Introduction: Navigating the Global Market for led strip dimmer switch

The global surge in LED lighting adoption has propelled the led strip dimmer switch into a critical role for businesses aiming to deliver adaptable, energy-efficient lighting solutions. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of dimmer switches is essential to sourcing products that meet diverse technical standards, application needs, and budget constraints.

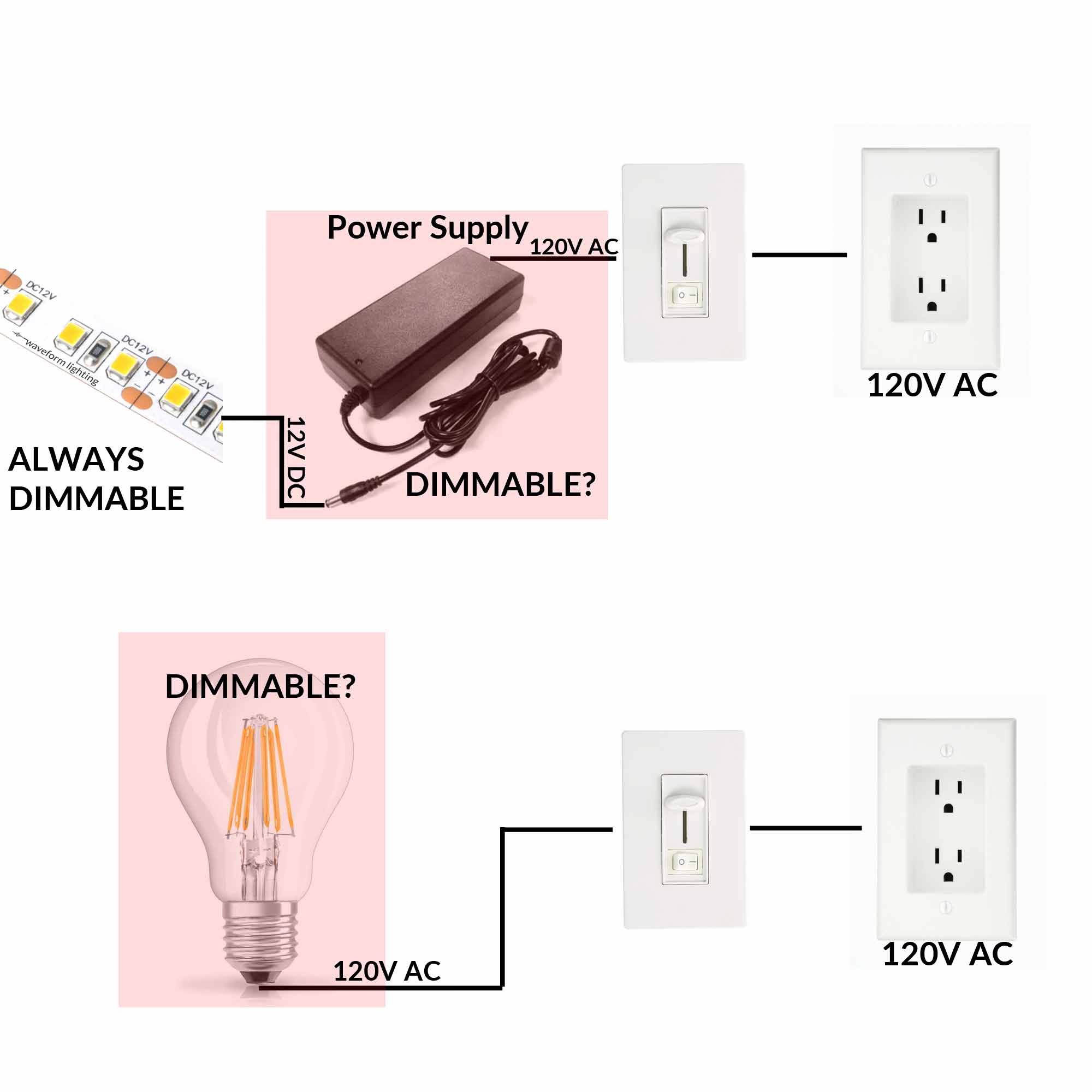

Led strip dimmer switches enable precise brightness control, enhancing user experience while optimizing energy consumption in commercial, residential, and industrial environments. Selecting the right dimmer involves navigating complex variables such as compatibility with LED types, dimming technologies (e.g., PWM, 0-10V, DALI), voltage requirements, and build quality—factors that directly impact performance and longevity.

This comprehensive guide offers an in-depth exploration of the led strip dimmer switch market, covering:

- Types and technical specifications to match various LED strip configurations

- Material and manufacturing insights emphasizing quality control and sustainability

- Key global suppliers and factory profiles, with a focus on reliable sourcing from major manufacturing hubs

- Cost considerations and market trends tailored to emerging and established markets

- Frequently asked questions addressing common challenges faced by international buyers

By consolidating these critical aspects, this guide empowers B2B buyers in regions like Turkey, Mexico, Nigeria, Brazil, and the UAE to make well-informed procurement decisions. Leveraging expert insights and actionable data, buyers can confidently select dimmer switches that optimize lighting solutions, ensure regulatory compliance, and maximize return on investment in their respective markets.

Understanding led strip dimmer switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PWM (Pulse Width Modulation) Dimmer | Uses rapid on/off switching to adjust brightness without color shift | Retail, hospitality, architectural lighting | + High efficiency and smooth dimming – Requires compatible LED drivers |

| 0-10V Analog Dimmer | Provides continuous voltage control signal between 0 and 10 volts | Commercial buildings, offices, industrial lighting | + Simple integration with existing systems – Limited to wired setups, less flexible |

| Triac (Leading/Trailing Edge) Dimmer | Works by cutting the AC waveform; compatible with AC mains LED strips | Residential and commercial retrofit projects | + Widely available and cost-effective – Can cause flicker if not compatible |

| Wireless RF/Bluetooth Dimmer | Remote control via radio frequency or Bluetooth connectivity | Smart buildings, event venues, outdoor installations | + Flexible control, no wiring needed – Requires pairing and potential interference management |

| DALI (Digital Addressable Lighting Interface) Dimmer | Digital protocol allowing individual addressing and control of multiple dimmers | Large commercial complexes, smart city lighting | + Advanced control, scalable and interoperable – Higher initial cost and complexity |

PWM (Pulse Width Modulation) Dimmer

PWM dimmers regulate brightness by switching the LED power on and off at high frequency, controlling the perceived light intensity without altering the color temperature. This type is highly efficient and offers smooth dimming, making it ideal for retail displays and architectural lighting where color fidelity and subtle ambiance control are critical. For B2B buyers, ensuring compatibility with LED drivers and power supplies is essential to avoid flickering or damage. Bulk orders for retail chains or hospitality groups often favor PWM dimmers for their reliability and energy savings.

0-10V Analog Dimmer

The 0-10V dimmer uses a simple analog voltage signal to vary light output, making it a popular choice in commercial and industrial environments where wired infrastructure is already in place. Its straightforward integration with existing lighting control systems offers cost-effective scalability for office buildings and factories. However, it requires physical wiring, which can limit flexibility in retrofit projects or locations with complex layouts. Buyers should evaluate installation costs and compatibility with existing LED drivers when procuring 0-10V dimmers for large-scale deployments.

Triac (Leading/Trailing Edge) Dimmer

Triac dimmers function by cutting the AC power waveform to reduce brightness and are widely used in residential and commercial retrofit applications. Their main advantage lies in their affordability and availability, especially in regions with established AC mains infrastructure such as Europe and parts of the Middle East. However, not all LED strips are compatible with Triac dimmers, potentially causing flicker or reduced lifespan. B2B buyers must verify compatibility and consider product certifications to ensure long-term reliability when sourcing these dimmers for retrofit lighting projects.

Wireless RF/Bluetooth Dimmer

Wireless dimmers use RF or Bluetooth technology to enable remote brightness control without the need for wiring, providing flexibility for dynamic environments such as event venues, outdoor installations, and smart buildings. This type supports convenient integration with IoT systems and mobile apps, appealing to buyers focusing on modern, scalable lighting solutions. However, wireless dimmers require careful management of signal interference and secure pairing protocols. For B2B buyers, assessing wireless range, compatibility with existing LED strips, and after-sales support is crucial when adopting wireless dimmer technology.

DALI (Digital Addressable Lighting Interface) Dimmer

DALI dimmers use a digital communication protocol that allows individual addressing and centralized control of multiple lighting fixtures. This system is favored in large commercial complexes, smart city projects, and other applications requiring precise, scalable lighting management. While DALI offers superior flexibility and interoperability, it demands higher upfront investment and technical expertise. B2B buyers should consider the total cost of ownership, integration with building management systems, and vendor support when selecting DALI dimmers for sophisticated lighting infrastructures.

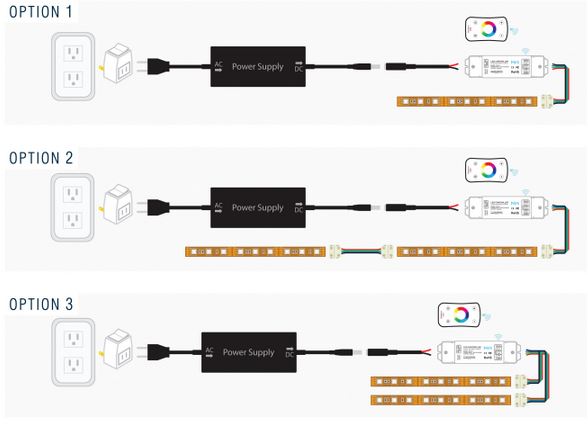

Related Video: How to Install a Dimmer for LED Strip Lighting

Key Industrial Applications of led strip dimmer switch

| Industry/Sector | Specific Application of led strip dimmer switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Ambient and accent lighting control in stores, restaurants, and hotels | Enhances customer experience by creating adaptable atmospheres; reduces energy costs through dimming | Compatibility with existing lighting systems; robust dimming range; user-friendly controls; compliance with local electrical standards |

| Architectural & Interior Design | Dynamic lighting for feature walls, coves, and ceilings in commercial buildings | Enables precise mood setting and energy-efficient operation; supports design flexibility | High-quality dimmers with smooth dimming curves; ability to integrate with smart building systems; durability in varied climates |

| Manufacturing & Warehousing | Adjustable task lighting on assembly lines and storage areas | Improves worker comfort and productivity; optimizes energy use during off-peak hours | Industrial-grade dimmers with high load capacity; resistance to dust and moisture; easy installation and maintenance |

| Healthcare Facilities | Patient room and corridor lighting with adjustable brightness | Enhances patient comfort and staff efficiency; supports circadian rhythm lighting | Dimmers with flicker-free performance; compliance with healthcare safety standards; quiet operation |

| Entertainment & Event Venues | Stage and decorative lighting with customizable intensity levels | Facilitates versatile lighting effects; supports energy savings and equipment longevity | High-precision dimming controls; compatibility with DMX or other lighting protocols; ruggedness for frequent use |

In the retail and hospitality sector, led strip dimmer switches are integral for controlling ambient and accent lighting to craft inviting environments in stores, restaurants, and hotels. Adjustable lighting helps businesses tailor the customer experience for different times of day or events, boosting sales and brand perception. International buyers from regions like Africa and the Middle East should prioritize dimmers that offer wide dimming ranges and are compatible with local voltage standards to ensure seamless integration and energy savings.

Illustrative Image (Source: Google Search)

Within architectural and interior design, dimmer switches enable dynamic illumination of feature walls, ceiling coves, and other design elements in commercial spaces. This flexibility supports creative lighting schemes that enhance aesthetics while reducing power consumption. Buyers from Europe and South America should seek dimmers capable of smooth, flicker-free dimming and compatibility with smart building automation systems to meet advanced design and sustainability goals.

In manufacturing and warehousing, led strip dimmer switches help regulate task lighting on assembly lines and storage zones, adapting brightness to operational needs. This not only improves worker comfort but also lowers energy costs during less intensive shifts. For B2B customers in industrial hubs such as Turkey and Mexico, sourcing dimmers with robust build quality, dust and moisture resistance, and high load tolerance is critical for maintaining reliable lighting in demanding environments.

Healthcare facilities utilize dimmer switches in patient rooms and corridors to adjust lighting levels according to medical and comfort requirements. Proper dimming supports patient recovery by minimizing glare and enabling circadian rhythm-friendly lighting schedules. Buyers from international healthcare sectors should focus on flicker-free dimmers that comply with stringent safety and hygiene standards while operating quietly to avoid patient disturbance.

Finally, in entertainment and event venues, led strip dimmer switches facilitate customizable stage and decorative lighting effects essential for performances and special occasions. Precision dimming enhances visual impact and prolongs fixture lifespan. International buyers must ensure dimmers support industry-standard protocols like DMX and offer ruggedness for frequent setup and teardown, especially in markets with active cultural event scenes such as South America and the Middle East.

Related Video: How to set up / use your LED strip light TRIAC Transformer & Dimmer

Strategic Material Selection Guide for led strip dimmer switch

When selecting materials for LED strip dimmer switches, international B2B buyers must consider factors such as electrical performance, durability, manufacturing complexity, and regional compliance standards. The choice of material directly influences the product’s reliability, cost-efficiency, and suitability for diverse environmental conditions, especially in markets like Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in LED strip dimmer switches, focusing on their key properties, pros and cons, application impacts, and considerations for global buyers.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its excellent impact resistance, high temperature tolerance (up to 135°C), and good electrical insulation properties. It also offers moderate resistance to UV radiation and chemicals.

Pros & Cons:

– Pros: High durability and toughness make PC ideal for protective switch housings. It is lightweight and can be molded into complex shapes, supporting intricate switch designs. Its electrical insulation properties reduce the risk of short circuits.

– Cons: Polycarbonate can be more expensive than other plastics and may yellow over time under prolonged UV exposure if not properly treated. Manufacturing requires precise injection molding processes, which can increase lead times.

Impact on Application:

PC is well-suited for indoor and moderately harsh environments, including commercial and residential lighting installations. However, for outdoor or high UV exposure applications common in Middle Eastern or African markets, UV-stabilized grades are recommended to maintain longevity.

International Buyer Considerations:

Buyers in Europe and Turkey should verify compliance with EN 60695 (fire safety) and RoHS directives for PC materials. South American and African buyers should consider the availability of UV-stabilized PC to ensure durability in high-sunlight regions. Additionally, ASTM D3935 standards for impact resistance may be referenced during procurement.

2. Acrylonitrile Butadiene Styrene (ABS)

Key Properties:

ABS is a widely used thermoplastic with good mechanical strength, moderate heat resistance (up to 100°C), and excellent surface finish capabilities. It provides decent electrical insulation but is less heat resistant than PC.

Pros & Cons:

– Pros: Cost-effective and easy to manufacture with injection molding, ABS allows for rapid prototyping and mass production. It offers good dimensional stability and surface aesthetics, suitable for consumer-facing switch components.

– Cons: Lower heat resistance limits its use in high-temperature environments. ABS is also less resistant to UV degradation and can become brittle over time if exposed to sunlight without additives.

Impact on Application:

ABS is ideal for indoor LED dimmer switches used in controlled environments such as offices or homes in Europe and South America. Its lower heat tolerance makes it less suitable for installations near heat sources or in outdoor settings without protective coatings.

International Buyer Considerations:

Compliance with UL 94 V-0 flammability standards is critical for safety certification in most markets. Buyers from the Middle East and Africa should request ABS grades with UV inhibitors if outdoor use is anticipated. The material’s widespread availability ensures competitive pricing, beneficial for budget-conscious buyers in emerging markets.

3. Aluminum Alloy

Key Properties:

Aluminum alloys offer excellent thermal conductivity, corrosion resistance (especially anodized finishes), and mechanical strength. They can withstand high temperatures and provide electromagnetic interference (EMI) shielding.

Pros & Cons:

– Pros: Superior heat dissipation protects sensitive electronic components in dimmer switches, enhancing longevity. Aluminum’s corrosion resistance suits humid or coastal environments. It also provides a premium aesthetic and robust structural support.

– Cons: Higher material and manufacturing costs, including machining or extrusion, increase overall product price. Aluminum is heavier than plastic alternatives and may require additional insulation to prevent electrical conduction issues.

Impact on Application:

Aluminum is preferred in industrial-grade or high-end LED dimmer switches where heat management and durability are paramount. It is especially advantageous in Middle Eastern and coastal African markets where corrosion resistance is essential.

International Buyer Considerations:

Buyers should ensure compliance with ISO 209-1 for anodized aluminum and check for adherence to regional corrosion resistance standards. European buyers may require REACH compliance, while South American buyers should evaluate local import tariffs affecting aluminum products.

4. Silicone Rubber (for Buttons and Seals)

Key Properties:

Silicone rubber is flexible, highly resistant to temperature extremes (-60°C to 230°C), and chemically inert. It offers excellent sealing capabilities and electrical insulation.

Pros & Cons:

– Pros: Ideal for tactile buttons and seals in dimmer switches, silicone rubber provides a comfortable user interface and protects internal electronics from dust and moisture. Its durability under harsh environmental conditions extends product lifespan.

– Cons: Silicone can be more expensive than standard rubber materials and may require specialized molding techniques. It has lower mechanical strength compared to hard plastics and metals.

Impact on Application:

Silicone rubber is essential for dimmer switches used in outdoor or industrial environments prevalent in Africa and the Middle East, where dust and moisture ingress are concerns. It enhances user experience through soft-touch buttons.

International Buyer Considerations:

Material certifications such as FDA food-grade or ISO 10993 biocompatibility may be relevant for buyers targeting healthcare or food industry applications. Buyers in Europe and Turkey should verify compliance with EU standards on chemical safety and RoHS.

| Material | Typical Use Case for led strip dimmer switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Switch housing for indoor and moderately harsh environments | High impact resistance and electrical insulation | Higher cost and potential UV yellowing | Medium |

| Acrylonitrile Butadiene Styrene (ABS) | Economical switch casing for indoor use | Cost-effective with good surface finish | Lower heat and UV resistance | Low |

| Aluminum Alloy | Premium or industrial switches requiring heat dissipation | Excellent thermal management and corrosion resistance | Higher manufacturing cost and weight | High |

| Silicone Rubber | Buttons and seals for dust/moisture protection | Excellent flexibility and environmental resistance | Higher cost and lower mechanical strength | Medium |

This material selection guide equips international B2B buyers with critical insights to optimize LED strip dimmer switch sourcing strategies, balancing performance, cost, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip dimmer switch

The manufacturing and quality assurance of LED strip dimmer switches involve intricate processes designed to ensure product reliability, safety, and performance. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding these processes and quality control (QC) measures is essential to selecting the right supplier and mitigating risks in procurement.

Manufacturing Process Overview

1. Material Preparation

The initial stage focuses on sourcing and preparing raw materials. Key components include semiconductor chips, printed circuit boards (PCBs), resistors, capacitors, microcontrollers, and casing materials (often flame-retardant plastics or metals). Suppliers typically source electronic-grade materials compliant with RoHS (Restriction of Hazardous Substances) to meet environmental and safety regulations, which is particularly critical for markets like Europe and Turkey with stringent eco-standards.

2. PCB Fabrication and Forming

The PCB is the backbone of the dimmer switch. Manufacturing begins with flexible or rigid PCBs etched with copper traces. Advanced techniques such as surface-mount technology (SMT) are used to mount LED drivers, microchips, and other electronic components accurately. Automated pick-and-place machines enhance precision and throughput. For dimmer switches, particular attention is given to the PCB’s heat dissipation capability, as dimming circuits generate heat that can affect longevity.

3. Assembly

Assembly integrates electronic components onto the PCB and incorporates mechanical parts such as the dimmer knob, buttons, or touch-sensitive panels. This step may include soldering (often wave or reflow soldering), wiring, and housing assembly. Manufacturers increasingly use automated assembly lines combined with manual inspections for complex parts. For dimmer switches with wireless or smart capabilities, firmware installation and programming are also part of assembly.

4. Finishing and Packaging

Post-assembly finishing includes applying protective coatings or conformal coatings to prevent moisture and dust ingress, crucial for products intended for humid or outdoor environments. The switches are then calibrated and undergo functional testing before packaging. Packaging is designed to protect against electrostatic discharge (ESD) and physical damage during shipping.

Quality Assurance and Control Measures

International Standards and Certifications

– ISO 9001: A fundamental quality management system (QMS) certification ensuring consistent manufacturing and continuous improvement. Suppliers with ISO 9001 demonstrate robust process control and documentation, vital for B2B buyers requiring traceability.

– CE Marking: Mandatory for products sold in the European Economic Area (EEA), confirming compliance with safety, health, and environmental protection directives. It is particularly important for European and Turkish buyers.

– RoHS Compliance: Ensures restricted use of hazardous materials, increasingly demanded by international buyers to meet environmental regulations.

– UL / ETL Certifications: Common for electrical safety verification, especially for North American and some Middle Eastern markets.

– API and Other Industry-Specific Standards: Depending on application (e.g., industrial automation), additional certifications may be required.

QC Checkpoints

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival. Parameters include material specifications, electrical properties, and physical dimensions. For dimmer switches, PCB quality and semiconductor chip integrity are critical focus areas.

– In-Process Quality Control (IPQC): During manufacturing, continuous checks ensure assembly precision, solder joint quality, and component placement accuracy. Automated optical inspection (AOI) and X-ray inspection are common methods to detect defects early.

– Final Quality Control (FQC): Completed dimmer switches undergo comprehensive testing, including:

– Functional testing for dimming range and responsiveness

– Electrical safety tests (insulation resistance, dielectric strength)

– Environmental tests such as thermal cycling and humidity exposure

– Mechanical durability tests (e.g., knob rotation cycles)

– EMC (Electromagnetic Compatibility) testing to ensure minimal interference

Testing Methods and Verification for B2B Buyers

Key Testing Procedures

– Electrical Performance Testing: Verifies voltage and current ratings, dimming smoothness, and power consumption.

– Safety and Reliability Testing: Includes surge protection, short circuit tests, and endurance tests simulating extended operation.

– Environmental Stress Testing: Simulates real-world conditions to assess durability against temperature fluctuations, moisture, and dust ingress (IP rating verification).

– Software/Firmware Validation: For smart dimmer switches, software reliability and compatibility with control systems are tested.

How Buyers Can Verify Supplier QC

– Factory Audits: On-site inspections focusing on manufacturing facilities, process controls, worker training, and QMS implementation. Buyers from regions with complex import regulations (e.g., Europe, Turkey) often require third-party audit reports.

– Review of QC Documentation: Including inspection reports, test certificates, and compliance declarations (e.g., CE Declaration of Conformity).

– Third-Party Testing and Inspection: Engaging independent labs (e.g., SGS, TÜV Rheinland) to conduct product testing and factory inspections enhances credibility and reduces risk.

– Sample Testing: Procuring product samples for in-house or local lab testing before placing bulk orders is a prudent step.

– Continuous Quality Monitoring: Establishing quality control agreements with suppliers that include periodic inspection schedules and corrective action processes.

Quality Assurance Nuances for International B2B Buyers

Regional Compliance Considerations

– Africa: Importers should verify electrical safety and energy efficiency certifications aligned with local regulations (e.g., SABS in South Africa). Environmental standards may be emerging, so RoHS compliance is a competitive advantage.

– South America: Countries like Brazil and Mexico have specific certification bodies (e.g., INMETRO in Brazil). Buyers should ensure dimmer switches meet local electromagnetic compatibility and safety standards to avoid customs delays.

– Middle East: Regulatory frameworks vary widely; however, Gulf Cooperation Council (GCC) countries require conformity marks (e.g., SASO in Saudi Arabia). Certification for voltage compatibility (e.g., 220V vs. 110V) is critical.

– Europe (including Turkey): Stringent CE marking and RoHS compliance are mandatory. Buyers must confirm suppliers provide up-to-date technical files and test reports for customs and market surveillance.

Customizing QC for Local Market Needs

International buyers should collaborate with suppliers to tailor quality assurance protocols that align with the end market’s regulatory and environmental conditions. For instance, dimmer switches destined for humid climates (e.g., coastal regions in Africa or South America) should have enhanced sealing and IP ratings verified through testing.

Final Recommendations for B2B Buyers

- Due Diligence: Rigorously assess supplier manufacturing capabilities and QC systems before engagement.

- Certifications Verification: Always request copies of relevant certifications and confirm their validity through official registries or third-party verification.

- Testing Samples: Conduct independent testing of samples to verify performance claims, especially for dimming smoothness and electrical safety.

- Long-term Partnerships: Work with suppliers committed to continuous improvement and transparent quality management, which is crucial for scaling orders and entering regulated markets.

- Leverage Technology: Use digital platforms for remote factory audits and real-time quality monitoring to overcome geographic barriers.

By thoroughly understanding the manufacturing and quality assurance landscape of LED strip dimmer switches, international B2B buyers can make informed decisions that minimize risk, ensure compliance, and secure high-quality products tailored to their regional market demands.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip dimmer switch Sourcing

When sourcing LED strip dimmer switches for international B2B operations, understanding the detailed cost structure and pricing dynamics is essential for making informed purchasing decisions. This section breaks down the core cost components, key price influencers, and practical buyer strategies tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip Dimmer Switch Production

-

Materials

The primary cost driver is the quality and type of electronic components such as semiconductors, resistors, capacitors, and PCBs (Printed Circuit Boards). Higher-grade materials with certifications (e.g., RoHS, CE) increase durability and compliance but raise costs. For dimmers, advanced chips that support smooth dimming and compatibility with various LED types command premium prices. -

Labor

Labor costs vary significantly by manufacturing location. Chinese factories, dominant in this space, offer competitive labor rates but are increasingly investing in automation to reduce manual labor costs and improve consistency. For buyers in regions with higher local labor costs, sourcing from Asia often remains cost-effective. -

Manufacturing Overhead

Overhead includes factory utilities, equipment depreciation, and indirect labor such as supervisors and quality engineers. Efficient factories with modern production lines typically have optimized overhead, which can translate into better pricing and quality stability. -

Tooling and Setup

Initial tooling for custom dimmer switches—such as molds for housings or programming of integrated circuits—adds upfront costs. These are amortized over production volume, so higher Minimum Order Quantities (MOQs) help reduce per-unit pricing. -

Quality Control (QC)

Rigorous QC processes, including functional testing, safety inspections, and certifications, ensure product reliability but increase costs. Buyers should balance QC levels with their quality requirements, especially for export to markets with strict regulations. -

Logistics and Shipping

Costs fluctuate depending on shipping mode (air freight vs. sea freight), destination port, and customs duties. International buyers must factor in tariffs, import taxes, and local handling fees. For example, shipments to Turkey or Mexico may incur different customs regimes compared to South Africa or Brazil. -

Supplier Margin

Supplier profit margins depend on brand positioning, exclusivity, and after-sales support. Established manufacturers with strong reputations may price higher but provide better reliability and service.

Influencing Factors on LED Strip Dimmer Switch Pricing

-

Order Volume and MOQ

Larger orders typically attract volume discounts. Some suppliers allow negotiation on MOQs, which is crucial for smaller businesses or pilot projects. Group purchasing or consolidating orders can improve pricing leverage. -

Technical Specifications and Customization

Customized dimmer switches tailored for specific LED types, voltage ranges, or control protocols (PWM, 0-10V, DALI) command higher prices. Standardized products are generally more cost-effective. -

Material Quality and Certifications

Compliance with international standards (CE, UL, RoHS) affects price but is often mandatory for import in Europe and parts of the Middle East. Buyers should verify certification authenticity to avoid hidden costs from rejected shipments. -

Supplier Location and Reputation

Suppliers in China dominate the market, offering competitive pricing and a wide product range. However, regional suppliers in Europe or the Middle East may provide faster lead times and localized support at a premium. -

Incoterms and Payment Terms

Pricing varies depending on Incoterms (e.g., FOB, CIF, DDP). Buyers should understand which party bears shipping, insurance, and customs costs. Favorable payment terms (e.g., letters of credit, escrow) can improve cash flow and reduce risk.

Practical Buyer Tips for International B2B Sourcing

-

Negotiate Based on Total Cost of Ownership (TCO)

Look beyond unit price. Factor in shipping, customs clearance, potential returns, and warranty support. Sometimes paying a slightly higher price for better quality or local certification can save costs downstream. -

Leverage Volume and Long-Term Relationships

Building relationships with suppliers can unlock better pricing tiers, priority production slots, and customized solutions. Consider consolidating orders across subsidiaries or partners. -

Verify Supplier Credentials and Quality

Request samples and certifications before committing to large orders. Use third-party inspections and audits, especially for new suppliers. -

Understand Regional Import Regulations and Duties

Engage customs brokers familiar with your target markets. For example, South American countries may have complex tariff regimes requiring specialized documentation. -

Consider Logistics Timing and Costs

Sea freight is cost-effective for large orders but slower; air freight suits urgent needs but is pricier. Plan inventory accordingly to avoid stockouts or high expedited shipping fees.

Indicative Pricing Disclaimer

Prices for LED strip dimmer switches vary widely based on specifications, order size, and supplier location. As a rough benchmark, standard dimmer switches sourced from major Chinese factories can range from USD 1.50 to USD 8.00 per unit depending on complexity and certification. Buyers should request quotations reflecting their exact requirements and negotiate terms based on comprehensive cost analysis.

By thoroughly analyzing these cost and pricing factors, international B2B buyers can optimize procurement strategies, ensuring competitive pricing without compromising on quality or compliance. This approach is especially critical in diverse markets like Africa, South America, the Middle East, and

Spotlight on Potential led strip dimmer switch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip dimmer switch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip dimmer switch

Critical Technical Properties of LED Strip Dimmer Switches

Understanding the technical specifications of LED strip dimmer switches is essential for international B2B buyers seeking reliable, compatible, and efficient lighting control solutions. Here are key properties to evaluate:

-

Voltage Compatibility (e.g., 12V, 24V DC):

LED strip dimmers must match the voltage rating of the LED strips they control. Incorrect voltage can cause malfunction or damage. For buyers in regions with varying power standards, verifying voltage compatibility ensures seamless integration with existing systems. -

Dimming Method (PWM, TRIAC, 0-10V):

The dimmer’s control technology affects performance and compatibility. Pulse Width Modulation (PWM) is common for LED strips, offering smooth, flicker-free dimming. TRIAC dimmers are usually for AC loads and may not suit low-voltage LED strips. Understanding the dimming method helps avoid costly mismatches. -

Maximum Load Capacity (Wattage):

This specifies the maximum total wattage of LED strips the dimmer can handle. Exceeding this limit risks overheating and failure. Buyers sourcing for commercial or large-scale projects must ensure the dimmer supports the total load of their LED setup. -

Control Interface (Manual knob, Remote, RF/Wi-Fi):

Dimmer switches vary by control type. Manual knobs are simple and cost-effective, while remote or wireless (RF, Wi-Fi) controls enable advanced features like scene setting and integration with smart building systems. Knowing the control interface aligns product choice with end-user needs. -

Material and Build Quality (Fire-resistant plastics, metal casing):

High-grade materials improve durability and safety, especially in demanding environments. Buyers from regions with strict safety regulations (e.g., EU’s CE standards) should prioritize products with certified materials to reduce risk and ensure compliance. -

Operating Temperature Range:

Dimmer switches used in outdoor or industrial settings must withstand wide temperature variations without performance degradation. Verifying this spec is crucial for buyers in regions with extreme climates, such as parts of Africa or the Middle East.

Common Industry and Trade Terminology for LED Strip Dimmer Switches

Navigating global B2B transactions requires familiarity with trade terms and industry jargon. Below are key terms every buyer should know:

-

OEM (Original Equipment Manufacturer):

Refers to manufacturers who produce products that other companies rebrand and sell. Many LED dimmer switches come from OEM suppliers, allowing buyers to customize branding and specifications, which is especially valuable for distributors and retailers. -

MOQ (Minimum Order Quantity):

The smallest number of units a supplier is willing to sell in one order. MOQs impact purchasing decisions and inventory management. Buyers from smaller markets or those testing new products should negotiate MOQs to align with their business scale. -

RFQ (Request for Quotation):

A formal inquiry sent to suppliers requesting price and terms for specified products. Preparing clear RFQs with detailed technical requirements expedites supplier responses and ensures accurate pricing for LED dimmer switches. -

Incoterms (International Commercial Terms):

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers control costs and logistics effectively. -

IP Rating (Ingress Protection):

Indicates the level of dust and water resistance of the dimmer switch enclosure. For outdoor or humid environments, IP65 or higher ensures protection against moisture and dust, critical for product longevity and safety. -

DALI (Digital Addressable Lighting Interface):

A communication protocol for intelligent lighting control. Some dimmers support DALI for integration into smart building systems, allowing centralized, programmable lighting management. Buyers targeting advanced installations should consider DALI-compatible dimmers.

For B2B buyers across Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms facilitates informed purchasing decisions. It helps ensure product compatibility, regulatory compliance, and optimized supply chain management tailored to diverse regional requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip dimmer switch Sector

Market Overview & Key Trends

The global market for LED strip dimmer switches is expanding rapidly, driven by rising demand for energy-efficient lighting solutions in both commercial and residential sectors. Key growth regions include Africa, South America, the Middle East, and Europe, where urbanization and infrastructure modernization are fueling lighting upgrades. Countries such as Turkey and Mexico are emerging as important hubs for both consumption and localized assembly, providing opportunities for importers and distributors to tap into growing regional markets.

Technological advancements are reshaping sourcing strategies in the LED strip dimmer switch sector. Buyers increasingly prioritize compatibility with smart home and IoT ecosystems, favoring dimmer switches that support wireless control protocols such as Zigbee, Wi-Fi, and Bluetooth. This demand is prompting manufacturers to innovate beyond traditional TRIAC or PWM dimmers to more sophisticated, app-enabled devices offering remote dimming, scheduling, and energy monitoring features.

From a sourcing perspective, international buyers must navigate a complex supply chain landscape. China remains the dominant manufacturing base due to its mature production capabilities and cost efficiencies. However, geopolitical tensions and supply chain disruptions have prompted buyers to diversify sourcing to Southeast Asia and emerging manufacturing centers closer to end markets. For B2B buyers in Africa and South America, this diversification reduces lead times and import costs, while European and Middle Eastern buyers benefit from proximity to Turkish and Eastern European manufacturers offering competitive quality and customization.

Market dynamics also reflect a growing emphasis on product certification and compliance with regional electrical standards (CE in Europe, SASO in the Middle East, INMETRO in Brazil). Buyers should engage suppliers with proven track records in meeting these regulatory requirements to ensure smooth market entry and avoid costly delays.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are increasingly pivotal in the procurement of LED strip dimmer switches. Energy efficiency is a core benefit of LED technology; however, the dimmer switches themselves must also contribute to reducing overall power consumption. Modern dimmers employing advanced PWM (Pulse Width Modulation) or digital control techniques optimize energy use, extending the lifecycle of LED strips and lowering operational costs.

Illustrative Image (Source: Google Search)

Ethical sourcing is gaining traction among B2B buyers, especially those operating in regions with growing environmental regulations and corporate social responsibility mandates. Buyers should seek suppliers committed to responsible labor practices and transparent supply chains, minimizing risks related to forced labor or unsafe working conditions common in unregulated factories.

Material selection is another sustainability vector. Leading manufacturers are shifting towards halogen-free PCBs and RoHS-compliant components, which reduce hazardous substances and improve recyclability. Certifications such as Energy Star, TÜV Rheinland, and ISO 14001 environmental management systems serve as reliable indicators of a supplier’s commitment to green manufacturing practices.

For buyers in Africa, South America, and the Middle East, partnering with suppliers who emphasize sustainability not only aligns with emerging local regulations but also enhances brand reputation and meets the expectations of increasingly eco-conscious end consumers. Incorporating sustainability criteria into supplier evaluation frameworks helps mitigate supply chain risks and supports long-term business resilience.

Evolution and Historical Context

The LED strip dimmer switch has evolved significantly from basic mechanical rotary dimmers to advanced digital controllers integrated with smart technologies. Early dimmers were predominantly analog TRIAC-based devices designed for incandescent bulbs, which posed compatibility challenges with low-voltage LED strips.

The transition to LED lighting necessitated the development of dimmers specifically engineered for LED drivers, with features like flicker reduction and load compatibility. More recently, the integration of microcontrollers and wireless communication has transformed dimmer switches into smart devices, enabling precise control over color temperature, brightness, and scene setting.

This evolution reflects broader trends in lighting technology, emphasizing energy efficiency, user convenience, and integration with building automation systems. For B2B buyers, understanding this progression is critical to selecting dimmer switches that not only meet current functional requirements but are also future-proofed against rapid technological advancements.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip dimmer switch

-

How can I effectively vet LED strip dimmer switch suppliers from overseas markets?

When sourcing LED strip dimmer switches internationally, conduct thorough supplier due diligence. Verify company registration and factory certifications such as ISO 9001 or relevant electrical safety standards (CE, RoHS). Request product samples to assess build quality and compatibility with your target markets’ voltage and dimming protocols. Utilize third-party inspection services to audit manufacturing facilities and quality control processes. Engage in direct communication to evaluate responsiveness and technical expertise. Checking references or client testimonials from similar regions (Africa, South America, Middle East, Europe) can also provide insights into reliability and after-sales support. -

Can LED strip dimmer switches be customized to fit specific regional voltage and control standards?

Yes, many manufacturers offer customization for voltage ratings (commonly 12V, 24V DC) and dimming protocols such as PWM, 0-10V, or DALI to meet regional electrical standards. For markets like Turkey or Mexico, ensure the dimmer switch supports local power supply and wiring norms. Custom firmware or hardware adaptations may be available for specific control systems or smart home integrations. Early engagement with suppliers about customization capabilities and minimum order quantities (MOQs) is crucial to align product specifications with your customers’ requirements. -

What are typical minimum order quantities (MOQs) and lead times for bulk orders of LED strip dimmer switches?

MOQs vary widely depending on the manufacturer and level of customization, typically ranging from 500 to 2,000 units for standard models. Customized orders usually require higher MOQs and longer lead times, often 4 to 8 weeks, due to tooling and testing requirements. For buyers in Africa or South America, consider additional time for shipping and customs clearance. Negotiating with suppliers for staggered deliveries or pilot orders can mitigate inventory risks while establishing reliable supply chains. -

Which payment terms are standard and safest when importing LED strip dimmer switches internationally?

Common payment terms include 30% deposit upfront with balance paid before shipment or upon receiving a letter of credit. For new suppliers, using secure payment methods such as escrow services, PayPal (for smaller orders), or confirmed letters of credit reduces financial risk. Established buyers might negotiate net terms or open accounts. Always clarify currency terms and potential banking fees upfront. Combining payment with clear contractual agreements on quality and delivery terms helps protect your investment. -

What quality assurance measures should I expect from reputable LED strip dimmer switch manufacturers?

Reputable manufacturers implement strict quality control protocols including incoming material inspections, in-process testing, and final product verification. Look for certifications such as CE, UL, RoHS compliance, and EMC testing reports. Quality assurance should cover dimming smoothness, electrical safety, and environmental durability (e.g., IP ratings for moisture resistance). Request detailed test reports and consider factory audits or third-party inspections to confirm adherence to international standards, especially for demanding markets with strict regulatory environments. -

How can I optimize logistics and shipping for large orders of LED strip dimmer switches to diverse regions?

Select suppliers with experience in international shipping and export compliance to avoid delays. Consolidate shipments when possible to reduce freight costs and customs complexities. Choose reliable freight forwarders familiar with your target regions’ import regulations, tariffs, and documentation requirements. Air freight suits urgent orders but is costlier; sea freight is economical for bulk shipments but requires longer lead times. Consider warehousing or distribution partners in strategic locations (e.g., Dubai for Middle East, Rotterdam for Europe) to streamline last-mile delivery. -

What steps should I take if there is a product quality dispute or shipment discrepancy with my LED strip dimmer switch supplier?

Promptly document the issue with photos and detailed descriptions. Refer to your purchase agreement and warranty terms to clarify responsibilities. Engage the supplier directly with clear evidence and request corrective actions such as replacement, repair, or refund. Involve third-party inspection agencies to provide impartial assessments if necessary. For persistent disputes, consider mediation through trade associations or arbitration clauses specified in contracts. Maintaining professional communication and clear contractual protections minimizes risks and helps resolve conflicts efficiently. -

Are there specific regulatory certifications required for LED strip dimmer switches in international markets?

Yes, compliance requirements vary by region. The European Union mandates CE marking and RoHS compliance to ensure safety and environmental standards. The Middle East often requires SASO certification (Saudi Arabia) or equivalent local approvals. In South America, INMETRO certification (Brazil) or similar may apply. Africa’s market is diverse, but key countries enforce safety and electromagnetic compatibility standards. Buyers should verify that suppliers provide relevant certification documentation to facilitate smooth customs clearance and market acceptance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip dimmer switch

The LED strip dimmer switch market presents significant opportunities for international B2B buyers seeking to enhance lighting solutions with energy-efficient, customizable controls. Strategic sourcing in this sector requires a deep understanding of product specifications—such as dimming compatibility, voltage requirements, and control protocols (PWM, 0-10V, DALI)—to ensure seamless integration with LED strip lighting systems. Prioritizing suppliers with proven quality control, innovation capabilities, and compliance with international standards will mitigate risks related to performance and longevity.

For buyers in Africa, South America, the Middle East, and Europe, cultivating partnerships with experienced manufacturers—particularly those with expertise in tailored solutions for diverse environments—is crucial. Leveraging insights into the evolving manufacturing landscape, including advancements in dimmer technology and sustainable production practices, can drive competitive advantage and operational efficiency.

Looking ahead, the demand for smart, IoT-enabled dimmer switches is expected to grow, enabling greater automation and energy management. Buyers are encouraged to proactively engage with suppliers who invest in R&D and offer flexible customization options to meet regional market nuances. By adopting a strategic sourcing approach that balances cost, quality, and innovation, international buyers can position themselves to capitalize on emerging trends and deliver superior lighting experiences.