Introduction: Navigating the Global Market for led strip for cpu

In today’s fast-evolving technology landscape, LED strips for CPUs have become essential components for enhancing both the functionality and aesthetics of computer systems. These specialized LED strips not only improve thermal visibility and system diagnostics but also add customizable lighting effects that appeal to a wide range of end-users—from gaming enthusiasts to enterprise-level data centers. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the nuances of this product category is crucial to making strategic sourcing decisions that balance quality, cost, and innovation.

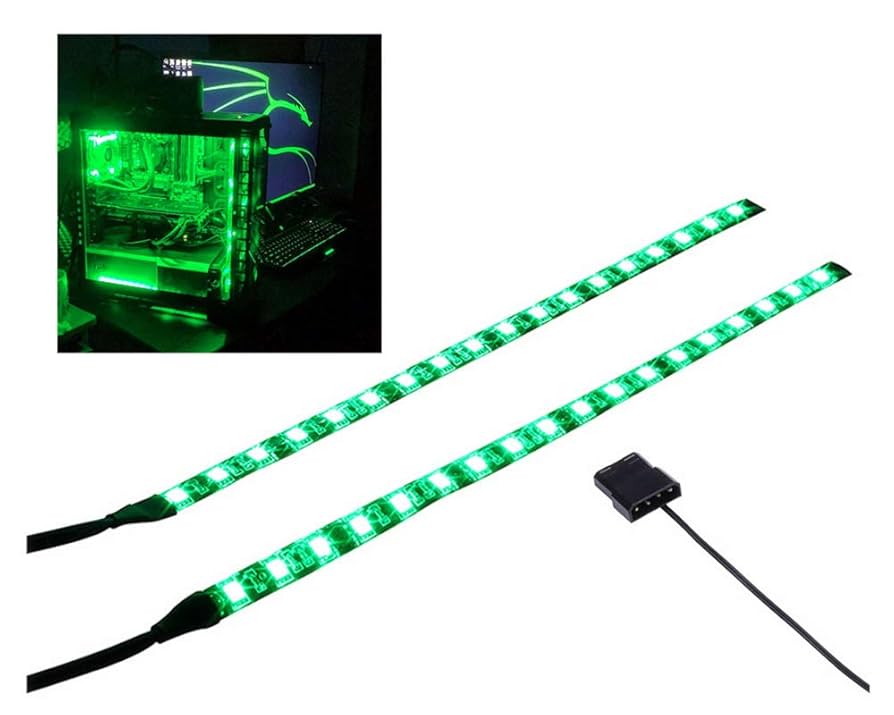

This comprehensive guide offers an in-depth exploration of the LED strip for CPU market, covering everything from types of LED strips—including flexible, rigid, RGB, and addressable models—to the critical materials and manufacturing processes that ensure durability and performance. We delve into quality control protocols and international compliance standards, empowering buyers to assess supplier reliability confidently.

Moreover, the guide navigates the complexities of global sourcing, spotlighting reputable suppliers and emerging markets tailored to diverse regional demands, such as those in Argentina and the UK. Cost considerations, scalability for large-scale deployments, and customization options are also examined to help businesses optimize procurement strategies.

By providing actionable insights into product selection, supplier evaluation, and market trends, this guide equips international B2B buyers with the knowledge needed to secure competitive advantages in the LED strip for CPU segment—ensuring investments translate into superior product performance and customer satisfaction.

Understanding led strip for cpu Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| RGB LED Strips | Multi-color LEDs with controllable color changes; often includes a controller | Gaming rigs, custom PC builds, aesthetic enhancements | Pros: Versatile lighting effects, high customization. Cons: Higher cost, requires compatible controllers. |

| White LED Strips | Single-color LEDs focused on white light with varying color temperatures (warm to cool) | Functional lighting inside CPU cases, workstations | Pros: Energy-efficient, simple installation. Cons: Limited aesthetic options, less dynamic. |

| Addressable LED Strips | Individually controllable LEDs allowing complex lighting patterns and animations | High-end gaming PCs, promotional displays, tech showcases | Pros: Advanced effects, high visual impact. Cons: More expensive, complex setup and control. |

| Flexible vs Rigid LED Strips | Flexible strips bend around corners; rigid strips provide structural support | Flexible for custom case designs; rigid for straightforward installations | Pros: Flexible for varied designs; rigid offers durability. Cons: Flexible may be less durable; rigid less adaptable. |

| Waterproof LED Strips | Encased in silicone or epoxy for protection against dust and moisture | Industrial CPU setups, outdoor or harsh environment use | Pros: Durable, suitable for challenging environments. Cons: Slightly bulkier, higher price point. |

RGB LED Strips

RGB LED strips are a popular choice for businesses catering to gaming and custom PC markets. They feature multi-color LEDs that can be controlled to display a wide spectrum of colors and dynamic effects. For B2B buyers, these strips offer the opportunity to provide clients with highly customizable and visually striking solutions. When sourcing RGB strips, consider supplier compatibility with popular controllers and software, as well as the quality of LEDs to ensure consistent color reproduction and longevity.

White LED Strips

White LED strips focus on providing efficient, functional lighting within CPU cases or workstations. Available in various color temperatures, these strips enhance visibility and reduce eye strain. For B2B buyers in office equipment or industrial sectors, white LED strips offer a cost-effective and reliable lighting solution. Key considerations include lumen output, energy consumption, and ease of installation, ensuring that products meet the specific operational needs of end users.

Addressable LED Strips

Addressable LED strips represent the cutting edge in LED lighting technology, allowing individual LEDs to be programmed independently. This capability enables complex animations and lighting patterns, ideal for high-end gaming PCs and tech showcases. From a procurement perspective, B2B buyers should evaluate the complexity of integration, compatibility with existing systems, and the supplier’s technical support. These strips typically command a premium price but can significantly enhance product differentiation.

Flexible vs Rigid LED Strips

The choice between flexible and rigid LED strips depends largely on the installation environment. Flexible strips are ideal for curved or irregular CPU case designs, offering adaptability and ease of installation. Rigid strips provide structural stability and are suited for straightforward, flat surfaces. B2B buyers should assess the design requirements of their projects and the durability demands to select the appropriate type. Flexible strips may require additional handling care, while rigid strips offer robustness but less design flexibility.

Waterproof LED Strips

Waterproof LED strips are encased in protective materials such as silicone or epoxy, making them suitable for industrial CPU setups or environments prone to moisture and dust. For buyers targeting sectors like manufacturing or outdoor installations, these strips ensure durability and reliability under harsh conditions. While they may be bulkier and more expensive than standard strips, their enhanced protection reduces maintenance costs and downtime, making them a prudent investment for long-term projects.

Related Video: The CPU and Von Neumann Architecture

Key Industrial Applications of led strip for cpu

| Industry/Sector | Specific Application of led strip for cpu | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Data Centers & Cloud Services | Cooling system status indication via LED strips on CPUs | Real-time visual monitoring reduces downtime and improves maintenance efficiency | High thermal resistance, long lifespan, and compliance with international standards (CE, RoHS) |

| Industrial Automation | Visual alerts and status lighting on CPU-controlled machinery | Enhances operational safety and quick fault detection | Durable adhesive backing for vibration resistance, IP-rated strips for harsh environments |

| Telecommunications | Rack-mounted server CPU illumination for maintenance visibility | Simplifies troubleshooting and reduces service time | Flexible PCB strips for tight spaces, consistent color and brightness for clear indication |

| Automotive Manufacturing | Integration in CPU control units for assembly line robotics | Improves precision and workflow monitoring | Custom length and color options, robust heat dissipation, and vibration tolerance |

| Consumer Electronics Assembly | Inspection lighting on CPU testing stations | Enhances quality control by improving visibility of micro components | Uniform light distribution, energy efficiency, and compatibility with automated systems |

Data Centers & Cloud Services

In data centers, LED strips for CPUs are primarily used as visual indicators for cooling system status and CPU health. These LED strips help technicians quickly assess operational conditions without interrupting server function, reducing downtime. For international buyers, particularly in regions like Europe and the Middle East where data center uptime is critical, sourcing LED strips with high thermal resistance and compliance certifications such as CE and RoHS is essential to meet stringent safety and environmental regulations.

Illustrative Image (Source: Google Search)

Industrial Automation

Industrial automation sectors rely on LED strips attached to CPU units within machinery to provide immediate visual alerts regarding system status or faults. This application enhances workplace safety and operational efficiency by enabling rapid problem identification. Buyers from South America and Africa should prioritize LED strips with durable adhesive backings and IP-rated protection to withstand vibration, dust, and moisture common in industrial environments.

Telecommunications

Telecommunication infrastructure often involves dense server racks where space is limited. LED strips on CPUs illuminate these units, aiding maintenance teams in identifying faulty components quickly. For B2B buyers in countries like the UK and Argentina, flexible PCB LED strips that fit into confined spaces without compromising brightness and consistency are crucial. Additionally, color accuracy supports clear status differentiation, which is vital for troubleshooting.

Automotive Manufacturing

In automotive manufacturing, LED strips integrated with CPU control units on robotic assembly lines provide real-time visual feedback on operational status and errors. This application enhances precision and streamlines workflow monitoring. Sourcing considerations for international buyers include customization options for length and color to match factory standards, as well as robust heat dissipation and vibration resistance to endure the harsh manufacturing environment.

Consumer Electronics Assembly

LED strips are used in CPU testing stations during consumer electronics assembly to provide bright, uniform lighting that highlights micro components for inspection. This improves quality control by reducing errors during testing. Buyers in all target regions must seek energy-efficient LED strips with consistent light distribution that are compatible with automated inspection systems, ensuring smooth integration and reliable performance in high-throughput production lines.

Related Video: The BEST FastLED Tutorial | WS2812b LED Strip Arduino Nano

Strategic Material Selection Guide for led strip for cpu

When selecting materials for LED strips designed for CPU cooling or illumination, the choice directly impacts thermal management, durability, and overall performance. International B2B buyers must consider these factors carefully, especially when sourcing for diverse markets such as Africa, South America, the Middle East, and Europe, where environmental conditions and regulatory standards vary.

Flexible Polyimide PCB Substrate

Key Properties:

Polyimide substrates are renowned for their excellent thermal stability, withstanding temperatures up to 260°C. They offer high flexibility, chemical resistance, and good dielectric properties, making them ideal for compact and curved installations around CPUs.

Pros & Cons:

– Pros: Superior heat resistance aids in effective thermal management near CPUs, flexibility allows for versatile installation, and chemical resistance enhances durability in various environments.

– Cons: Higher manufacturing complexity and cost compared to standard materials; may require specialized handling during assembly.

Impact on Application:

Polyimide PCBs are particularly suited for high-performance CPUs where heat dissipation is critical. Their flexibility allows integration into tight spaces within computer cases or cooling systems.

International Considerations:

Buyers in regions like Europe (UK) and the Middle East should verify compliance with standards such as IPC-4202 for flexible PCBs and RoHS directives. In Africa and South America (e.g., Argentina), ensuring supplier adherence to ASTM D 150 or DIN standards for thermal and electrical properties is advisable to guarantee product reliability under varying climate conditions.

Copper Clad FR4 PCB

Key Properties:

FR4 is a glass-reinforced epoxy laminate with moderate thermal resistance (up to approximately 130°C) and excellent mechanical strength. Copper cladding provides efficient electrical conductivity and heat dissipation.

Pros & Cons:

– Pros: Cost-effective, widely available, and easy to manufacture; good mechanical rigidity supports stable LED mounting.

– Cons: Limited flexibility restricts use in curved or compact CPU setups; lower thermal tolerance may reduce lifespan in high-temperature environments.

Impact on Application:

Ideal for standard CPU LED strips where rigid mounting is acceptable, and thermal loads are moderate. Not recommended for high-performance or compact cooling systems requiring flexible materials.

International Considerations:

FR4 PCBs are globally standardized, with compliance to IPC-4101 and UL94 flammability ratings being common. Buyers in Europe and the Middle East should ensure suppliers provide CE certification, while in South America and Africa, ASTM and IEC compliance are critical to meet import regulations and ensure safety.

Silicone-Based Adhesive Backing

Key Properties:

Silicone adhesives exhibit excellent temperature resistance (up to 200°C), strong adhesion on various surfaces, and good resistance to moisture and UV exposure.

Pros & Cons:

– Pros: Maintains adhesive strength in high-heat CPU environments, resists degradation over time, and supports easy installation on irregular surfaces.

– Cons: Higher cost than acrylic adhesives; potential compatibility issues with some plastics if not properly formulated.

Impact on Application:

Essential for LED strips mounted directly onto CPU coolers or heat sinks where heat and vibration are concerns. Silicone backing ensures strips remain securely attached without peeling.

International Considerations:

For markets like the Middle East and Europe, adherence to REACH and RoHS for chemical safety is important. In Africa and South America, buyers should confirm adhesive certifications for heat resistance and environmental safety, ensuring long-term performance in diverse climates.

Aluminum Channel Housing

Key Properties:

Aluminum channels provide structural support, excellent heat dissipation, and corrosion resistance. They are lightweight and can be anodized for enhanced durability.

Pros & Cons:

– Pros: Enhances thermal management by acting as a heat sink, protects LED strips from physical damage, and offers aesthetic appeal.

– Cons: Adds to overall product cost and weight; requires precise manufacturing to fit LED strips and CPU configurations.

Impact on Application:

Aluminum housings are ideal for premium CPU LED strip solutions where durability and heat dissipation are priorities. They are especially useful in industrial or gaming PC builds demanding robust performance.

International Considerations:

Buyers should verify compliance with ISO 209 (aluminum anodizing) and ASTM B221 standards. In Europe and the UK, CE marking for electrical safety and material quality is essential. For African and South American markets, corrosion resistance certifications are important due to varied humidity and temperature conditions.

| Material | Typical Use Case for led strip for cpu | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Polyimide PCB | High-performance, flexible LED strips near CPUs | Excellent heat resistance and flexibility | Higher manufacturing complexity and cost | High |

| Copper Clad FR4 PCB | Standard rigid LED strips for moderate thermal loads | Cost-effective and mechanically strong | Limited flexibility and lower heat tolerance | Low |

| Silicone-Based Adhesive | Adhesive backing for heat-resistant, secure mounting | High temperature and chemical resistance | More expensive than acrylic adhesives | Medium |

| Aluminum Channel Housing | Protective and heat-dissipating housing for LED strips | Superior heat dissipation and durability | Adds cost and weight to the product | Medium |

This guide empowers international B2B buyers to make informed decisions based on material properties, application needs, and regional compliance requirements. Selecting the right combination of PCB substrate, adhesive, and housing materials ensures optimal LED strip performance and longevity in CPU environments across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip for cpu

Manufacturing Processes for LED Strips Designed for CPU Cooling

Producing high-quality LED strips tailored for CPU cooling applications involves a multi-stage manufacturing process that ensures reliability, performance, and durability. Each stage demands precision and careful material selection to meet the stringent requirements of computer hardware environments, where thermal management and compact design are critical.

1. Material Preparation

- Selection of LED Chips: Manufacturers source premium LED chips from reputable suppliers, focusing on chips that provide high luminous efficacy, low power consumption, and long lifespan. For CPU LED strips, chips often need to withstand elevated temperatures.

- PCB Fabrication: The printed circuit board (PCB) forms the backbone of the LED strip. For CPU applications, PCBs are typically made from high-quality, heat-resistant materials such as aluminum or copper-clad substrates to facilitate effective heat dissipation.

- Adhesive and Protective Layers: Heat-resistant adhesive backings and protective coatings (like silicone or epoxy encapsulation) are prepared to ensure durability in the thermal environment of a CPU.

2. Forming and Circuit Board Assembly

- PCB Cutting and Shaping: PCBs are cut to precise dimensions compatible with CPU cooler sizes, often requiring flexible PCBs to accommodate curved or irregular surfaces.

- Solder Paste Application: A solder paste is applied to the PCB pads using stencil printing to prepare for LED chip mounting.

- Pick-and-Place Mounting: Automated machines place the LED chips and other surface-mount components with high accuracy onto the PCB.

- Reflow Soldering: The assembly passes through a reflow oven where solder paste melts and forms strong electrical and mechanical bonds between components and PCB.

3. Assembly and Integration

- Wiring and Connector Attachment: Electrical connectors or wires are attached to enable easy integration with CPU cooling systems and power sources.

- Encapsulation and Sealing: LED strips are coated with heat-resistant encapsulants to protect against dust, moisture, and mechanical stress, ensuring longevity within the CPU environment.

- Adhesive Application: High-grade adhesives are applied to the backside of the strip to guarantee firm attachment to CPU coolers or chassis without peeling under heat cycles.

4. Finishing and Packaging

- Cutting and Customization: LED strips are cut into standard or custom lengths based on client specifications.

- Labeling and Branding: Packaging includes detailed product information, batch numbers, and quality certification marks to facilitate traceability.

- Protective Packaging: Each strip is carefully packaged with anti-static and shock-absorbing materials to prevent damage during international shipping.

Quality Assurance and Control (QA/QC) Framework

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the quality assurance framework behind LED strips for CPUs is essential. Rigorous QC processes ensure product consistency, safety, and compliance with international regulations.

Key Quality Standards and Certifications

- ISO 9001: This international standard for quality management systems confirms that the manufacturer maintains consistent quality processes, risk management, and continuous improvement.

- CE Marking: Required for products entering the European Economic Area, CE certification ensures compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electronic components, a critical certification for environmental safety, especially in Europe and increasingly in other regions.

- UL and ETL Certifications: These US-based safety standards may be requested by buyers dealing with markets requiring stringent electrical safety tests.

- API or Industry-Specific Standards: Some B2B buyers in specialized sectors may require compliance with additional certifications related to electronics or thermal management.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components such as LED chips, PCBs, adhesives, and connectors undergo rigorous inspection upon arrival to verify specifications and detect defects early.

- In-Process Quality Control (IPQC): During assembly, continuous checks monitor soldering quality, component placement accuracy, and electrical connectivity to prevent defects from propagating.

- Final Quality Control (FQC): Finished LED strips are subjected to comprehensive testing, including visual inspections, functional testing, and stress testing, to confirm overall product integrity.

Common Testing Methods

- Electrical Testing: Measures voltage, current, and luminous output to ensure LED strips meet specified performance criteria.

- Thermal Cycling Tests: Simulate CPU operating conditions by exposing strips to repeated heating and cooling cycles to verify durability.

- Adhesion Tests: Evaluate the strength and longevity of the adhesive backing under simulated environmental stresses.

- Environmental Resistance Testing: Includes moisture, dust, and UV exposure tests to assess strip resilience in varying conditions.

- Spectral and Color Consistency Testing: Ensures LEDs emit consistent color temperature and brightness across batches, crucial for aesthetic uniformity in PC builds.

Verifying Supplier Quality Assurance for International B2B Buyers

For buyers in regions such as Africa, South America, the Middle East, and Europe, due diligence in supplier quality verification is vital to mitigate risks related to product failures, regulatory non-compliance, or shipment delays.

Supplier Audit and Certification Review

- Factory Audits: On-site or remote audits evaluate manufacturing facilities’ adherence to quality standards, production capacity, workforce skills, and environmental controls.

- Certification Verification: Buyers should request copies of quality management certificates (ISO 9001), product certifications (CE, RoHS), and test reports from accredited laboratories.

- Third-Party Inspections: Engaging independent inspection agencies to perform random sampling and testing provides unbiased assurance of product quality before shipment.

Documentation and Traceability

- Quality Control Reports: Detailed QC documentation, including inspection results from IQC, IPQC, and FQC stages, should be provided with shipments.

- Batch and Serial Numbering: Enables traceability for warranty claims and quality tracking.

- Compliance and Test Certificates: Essential for customs clearance and market acceptance, especially in regulated regions like the EU and UK.

Nuances for Different Regional Markets

- Africa and South America: Logistics challenges and import regulations often necessitate robust packaging and clear certification to avoid customs delays. Buyers may prioritize suppliers offering local language documentation and responsive customer support.

- Middle East: Compliance with both international and regional standards (e.g., SASO in Saudi Arabia) is crucial. Buyers often require suppliers to provide detailed product safety data sheets and certifications aligned with Gulf Cooperation Council (GCC) regulations.

- Europe (including UK): Strict environmental and safety standards mean buyers must ensure full compliance with CE marking, RoHS, and WEEE directives. Post-Brexit, UKCA marking has become mandatory for UK imports, requiring additional verification.

Actionable Insights for B2B Buyers

- Prioritize suppliers with transparent quality management systems certified to ISO 9001 and recognized product certifications.

- Request detailed QC checkpoints and testing protocols tailored to CPU LED strip applications, focusing on thermal resistance and adhesion durability.

- Insist on third-party inspection reports or conduct factory audits to validate supplier claims, especially when sourcing from new or overseas manufacturers.

- Understand the regulatory landscape of your target market to ensure all necessary certifications and documentation are in place to avoid customs and compliance issues.

- Consider ordering samples for in-house testing under your specific operating conditions before committing to large orders.

By thoroughly evaluating manufacturing processes and quality assurance practices, international B2B buyers can secure reliable, high-performance LED strips designed for CPU cooling applications that meet the demands of their markets and end-users.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip for cpu Sourcing

When sourcing LED strips for CPU applications, understanding the underlying cost structure and pricing drivers is essential for making informed purchasing decisions. This analysis breaks down the key cost components, price influencers, and strategic considerations tailored for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip for CPU Manufacturing

- Materials: The largest cost driver, including high-quality LED chips, PCBs (flexible or rigid), adhesives, and protective coatings. Premium LED chips and heat-dissipating PCB materials can raise costs but significantly improve performance and lifespan.

- Labor: Skilled assembly labor for precise soldering of LED chips and PCB fabrication. Labor costs vary significantly by country and factory location, influencing final pricing.

- Manufacturing Overhead: Factory utilities, equipment depreciation, and operational expenses tied to maintaining quality control and production efficiency.

- Tooling and Equipment: Initial investments in molds, PCB fabrication tools, and automated assembly machines. These costs are amortized over production volume.

- Quality Control (QC): Rigorous testing for brightness, durability, and compliance with certifications such as CE, RoHS, and UL. High QC standards reduce defect rates but add to cost.

- Logistics and Shipping: Freight charges, customs duties, and insurance for international shipments. Costs vary depending on shipping mode (air vs. sea), Incoterms, and destination country infrastructure.

- Supplier Margin: Profit margins set by manufacturers and distributors, influenced by brand reputation, exclusivity, and service level agreements.

Price Influencers Affecting LED Strip for CPU Sourcing

- Order Volume and Minimum Order Quantity (MOQ): Larger volumes typically unlock significant per-unit price reductions due to economies of scale. Many suppliers require MOQs that can range from a few hundred to several thousand units.

- Product Specifications and Customization: Custom lengths, colors, brightness levels, and packaging increase unit costs due to setup and tooling adjustments. Complex features like RGB or smart controls further add to pricing.

- Material Quality and Certifications: Strips using premium-grade LED chips, superior PCB materials, and certified components command higher prices but offer better reliability and longevity, reducing total cost of ownership.

- Supplier Reliability and Location: Established suppliers with proven track records may charge a premium but provide consistent quality and better post-sale support. Proximity to manufacturing hubs can reduce lead times and shipping costs.

- Incoterms and Payment Terms: Shipping terms such as FOB, CIF, or DDP influence who bears transportation and customs risks and costs. Favorable payment terms (e.g., letter of credit, net 30) can improve cash flow for buyers.

Strategic Buyer Tips for International B2B Procurement

- Negotiate on Volume and Terms: Leverage bulk purchasing power to negotiate better pricing, lower MOQs, or extended payment terms. Suppliers may offer discounts for repeat orders or long-term contracts.

- Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also durability, energy efficiency, warranty, and after-sales service. Higher initial costs for quality products often yield savings in maintenance and replacements.

- Request Samples and Certifications: Always test product samples to verify performance and compatibility. Confirm supplier certifications to ensure compliance with local regulations, especially critical for markets like the EU and UK.

- Factor in Logistics and Import Costs: For buyers in Africa, South America, and the Middle East, shipping delays and customs duties can inflate costs. Consolidate shipments and choose optimal Incoterms to minimize unexpected expenses.

- Understand Pricing Nuances by Region: Currency fluctuations, import tariffs, and local taxes can impact landed costs. Engage local trade experts or freight forwarders to navigate these complexities effectively.

Indicative Pricing Disclaimer

Prices for LED strips tailored for CPU use vary widely based on specifications, volume, and supplier location. Indicative unit prices may range from $1 to $5 per meter, excluding shipping and taxes. Buyers should conduct detailed quotations and cost comparisons with multiple suppliers to secure the best deal aligned with their quality and delivery requirements.

This cost and pricing overview equips international B2B buyers with actionable insights to optimize sourcing strategies for LED strips designed for CPU applications, balancing quality, cost-efficiency, and supply chain robustness.

Spotlight on Potential led strip for cpu Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip for cpu’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip for cpu

Critical Technical Properties of LED Strips for CPU Applications

-

LED Chip Quality and Type

The LED chip is the core light-emitting component. High-grade chips, often from reputable manufacturers, ensure better luminous efficacy (brightness per watt) and longer operational lifespan. For B2B buyers, choosing LED strips with premium chips translates into energy savings and reduced maintenance costs over time, especially important in demanding CPU cooling or aesthetic setups. -

Printed Circuit Board (PCB) Material and Design

PCBs in LED strips support and connect the LED chips. Common materials include flexible polyimide or rigid FR4. The PCB’s thermal conductivity is crucial as it dissipates heat generated by LEDs. Superior PCB materials prevent overheating, which can cause flickering or premature failure—key considerations for industrial or extended use cases in CPU environments. -

Color Temperature and Brightness (Luminous Flux)

Color temperature (measured in Kelvins) affects the appearance of the LED light, ranging from warm (2700K) to cool white (6500K) and RGB options. Brightness, measured in lumens, dictates how intense the light output is. For CPU lighting, buyers often seek specific color tones or brightness levels to complement system aesthetics or visibility without causing glare. -

Voltage and Power Consumption

LED strips typically operate at 5V, 12V, or 24V DC. Power consumption per meter (watts/meter) impacts both energy efficiency and compatibility with power supplies. B2B buyers must match voltage and power specs with their hardware to avoid electrical issues and optimize operational costs. -

Adhesive Backing Quality

Adhesive backing enables easy installation of LED strips on CPU cases or components. High-quality adhesives ensure long-lasting attachment without peeling, even under heat or vibration. This property reduces installation time and prevents downtime caused by falling or misaligned strips. -

Ingress Protection (IP) Rating

Though not always critical for internal CPU lighting, some buyers may require IP-rated LED strips for dust or moisture resistance in specialized environments. Understanding IP ratings (e.g., IP20 for indoor use, IP65 for water resistance) is important for sourcing the right product for intended applications.

Common Industry and Trade Terms for B2B Buyers

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce products or components that are purchased by another company and retailed under that purchasing company’s brand. For LED strips, OEM agreements allow buyers to source customized products with specific branding or technical requirements, providing competitive advantages in their markets. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. Understanding MOQ is essential for cost planning and inventory management. Buyers from emerging markets or small businesses should negotiate MOQs to avoid overstocking or excessive upfront investment. -

RFQ (Request for Quotation)

A formal process where buyers solicit price and specification quotes from multiple suppliers. RFQs help businesses compare offers, negotiate better terms, and ensure product compliance. Clear and detailed RFQs reduce misunderstandings and speed up procurement cycles. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers regarding shipping, insurance, and tariffs. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowing Incoterms helps buyers from Africa, South America, the Middle East, and Europe manage logistics and costs efficiently. -

Luminous Efficacy

A measure of how well a light source produces visible light, expressed as lumens per watt (lm/W). Higher efficacy means more light output for less energy consumed, translating into operational savings and better sustainability credentials. -

Bin Sorting

The process of categorizing LED chips based on brightness, color, and voltage characteristics. Bin sorting ensures uniformity and consistency in LED strip batches, critical for projects requiring precise color matching or consistent lighting performance.

Understanding these technical properties and trade terms empowers international B2B buyers to make informed purchasing decisions, optimize their supply chains, and secure LED strip products that meet both technical and commercial expectations in the CPU lighting market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip for cpu Sector

Market Overview & Key Trends

The global LED strip market for CPU applications is experiencing robust growth driven by increasing demand for enhanced aesthetics and thermal management in computing systems. LED strips are extensively used in gaming rigs, data centers, and high-performance workstations to provide customizable lighting and improve visibility inside CPU cases. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the market dynamics is critical to sourcing the right products that balance quality, cost, and innovation.

Key market drivers include the rising popularity of gaming and e-sports, growing awareness of energy-efficient lighting, and the expansion of PC manufacturing hubs, especially in Asia, which serve as major suppliers. Buyers from countries like Argentina and the UK increasingly seek LED strips that combine flexibility, durability, and advanced features such as addressable RGB lighting and smart control compatibility.

Current sourcing trends reveal a shift toward wholesale procurement from reliable manufacturers offering customization in length, color temperature, and adhesive backing. This trend supports large-scale PC builders and system integrators aiming to maintain consistent product quality and branding. Suppliers providing direct-to-buyer shipping and competitive lead times are highly favored, as they enable smoother supply chains and reduced inventory costs.

Emerging technologies such as dimmable LEDs, integrated thermal sensors, and app-controlled lighting are becoming standard expectations in the B2B market. Additionally, the demand for flexible PCBs that enhance heat dissipation and installation ease is rising. Buyers also prioritize suppliers with rigorous quality control and certifications like CE and RoHS to ensure compliance with international standards and reduce the risk of returns.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly a decisive factor in the procurement of LED strips for CPU applications. The environmental impact of electronics manufacturing, including energy consumption and e-waste, places a premium on green sourcing practices. International buyers are progressively demanding LED strips made from eco-friendly materials such as lead-free solder and recyclable PCBs, which reduce hazardous waste and carbon footprint.

Ethical supply chain management is critical, especially for buyers in regions with stringent import regulations like the European Union. Transparency about raw material sourcing, labor conditions, and manufacturing processes helps businesses meet corporate social responsibility (CSR) commitments and avoid reputational risks. Suppliers adhering to ISO 14001 environmental management standards and providing certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are preferred partners.

Moreover, energy efficiency is a core sustainability attribute. LED strips with high luminous efficacy reduce power consumption in CPU lighting without compromising brightness, directly supporting clients’ sustainability goals. Packaging also plays a role—biodegradable or minimal packaging solutions reduce waste and appeal to environmentally conscious buyers.

Illustrative Image (Source: Google Search)

For B2B buyers from Africa, South America, the Middle East, and Europe, prioritizing suppliers with strong sustainability credentials and ethical sourcing policies not only aligns with global trends but also future-proofs procurement strategies against evolving regulations and market expectations.

Evolution and Historical Context

The LED strip for CPU lighting sector has evolved significantly since its inception. Initially, LED strips were simple, single-color light sources used primarily for basic indicator lighting inside computer cases. As PC gaming and modding communities grew in the early 2000s, demand surged for more customizable, vibrant, and flexible lighting solutions.

The introduction of RGB LED technology revolutionized the market, allowing users to select from millions of colors and dynamic lighting effects. This shift transformed LED strips from purely functional components into essential aesthetic features that enhance user experience and brand differentiation.

More recently, advances in smart lighting control systems and improvements in PCB materials for better heat dissipation have further elevated LED strips’ role in CPU setups. The sector now focuses not only on illumination but also on energy efficiency, durability, and integration with smart home ecosystems, reflecting broader trends in IoT and sustainable electronics.

This evolution underscores the importance of sourcing from manufacturers that innovate continuously while maintaining stringent quality and environmental standards, ensuring that B2B buyers receive cutting-edge products aligned with modern computing needs.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip for cpu

-

How can I effectively vet suppliers of LED strips for CPU applications in international markets like Africa or South America?

To vet suppliers, start by verifying their business licenses and certifications such as CE, RoHS, or UL that assure product safety and compliance. Request detailed product datasheets and inquire about their quality control processes, including testing protocols. Check references or reviews from other international clients, particularly those in similar regions, to assess reliability. If possible, visit the factory or request virtual tours. Confirm their experience with exporting to your region to ensure they understand local import regulations and standards. -

What customization options are typically available when ordering LED strips for CPUs, and how can they add value?

Many manufacturers offer customization including specific LED chip types for brightness and color temperature, strip length, PCB flexibility, adhesive backing strength, and connector types. Custom packaging and branding are also common. These options allow you to tailor the product to your clients’ exact needs, improving product differentiation and satisfaction. For international buyers, customization can help meet regional compliance or environmental requirements, making your product more competitive in diverse markets. -

What are common Minimum Order Quantities (MOQs), lead times, and payment terms for bulk LED strip purchases from international suppliers?

MOQs vary widely depending on supplier scale but typically range from 500 to 5000 meters per SKU. Lead times generally span 3 to 8 weeks, factoring production and shipping. Payment terms often include a 30-50% deposit upfront, with the balance paid upon shipment or after inspection. Negotiating flexible terms may be possible with established suppliers or larger orders. Always clarify these details upfront to align procurement schedules and cash flow, especially when dealing with cross-border transactions. -

Which quality assurance certifications should I prioritize to ensure reliable LED strips for CPU use?

Prioritize internationally recognized certifications like CE (European conformity), RoHS (restriction of hazardous substances), UL (Underwriters Laboratories), and ISO 9001 (quality management). These certifications indicate compliance with safety, environmental, and manufacturing standards. For buyers in Africa, South America, and the Middle East, also check if suppliers meet local or regional certifications. Request test reports and certification documents to verify authenticity and ensure the products meet your market’s regulatory requirements. -

How can I manage logistics and shipping challenges when importing LED strips for CPUs from Asia or Europe to regions like the Middle East or South America?

Work with suppliers who have experience with international freight forwarders and understand customs clearance processes in your region. Opt for consolidated shipments to reduce costs and consider using Incoterms like FOB or CIF to clarify responsibility and costs. Ensure packaging protects against humidity and mechanical damage during transit. Track shipments proactively and prepare for potential delays due to customs or regional holidays. Establish a local customs broker relationship to expedite clearance and reduce unexpected fees. -

What steps should I take to handle disputes related to product quality or delivery delays in international LED strip transactions?

First, maintain clear, documented communication including contracts specifying quality standards, delivery schedules, and penalties for non-compliance. Upon disputes, request detailed evidence such as photos, test results, and shipping documents. Engage the supplier promptly to negotiate solutions like replacement shipments or refunds. If unresolved, consider mediation or arbitration through international trade bodies or chambers of commerce. Having a well-defined dispute resolution clause in your contract is critical for protecting your interests. -

How important is sample testing before placing large orders for LED strips, and what should I look for?

Sample testing is crucial to verify product quality, color consistency, brightness, adhesion strength, and compatibility with your CPU setups. It helps identify manufacturing defects or mismatched specifications before committing to bulk orders. Request samples from multiple suppliers to compare performance and durability under expected operating conditions. Testing samples locally or via third-party labs adds credibility. This step minimizes risks and ensures your final product meets client expectations and regional standards. -

Are there specific considerations for warranty and after-sales support when purchasing LED strips for CPUs internationally?

Yes, ensure the supplier offers a clear warranty covering defects and performance issues, typically ranging from 1 to 3 years. Understand the process for claiming warranty, including who bears shipping costs for replacements. Reliable after-sales support is critical for troubleshooting and maintaining long-term client satisfaction. Suppliers with multilingual support and local service partners in your region can expedite resolutions. Clarify these terms before purchase to avoid costly downtime and protect your business reputation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip for cpu

Strategic Sourcing Insights for LED Strip Solutions in CPU Applications

For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, strategic sourcing of LED strips for CPU lighting demands a focus on quality, reliability, and supplier credibility. Prioritizing suppliers who use premium LED chips, robust PCB fabrication, and durable adhesive backings ensures superior performance and longevity—critical factors for applications where consistent cooling and aesthetic lighting are essential. Rigorous quality control and compliance certifications like CE and RoHS further safeguard your investment by minimizing defects and aligning with international standards.

Cost efficiency is another pivotal consideration. Leveraging wholesale purchasing options unlocks economies of scale, enabling competitive pricing without compromising product quality. Additionally, sourcing partners offering customization—such as tailored lengths, colors, or packaging—can provide differentiation and better integration with your product ecosystem.

Looking ahead, the LED strip market for CPU applications is poised for innovation with advancements in smart lighting and energy-efficient designs. International buyers are encouraged to cultivate partnerships with forward-thinking manufacturers who embrace these technologies, ensuring access to cutting-edge solutions that meet evolving market demands. By combining diligent supplier evaluation with strategic bulk procurement, businesses across diverse regions can enhance their supply chain resilience and deliver superior value to their customers.