurance measures and certifications should I look for to ensure reliable LED strip light holders?

Prioritize suppliers who implement strict quality control processes such as in-line inspections, functional testing, and final product audits. Certifications like CE (European conformity), RoHS (restriction of hazardous substances), and UL (safety standards) validate product safety and environmental compliance. Request documentation on material traceability and testing reports, especially for adhesive strength and heat resistance, which are critical for LED strip light holders. Regular factory audits and third-party inspections further safeguard your supply chain against quality risks. -

What are the best logistics practices for importing LED strip light holders internationally, especially to Africa, South America, the Middle East, and Europe?

Plan logistics by choosing suppliers experienced in international shipping with established freight forwarders. Clarify Incoterms (e.g., FOB, CIF) to understand cost responsibilities and risk transfer points. Use consolidated shipments to reduce freight costs and customs complexities when sourcing multiple components. For regions with less developed infrastructure, select air freight for urgent orders or ocean freight for bulk shipments, balancing cost and delivery speed. Ensure your supplier provides accurate packing lists and commercial invoices to streamline customs clearance. -

How can I manage payment terms and currency risks when sourcing LED strip light holders internationally?

Negotiate payment terms that balance risk, such as partial upfront deposits with the balance paid after inspection or delivery. Use secure payment methods like letters of credit or escrow services to protect both parties. When dealing with volatile currencies, consider contracts in stable currencies like USD or EUR and explore hedging options through financial institutions. Maintain transparent communication with suppliers about payment schedules and confirm their banking credentials to prevent fraud. -

What steps should I take to handle disputes or quality issues with LED strip light holder suppliers?

First, establish clear contract terms including warranty, return policies, and defect thresholds before placing orders. If issues arise, document them with photos and detailed descriptions, and communicate promptly with the supplier to seek resolution. Use third-party inspection or mediation services if disputes escalate. Maintaining good relationships encourages suppliers to prioritize your concerns. For persistent problems, consider legal recourse aligned with the contract’s governing law, or shift to alternative suppliers after thorough evaluation. -

How important is after-sales support from LED strip light holder manufacturers, and what should I expect?

After-sales support is critical for troubleshooting installation issues, warranty claims, and future product upgrades. Expect suppliers to provide technical assistance, replacement parts, and timely responses to inquiries. Reliable manufacturers often offer training materials or guides to help your team and end customers. Prioritize partners who invest in long-term relationships, as consistent after-sales service reduces downtime and builds trust, especially when scaling operations across multiple international markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip light holder

Strategic sourcing of LED strip light holders demands a careful balance of quality, reliability, and cost-efficiency. International B2B buyers from Africa, South America, the Middle East, and Europe should prioritize manufacturers with proven industry experience, robust certifications, and transparent supply chains to ensure consistent product performance and timely delivery. Testing samples for durability, fit, and compatibility is essential before scaling orders, minimizing risk and optimizing inventory management.

Key takeaways for successful sourcing include:

- Establishing long-term partnerships with trusted suppliers to benefit from stable pricing and dependable support.

- Verifying supplier capabilities through certifications like CE, RoHS, and ISO, and reviewing client testimonials or case studies.

- Evaluating logistical factors such as lead times and shipping options tailored to regional infrastructure challenges.

- Considering customization and R&D collaboration to align product specifications with evolving market needs.

Looking ahead, the LED strip light holder market will continue to evolve with advances in materials and mounting technologies, offering new opportunities for differentiation. Buyers who invest in strategic sourcing today will secure competitive advantages through supply chain resilience and product innovation. For businesses across emerging and established markets, now is the time to deepen supplier relationships and embrace sourcing strategies that drive sustainable growth and operational excellence.