Guide to Led Strip Blue Lights

- Introduction: Navigating the Global Market for led strip blue lights

- Understanding led strip blue lights Types and Variations

- Key Industrial Applications of led strip blue lights

- Strategic Material Selection Guide for led strip blue lights

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip blue lights

- Comprehensive Cost and Pricing Analysis for led strip blue lights Sourcing

- Spotlight on Potential led strip blue lights Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip blue lights

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip blue lights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip blue lights

- Strategic Sourcing Conclusion and Outlook for led strip blue lights

Introduction: Navigating the Global Market for led strip blue lights

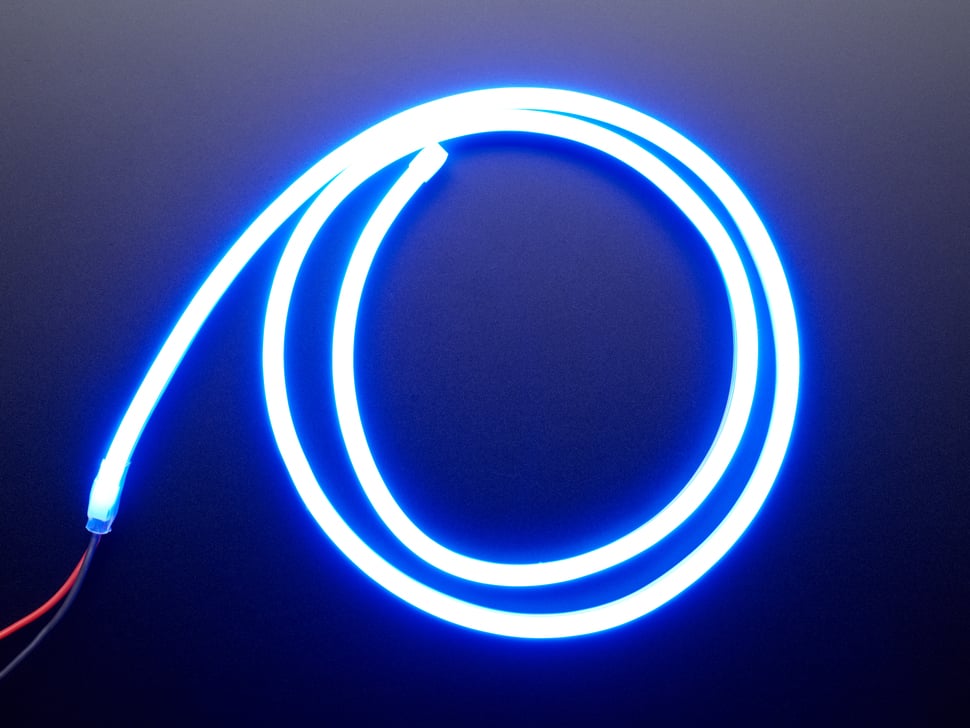

LED strip blue lights have emerged as a pivotal component in modern lighting solutions, offering unparalleled versatility and energy efficiency for a wide array of commercial, industrial, and architectural applications. Their ability to deliver vibrant, consistent illumination in flexible formats makes them indispensable for businesses seeking innovative lighting that enhances both aesthetics and functionality. For international B2B buyers, particularly from dynamic markets in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these products is crucial to capitalizing on their full potential.

This comprehensive guide delves deep into the global landscape of LED strip blue lights, providing actionable insights on types and materials, manufacturing standards and quality control, trusted supplier networks, cost structures, and evolving market trends. Whether you are procuring for large-scale infrastructure projects in Nigeria, retail environments in Colombia, or hospitality venues across the Middle East, this resource equips you with the knowledge to make informed decisions that balance quality, cost-efficiency, and supply chain reliability.

With an emphasis on practical strategies, the guide also addresses common challenges faced by international buyers, including navigating import regulations, assessing supplier credibility, and managing logistics complexities. Additionally, a detailed FAQ section clarifies technical specifications and procurement best practices, empowering buyers to streamline their sourcing process and minimize risks.

By leveraging this expert-curated information, B2B buyers can confidently select the right LED strip blue lights tailored to their market demands, ensuring superior performance and sustained competitive advantage in an increasingly interconnected global marketplace.

Understanding led strip blue lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color Blue LED Strips | Emits uniform blue light, typically with fixed brightness levels | Retail displays, signage, architectural accents | Pros: Cost-effective, easy installation; Cons: Limited color flexibility |

| RGB Blue-Enabled LED Strips | Blue component within multi-color RGB strips allowing color mixing | Hospitality, event lighting, entertainment venues | Pros: Versatile color options; Cons: Higher cost and complexity |

| Waterproof (IP65/IP67) Blue LED Strips | Encased in protective silicone or epoxy for moisture resistance | Outdoor signage, landscape lighting, marine applications | Pros: Durable for harsh environments; Cons: Slightly higher price and thickness |

| High-Brightness Blue LED Strips | Enhanced lumen output for intense blue illumination | Industrial task lighting, automotive, large-scale commercial projects | Pros: Superior visibility and impact; Cons: Higher power consumption |

| Flexible PCB Blue LED Strips | Ultra-thin, bendable strips for intricate installations | Custom architectural projects, wearable tech, creative displays | Pros: Highly adaptable; Cons: Requires careful handling and installation |

Single-Color Blue LED Strips

These strips produce a consistent blue light with fixed brightness, making them ideal for businesses focusing on straightforward illumination needs. Their simplicity and cost-effectiveness appeal to buyers in retail and architectural sectors where uniform blue lighting is required without the need for color changes. When purchasing, B2B buyers should consider the quality of LEDs for longevity and color consistency, especially for large-scale installations.

RGB Blue-Enabled LED Strips

RGB strips incorporate blue LEDs alongside red and green, enabling dynamic color mixing and customizable lighting effects. This versatility suits hospitality venues, event organizers, and entertainment businesses seeking to create immersive environments. Buyers should evaluate the control systems compatibility and power requirements, as these strips often need controllers and power supplies to maximize functionality.

Waterproof (IP65/IP67) Blue LED Strips

Designed with protective coatings, waterproof blue LED strips withstand moisture, dust, and outdoor elements. They are essential for businesses in landscaping, marine, and outdoor signage sectors. B2B buyers must verify the IP rating matches the environmental exposure and consider packaging options that facilitate easier installation in outdoor settings.

High-Brightness Blue LED Strips

These strips offer intense blue illumination with higher lumen output, suitable for industrial and automotive applications where visibility and impact are critical. While their performance is superior, they consume more power and may require advanced heat dissipation solutions. Buyers should factor in energy costs and ensure compatibility with existing electrical infrastructure.

Flexible PCB Blue LED Strips

With ultra-thin and bendable printed circuit boards, these LED strips enable creative and complex installations in architectural designs and wearable technology. Their adaptability is a significant advantage for innovative projects; however, they require careful handling to avoid damage. B2B buyers should assess supplier quality controls and request samples to verify flexibility and durability before bulk purchasing.

Related Video: Beginner’s Guide to Using LED Strips with Arduino

Key Industrial Applications of led strip blue lights

| Industry/Sector | Specific Application of led strip blue lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Medical | Medical device illumination and diagnostic aids | Enhances visibility in diagnostic equipment, improves accuracy | Compliance with medical safety standards, non-toxic, low heat emission |

| Agriculture & Horticulture | Controlled environment plant growth lighting | Stimulates photosynthesis and growth cycles for higher yields | Waterproof, energy-efficient, customizable wavelength spectrum |

| Automotive Manufacturing | Assembly line inspection and quality control | Improves defect detection and reduces errors during production | Durable, vibration-resistant, consistent color output |

| Food & Beverage Industry | Food display and preservation lighting | Maintains food freshness, highlights product appeal without heat | Food-grade materials, waterproof, low UV emission |

| Electronics & Semiconductor | Cleanroom and inspection lighting | Provides precise illumination for microelectronics assembly | Anti-static properties, flicker-free, high CRI (color rendering index) |

Healthcare & Medical

In healthcare settings, blue LED strip lights are used to enhance illumination in medical devices and diagnostic tools, such as endoscopes and lab analyzers. Their precise wavelength supports better visualization of biological tissues, aiding in more accurate diagnoses. For international buyers in regions like Nigeria or Colombia, sourcing medical-grade LED strips requires compliance with strict safety and hygiene standards, ensuring non-toxicity and minimal heat emission to maintain patient safety and equipment longevity.

Agriculture & Horticulture

Blue LED strip lights play a critical role in controlled environment agriculture by stimulating specific plant growth phases such as vegetative development. Their energy-efficient design helps reduce operational costs for large-scale growers in South America and Africa. Buyers should prioritize waterproof and durable strips capable of withstanding humid conditions, with customizable spectral outputs tailored to crop types, ensuring optimized photosynthesis and improved yield quality.

Automotive Manufacturing

In automotive assembly lines, blue LED strips provide high-contrast lighting essential for detailed inspections and quality control processes. This reduces the likelihood of defects slipping through, enhancing overall product reliability. Businesses in Europe and the Middle East must source LED strips that offer resistance to vibration and temperature fluctuations common in industrial environments, ensuring consistent performance and minimal maintenance downtime.

Food & Beverage Industry

Blue LED strip lights are widely used in food display cases and preservation units to maintain product freshness while enhancing visual appeal. Their low heat and UV emissions prevent food spoilage, a vital consideration for markets in hot climates such as the Middle East and parts of Africa. Buyers should ensure the LED strips meet food safety regulations, are waterproof, and constructed with materials safe for direct or indirect food contact.

Electronics & Semiconductor

In semiconductor fabrication and electronics manufacturing, blue LED strips provide cleanroom-compatible illumination that supports precision assembly and inspection. Their flicker-free and high color rendering capabilities enable workers to detect minute defects. For B2B buyers in technologically advanced regions like Europe, sourcing anti-static and dust-resistant LED strips is critical to maintain the integrity of sensitive electronic components and comply with stringent cleanroom standards.

Related Video: Global Industrial Forklift Blue LED Safety Warning Light 988717

Strategic Material Selection Guide for led strip blue lights

Analysis of Common Materials for LED Strip Blue Lights

1. Flexible Printed Circuit Boards (FPC) – Polyimide and PET Substrates

Key Properties:

FPCs are the foundational material for LED strip lights, typically made from polyimide or polyethylene terephthalate (PET) substrates. Polyimide offers excellent thermal stability (up to 260°C), good chemical resistance, and flexibility, while PET is more cost-effective but has a lower temperature tolerance (~150°C). Both provide a lightweight, flexible base that supports the LED chips and circuitry.

Pros & Cons:

Polyimide-based FPCs are highly durable, resistant to heat and chemicals, and suitable for complex bending and shaping. PET substrates are cheaper and suitable for less demanding applications but degrade faster under high heat or UV exposure. Manufacturing complexity is moderate, requiring precise lamination and etching processes.

Impact on Application:

Polyimide FPCs are ideal for high-performance blue LED strips used in industrial, automotive, or outdoor applications where heat dissipation and durability are critical. PET-based FPCs suit indoor decorative lighting or short-term installations. For humid or corrosive environments common in regions like Nigeria or Colombia, polyimide’s chemical resistance is advantageous.

International B2B Considerations:

Buyers should ensure FPC materials comply with international standards such as IPC-6013 for flexible circuits. Polyimide FPCs are preferred in Europe and the Middle East for their robustness and compliance with RoHS and REACH regulations. In Africa and South America, cost sensitivity may favor PET-based FPCs, but buyers must verify durability for local climate conditions.

2. Silicone or Polyurethane Coating (Encapsulation Layer)

Key Properties:

Encapsulation materials protect LED strips from moisture, dust, and mechanical damage. Silicone coatings offer excellent UV resistance, flexibility, and a wide operating temperature range (-60°C to 200°C). Polyurethane coatings provide good abrasion resistance and chemical protection but have lower UV stability.

Pros & Cons:

Silicone encapsulation enhances longevity and outdoor suitability, making it ideal for harsh environments. It is more expensive and requires specialized curing processes. Polyurethane is more cost-effective but less durable under prolonged sun exposure, which can lead to yellowing and cracking.

Impact on Application:

Silicone-coated blue LED strips are suited for outdoor signage, architectural lighting, and marine applications, especially in humid or high-UV regions like the Middle East and coastal Africa. Polyurethane coatings are better for indoor or semi-protected environments where cost constraints are significant.

International B2B Considerations:

Compliance with IP ratings (e.g., IP65, IP67) is crucial for waterproofing claims. Buyers in Europe and the Middle East often require certifications such as EN 60598 for luminaires. In South America and Africa, verifying supplier adherence to these standards ensures product reliability in tropical climates.

3. Aluminum or Copper Backing (Heat Dissipation Layer)

Key Properties:

Metal backing layers provide structural support and improve heat dissipation, critical for maintaining LED efficiency and lifespan. Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity (~205 W/m·K). Copper offers superior thermal conductivity (~400 W/m·K) but is heavier and more expensive.

Pros & Cons:

Aluminum backing balances cost and performance, widely used in commercial LED strips. Copper backing is preferred for high-power or industrial blue LED strips requiring superior heat management but increases material and manufacturing costs. Both metals require surface treatments to prevent corrosion.

Impact on Application:

Aluminum-backed strips are versatile for architectural, retail, and residential lighting across diverse markets. Copper-backed strips are suitable for high-intensity applications such as automotive lighting or industrial settings common in Europe and the Middle East. In humid or corrosive environments like Nigeria, anodized aluminum offers better corrosion resistance.

International B2B Considerations:

Buyers should verify compliance with ASTM B209 for aluminum and ASTM B152 for copper to ensure material quality. Surface finish standards (e.g., anodizing thickness) affect corrosion resistance and are critical for buyers in coastal or high-humidity regions. Lead times and costs can vary significantly between these metals, influencing procurement strategies in Africa and South America.

4. LED Chip Encapsulation Resin (Epoxy or Silicone-Based)

Key Properties:

The resin encapsulates individual blue LED chips, protecting them from mechanical damage and environmental exposure. Epoxy resins are cost-effective and provide good adhesion but have limited UV resistance and can yellow over time. Silicone resins offer superior UV stability, flexibility, and thermal resistance.

Pros & Cons:

Epoxy encapsulation is suitable for indoor applications with controlled environments but may degrade faster outdoors. Silicone encapsulation extends LED lifespan and maintains color stability, essential for high-quality blue light output but at higher cost and manufacturing complexity.

Impact on Application:

Silicone encapsulated LEDs are preferred in outdoor, automotive, and high-reliability industrial applications across Europe and the Middle East. Epoxy encapsulated LEDs are common in budget-sensitive markets or indoor decorative lighting in South America and Africa.

International B2B Considerations:

Buyers should request datasheets confirming compliance with IEC 62031 for LED modules. Regional preferences for silicone encapsulation are growing due to climate challenges, but cost remains a barrier in emerging markets. Establishing supplier transparency on resin formulations helps mitigate risks of premature LED failure.

Summary Table of Materials for LED Strip Blue Lights

| Material | Typical Use Case for led strip blue lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide Flexible Printed Circuit Board (FPC) | High-performance, industrial, outdoor blue LED strips | Excellent thermal and chemical resistance | Higher cost than PET; moderate manufacturing complexity | High |

| PET Flexible Printed Circuit Board (FPC) | Indoor decorative or short-term installations | Cost-effective, flexible | Lower heat tolerance; less durable in harsh environments | Low |

| Silicone Coating (Encapsulation) | Outdoor, marine, architectural lighting | Superior UV resistance and flexibility | Higher cost; requires specialized curing | High |

| Polyurethane Coating (Encapsulation) | Indoor or semi-protected environments | Cost-effective, good abrasion resistance | Poor UV stability; prone to yellowing | Medium |

| Aluminum Backing Layer | Versatile commercial and residential LED strips | Good thermal conductivity and corrosion resistance | Moderate thermal conductivity compared to copper | Medium |

| Copper |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip blue lights

Manufacturing Process of LED Strip Blue Lights

The production of LED strip blue lights involves several critical stages to ensure both performance and durability. Understanding these stages allows B2B buyers to assess supplier capabilities and product quality effectively.

1. Material Preparation

The foundation of LED strip blue lights lies in high-quality raw materials:

– LED Chips: Blue LED chips are carefully selected based on brightness, wavelength accuracy, and energy efficiency. Top-tier suppliers often source from reputable semiconductor manufacturers.

– Flexible PCB (Printed Circuit Board): The PCB substrate, usually made from polyimide or fiberglass, is prepared with copper layers that will conduct electricity.

– Resistors and Drivers: These components regulate current to protect LEDs from overvoltage and ensure consistent brightness.

– Adhesive Backing and Protective Coatings: Materials such as silicone or epoxy coatings provide waterproofing and mechanical protection.

2. Forming and Circuit Fabrication

- PCB Fabrication: The flexible PCB is etched or printed with circuits according to design specifications, ensuring precise pathways for electrical flow.

- Solder Paste Application: Automated machines apply solder paste to designated points where LED chips and components will be mounted.

3. Assembly and Soldering

- Component Placement: Surface Mount Technology (SMT) machines place LED chips and electronic components accurately on the PCB.

- Reflow Soldering: The assembly passes through a reflow oven where solder paste melts and solidifies, securing components firmly.

- Encapsulation: For blue LED strips, encapsulating the diodes with clear silicone enhances light diffusion and protects against environmental factors.

4. Finishing and Cutting

- Cutting to Length: LED strips are cut into standard or customized lengths, often with designated cutting points to maintain circuit integrity.

- Quality Adhesive Application: High-quality 3M or equivalent adhesive backing is applied to ensure ease of installation and long-term adherence.

- Packaging: The strips are rolled or packaged carefully to prevent damage during transit, often including anti-static bags and moisture-proof materials.

Quality Assurance (QA) and Quality Control (QC) in LED Strip Blue Lights Production

Ensuring the reliability and safety of LED strip blue lights requires rigorous QA and QC processes aligned with international standards. These controls are vital for B2B buyers who need consistent product performance and regulatory compliance.

Illustrative Image (Source: Google Search)

International and Industry Standards

- ISO 9001: This globally recognized standard certifies that a manufacturer maintains a robust quality management system, focusing on continuous improvement and customer satisfaction.

- CE Marking: Essential for the European market, CE certification indicates conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restriction of hazardous substances ensures the LED strips are free from harmful materials like lead or mercury, important for environmental regulations worldwide.

- UL Certification: Particularly relevant for North America but also valued globally, UL marks confirm electrical safety and fire resistance.

- IP Ratings: For blue LED strips intended for outdoor or industrial use, an IP65 or higher rating confirms water and dust resistance.

- Additional Certifications: Depending on the target market, certifications such as API (American Petroleum Institute) standards may apply for industrial-grade lighting solutions.

QC Checkpoints Throughout Manufacturing

- Incoming Quality Control (IQC): Raw materials and components, especially LED chips and PCBs, are inspected for defects, electrical parameters, and compliance with specifications before entering production.

- In-Process Quality Control (IPQC): During assembly, continuous inspections check soldering quality, component placement accuracy, and electrical functionality using automated optical inspection (AOI) and manual checks.

- Final Quality Control (FQC): Completed LED strips undergo comprehensive testing including:

- Electrical Testing: Verifying voltage, current, and power consumption to ensure optimal performance.

- Light Output and Color Consistency: Spectrometers measure wavelength accuracy and brightness uniformity, critical for blue light applications.

- Durability Tests: These include bending/flexing tests, waterproofing (for IP-rated products), and thermal cycling to simulate real-world conditions.

Testing Methods and Verification Tools

B2B buyers should be aware of standard testing methodologies to validate supplier claims and product reliability:

- Spectral Analysis: Confirms the exact wavelength of blue light (typically around 450-495 nm) to ensure color accuracy.

- Lumen Measurement: Quantifies the brightness output to match project requirements.

- Thermal Imaging: Detects hotspots or uneven heat distribution that could affect lifespan.

- Electrical Safety Testing: Includes insulation resistance, dielectric strength, and surge protection tests.

- Environmental Stress Screening: Simulates exposure to humidity, temperature extremes, and mechanical stress.

How B2B Buyers Can Verify Supplier Quality Control

Given the complexity of manufacturing and the importance of quality assurance, B2B buyers—especially those in Africa, South America, the Middle East, and Europe—should adopt a multi-faceted approach to supplier verification:

-

Supplier Audits:

– Request on-site or virtual factory audits focusing on manufacturing processes, quality control systems, and compliance with international standards.

– Use third-party inspection agencies specializing in electronics and LED lighting to provide unbiased evaluations. -

Review of Quality Documentation:

– Obtain ISO 9001 certification documents, CE and RoHS certificates, and test reports for each batch.

– Ask for detailed QC reports including results from IQC, IPQC, and FQC stages. -

Sample Testing:

– Order product samples for independent laboratory testing in your region or through trusted global labs.

– Verify color consistency, brightness, and durability claims firsthand before committing to large orders.

Illustrative Image (Source: Google Search)

- Third-Party Inspections:

– Engage inspection companies to conduct pre-shipment inspections (PSI) ensuring products meet contractual specifications and are free from defects.

– Inspections can include random batch testing, packaging checks, and compliance verification.

QC and Certification Nuances for International B2B Buyers

When sourcing LED strip blue lights internationally, buyers must consider regional regulatory differences and market-specific requirements:

- Africa and South America (e.g., Nigeria, Colombia):

- Regulatory environments may vary; some countries require local certifications or import approvals.

- Emphasis on product durability and ease of maintenance due to challenging environmental conditions.

-

Importers should verify compliance with local electrical safety standards and consider logistics-related packaging robustness.

-

Middle East:

- Preference for high-quality, energy-efficient lighting solutions compliant with Gulf Cooperation Council (GCC) standards.

- Certifications like SASO (Saudi Standards, Metrology and Quality Organization) may apply.

-

Buyers should ensure suppliers provide detailed documentation and support for customs clearance.

-

Europe:

- Strict adherence to CE marking, RoHS, and WEEE (Waste Electrical and Electronic Equipment) directives.

- Buyers often require detailed product lifecycle and environmental impact data.

- Traceability and supplier transparency are critical for market acceptance and sustainability goals.

Key Takeaways for B2B Buyers

- Prioritize suppliers with certified quality management systems (ISO 9001) and relevant product certifications (CE, RoHS).

- Insist on comprehensive QC processes covering raw materials, in-process checks, and final product testing.

- Leverage third-party audits and inspections to mitigate risks of substandard products.

- Request and independently test samples to validate supplier quality claims before large-scale procurement.

- Understand regional certification requirements and ensure supplier documentation aligns with local regulations.

By thoroughly understanding manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions, reducing risks and securing reliable, high-performance blue LED strip lighting solutions tailored to their markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip blue lights Sourcing

When sourcing LED strip blue lights for international B2B purposes, understanding the underlying cost structure and pricing dynamics is essential to making informed purchasing decisions. This knowledge is particularly vital for buyers from Africa, South America, the Middle East, and Europe, where import complexities and market conditions vary widely.

Key Cost Components in LED Strip Blue Lights

-

Raw Materials: The primary cost driver is the LED chips themselves, along with the flexible PCB, resistors, and connectors. Blue LEDs often command a slightly higher price compared to standard white LEDs due to specialized semiconductor materials and manufacturing processes. High-grade materials improve brightness and longevity but increase costs.

-

Labor and Manufacturing Overhead: Labor costs depend on the country of manufacture, with China and Southeast Asia typically offering competitive rates. Overhead includes utilities, factory maintenance, and quality control processes, all factored into the unit cost.

-

Tooling and Setup: Custom lengths, specialized adhesives, or packaging require tooling investments. For buyers requesting bespoke designs or branding, tooling costs can be amortized over large orders but may increase unit prices for smaller runs.

-

Quality Control (QC): Rigorous testing for color accuracy, brightness uniformity, waterproofing, and durability adds to costs but ensures reliability. Suppliers offering certifications (e.g., CE, RoHS) typically embed higher QC costs into their pricing.

-

Logistics and Shipping: Freight charges, import duties, and customs clearance fees vary significantly by region. Buyers from Nigeria, Colombia, or the Middle East should anticipate additional costs linked to port handling, inland transportation, and possible tariffs.

-

Supplier Margin: Wholesale suppliers include profit margins that reflect market positioning, order volumes, and service levels. Premium suppliers with strong reputations and after-sales support may price higher but offer better risk mitigation.

Influential Pricing Factors

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders benefit from economies of scale, reducing per-unit costs. MOQ requirements can be a barrier for smaller businesses but serve as a negotiation point for bulk buyers.

-

Product Specifications and Customization: Features such as waterproofing (IP65/IP67), dimmability, or smart controls increase complexity and cost. Custom colors or packaging also add to the final price.

-

Material Quality and Certifications: LED strips with certified components and compliance with international standards command premium pricing but reduce long-term risks of product failures or regulatory issues.

-

Supplier Reliability and Location: Established suppliers with strong supply chains may charge more but ensure consistent quality and delivery times. Proximity to buyers can reduce shipping costs and lead times.

-

Incoterms and Payment Terms: Understanding Incoterms (e.g., FOB, CIF, DDP) affects who bears shipping and insurance costs, influencing total landed cost. Favorable payment terms can improve cash flow and reduce financial risk.

Practical Buyer Tips for Cost-Efficiency

-

Negotiate on Volume and Terms: Leverage bulk purchasing to negotiate price breaks, better payment terms, or free shipping. Consolidate orders where possible to optimize logistics.

-

Assess Total Cost of Ownership (TCO): Beyond unit price, consider warranty, expected lifespan, energy consumption, and potential maintenance costs. Higher upfront investment in quality LED strips often translates into lower TCO.

-

Request Samples and Conduct Testing: Validate product quality and compatibility with your applications before committing to large orders. This reduces risks of costly returns or project delays.

-

Factor in Regional Import Costs: Budget for customs duties, VAT, and local compliance testing. Work with freight forwarders experienced in your region to optimize shipping routes and reduce delays.

-

Build Long-Term Supplier Relationships: Reliable partnerships can unlock volume discounts, priority production slots, and better after-sales support, crucial for repeat buyers in emerging markets.

Indicative Pricing Disclaimer

Prices for LED strip blue lights vary widely based on specifications, order volume, and supplier location. As a general guideline, wholesale prices may range from approximately $0.50 to $3.00 per meter, exclusive of shipping and import duties. Buyers should treat these figures as indicative and conduct direct negotiations with suppliers for accurate quotes tailored to their requirements.

By dissecting the cost structure and understanding the pricing influencers, international B2B buyers can strategically source LED strip blue lights that balance quality, cost, and supply reliability — thereby maximizing value in their lighting projects and commercial ventures.

Spotlight on Potential led strip blue lights Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip blue lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip blue lights

Key Technical Properties of LED Strip Blue Lights

Understanding the critical technical specifications of LED strip blue lights is essential for international B2B buyers to ensure product quality, compatibility, and suitability for their projects. Here are the most important properties to consider:

-

Color Temperature and Wavelength

Blue LED strips typically emit light in the range of 450-495 nanometers. The precise wavelength affects the hue and intensity of the blue light. For B2B buyers, knowing the exact color temperature ensures the lighting meets design requirements, especially for applications like branding, signage, or mood lighting where color accuracy is vital. -

LED Chip Quality (Material Grade)

The type and grade of LED chips used directly influence brightness, energy efficiency, and lifespan. High-quality chips (often from reputable manufacturers) provide consistent light output and longer durability. Buyers should prioritize strips with premium-grade chips to minimize maintenance costs and warranty claims. -

Power Consumption (Wattage per Meter)

This metric defines how much electricity the strip consumes per unit length, commonly expressed in watts per meter (W/m). Lower power consumption means energy savings, which is crucial for large installations. Buyers should balance power usage with desired brightness to optimize operational costs. -

Lumen Output (Brightness)

Measured in lumens per meter, this indicates the brightness level of the LED strip. A higher lumen count means more intense light. For commercial or industrial projects requiring strong illumination, selecting strips with adequate lumen output is important to avoid under-lighting. -

Ingress Protection (IP Rating)

The IP rating specifies the strip’s resistance to dust and water. For outdoor or harsh environment applications, strips with IP65 or higher are recommended. This protects against damage and extends product life, reducing replacement frequency and ensuring reliability. -

Cutting and Soldering Tolerance

LED strips can usually be cut at designated points to fit specific lengths. Understanding the cutting tolerance and soldering requirements ensures proper installation without damaging the circuitry. This flexibility is crucial for custom projects or irregular spaces.

Common Trade Terminology in LED Strip Blue Lights Procurement

Familiarity with industry jargon helps B2B buyers navigate supplier communications, negotiate better deals, and streamline procurement processes. Here are key terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that other companies rebrand and sell. OEM partnerships allow buyers to request customized products, such as specific colors, packaging, or technical specs, enabling unique offerings in their markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and budget accordingly, especially important for small or medium-sized enterprises in regions like Africa and South America where capital may be limited. -

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, lead times, and terms for a specified product quantity and configuration. Using RFQs enables buyers to compare offers systematically and secure the best possible terms. -

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is critical for managing cross-border transactions efficiently. -

Lead Time

The period between placing an order and receiving the goods. Knowing the lead time helps buyers schedule projects and manage inventory, minimizing delays especially in markets with complex logistics like the Middle East and Europe. -

Bin or Reel Quantity

LED strips are often sold in reels or bins containing fixed lengths (e.g., 5m, 10m). Understanding packaging quantities aids in logistics planning and cost estimation, ensuring orders match installation needs without excessive waste.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and build stronger supplier relationships—key factors for success in the competitive LED strip blue lights market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip blue lights Sector

Market Overview & Key Trends

The global market for LED strip blue lights is expanding rapidly, driven by the increasing demand for energy-efficient, customizable lighting solutions across residential, commercial, and industrial sectors. International B2B buyers from regions like Africa, South America, the Middle East, and Europe—countries such as Nigeria and Colombia—are capitalizing on this trend to enhance urban infrastructure, retail environments, and hospitality venues. The blue LED segment is particularly favored for its applications in signage, accent lighting, and specialized environments requiring specific wavelength lighting.

Key market drivers include:

- Energy Efficiency and Cost Savings: Blue LED strip lights consume significantly less power compared to traditional lighting, a crucial factor in regions with high energy costs or unreliable power grids.

- Technological Advancements: Innovations such as dimmable strips, smart control compatibility (via apps or IoT platforms), and improved luminescence have made blue LED strips more versatile and appealing for diverse applications.

- Customization and Flexibility: Wholesale suppliers increasingly offer bespoke solutions, including custom lengths, waterproof designs, and specific color temperatures, allowing buyers to tailor products to unique project requirements.

- Supply Chain Resilience: Recent global disruptions have underscored the importance of diversified sourcing. Buyers are prioritizing suppliers with robust supply chains and multiple component sourcing options, especially for LED modules and drivers.

- Growing Infrastructure and Commercial Projects: Emerging economies in Africa and South America are investing in modern commercial infrastructure and urban lighting projects, stimulating demand for bulk LED strip blue lights with consistent quality and reliable delivery schedules.

For B2B buyers, understanding these dynamics means focusing on suppliers that offer not only competitive pricing but also technological innovation, reliable supply, and customization capabilities. Leveraging digital platforms for supplier comparison and sample testing is increasingly standard practice to mitigate risks and optimize procurement.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central concern for businesses sourcing LED strip blue lights. The environmental impact of lighting products encompasses raw material extraction, manufacturing, energy consumption during use, and end-of-life disposal. Blue LED strip lights, while inherently energy-efficient, vary significantly in their sustainability profiles depending on the materials and manufacturing processes used.

Key sustainability considerations for B2B buyers include:

- Eco-Friendly Materials: Preference should be given to LED strips manufactured with recyclable substrates and non-toxic soldering materials. Suppliers adopting lead-free components and halogen-free flame retardants contribute to reducing environmental hazards.

- Certifications and Standards: Buyers should demand products certified by recognized bodies such as RoHS (Restriction of Hazardous Substances), CE, and Energy Star, which ensure compliance with environmental and safety standards. Additionally, ISO 14001 certification for environmental management systems indicates a supplier’s commitment to sustainable manufacturing.

- Energy Consumption and Longevity: Opting for high-quality LED modules with longer lifespans reduces waste and the frequency of replacements, thus minimizing environmental impact over the product lifecycle.

- Ethical Supply Chains: Transparency in sourcing raw materials like phosphors and semiconductor components is vital. Ethical sourcing policies help avoid conflict minerals and ensure fair labor practices, which are increasingly important to buyers in Europe and the Middle East who face stringent regulatory and consumer pressures.

- Circular Economy Initiatives: Some suppliers now offer take-back programs or design products for easier disassembly and recycling, aligning with global circular economy goals.

For international buyers, integrating sustainability criteria into procurement processes not only supports global environmental goals but also enhances brand reputation and compliance with import regulations in developed markets.

Evolution of LED Strip Blue Lights: A Brief History

LED technology has evolved from simple indicator lights in the 1960s to highly sophisticated, energy-efficient lighting solutions. Blue LEDs were a breakthrough in the early 1990s, enabling full-color LED displays and white LED lighting when combined with phosphors. This innovation paved the way for the flexible LED strip lights market.

Initially used primarily for decorative and signage purposes, LED strip lighting has expanded into architectural, automotive, and industrial applications due to advancements in brightness, durability, and control technologies. The integration of smart features and waterproof designs in the 2010s further broadened their use cases.

For B2B buyers, this historical evolution underscores the maturity and reliability of blue LED strip technology, which now offers a range of customizable, high-performance options suitable for complex international projects requiring consistency and innovation.

By understanding these market dynamics, sourcing trends, and sustainability imperatives, international B2B buyers can make informed decisions that balance cost, quality, and environmental responsibility in the procurement of LED strip blue lights.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip blue lights

-

How can I effectively vet suppliers of LED strip blue lights for international B2B purchases?

Vetting suppliers involves verifying their business credentials, such as business licenses and export permits, especially when sourcing from regions like Asia or Europe. Check for customer reviews and case studies, and request product samples to assess quality firsthand. Engage suppliers who provide clear warranty terms and after-sales support. For buyers in Africa, South America, or the Middle East, prioritizing suppliers with experience in international shipping and customs compliance reduces risks of delays or non-compliance. Establishing direct communication channels and visiting supplier facilities (virtually or physically) can further enhance trust and transparency. -

What customization options are typically available for LED strip blue lights, and how should I approach these?

Many wholesale suppliers offer customization in length, brightness, color temperature, waterproofing, and packaging. For branding purposes, custom packaging or private labeling can differentiate your products in local markets. Before committing, clearly define your technical requirements and confirm minimum order quantities (MOQs) for custom items. Engage suppliers early in the design phase to accommodate specific certifications or regulatory requirements pertinent to your region (e.g., CE for Europe, SONCAP for Nigeria). Ensure prototype samples are approved before full production to avoid costly errors. -

What are the typical MOQ and lead times for LED strip blue lights, and how can I negotiate favorable terms?

MOQs vary widely depending on supplier capacity and customization level but generally range from 500 to 5,000 meters per order. Lead times can span 2 to 8 weeks, factoring in manufacturing and shipping. Buyers should consolidate orders to meet MOQs while optimizing inventory costs. Negotiating with suppliers on partial shipments or trial orders can mitigate risk, especially for new buyers. Establish clear payment terms—such as deposits with balance on delivery—and consider escrow or letter of credit options to protect transactions. Understanding supplier production cycles also helps in planning timely reorders. -

What quality assurance certifications should I look for when sourcing LED strip blue lights internationally?

Prioritize suppliers whose products carry internationally recognized certifications like CE (Europe), RoHS (restriction on hazardous substances), UL or ETL (for North American markets), and ISO 9001 quality management. For buyers in Africa or South America, local certifications such as SONCAP (Nigeria) or INMETRO (Brazil) may apply. Certifications ensure compliance with safety, environmental, and performance standards, reducing liability risks. Request test reports from accredited laboratories and confirm that certifications are current. Incorporating these standards into supplier contracts strengthens quality accountability. -

How can I manage logistics effectively when importing LED strip blue lights to regions like Africa, South America, or the Middle East?

Efficient logistics require partnering with experienced freight forwarders familiar with your destination’s customs regulations and infrastructure. Choose suppliers who offer consolidated shipping options to reduce costs and minimize damage risks. Understand import duties, taxes, and documentation requirements early to avoid clearance delays. For perishable or fragile items, verify packaging standards and insurance coverage. Leveraging Incoterms like FOB or CIF clarifies cost and risk responsibilities between buyer and supplier. Regular communication with logistics partners and tracking shipments in real-time enhances supply chain visibility. -

What payment methods are safest and most practical for international B2B transactions involving LED strip blue lights?

Common methods include wire transfers, letters of credit (LC), PayPal, and escrow services. Letters of credit provide strong protection by ensuring payment only upon fulfillment of agreed terms and documentation, ideal for new supplier relationships. Wire transfers are faster but riskier without established trust. For smaller orders or repeat suppliers, PayPal or escrow platforms offer convenience and dispute resolution. Always verify supplier bank details independently to prevent fraud. Negotiating staged payments tied to production milestones can also safeguard cash flow. -

How should I handle disputes or quality issues with LED strip blue light suppliers?

Clearly define dispute resolution processes in contracts, including timelines for reporting defects and remedies such as replacements, refunds, or repairs. Maintain thorough documentation of communications, samples, and test reports. Engage suppliers promptly upon identifying issues and use third-party inspections if necessary. For international disputes, consider arbitration clauses under recognized bodies (e.g., ICC). Building long-term supplier relationships encourages cooperative problem-solving. In markets with weaker legal frameworks, leveraging trade platforms or sourcing agents can provide additional support. -

What are the key considerations for ensuring compliance with import regulations and standards in my country?

Research and comply with local import regulations, including product safety standards, labeling, and certification requirements. Engage customs brokers or consultants to navigate country-specific procedures, especially in complex markets like Nigeria or Brazil. Ensure your LED strip blue lights meet electrical safety and environmental norms to avoid detention or fines. Prepare accurate commercial invoices, packing lists, and certificates of origin. Staying updated on regulatory changes and trade agreements can optimize tariffs and clearance times, enhancing your supply chain reliability.

Strategic Sourcing Conclusion and Outlook for led strip blue lights

Strategic sourcing of LED strip blue lights presents a compelling opportunity for international B2B buyers to capitalize on cost efficiencies, product innovation, and supply chain resilience. By prioritizing partnerships with reputable suppliers who offer high-quality LED modules and customizable options, businesses can secure lighting solutions tailored to diverse applications — from commercial installations to creative architectural projects. Bulk purchasing not only drives significant price advantages but also ensures consistency across large-scale deployments, a critical factor for maintaining brand and project integrity.

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of supplier reliability, warranty terms, and logistics capabilities is essential to mitigate risks associated with delivery delays and product defects. Leveraging technology-enabled supply chain management tools can further enhance inventory visibility and streamline order fulfillment, enabling agile responses to market demands.

Looking ahead, the LED strip blue lights market is poised for continuous innovation, including smarter, energy-efficient designs that integrate with IoT platforms. International buyers should remain proactive in exploring emerging technologies and diversifying their supplier base to secure competitive advantage and long-term sustainability. Engaging in strategic sourcing today will empower your business to illuminate tomorrow’s opportunities with confidence and efficiency.