Introduction: Navigating the Global Market for led strip diffuser cover

In the rapidly evolving landscape of LED lighting solutions, the LED strip diffuser cover stands as a vital component that enhances both functionality and aesthetics. For international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of this product is crucial for making strategic procurement decisions. The diffuser cover not only protects LED strips from dust and damage but also ensures optimal light diffusion, reducing glare and creating uniform illumination—qualities highly valued in commercial, residential, and industrial applications.

This comprehensive guide is designed to equip buyers with actionable insights into every aspect of LED strip diffuser covers. It covers a broad spectrum including the various types and materials available, key considerations in manufacturing and quality control, and how to identify reliable suppliers across global markets. Additionally, it addresses cost structures, regional market trends, and answers frequently asked questions that can influence purchasing decisions.

By delving into these critical factors, buyers from regions like the UK, South Africa, Brazil, and the UAE will gain clarity on how to source products that meet international standards while aligning with local market demands. This knowledge empowers businesses to optimize their supply chains, reduce risks, and enhance product offerings through informed vendor selection and specification alignment. Ultimately, this guide aims to be an indispensable resource for B2B buyers seeking to navigate the complexities of the global LED strip diffuser cover market with confidence and precision.

Understanding led strip diffuser cover Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frosted Diffuser Covers | Semi-opaque plastic, softens and diffuses light evenly | Retail displays, hospitality, architectural lighting | Pros: Reduces glare, smooth light output; Cons: Slight light loss, may reduce brightness |

| Clear Diffuser Covers | Transparent, minimal light diffusion, protects LEDs | Industrial, commercial signage, high-brightness needs | Pros: Maximizes brightness, protects LEDs; Cons: Harsh light, potential glare issues |

| Milky White Diffuser Covers | Opaque white finish, diffuses light with warmer tone | Residential, office ambient lighting, decorative fixtures | Pros: Creates warm, inviting light; Cons: Greater light attenuation, not for high-intensity needs |

| Aluminum Channel Diffusers | Integrated diffuser with aluminum housing for heat dissipation | Architectural projects, outdoor installations, long runs | Pros: Enhances durability, heat management; Cons: Higher cost, installation complexity |

| Snap-on Diffuser Covers | Easy to install/removable, various finishes available | Modular lighting systems, temporary setups, exhibitions | Pros: Flexibility, ease of maintenance; Cons: Less secure fit, limited weather resistance |

Frosted Diffuser Covers

Frosted covers are designed to soften LED strip light output by scattering light, reducing harsh shadows and glare. This type is ideal for retail and hospitality sectors where visual comfort and aesthetic appeal are paramount. B2B buyers should consider the trade-off between light diffusion and a slight reduction in brightness. These covers are typically made from durable plastics suitable for indoor use, making them a cost-effective option for projects requiring consistent, eye-pleasing illumination.

Clear Diffuser Covers

Clear diffuser covers offer minimal light diffusion, preserving the LED strip’s original brightness and color accuracy. They are highly suitable for industrial and commercial signage applications where maximum visibility is critical. Buyers from regions with high ambient light conditions, such as parts of the Middle East and South America, will find these covers advantageous. However, the potential for glare necessitates careful planning in environments where visual comfort is essential.

Milky White Diffuser Covers

With their opaque, milky white finish, these covers provide a warmer, more diffused light output, enhancing ambiance in residential and office spaces. They are preferred in markets such as Europe and South Africa where warm lighting is often favored for comfort and style. The key consideration for B2B buyers is their higher light attenuation, which may limit their use in applications demanding high luminosity. They also contribute to a softer, more inviting atmosphere.

Aluminum Channel Diffusers

These combine a diffuser cover with an aluminum channel that aids in heat dissipation and provides structural support. Ideal for architectural lighting and outdoor installations, aluminum channels enhance LED strip longevity and performance. This type is particularly relevant for large-scale projects in Europe and the Middle East where durability and compliance with safety standards are critical. The higher initial investment and installation complexity should be weighed against long-term benefits.

Snap-on Diffuser Covers

Snap-on covers are designed for quick installation and removal, offering versatility for modular lighting systems and temporary setups such as exhibitions. They come in various finishes, allowing buyers to customize light diffusion based on project needs. While their ease of maintenance is attractive for B2B buyers in dynamic environments, these covers may lack the secure fit and weather resistance required for permanent outdoor applications, a crucial factor for buyers in regions with diverse climates.

Related Video: Neon Silicone Diffuser Cover for LED Strip for DIY Design

Key Industrial Applications of led strip diffuser cover

| Industry/Sector | Specific Application of led strip diffuser cover | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting in retail displays and commercial interiors | Enhances product visibility and customer experience; reduces glare | Durability, light diffusion quality, compatibility with various LED strips, UV resistance for sunny climates |

| Hospitality & Leisure | Decorative and functional lighting in hotels, restaurants, and lounges | Creates inviting atmosphere; improves energy efficiency and lighting uniformity | Custom sizing, fire safety certifications, ease of installation, aesthetic finish options |

| Industrial & Manufacturing | Task lighting and safety illumination in factories and warehouses | Improves workplace safety; reduces eye strain and shadows | High-impact resistance, dust and moisture protection, compliance with industrial standards |

| Architectural & Interior Design | Concealed lighting for coves, ceilings, and wall features | Provides seamless, soft light; enhances architectural aesthetics | Flexibility in shape and length, color temperature compatibility, ease of maintenance |

| Automotive & Transportation | Interior ambient lighting in vehicles and public transport systems | Enhances passenger comfort and safety; protects LED strips from damage | Heat resistance, vibration durability, custom profiles for vehicle interiors |

In the retail and commercial sector, led strip diffuser covers are primarily used to create ambient and accent lighting that highlights products and enhances the shopping experience. These covers soften the intense brightness of LED strips, reducing glare and preventing harsh shadows, which is crucial in environments where product visibility directly impacts sales. For international buyers, especially in regions like Africa and South America where sunlight can be intense, sourcing covers with UV resistance and durable materials is essential to ensure long-term performance.

In hospitality and leisure, diffuser covers are integral to achieving the desired mood lighting in hotels, restaurants, and lounges. They help diffuse light evenly, creating a warm and inviting atmosphere that can elevate the guest experience. Buyers from the Middle East and Europe should prioritize fire safety certifications and customizable sizing options to meet local regulations and design preferences. Ease of installation and the aesthetic finish of the covers are also important factors to consider for large-scale projects.

The industrial and manufacturing sector benefits from led strip diffuser covers by improving task lighting and safety illumination. These covers protect LED strips from dust, moisture, and mechanical impact, which are common in factory and warehouse environments. This protection helps maintain consistent light quality and reduces eye strain for workers. Buyers must ensure the covers comply with industrial safety standards and offer high-impact resistance, especially when sourcing for markets with stringent regulatory requirements such as the UK and South Africa.

In architectural and interior design, diffuser covers enable designers to conceal lighting fixtures while delivering soft, uniform illumination in coves, ceilings, and wall features. This enhances the aesthetic appeal of spaces without exposing harsh LED points. For international B2B buyers, selecting covers that offer flexibility in shape and length is crucial to accommodate diverse architectural designs. Compatibility with different color temperatures and ease of maintenance are additional considerations to support long-term usage.

Within the automotive and transportation industries, led strip diffuser covers are used to provide interior ambient lighting that enhances passenger comfort and safety. These covers shield delicate LED strips from heat, vibration, and physical damage, which are prevalent in vehicle interiors and public transport systems. Buyers focusing on this sector should look for covers with excellent heat resistance and vibration durability, as well as custom profiles that fit specific vehicle designs, ensuring both functionality and aesthetic integration.

Related Video: How To Set Up Govee RGB LED Strip Lights With Corners Angles And More Tips

Strategic Material Selection Guide for led strip diffuser cover

When selecting materials for LED strip diffuser covers, international B2B buyers must weigh factors such as optical clarity, durability, thermal resistance, and compliance with regional standards. The choice directly affects product lifespan, light diffusion quality, and installation environments. Below is a detailed analysis of four common materials used in LED strip diffuser covers: Polycarbonate (PC), Acrylic (PMMA), Polyethylene Terephthalate (PET), and Silicone.

Polycarbonate (PC)

Key Properties:

Polycarbonate is known for its excellent impact resistance and high thermal stability, typically withstanding temperatures up to 120°C. It offers good UV resistance when treated and has strong dimensional stability, making it suitable for long-term outdoor and indoor use.

Pros & Cons:

PC is highly durable and resistant to cracking under mechanical stress, which makes it ideal for harsh environments. However, it is more expensive than other plastics and can yellow over time if not UV stabilized. Manufacturing complexity is moderate due to its toughness, requiring precise molding techniques.

Impact on Application:

PC diffuser covers provide uniform light diffusion while protecting LED strips from dust and moisture. They are well-suited for commercial and industrial lighting where mechanical protection is critical. Its thermal resistance supports use in high-power LED applications without deformation.

International B2B Considerations:

Buyers in regions with intense sunlight such as Africa and the Middle East should prioritize UV-stabilized PC to prevent discoloration. Compliance with ASTM D3935 (UV resistance) and DIN EN ISO 1183 (density) standards is common in Europe and South Africa. PC’s higher cost might be a consideration in price-sensitive South American markets, but its durability often justifies the investment.

Acrylic (PMMA)

Key Properties:

Acrylic offers excellent optical clarity and light transmission, typically above 92%. It has moderate thermal resistance (up to 80°C) and good weatherability, though it is more brittle compared to PC.

Pros & Cons:

PMMA is cost-effective and easier to fabricate with standard thermoforming and cutting processes. It provides superior light diffusion and aesthetic appeal. However, it is prone to cracking under impact and less resistant to high temperatures, limiting its use in high-heat environments.

Impact on Application:

Acrylic diffuser covers are ideal for decorative and retail lighting where visual quality is paramount. Its brittleness restricts use in industrial or outdoor settings with mechanical stress or temperature fluctuations.

International B2B Considerations:

European buyers often prefer PMMA for indoor architectural lighting due to its clarity and compliance with EN 12464-1 lighting standards. In South America and Africa, acrylic’s affordability and ease of customization are attractive, but buyers should confirm local standards like ASTM D4802 for weather resistance. PMMA’s lower heat tolerance requires careful selection for Middle Eastern markets with high ambient temperatures.

Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight, chemically resistant plastic with good dimensional stability. It has moderate thermal resistance (up to 70°C) and excellent resistance to moisture and many chemicals.

Pros & Cons:

PET is cost-efficient and recyclable, making it attractive for environmentally conscious buyers. It offers good diffusion but lower impact resistance compared to PC. Manufacturing is straightforward with film extrusion and thermoforming methods.

Impact on Application:

PET diffuser covers are commonly used in low-heat, indoor applications such as office lighting or retail displays. Its chemical resistance makes it suitable for environments exposed to cleaning agents or humidity.

International B2B Considerations:

European and South African buyers increasingly demand recyclable materials like PET to meet sustainability goals and regulations such as the EU’s Circular Economy Action Plan. In South America, PET’s affordability and recyclability align well with growing green procurement policies. However, buyers in hotter climates like the Middle East should assess PET’s heat limitations carefully.

Silicone

Key Properties:

Silicone offers excellent flexibility, high temperature resistance (up to 200°C), and outstanding UV and weather resistance. It is also highly resistant to yellowing and chemical degradation.

Pros & Cons:

Silicone diffuser covers are highly durable and maintain optical clarity over time, even under extreme conditions. However, silicone is more expensive and less rigid than plastics, which can complicate manufacturing and installation.

Impact on Application:

Silicone is ideal for outdoor and industrial LED strip lighting where temperature extremes and environmental exposure are concerns. Its flexibility allows for curved or irregular installations, expanding design possibilities.

International B2B Considerations:

For buyers in the Middle East and Africa, silicone’s heat resistance and UV stability offer long-term reliability. European markets appreciate silicone for premium outdoor lighting solutions compliant with EN 60598-1 electrical safety standards. South American buyers should weigh the higher cost against longevity benefits, especially for outdoor or industrial projects.

| Material | Typical Use Case for led strip diffuser cover | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Industrial and commercial lighting requiring durability and UV resistance | High impact and thermal resistance; UV stabilized options | Higher cost; potential yellowing without treatment | High |

| Acrylic (PMMA) | Decorative indoor lighting where optical clarity is critical | Excellent light transmission and clarity | Brittle; lower heat resistance | Medium |

| Polyethylene Terephthalate (PET) | Cost-sensitive indoor applications with chemical exposure | Lightweight, recyclable, good chemical resistance | Lower heat and impact resistance | Low |

| Silicone | Outdoor and high-temperature environments requiring flexibility | Superior heat resistance and UV stability | Higher cost; less rigid, complex handling | High |

This guide equips international B2B buyers with actionable insights to select the optimal diffuser cover material based on performance requirements, environmental conditions, and regional standards. Prioritizing material compatibility with local climates and compliance frameworks ensures product longevity and customer satisfaction across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip diffuser cover

Manufacturing Processes for LED Strip Diffuser Covers

The production of LED strip diffuser covers involves a series of carefully controlled stages to ensure optimal light diffusion, durability, and compatibility with LED strips. For B2B buyers sourcing from international suppliers, understanding these manufacturing stages is crucial for assessing product quality and supplier capability.

1. Material Preparation

LED strip diffuser covers are typically made from high-grade plastics such as polycarbonate (PC) or acrylic (PMMA), chosen for their excellent light transmission and impact resistance. Material preparation involves:

– Raw Material Inspection: Ensuring plastics meet specifications for clarity, UV resistance, and thermal stability.

– Pellet Drying: Moisture removal from plastic pellets to prevent defects during molding.

– Color and Additive Mixing: Incorporation of UV stabilizers, anti-yellowing agents, or flame retardants tailored to buyer needs.

2. Forming Techniques

The core shaping of diffuser covers is achieved primarily through:

– Extrusion: Most common for continuous LED strip covers, extrusion pushes molten plastic through a die to form long, uniform profiles. This process allows for consistent thickness and surface texture.

– Injection Molding: Used for custom shapes or end caps, injection molding offers precision in complex geometries but at higher tooling costs.

– Thermoforming: Occasionally used for shaping diffuser sheets by heating and molding over a form, suitable for curved or specialized profiles.

3. Assembly and Secondary Processes

Post-forming, diffuser covers may undergo several assembly steps:

– Cutting and Sizing: Automated cutting to exact lengths matching LED strip specifications.

– Surface Finishing: Techniques such as sanding, polishing, or matte finishing are applied to optimize light diffusion and aesthetics.

– End Cap Attachment: For assembled units, end caps or mounting clips are installed to facilitate easy integration with LED strips.

4. Finishing and Packaging

Final touches ensure product integrity and ease of use:

– Surface Treatment: Anti-static coatings or anti-scratch layers may be applied.

– Protective Film Application: To prevent damage during shipping.

– Labeling and Packaging: Customized packaging with batch numbers and compliance marks for traceability.

Quality Assurance and Control (QA/QC) Framework

Robust quality control is essential to guarantee the performance and reliability of LED strip diffuser covers, particularly for international B2B buyers who must meet diverse market standards.

Key International and Industry Standards

- ISO 9001: The foundational quality management system standard that ensures consistent manufacturing processes and continuous improvement.

- CE Marking (Europe): Indicates conformity with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in materials, critical for buyers in Europe and increasingly in other regions.

- UL Certification (North America, recognized globally): Safety standard for electrical components, sometimes relevant if covers incorporate electrical parts.

- API or Regional Standards: While API is more relevant to oil and gas, some buyers in the Middle East or Africa may require compliance with local safety or environmental standards.

Critical QC Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials for chemical composition, clarity, and physical properties.

- In-Process Quality Control (IPQC): Continuous monitoring during extrusion or molding, including dimensional accuracy, surface finish, and defect detection.

- Final Quality Control (FQC): Comprehensive testing of finished diffuser covers before shipment, including optical clarity, mechanical strength, and fit tests with LED strips.

Common Testing Methods

- Optical Transmittance Testing: Measuring light diffusion and transmission rates using spectrophotometers to ensure even illumination.

- Mechanical Testing: Impact resistance, hardness, and flexibility tests to confirm durability under installation conditions.

- Environmental Stress Testing: UV exposure and thermal cycling to simulate long-term outdoor or indoor use.

- Dimensional Inspection: Using calipers or laser measurement tools to verify adherence to precise specifications.

How B2B Buyers Can Verify Supplier Quality Control

For buyers in Africa, South America, the Middle East, and Europe, where supply chain transparency and compliance may vary, proactive verification of supplier QC is critical.

Supplier Audits

- On-site Factory Audits: Engage third-party inspection agencies to assess manufacturing processes, quality control systems, and working conditions firsthand.

- Virtual Audits: Remote video inspections can be a cost-effective alternative for initial supplier assessments.

Documentation Review

- Quality Certificates: Request ISO 9001 certificates and product-specific compliance documents (e.g., CE, RoHS).

- Test Reports: Obtain detailed batch-wise testing reports for optical and mechanical properties.

- Process Control Records: Review IPQC logs and corrective action reports to assess process stability.

Third-Party Inspections

- Employ independent laboratories or inspection firms to conduct random sampling and testing before shipment, ensuring unbiased quality verification.

QC and Certification Nuances for International Markets

Understanding regional requirements and buyer expectations can significantly influence supplier selection and product acceptance.

- Africa and South America: Buyers often prioritize durability and environmental resistance due to varied climatic conditions. Certifications like ISO and RoHS are increasingly demanded, though CE may not be mandatory. Emphasis on supplier transparency and traceability is vital.

- Middle East: Regulatory frameworks may require compliance with local standards in addition to international ones. Suppliers offering dual certifications (e.g., CE + GCC Conformity) provide added assurance.

- Europe (including the UK): Strict adherence to CE marking, RoHS, and REACH regulations is mandatory. Post-Brexit, UKCA marking is also relevant for UK markets. Buyers expect detailed technical dossiers and environmental compliance documentation.

- Documentation Language and Format: Providing certificates and reports in English and/or the local language facilitates smoother customs clearance and quality verification.

Strategic Recommendations for B2B Buyers

- Specify Standards Early: Clearly communicate required certifications and testing standards in RFQs to avoid quality mismatches.

- Sample Testing: Always request pre-production samples and conduct independent testing to verify diffuser cover performance.

- Long-Term Partnerships: Prioritize suppliers with proven QA systems and willingness to undergo audits, fostering trust and consistent quality.

- Consider Total Cost of Ownership: Factor in the cost of potential quality failures, shipping delays, and certification compliance when evaluating bids.

By comprehensively understanding manufacturing processes and quality assurance mechanisms, international B2B buyers can make informed sourcing decisions for LED strip diffuser covers that meet their technical requirements and regulatory obligations.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip diffuser cover Sourcing

When sourcing LED strip diffuser covers, understanding the intricate cost structure and pricing dynamics is crucial for international B2B buyers. This knowledge empowers procurement teams, especially those operating in Africa, South America, the Middle East, and Europe, to make informed decisions, negotiate effectively, and optimize total cost of ownership.

Key Cost Components in LED Strip Diffuser Cover Production

-

Materials

The primary raw materials include polycarbonate (PC), acrylic, or other thermoplastics, chosen for their light diffusion properties and durability. Material quality directly impacts cost—premium-grade UV-resistant plastics command higher prices but ensure longer lifespan and performance. -

Labor

Labor costs vary significantly by manufacturing location. Regions with lower labor rates, such as certain parts of Asia, typically offer more competitive pricing. However, buyers should balance cost savings with quality assurance and ethical sourcing standards. -

Manufacturing Overhead

This encompasses factory utilities, equipment depreciation, and indirect labor. Efficient production lines and automation reduce overhead, contributing to better pricing. -

Tooling and Molds

Creating injection molds or extrusion dies for diffuser covers involves significant upfront investment. Tooling costs are amortized over production volume, so larger orders reduce per-unit cost. Custom designs require bespoke tooling, increasing initial expenses. -

Quality Control (QC)

QC processes—including dimensional checks, light diffusion tests, and material certifications—add to costs but are essential for ensuring product consistency and compliance with international standards. -

Logistics and Shipping

Freight costs depend on shipment size, mode (air, sea, land), and destination. Buyers from Africa, South America, and the Middle East should consider port accessibility, customs clearance fees, and potential delays that can affect landed cost. -

Supplier Margin

Manufacturers and distributors include a margin that reflects market demand, competition, and business risk. Margins can be negotiated, especially for large or repeat orders.

Pricing Influencers for LED Strip Diffuser Covers

-

Order Volume / Minimum Order Quantity (MOQ)

Higher volumes typically unlock tiered pricing discounts. MOQ policies vary; some suppliers set minimums to justify tooling and production runs. -

Specifications and Customization

Custom lengths, colors (e.g., frosted, opal), profiles, or integrated features like clips and channels increase complexity and price. -

Material Selection and Quality Certifications

Certifications such as RoHS, REACH, or UL approval may increase costs but facilitate market acceptance and regulatory compliance, especially in Europe and the UK. -

Supplier Location and Reputation

Established suppliers with proven track records may command premium pricing but reduce risks related to quality and delivery. -

Incoterms and Payment Terms

Pricing varies significantly depending on terms like FOB, CIF, or DDP, which dictate responsibility for shipping costs and risks. Buyers should clarify terms to avoid unexpected expenses.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price

Seek value-added services such as flexible MOQs, extended payment terms, or bundled shipping to improve overall cost-efficiency. -

Evaluate Total Cost of Ownership (TCO)

Consider not only unit price but also factors like durability, warranty, replacement frequency, and after-sales support. A slightly higher upfront cost may reduce long-term expenses. -

Leverage Local Import Expertise

Engage customs brokers or local agents familiar with regional regulations and tariffs to minimize delays and unforeseen charges. -

Request Samples and Certifications

Always verify product quality through samples and check for compliance documents to avoid costly returns or non-compliance penalties. -

Consider Currency Fluctuations and Payment Methods

Use hedging strategies or negotiate contracts in stable currencies to mitigate exchange rate risks, especially relevant for buyers in emerging markets.

Indicative Pricing Disclaimer

Prices for LED strip diffuser covers vary widely based on design complexity, order size, supplier, and market conditions. Typical price ranges can be from $0.50 to $3.00 per meter or unit, excluding shipping and taxes. Buyers should request detailed quotations tailored to their specifications and conduct thorough supplier evaluations.

By dissecting these cost elements and pricing drivers, international B2B buyers can strategically navigate the procurement of LED strip diffuser covers, securing competitive pricing while ensuring product quality and supply chain reliability.

Spotlight on Potential led strip diffuser cover Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip diffuser cover’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip diffuser cover

Critical Technical Properties of LED Strip Diffuser Covers

Understanding the essential technical specifications of LED strip diffuser covers is crucial for international B2B buyers to ensure product compatibility, durability, and performance in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Material Grade

Typically made from polycarbonate (PC) or acrylic (PMMA), the material grade affects light diffusion efficiency, UV resistance, and impact strength. Polycarbonate is favored for its high durability and heat resistance, making it ideal for outdoor or industrial applications. Acrylic offers superior clarity and better light transmission but is less impact-resistant. Selecting the right material grade ensures longevity and optimal lighting quality, reducing replacement costs. -

Light Transmission Rate (%)

This metric indicates the percentage of light passing through the diffuser cover. A higher transmission rate (usually between 80% to 95%) means brighter illumination but less diffusion, while a lower rate offers softer, more uniform light distribution. Buyers targeting hospitality or retail sectors might prefer higher diffusion for aesthetic appeal, whereas industrial clients may prioritize brightness. -

Tolerance and Dimensional Accuracy (mm)

Precise dimensions and tight manufacturing tolerances (±0.1mm or better) are essential to guarantee proper fit with LED strip profiles and mounting channels. Variations can cause installation issues or reduce the effectiveness of light diffusion. For B2B buyers, especially those specifying custom sizes, confirming tolerance standards prevents costly project delays and returns. -

UV and Heat Resistance

Exposure to sunlight and heat can degrade diffuser covers, causing yellowing or warping over time. A cover with high UV resistance and thermal stability (up to 120°C or more) is vital for outdoor or high-temperature environments. This property ensures product longevity and maintains consistent light quality, which is critical in regions with intense sun exposure like the Middle East and parts of Africa. -

Impact Resistance (ISO or ASTM standards)

Impact resistance ratings measure the cover’s ability to withstand physical shocks. Higher impact resistance is important for industrial or public installations where accidental knocks or vandalism may occur. Compliance with international standards (e.g., ISO 179 or ASTM D256) reassures buyers of product robustness and safety. -

Surface Finish and Color Options

Diffuser covers come in various finishes—matte, frosted, or clear—that influence light diffusion and aesthetic appeal. Color tints (e.g., opal white, smoke gray) can also affect ambiance and glare reduction. For B2B buyers, offering a range of finishes and colors enables customization tailored to regional design preferences and project requirements.

Key Trade Terminology for LED Strip Diffuser Covers

Familiarity with common industry terms is essential for smooth communication and efficient procurement processes in global B2B transactions.

-

OEM (Original Equipment Manufacturer)

Refers to suppliers or manufacturers who produce diffuser covers that can be branded or customized for another company. For buyers, working with OEMs allows for tailored product specifications and private labeling, enhancing brand identity in local markets. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. MOQs vary widely and impact inventory planning and cash flow. Buyers from emerging markets should negotiate MOQs that align with their sales volume and storage capacity to avoid overstocking or supply shortages. -

RFQ (Request for Quotation)

A formal document sent by buyers to suppliers asking for price, lead time, and terms based on specific product requirements. A clear and detailed RFQ accelerates supplier response time and ensures accurate pricing and product matching. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities and costs between buyers and sellers during shipping. Understanding Incoterms helps buyers in Africa, South America, and Europe manage logistics, customs clearance, and risk effectively. -

Lead Time

The period from order confirmation to product delivery. Accurate knowledge of lead times is critical for project scheduling and inventory management, especially for buyers importing from overseas manufacturers. -

Quality Certification (e.g., CE, RoHS)

Certifications verify compliance with safety, environmental, and performance standards. European buyers often require CE marking, while RoHS compliance ensures hazardous substances are restricted. Verifying these certifications minimizes regulatory risks and facilitates market access.

By prioritizing these technical properties and mastering key trade terms, international B2B buyers can make informed purchasing decisions, optimize supply chain efficiency, and secure high-quality LED strip diffuser covers tailored to their regional market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip diffuser cover Sector

Market Overview & Key Trends

The global market for LED strip diffuser covers is experiencing dynamic growth driven by increasing adoption of LED lighting solutions in commercial, residential, and industrial sectors. Key growth drivers include rising demand for energy-efficient lighting, advancements in LED technology, and expanding applications in architectural and ambient lighting. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial for strategic sourcing.

In Africa and South America, infrastructural development and urbanization are accelerating demand for cost-effective, durable lighting solutions. LED strip diffuser covers are increasingly favored for their ability to enhance light diffusion and protect LED strips, thus improving longevity and performance in harsh environments. The Middle East market is propelled by luxury real estate and commercial projects that prioritize sophisticated lighting aesthetics combined with energy efficiency. European buyers, including those in the UK, are influenced by stringent energy regulations and a growing emphasis on sustainable building practices, which elevate the importance of high-quality, eco-friendly diffuser covers.

Current B2B sourcing trends emphasize customization, with buyers seeking diffuser covers that can be tailored in shape, size, and material to meet specific project requirements. Technological innovations such as UV-resistant and fire-retardant materials are gaining traction, especially in regions with extreme climates. Additionally, digital platforms and integrated supply chain solutions are streamlining procurement processes, enabling buyers to access global suppliers with greater transparency and efficiency. Buyers are also prioritizing suppliers who can offer reliable lead times and logistics support to mitigate supply chain disruptions experienced in recent years.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration for B2B buyers in the LED strip diffuser cover sector. The environmental impact of manufacturing processes and materials used directly affects corporate social responsibility goals and compliance with international green standards. Buyers are increasingly scrutinizing the lifecycle footprint of diffuser covers—from raw material extraction through production to end-of-life disposal.

Ethical sourcing is gaining prominence, with buyers favoring suppliers that adhere to transparent labor practices and minimize environmental harm. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management systems are often prerequisites for European and Middle Eastern markets. The use of recyclable and bio-based plastics, such as PC (polycarbonate) or PMMA (acrylic) alternatives, is encouraged to reduce plastic waste and carbon emissions.

For African and South American buyers, engaging with suppliers who implement sustainable practices can also enhance local market credibility and align with emerging government regulations on environmental protection. Collaborative initiatives between buyers and manufacturers to develop diffuser covers that are easier to recycle or reuse are emerging as a differentiator in competitive tenders. Furthermore, sustainability-focused buyers are leveraging supplier audits and third-party verifications to ensure compliance, thereby mitigating risks associated with supply chain disruptions and reputational damage.

Evolution of LED Strip Diffuser Covers

Originally, LED strip diffuser covers were simple plastic sleeves designed solely to protect LED strips from dust and physical damage. Over time, as LED lighting technology advanced, diffuser covers evolved to enhance light quality by softening and evenly distributing illumination, reducing glare, and improving aesthetic appeal. The introduction of materials with improved UV resistance and thermal stability has extended their application to outdoor and industrial settings.

From a B2B perspective, the evolution also reflects a shift from generic, off-the-shelf products to highly engineered components tailored for specific lighting solutions. This development has been driven by the need to meet diverse architectural and commercial requirements across different global markets. Today, diffuser covers integrate functionality with sustainability, offering buyers a product that supports energy-efficient lighting systems while adhering to environmental and regulatory standards worldwide.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip diffuser cover

-

How can I effectively vet suppliers of LED strip diffuser covers for international trade?

When sourcing LED strip diffuser covers internationally, particularly from regions like Asia or Europe, conduct thorough due diligence. Verify supplier credentials through third-party audits, request ISO or relevant certifications, and review client testimonials or case studies. Utilize platforms that offer supplier verification services and request samples before bulk orders. Engaging in video calls and factory visits, if feasible, also provides insight into production capabilities and quality controls. For buyers in Africa, South America, the Middle East, and Europe, partnering with suppliers familiar with local import regulations minimizes risk. -

Is customization available for LED strip diffuser covers, and how do I communicate my specifications clearly?

Most reputable manufacturers offer customization in terms of size, material, opacity, and mounting options to suit specific lighting designs. To ensure your requirements are met, provide detailed technical drawings, material preferences, and performance criteria upfront. Use standardized measurement units and clarify any industry-specific terms. For international buyers, confirm if the supplier supports multilingual communication or can provide documentation in your preferred language to avoid misunderstandings. Early prototype approval is critical to align expectations and avoid costly revisions. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders?

MOQs for LED strip diffuser covers often range from a few hundred to several thousand units, depending on customization and supplier scale. Lead times usually span 3 to 8 weeks, influenced by order complexity and production schedules. Payment terms commonly include a 30-50% deposit upfront with balance due before shipment, but some suppliers may offer trade assurance or letter of credit arrangements for trusted buyers. Buyers from emerging markets should discuss flexible payment options early to accommodate local banking constraints and currency fluctuations. -

What quality assurance measures and certifications should I look for in LED strip diffuser covers?

Ensure the diffuser covers meet international quality standards such as CE (Europe), RoHS (restriction of hazardous substances), and UL (safety certification common in the US but recognized globally). These certifications demonstrate compliance with environmental and safety regulations. Request detailed quality inspection reports, including material tests and durability assessments. For buyers in Africa and South America, also confirm adherence to any regional standards to ensure smooth customs clearance and product acceptance in your market. -

How can I optimize logistics and shipping when importing LED strip diffuser covers internationally?

Choosing the right shipping method—air, sea, or express courier—depends on order volume, urgency, and cost considerations. For bulk orders, sea freight offers cost efficiency but requires longer lead times; air freight suits smaller, urgent shipments. Work with freight forwarders experienced in your region to navigate customs, taxes, and import duties effectively. Consolidate shipments when possible to reduce costs, and ensure packaging protects the diffuser covers from damage during transit. Clear Incoterms (e.g., FOB, CIF) should be agreed upon to define responsibilities. -

What are the best practices for handling disputes or quality issues with overseas suppliers?

Establish clear contractual terms detailing quality standards, inspection protocols, and dispute resolution mechanisms before placing orders. If defects arise, document issues thoroughly with photos and inspection reports, then communicate promptly with the supplier. Utilize third-party inspection agencies to mediate if needed. For persistent problems, leverage trade assurance services or escrow payments to protect funds. Maintaining a professional relationship and clear communication channels helps resolve disputes amicably, minimizing supply chain disruptions. -

Are there specific considerations for sourcing LED strip diffuser covers in regions like Africa, the Middle East, or South America?

Yes, these regions may present unique challenges such as longer shipping times, import tariffs, or limited local infrastructure. Buyers should work with suppliers experienced in exporting to these markets and understand local regulatory requirements. Additionally, consider cultural differences in negotiation and communication styles. Establishing local partnerships or agents can facilitate smoother transactions and after-sales support. Also, factor in regional climate conditions that might affect product material choice and durability. -

How can I ensure sustainability and environmental compliance when sourcing LED strip diffuser covers?

Demand transparency on the materials used—prefer suppliers that use recyclable or non-toxic plastics and comply with environmental regulations like RoHS. Assess the supplier’s commitment to sustainable manufacturing processes, such as waste reduction and energy efficiency. For B2B buyers in Europe and other regions with strict environmental standards, prioritize suppliers with eco-certifications and those who provide lifecycle impact data. This not only meets regulatory demands but also enhances your brand’s reputation among environmentally conscious clients.

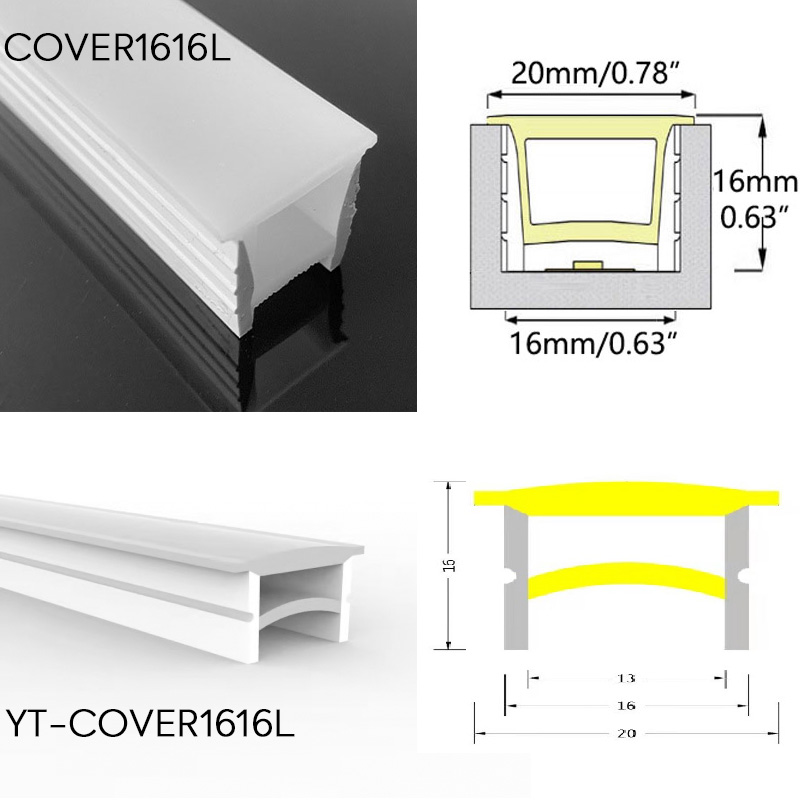

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip diffuser cover

Effective strategic sourcing of LED strip diffuser covers is pivotal for international B2B buyers aiming to optimize product quality, cost-efficiency, and supply chain resilience. Key considerations include evaluating material durability, compatibility with diverse LED strip types, and supplier reliability—especially when catering to varied regional requirements across Africa, South America, the Middle East, and Europe. Prioritizing partners who demonstrate agility in customization and compliance with international standards ensures that diffuser covers meet both functional and aesthetic demands in commercial and industrial applications.

Strategic sourcing offers multiple advantages:

- Enhanced product longevity through superior materials and design

- Reduced operational risks by selecting suppliers with proven delivery consistency

- Cost optimization via volume negotiation and streamlined logistics

- Adaptability to market trends, such as energy efficiency and sustainability standards

Looking ahead, the global push toward smarter, energy-conscious lighting solutions will intensify demand for innovative diffuser covers that improve light diffusion and thermal management. Buyers who proactively engage with manufacturers offering cutting-edge materials and flexible production capabilities will secure a competitive edge.

For businesses in emerging and established markets alike, investing in strategic supplier relationships and staying abreast of technological advancements is essential. Begin your sourcing journey with a clear understanding of your project specifications and regional market nuances to unlock long-term value and growth opportunities in the LED strip lighting sector.

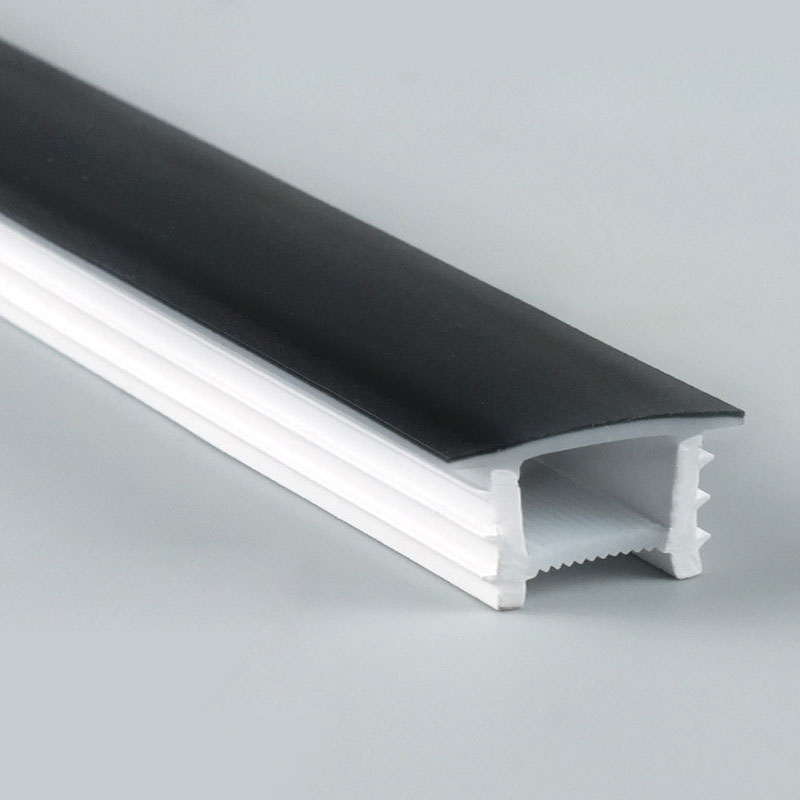

Illustrative Image (Source: Google Search)