Introduction: Navigating the Global Market for led strip connector 4 pin

The global demand for 4-pin LED strip connectors is surging as LED lighting solutions become integral across diverse commercial, industrial, and architectural applications. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—sourcing the right 4-pin connectors is crucial to ensuring seamless integration, reliable performance, and scalability of RGB LED strip installations. These connectors are the backbone of flexible lighting systems, enabling efficient power distribution and signal control across complex setups.

Illustrative Image (Source: Google Search)

This comprehensive guide provides a deep dive into the world of 4-pin LED strip connectors, offering actionable insights tailored to the unique challenges faced by global buyers. It covers the various types and configurations of connectors, the materials and manufacturing standards that impact durability and electrical performance, as well as stringent quality control processes essential for consistent product reliability. Buyers will also gain clarity on pricing structures, supplier evaluation criteria, and market trends influencing availability and innovation.

By navigating this guide, procurement professionals and technical decision-makers will be empowered to make informed, strategic sourcing decisions that align with their project specifications and budget constraints. Whether you are specifying components for large-scale commercial lighting projects in Germany or customizing vibrant retail displays in Indonesia, understanding the nuances of 4-pin LED strip connectors is key to unlocking superior system functionality and long-term value. This resource aims to bridge knowledge gaps and facilitate confident supplier partnerships in an increasingly competitive global marketplace.

Understanding led strip connector 4 pin Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snap-On 4-Pin Connectors | Tool-free clip design, quick connect/disconnect | Retail displays, temporary installations | + Fast installation, no soldering needed – Limited durability under heavy use |

| Soldered 4-Pin Connectors | Permanent connection, requires soldering skills | Industrial lighting, long-term fixed installations | + Reliable electrical contact, high durability – Requires skilled labor, less flexible for modifications |

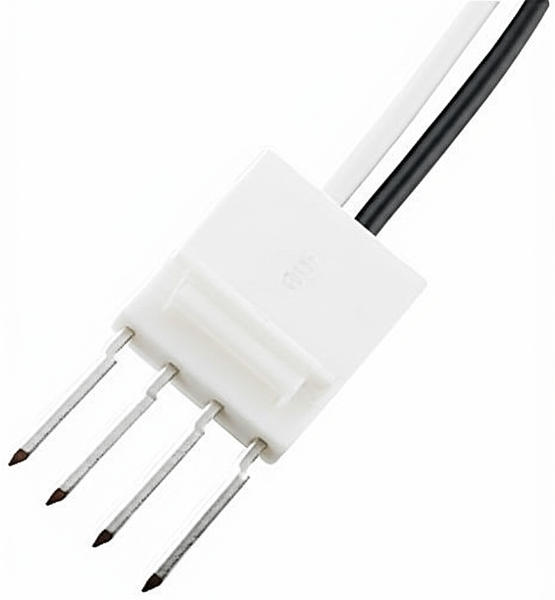

| IDC (Insulation Displacement Connector) | Pierces insulation to connect wires without stripping | Commercial projects needing fast, reliable wiring | + Efficient wiring, no wire stripping – May require specialized tools, less common in some regions |

| Waterproof 4-Pin Connectors | Sealed connectors with IP65+ rating for moisture protection | Outdoor lighting, marine and architectural lighting | + Protects against water and dust ingress – Higher cost, bulkier design |

| Flexible Ribbon 4-Pin Connectors | Flat, flexible connectors designed for tight or curved spaces | Automotive, custom signage, and compact installations | + Adaptable to complex layouts, lightweight – Less robust for heavy-duty industrial use |

Snap-On 4-Pin Connectors

Snap-On connectors are popular for their ease of use, allowing installers to quickly connect LED strips without soldering. This type is ideal for retail environments and short-term projects where speed and flexibility are priorities. For B2B buyers, these connectors reduce labor costs and installation time but may lack the robustness required for heavy industrial use or outdoor environments. When sourcing, ensure compatibility with the LED strip width and pin spacing.

Soldered 4-Pin Connectors

Soldered connectors provide a permanent, highly reliable connection and are favored in industrial and commercial lighting projects requiring durability and consistent electrical contact. Although installation demands skilled labor and more time, the result is a stable connection ideal for long-term fixed installations. B2B buyers should consider the availability of technical staff and whether the installation environment justifies the higher upfront labor costs.

IDC (Insulation Displacement Connector)

IDC connectors simplify wiring by connecting directly through insulation without stripping wires. This feature accelerates large-scale commercial installations where time efficiency is critical. However, IDC connectors may require specialized tools and are less common in some markets, so buyers must assess local availability and technical support. Their use is recommended when rapid deployment and reliable connections are priorities.

Waterproof 4-Pin Connectors

Designed for environments exposed to moisture and dust, waterproof connectors provide IP65 or higher protection. These are essential for outdoor architectural lighting, marine applications, and industrial settings where environmental resistance is critical. B2B buyers should factor in the higher cost and size of these connectors but balance this against the reduced maintenance and increased lifespan they offer in harsh conditions.

Flexible Ribbon 4-Pin Connectors

Flexible ribbon connectors are tailored for installations requiring tight bends or compact layouts, such as automotive lighting or custom signage. Their slim, lightweight design enables creative flexibility but may not withstand heavy mechanical stress. Buyers in sectors emphasizing design innovation and space constraints will find these connectors valuable, though they should evaluate mechanical protection strategies to ensure longevity.

Related Video: How to Cut, Connect & Power COB LED Strip Lighting | Solderless Connector Tutorial

Key Industrial Applications of led strip connector 4 pin

| Industry/Sector | Specific Application of led strip connector 4 pin | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Dynamic RGB lighting for storefronts and interior displays | Enhances visual appeal, attracts customers, and supports branding | Durability, ease of installation, compatibility with controllers, voltage ratings |

| Hospitality & Entertainment | Ambient and stage lighting in hotels, clubs, and theaters | Creates customizable atmospheres, improves guest experience | High color fidelity, reliable connectors for long runs, IP rating for moisture protection |

| Automotive Manufacturing | Interior and accent lighting in vehicle cabins and dashboards | Adds luxury feel, improves ergonomics, and supports brand identity | Heat resistance, vibration-proof connectors, compliance with automotive standards |

| Architectural & Urban Planning | Façade lighting and decorative installations on buildings | Energy-efficient illumination with flexible design options | Weatherproof connectors, long cable runs support, ease of maintenance and replacement |

| Electronics & Consumer Goods | Integration in smart home devices and electronic appliances | Enables compact, customizable lighting solutions | Miniaturized connectors, consistent electrical performance, compatibility with IoT controllers |

Retail & Commercial Spaces

In retail environments across Europe, South America, and the Middle East, 4-pin LED strip connectors are widely used to install RGB LED strips that highlight storefronts, product displays, and interior architectural features. These connectors facilitate quick and secure linking of LED segments, enabling businesses to create dynamic, eye-catching lighting that adapts to promotional campaigns or seasonal themes. International buyers should prioritize sourcing connectors that ensure consistent voltage delivery over longer runs, especially in large stores, while also offering compatibility with widely used controllers to streamline installation and maintenance.

Hospitality & Entertainment

Hotels, nightclubs, and theaters in regions such as Africa and Europe increasingly adopt 4-pin LED strip connectors for ambient lighting and stage effects. These connectors support RGB strips that allow for customizable color schemes, enhancing the atmosphere and guest experience. For B2B buyers, selecting connectors with robust locking mechanisms and IP-rated protection is critical to withstand humid or dusty environments. Additionally, sourcing from suppliers who provide technical support for integrating lighting control systems ensures seamless operation in complex entertainment setups.

Automotive Manufacturing

The automotive sector, notably in Germany and Indonesia, uses 4-pin connectors to integrate RGB LED strips into vehicle interiors for dashboard illumination and accent lighting. These connectors must endure high temperatures and mechanical vibrations, ensuring long-lasting performance without signal loss. Buyers should focus on connectors certified to automotive industry standards and capable of withstanding harsh operating conditions. Reliable sourcing guarantees compliance with safety regulations and supports premium vehicle branding through sophisticated lighting designs.

Architectural & Urban Planning

Urban planners and architects deploy 4-pin LED strip connectors for façade lighting and decorative installations on commercial and public buildings, especially in Europe and the Middle East. These connectors enable the assembly of long LED runs that require minimal voltage drop and ease of maintenance. For international buyers, sourcing weatherproof connectors with corrosion resistance is essential to ensure durability in outdoor environments. Additionally, connectors that support parallel wiring configurations facilitate scalable and energy-efficient lighting solutions.

Electronics & Consumer Goods

In the consumer electronics industry, 4-pin connectors are integrated into smart home devices and electronic appliances to provide customizable lighting effects. This application is prevalent in emerging markets across Africa and South America, where compact and reliable connectors enable manufacturers to offer innovative lighting features. B2B buyers should prioritize connectors with consistent electrical contact, small form factors, and compatibility with IoT controllers to meet the growing demand for smart, connected lighting products.

Related Video: LED light Strip connector For Beginners

Strategic Material Selection Guide for led strip connector 4 pin

When selecting materials for 4-pin LED strip connectors, international B2B buyers must consider a range of factors including electrical performance, mechanical durability, environmental resistance, and compliance with regional standards. This is especially critical for buyers operating in diverse climates and regulatory environments across Africa, South America, the Middle East, and Europe. Below is a detailed analysis of four common materials used in manufacturing 4-pin LED strip connectors, highlighting their properties, advantages, limitations, and regional considerations.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its excellent impact resistance, high heat tolerance (typically up to 120°C), and good electrical insulation properties. It also offers moderate UV resistance and dimensional stability, making it suitable for indoor and some outdoor applications.

Pros & Cons:

– Pros: High mechanical strength, clear/translucent options for visual inspection, good flame retardancy, and ease of molding complex shapes.

– Cons: Moderate chemical resistance; prolonged exposure to harsh chemicals or UV radiation can cause degradation. Also, PC connectors may be more expensive than basic plastics.

Impact on Application:

Polycarbonate connectors are ideal for commercial and industrial LED strip installations requiring robust mechanical protection and moderate environmental exposure. Their electrical insulation supports safe operation in 12V/24V systems common in RGB LED strips.

International B2B Considerations:

Buyers in Europe (e.g., Germany) benefit from PC’s compliance with strict RoHS and REACH regulations. In regions like the Middle East and Africa, where high ambient temperatures prevail, PC’s heat resistance is advantageous. However, buyers should verify UV stabilization additives for outdoor use in South America’s tropical climates to prevent premature aging.

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used plastic with good electrical insulation, flexibility, and chemical resistance. It typically withstands temperatures up to 70-80°C and offers moderate resistance to moisture and corrosion.

Pros & Cons:

– Pros: Cost-effective, easy to manufacture, flexible for tight installations, and good chemical resistance against acids and alkalis.

– Cons: Lower heat resistance limits use in high-temperature environments; less impact resistant than PC; environmental concerns due to chlorine content.

Impact on Application:

PVC connectors are suitable for indoor LED strip applications with stable, moderate temperature environments. Their flexibility helps in installations requiring bending or tight corners but may not be ideal for heavy-duty commercial use.

International B2B Considerations:

In South America and Africa, where cost sensitivity is high, PVC offers an economical solution. However, buyers in Europe must ensure compliance with stringent environmental directives limiting PVC use. The Middle East’s high temperatures may necessitate alternative materials or specialized PVC formulations with enhanced heat resistance.

3. Nylon (Polyamide)

Key Properties:

Nylon is a strong, durable engineering plastic with excellent abrasion resistance, good electrical insulation, and high melting points (typically 190-250°C depending on the grade). It also exhibits good chemical resistance but can absorb moisture, affecting dimensional stability.

Pros & Cons:

– Pros: High mechanical strength, excellent wear resistance, good thermal stability, and resistance to many chemicals.

– Cons: Moisture absorption can cause swelling and dimensional changes; higher manufacturing complexity and cost compared to PVC.

Impact on Application:

Nylon connectors are well-suited for industrial or outdoor LED strip installations requiring mechanical robustness and exposure to chemicals or physical stress. Their thermal stability supports use in environments with fluctuating temperatures.

International B2B Considerations:

For buyers in Europe and the Middle East, nylon’s durability and compliance with DIN and ASTM standards make it a preferred choice for professional-grade connectors. In humid climates of South America and Africa, moisture absorption must be managed through design or material treatment.

4. Brass (with Plating, e.g., Tin or Nickel)

Key Properties:

Brass is a metal alloy known for excellent electrical conductivity, corrosion resistance (especially when plated), and mechanical strength. Tin or nickel plating enhances corrosion resistance and solderability.

Pros & Cons:

– Pros: Superior electrical performance, durable mechanical connection, excellent corrosion resistance with plating, and long service life.

– Cons: Higher cost, heavier weight, and more complex manufacturing processes compared to plastics.

Impact on Application:

Brass pins within connectors ensure reliable electrical contact and longevity, critical for commercial and industrial LED strip systems. They perform well in harsh environments, including coastal or humid areas.

International B2B Considerations:

European buyers expect brass connectors to meet DIN and IEC standards for electrical components. In the Middle East and Africa, brass connectors with appropriate plating resist corrosion from dust and humidity. South American buyers should consider the cost-benefit balance due to brass’s higher price point but appreciate its reliability in tropical conditions.

Summary Table

| Material | Typical Use Case for led strip connector 4 pin | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor/outdoor commercial LED strip connectors requiring impact resistance and heat tolerance | High mechanical strength and heat resistance | Moderate UV and chemical degradation without additives | Medium |

| Polyvinyl Chloride (PVC) | Cost-sensitive indoor installations with flexible wiring needs | Low cost and good chemical resistance | Limited heat resistance and environmental concerns | Low |

| Nylon (Polyamide) | Industrial and outdoor connectors needing durability and thermal stability | Excellent wear resistance and thermal stability | Moisture absorption affecting dimensional stability | Medium to High |

| Brass (with plating) | Electrical contact pins in connectors for reliable conductivity and corrosion resistance | Superior electrical conductivity and durability | Higher cost and manufacturing complexity | High |

This material selection guide equips international B2B buyers with critical insights to choose the optimal 4-pin LED strip connector materials tailored to their regional and application-specific needs. Prioritizing compliance, environmental suitability, and cost-effectiveness will ensure durable, high-performance lighting solutions across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip connector 4 pin

Manufacturing Processes for 4-Pin LED Strip Connectors

The production of 4-pin LED strip connectors involves a series of precise and controlled manufacturing stages designed to ensure durability, electrical reliability, and ease of installation. Understanding these stages helps B2B buyers assess supplier capabilities and product quality before procurement.

1. Material Preparation

- Raw Materials Selection: High-quality copper alloys or phosphor bronze are commonly chosen for the connector pins due to their excellent electrical conductivity and corrosion resistance. The housing typically uses flame-retardant, heat-resistant plastics such as polycarbonate (PC) or polyamide (PA).

- Material Inspection: Incoming raw materials undergo incoming quality control (IQC) checks for chemical composition, mechanical properties, and dimensional accuracy. This step is critical for ensuring consistent performance and compliance with industry standards.

2. Forming and Pin Fabrication

- Stamping and Punching: Connector pins are typically formed using precision stamping machines that cut and shape metal sheets into the desired pin profile. This method ensures tight tolerances critical for reliable electrical contact.

- Plating: Pins undergo electroplating (commonly tin or gold plating) to enhance corrosion resistance, improve solderability, and reduce contact resistance. The plating thickness and uniformity are closely monitored.

- Plastic Injection Molding: The connector housing is formed via injection molding, allowing for complex shapes with tight dimensional control. Molds are regularly inspected and maintained to avoid defects like flash or warping.

3. Assembly

- Pin Insertion: Pins are inserted into the molded housing either manually or by automated insertion machines. This process demands precision to ensure proper alignment and secure mechanical retention.

- Soldering or Welding: In some designs, pins are soldered or ultrasonically welded to internal contacts or wires to establish strong, stable electrical connections.

- Connector Clamping Mechanism: For connectors with locking clips or clamps, assembly includes fitting these parts to provide secure, vibration-resistant connections for LED strip installation.

4. Finishing and Packaging

- Cleaning: Connectors are cleaned to remove residues like oils, dust, or mold release agents which could impair electrical performance or adhesion.

- Marking: Product markings (such as part numbers, batch codes) are applied for traceability.

- Packaging: Final products are packaged in anti-static, moisture-resistant materials to prevent damage during shipping and storage.

Quality Assurance and Control Frameworks

Quality assurance (QA) and quality control (QC) are integral to manufacturing 4-pin LED strip connectors. They ensure that products meet strict international standards and function reliably in diverse environments, which is paramount for B2B buyers seeking dependable suppliers.

International and Industry Standards

- ISO 9001: The globally recognized standard for quality management systems (QMS). Suppliers certified under ISO 9001 demonstrate consistent product quality, robust process control, and continuous improvement.

- CE Marking: Indicates compliance with EU safety, health, and environmental requirements. Essential for B2B buyers targeting European markets.

- RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment, ensuring environmental safety.

- UL Certification: Important for North American markets, UL standards verify safety in electrical connectors.

- IP Rating Standards: For connectors exposed to moisture or dust, ingress protection ratings (e.g., IP20, IP65) certify suitability for various installation conditions.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected for compliance with specifications before entering production.

- In-Process Quality Control (IPQC): Monitoring occurs at critical production stages, including pin stamping accuracy, plating thickness, housing dimensions, and assembly precision.

- Final Quality Control (FQC): Finished connectors undergo comprehensive testing to verify mechanical integrity, electrical performance, and visual appearance before shipment.

Common Testing Methods

- Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMM) to verify physical tolerances.

- Electrical Testing: Continuity, insulation resistance, and contact resistance tests ensure reliable current flow and isolation between pins.

- Mechanical Testing: Includes insertion force measurement, retention force testing, and vibration resistance to simulate real-world installation stresses.

- Environmental Testing: Thermal cycling, humidity exposure, and salt spray tests evaluate durability under harsh conditions.

- Visual Inspection: Automated optical inspection (AOI) or manual checks detect defects such as cracks, burrs, or plating inconsistencies.

Verifying Supplier Quality: Actionable Steps for B2B Buyers

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier quality assurance processes is crucial to minimize risks and ensure compliance with regional standards.

Supplier Audits

- On-site Factory Audits: Conduct or commission third-party audits to assess manufacturing capabilities, QMS implementation, and compliance with certifications like ISO 9001.

- Process Audits: Focus on critical production steps such as pin stamping, plating, and assembly to verify adherence to quality protocols.

Documentation and Reporting

- Request Quality Certificates: Ensure suppliers provide relevant certifications (ISO, CE, RoHS, UL) and testing reports for each batch.

- Batch Traceability: Confirm that suppliers maintain detailed production records, including raw material lot numbers and inspection results.

- Sample Testing: Order pre-shipment samples for independent laboratory testing to verify electrical and mechanical specifications.

Third-Party Inspection Services

- Engaging independent inspection agencies (e.g., SGS, Bureau Veritas) can provide unbiased verification of product quality and conformity, reducing risks associated with international shipping and customs clearance.

Quality Control Nuances for Global Markets

- Africa & South America: Buyers should emphasize RoHS and CE compliance, especially for products destined for export to Europe or North America. Due to variable climate conditions, connectors with robust environmental resistance (higher IP ratings) are advisable.

- Middle East: Given high temperatures and dust exposure, focus on thermal and ingress protection testing. Certifications like UL and CE are often required for governmental and commercial projects.

- Europe (e.g., Germany): Strict adherence to ISO 9001 and CE marking is mandatory. German buyers often demand detailed process documentation and supplier traceability. Environmental standards such as REACH may also apply.

- Emerging Markets (e.g., Indonesia): While cost-effectiveness is important, buyers should still prioritize suppliers with transparent QC processes and relevant certifications to avoid counterfeit or substandard products.

Summary for B2B Buyers

When sourcing 4-pin LED strip connectors, international B2B buyers should prioritize suppliers that demonstrate:

- Rigorous material selection and controlled manufacturing processes, including precision stamping, plating, and assembly.

- Comprehensive quality assurance systems aligned with ISO 9001 and relevant regional certifications.

- Multiple QC checkpoints (IQC, IPQC, FQC) with documented testing methods covering electrical, mechanical, and environmental performance.

- Transparency through audits, certification provision, and willingness to accommodate independent inspections.

- Awareness of regional quality and certification nuances to ensure smooth market entry and long-term reliability.

By understanding these manufacturing and quality assurance intricacies, B2B buyers can make informed decisions that reduce supply chain risks and secure high-quality 4-pin LED strip connectors for their commercial and industrial applications.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip connector 4 pin Sourcing

When sourcing 4-pin LED strip connectors, understanding the detailed cost structure and pricing dynamics is essential for international B2B buyers aiming to optimize procurement budgets and ensure supply chain efficiency. The pricing of these connectors is influenced by multiple cost components and external factors that vary significantly by region and supplier.

Key Cost Components in 4-Pin LED Strip Connector Pricing

- Materials: The primary cost driver includes the quality and type of plastics, metals (typically copper or brass for pins), and plating materials (such as gold or nickel) used in connectors. Higher-grade materials improve conductivity and durability but increase costs.

- Labor: Manufacturing labor costs depend on the country of origin. Regions like Southeast Asia may offer lower labor expenses compared to Europe, while Middle Eastern or South American suppliers may fall somewhere in between, impacting unit prices.

- Manufacturing Overhead: This encompasses factory utilities, equipment depreciation, and indirect labor. Efficient production processes and automation can reduce overhead, allowing for competitive pricing.

- Tooling and Setup: Initial tooling for molding plastic housings and stamping metal pins represents a significant upfront investment. Larger orders typically amortize tooling costs over volume, lowering per-unit costs.

- Quality Control (QC): Stringent QC processes, including electrical testing and durability checks, add to production costs but are critical to ensure compliance with international standards.

- Logistics and Shipping: Freight charges, customs duties, and insurance vary widely based on shipping method (air vs. sea), origin, and destination. Buyers from Africa, South America, and the Middle East should anticipate longer lead times and potentially higher logistics costs compared to European buyers.

- Supplier Margin: Profit margins vary with supplier scale, brand reputation, and market positioning. Established manufacturers may charge premium prices for certified products, while smaller suppliers might offer more competitive pricing but with variable quality.

Influencing Factors on Final Pricing

- Order Volume and Minimum Order Quantity (MOQ): Bulk orders significantly reduce unit prices due to economies of scale. MOQ policies can range from a few hundred to thousands of units, influencing buyers’ upfront investment.

- Specifications and Customization: Custom pin layouts, enhanced waterproofing, or specific certifications (RoHS, CE, UL) increase costs. Buyers requiring specialized connectors for industrial or outdoor use should budget accordingly.

- Material Grade and Certification: Connectors made with higher-grade metals and compliant with international safety standards command higher prices but reduce long-term risks and warranty claims.

- Supplier Location and Reliability: Suppliers in Asia often provide lower prices but require careful vetting to avoid quality issues. European and Middle Eastern suppliers may offer faster turnaround and stronger after-sales support at a premium.

- Incoterms: The choice of Incoterms (FOB, CIF, DDP) impacts who bears shipping and customs costs, affecting the landed cost. Buyers unfamiliar with these terms should negotiate clearly to avoid unexpected expenses.

Practical Tips for B2B Buyers Across Africa, South America, the Middle East, and Europe

- Negotiate Volume Discounts: Consolidate orders to exceed MOQ thresholds and unlock lower per-unit prices. Consider group purchasing with other buyers in your region to leverage bulk pricing.

- Evaluate Total Cost of Ownership (TCO): Look beyond unit price to include shipping, customs, potential import taxes, and quality-related costs such as returns or replacements.

- Insist on Certifications: For markets like Europe and Germany, certifications (CE, RoHS) are mandatory. Buyers in emerging markets should also prioritize these to ensure safety and compatibility.

- Clarify Lead Times and Logistics: Longer shipping routes to Africa and South America necessitate early ordering and buffer stock to avoid project delays.

- Request Samples and Conduct Quality Audits: Before large purchases, obtain samples to verify fit, finish, and electrical performance. For critical projects, consider factory audits or third-party inspections.

- Understand Pricing Nuances: Be aware that lower prices may come with compromises in durability or warranty. Balance cost savings with supplier reliability to minimize operational risks.

Disclaimer on Pricing

Prices for 4-pin LED strip connectors vary widely based on supplier, order size, customization, and market conditions. The figures and strategies provided here serve as indicative guidance to assist buyers in making informed sourcing decisions. It is recommended to conduct direct supplier negotiations and obtain multiple quotations for precise pricing tailored to your specific requirements and region.

By thoroughly analyzing these cost factors and applying strategic negotiation and sourcing practices, international B2B buyers can achieve a cost-efficient procurement process while ensuring quality and supply reliability for their LED strip connector needs.

Spotlight on Potential led strip connector 4 pin Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip connector 4 pin’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip connector 4 pin

Critical Technical Properties of 4-Pin LED Strip Connectors

-

Material Grade and Conductivity

High-quality connectors typically use copper alloy or phosphor bronze with a nickel or gold plating. These materials ensure excellent electrical conductivity and corrosion resistance, critical for maintaining stable connections in diverse environmental conditions. For B2B buyers, specifying material grade guarantees durability and minimizes maintenance costs, especially in humid or industrial settings common in Africa, the Middle East, and parts of South America. -

Pin Configuration and Pitch

The standard 4-pin layout corresponds to the RGB channels plus a common positive or negative line, with typical pin spacing (pitch) of 2.54mm or 3.96mm. Precise pin pitch compatibility is essential to ensure seamless integration with LED strips from different manufacturers. Buyers should verify connector pitch to avoid costly mismatches or custom tooling. -

Current and Voltage Ratings

Connectors are rated for specific maximum current (typically 3-5A per pin) and voltage (commonly 12V or 24V DC). These ratings must align with the LED strip’s power requirements to prevent overheating and electrical failure. For large-scale commercial projects, understanding these ratings helps in selecting connectors that support high-power RGB installations without compromising safety or performance. -

Tolerance and Mechanical Fit

Manufacturing tolerance—how precisely the connector components fit together—affects connection stability and ease of installation. Tight tolerances reduce the risk of loose contacts or intermittent failures. For international buyers, especially those sourcing from multiple suppliers, specifying tolerance standards (e.g., ±0.1mm) ensures consistent quality and compatibility. -

Ingress Protection (IP) Rating

While the LED strips themselves often carry IP ratings for water and dust resistance, connectors should ideally have matching or complementary IP ratings (e.g., IP65 or higher) for outdoor or humid environment applications. This protects against corrosion and short circuits, crucial for markets in tropical climates or outdoor architectural lighting.

- Connection Method and Mounting Style

4-pin connectors come in various styles—clip-on, solderless push-fit, or soldered. Each offers trade-offs between installation speed, reliability, and reusability. For B2B buyers, selecting the appropriate connection method depends on installation scale, labor skill level, and maintenance plans. For example, solderless connectors reduce labor time for large projects in emerging markets.

Key Industry and Trade Terms for International B2B Buyers

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing components or complete LED strip connectors that other brands rebrand and sell. OEM partnerships allow buyers to customize specifications, branding, and packaging, which is vital for companies targeting local markets in Africa, South America, or Europe with tailored products. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. Understanding MOQ is critical for budget planning and inventory management. Buyers in developing markets often negotiate MOQs to balance upfront costs with supply chain reliability. -

RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and specification proposals from multiple suppliers. An RFQ helps compare offers on price, lead time, and technical compliance, enabling informed procurement decisions for bulk LED strip connector purchases. -

Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Clarity on Incoterms prevents misunderstandings and unexpected costs during international shipment. -

Voltage Drop

A technical term describing the loss of voltage as electricity travels through connectors and wiring. Excessive voltage drop can cause color inconsistency and dimming in LED strips. Buyers should ensure connectors and cables are rated to minimize voltage drop over long distances, a frequent requirement in large commercial installations. -

Lead Time

The total time from order placement to delivery. Knowing lead times helps buyers plan installation schedules and manage project timelines, particularly when sourcing from overseas suppliers with longer shipping durations to Africa, the Middle East, or Europe.

Understanding these critical technical properties and trade terms empowers international B2B buyers to make well-informed purchasing decisions for 4-pin LED strip connectors. Prioritizing material quality, electrical ratings, and compatibility alongside clear contractual terms ensures efficient supply chains and robust lighting installations across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip connector 4 pin Sector

Market Overview & Key Trends

The global market for 4-pin LED strip connectors is experiencing robust growth driven by expanding applications in architectural lighting, commercial displays, automotive lighting, and smart home systems. Increasing adoption of RGB LED strip technology in sectors such as retail, hospitality, and entertainment is fueling demand for reliable, easy-to-install connectors that ensure seamless color control and power distribution. For international B2B buyers—especially from Africa, South America, the Middle East, and Europe—this market presents both opportunities and challenges shaped by regional infrastructure development, regulatory frameworks, and technological adoption rates.

Key market dynamics include the shift towards higher voltage systems (e.g., 24V) that enable longer LED strip runs with lower voltage drop, reducing installation complexity and costs. This trend is particularly relevant for large-scale commercial projects common in Europe and the Middle East. Meanwhile, African and South American markets are increasingly sourcing from cost-competitive Asian manufacturers, balancing affordability with quality and compliance. Buyers from Germany and Indonesia, known for stringent quality standards, prioritize connectors with verified durability, electrical safety certifications, and compatibility with advanced RGB controllers.

Emerging sourcing trends emphasize modularity and plug-and-play designs that reduce installation time and labor costs. The rise of smart lighting ecosystems also necessitates connectors compatible with IoT-enabled controllers, enabling remote color and brightness adjustments. Additionally, international buyers are leveraging digital B2B platforms and virtual sampling to streamline supplier selection and mitigate risks associated with cross-border transactions. Strategic sourcing now involves assessing supplier capabilities in technical support, customization, and after-sales service to ensure project success.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor for B2B buyers in the 4-pin LED strip connector sector, driven by global environmental regulations and growing corporate responsibility mandates. The production of connectors involves materials such as plastics, metals (copper, tin, nickel), and electronic components that can contribute to resource depletion and hazardous waste if not managed responsibly. Buyers are increasingly demanding suppliers who demonstrate commitment to reducing environmental impact through use of recycled or bio-based plastics, lead-free solder, and RoHS-compliant components.

Ethical sourcing extends beyond material selection to include labor practices, transparency in supply chains, and adherence to international standards such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability). For buyers in regions like Europe and the Middle East, compliance with the EU’s Ecodesign Directive and WEEE (Waste Electrical and Electronic Equipment) regulations is often mandatory, influencing supplier selection criteria.

Green certifications like UL Environment, TUV Rheinland’s Eco-Label, and EPEAT registration serve as benchmarks for sustainability and product safety, providing assurance to buyers that connectors meet rigorous environmental and health standards. Furthermore, energy efficiency in the overall LED lighting system—enabled by quality connectors that minimize power loss—contributes to lower operational carbon footprints, aligning with corporate sustainability goals.

B2B buyers are advised to incorporate sustainability audits and supplier scorecards into their procurement processes to verify claims and foster long-term partnerships with responsible manufacturers. Investing in sustainable sourcing not only mitigates regulatory risks but also enhances brand reputation and appeals to increasingly eco-conscious end customers.

Brief Evolution and Historical Context

The evolution of the 4-pin LED strip connector reflects broader advancements in LED lighting technology over the past two decades. Initially, LED strips were simple, single-color modules requiring manual soldering for connections, which limited scalability and flexibility. The introduction of 4-pin connectors aligned with the rise of RGB LED strips, allowing separate control of red, green, and blue diodes to produce millions of colors.

Over time, connector designs have evolved from basic mechanical clamps to sophisticated, tool-free locking systems that ensure secure electrical contact while simplifying installation. Innovations in connector materials and form factors have enhanced durability and resistance to environmental factors, supporting expansion into outdoor and industrial applications.

For international B2B buyers, understanding this evolution is crucial for selecting connectors that not only meet current technical demands but also integrate seamlessly with emerging smart lighting platforms. The historical shift towards standardized 4-pin configurations has enabled global interoperability, reducing compatibility issues and streamlining global sourcing strategies.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of led strip connector 4 pin

-

How can I effectively vet suppliers of 4-pin LED strip connectors for international B2B sourcing?

To vet suppliers, prioritize those with verifiable certifications such as ISO 9001 for quality management and RoHS compliance for environmental standards. Request detailed product datasheets and samples to test compatibility with your LED strips. Check supplier reputation through trade platforms, customer reviews, and references. For buyers in Africa, South America, the Middle East, and Europe, confirm suppliers’ export experience to your region and their ability to provide after-sales support. Establish clear communication channels and assess responsiveness to technical inquiries as part of your due diligence. -

What customization options are typically available for 4-pin LED strip connectors, and how can I leverage these in bulk orders?

Most manufacturers offer customization in connector length, pin material (e.g., gold-plated for corrosion resistance), wire gauge, and cable length. Some can provide connectors with waterproofing or enhanced locking mechanisms for industrial applications. For bulk orders, negotiate tailored specifications that suit your product line or regional installation standards. Custom branding on packaging or connectors may also be available. Ensure customization requests are clearly documented in the purchase agreement to avoid misunderstandings and confirm lead times for bespoke items. -

What are common minimum order quantities (MOQs) and lead times for 4-pin LED strip connectors when importing internationally?

MOQs typically range from 500 to 5,000 units depending on the supplier and customization level. Lead times vary but generally span 3 to 8 weeks, factoring in production and shipping. For African, South American, Middle Eastern, and European buyers, shipping modes (air vs. sea freight) and customs clearance can impact delivery schedules. To optimize costs and timelines, consider consolidating orders and establishing long-term contracts. Early engagement with suppliers to confirm MOQs and lead times is crucial for aligning procurement with project deadlines. -

Which quality assurance certifications should B2B buyers require for 4-pin LED strip connectors?

Key certifications include ISO 9001 for quality management systems, CE marking for European market compliance, RoHS for hazardous substances restriction, and UL or ETL for safety standards in electrical components. These certifications ensure the connectors meet international safety, environmental, and performance criteria, critical for reliable LED installations. Request copies of certification documents and, if possible, factory audit reports. For buyers in regulated markets like Germany or the EU, compliance with local directives is mandatory to avoid shipment rejections or penalties.

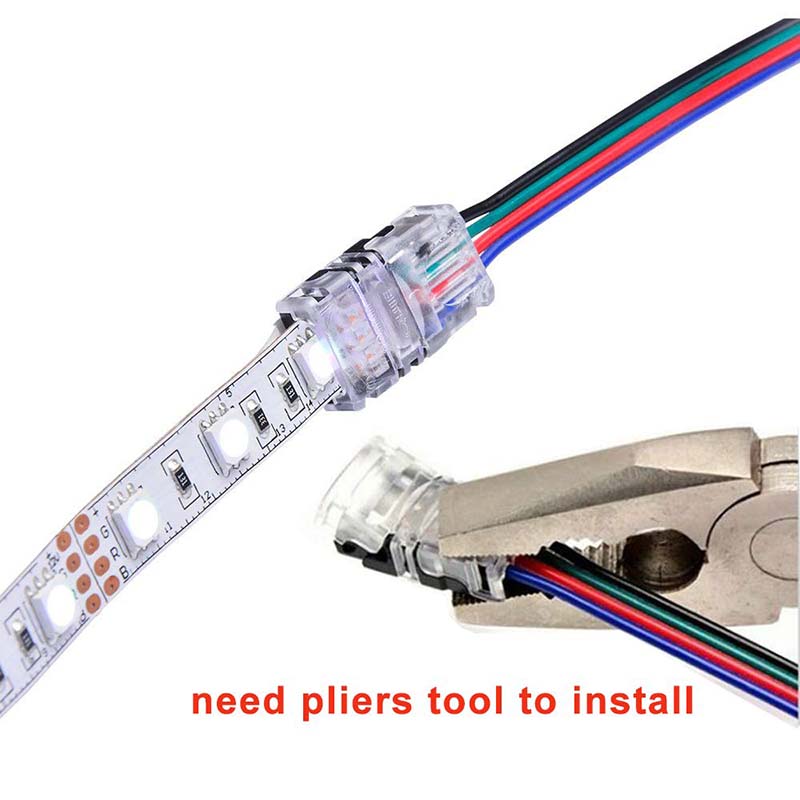

Illustrative Image (Source: Google Search)

-

What payment terms and methods are advisable when purchasing 4-pin LED strip connectors from international suppliers?

Secure payment methods such as Letters of Credit (LC), PayPal Escrow, or verified bank transfers provide protection against fraud. Negotiate favorable payment terms like 30% deposit upfront and 70% upon shipment or inspection to balance risk. For new suppliers, smaller trial orders with full payment upfront can reduce exposure. Large buyers in Europe or the Middle East may leverage trade finance solutions or supplier credit lines to optimize cash flow. Always confirm currency exchange risks and include clear terms on delivery and quality acceptance in the contract. -

How should B2B buyers manage logistics and shipping challenges when importing 4-pin LED strip connectors?

Choose suppliers experienced in exporting to your region and request assistance with documentation such as commercial invoices, packing lists, and certificates of origin. Opt for consolidated shipments to reduce freight costs and customs delays. Understand import duties and VAT applicable in your country to avoid unexpected costs. For Africa and South America, consider port infrastructure and inland transport reliability. Employ freight forwarders with local expertise and track shipments closely. Insure high-value shipments to mitigate losses from damage or delays. -

What are best practices for handling disputes or quality issues with international suppliers of 4-pin LED strip connectors?

Establish clear contractual terms covering quality standards, inspection protocols, and dispute resolution mechanisms before ordering. Use third-party quality inspection services to verify shipments before dispatch. If defects arise, document issues with photos and detailed descriptions and communicate promptly with the supplier. Negotiate remedies such as replacement shipments, partial refunds, or credit notes. For persistent issues, involve trade mediation bodies or use arbitration clauses. Maintaining professional and open communication often leads to faster, mutually beneficial resolutions. -

How can international buyers ensure compatibility of 4-pin LED strip connectors with varying LED strip standards across regions?

Confirm the connector pin configuration (common anode vs. common cathode) matches your LED strip type to avoid installation errors. Verify voltage ratings (12V or 24V) and wire gauge suitability for your application. Request sample connectors to test physical fit and electrical continuity with your LED strips. Some regions may use different standards or color coding; clarify these details with suppliers. For complex or large projects, consider working with suppliers who provide technical support or customized connectors tailored to your market’s specific requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip connector 4 pin

Strategic sourcing of 4-pin LED strip connectors is essential for international B2B buyers aiming to optimize product performance, installation efficiency, and cost-effectiveness. Understanding technical specifications—such as voltage compatibility, wiring configurations, and connector quality—enables buyers to select components that ensure reliable, scalable lighting solutions. For markets across Africa, South America, the Middle East, and Europe, prioritizing suppliers who offer certified products with robust technical support can mitigate risks associated with electrical compatibility and long-term durability.

Key considerations include:

- Verifying adherence to international electrical standards to ensure safety and interoperability.

- Choosing 24V systems where feasible to reduce voltage drop and expand installation flexibility.

- Leveraging modular connector designs to simplify maintenance and future scalability.

- Establishing strong supplier partnerships that provide transparent lead times and responsive after-sales service.

Looking ahead, the growing demand for smart, energy-efficient lighting solutions across emerging and mature markets underscores the importance of sourcing connectors that integrate seamlessly with advanced controllers and IoT platforms. B2B buyers are encouraged to engage with manufacturers who innovate in connector technology and offer customizable options tailored to regional needs. By adopting a strategic sourcing approach, businesses can secure competitive advantages and confidently meet evolving market expectations in the global LED lighting industry.