Introduction: Navigating the Global Market for led strip adhesive

In the rapidly evolving LED lighting industry, the role of LED strip adhesive is often underestimated despite being a critical determinant of product performance and installation reliability. For international B2B buyers—particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe—the choice of adhesive directly impacts the durability, ease of application, and overall success of LED strip lighting projects. Whether used in commercial installations, architectural designs, or industrial environments, selecting the right adhesive ensures that LED strips maintain firm adhesion under varying temperatures, humidity, and surface conditions.

This comprehensive guide is crafted to empower procurement professionals and technical buyers with actionable insights into the global LED strip adhesive market. It covers types of adhesives and their material compositions, highlighting how each formulation affects installation flexibility and long-term performance. Additionally, the guide explores manufacturing processes and quality control standards, helping buyers assess supplier reliability and product consistency. Key considerations such as cost structures, supplier selection strategies, and compliance with international certifications are also addressed to facilitate informed decision-making.

By understanding the nuanced factors influencing adhesive quality—from raw material sourcing to environmental resilience—buyers can confidently navigate supplier landscapes and negotiate terms that optimize both cost-efficiency and product longevity. This resource is especially valuable for stakeholders in emerging and established markets like Mexico, Brazil, Turkey, and the UK, where tailored adhesive solutions can unlock competitive advantages in LED lighting deployments.

With this guide, international B2B buyers will gain a strategic edge in sourcing LED strip adhesives that meet stringent performance criteria while supporting sustainable and scalable lighting innovations worldwide.

Understanding led strip adhesive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic-Based Adhesive | Strong initial tack, weather-resistant, medium peel strength | Indoor installations, retail displays, signage | Pros: Easy application, reliable hold on smooth surfaces; Cons: May degrade under prolonged UV exposure |

| Silicone-Based Adhesive | High flexibility, excellent heat and moisture resistance | Industrial, automotive, outdoor lighting | Pros: Durable in harsh environments, repositionable; Cons: Higher cost, slower curing time |

| Double-Sided Foam Tape | Thick cushioning layer, excellent gap-filling properties | Uneven surfaces, curved installations | Pros: Provides vibration dampening, strong adhesion on rough surfaces; Cons: Bulkier, less aesthetic |

| Hot Melt Adhesive | Fast curing, thermoplastic properties | Mass production, automated assembly lines | Pros: Rapid bonding, strong adhesion; Cons: Requires heat application, less suitable for delicate surfaces |

| Pressure-Sensitive Adhesive (PSA) | Activates with light pressure, no curing needed | Temporary fixtures, prototyping, flexible layouts | Pros: Easy to use, repositionable; Cons: Lower adhesion strength for permanent applications |

Acrylic-Based Adhesive

Acrylic-based adhesives are widely used in LED strip applications due to their strong initial tack and reliable adhesion on smooth, clean surfaces. They offer good resistance to weathering, making them suitable for indoor environments such as retail displays and architectural lighting. For B2B buyers, acrylic adhesives represent a cost-effective choice with predictable performance, but care should be taken when specifying products for outdoor use where UV exposure can degrade the bond over time.

Silicone-Based Adhesive

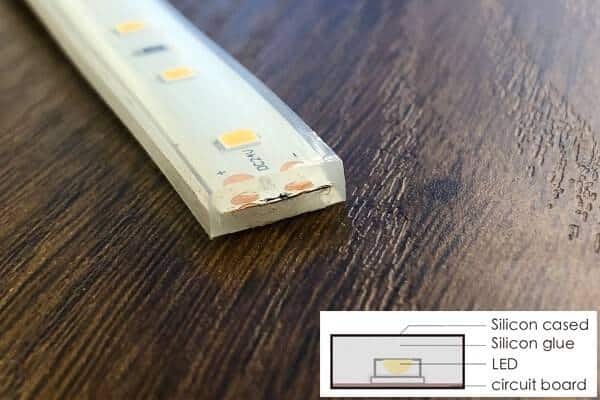

Silicone adhesives excel in environments that demand flexibility and resistance to extreme temperatures and moisture. This makes them ideal for industrial and automotive lighting applications where durability is critical. While silicone adhesives typically come at a higher price point and require longer curing times, their longevity and resistance to environmental stressors justify the investment for buyers targeting markets with challenging conditions, such as the Middle East or coastal regions in South America.

Double-Sided Foam Tape

Double-sided foam tapes provide a thick, cushioning adhesive layer that is particularly effective for mounting LED strips on uneven or textured surfaces. This type is favored in applications requiring vibration dampening or where the substrate is curved or irregular, such as in automotive interiors or architectural features. B2B buyers should weigh the trade-off between the foam tape’s bulkier profile and its superior adhesion on difficult surfaces, especially in projects demanding both durability and aesthetics.

Hot Melt Adhesive

Hot melt adhesives are thermoplastic and cure rapidly when cooled, making them suitable for high-volume manufacturing environments with automated assembly lines. They provide strong bonds quickly but require heat application during installation, which may limit their use on heat-sensitive materials. For international buyers, hot melt adhesives offer efficiency gains in production but necessitate compatible equipment and training to optimize application.

Pressure-Sensitive Adhesive (PSA)

PSAs activate adhesion with light pressure and do not require curing, offering ease of use and repositionability. These adhesives are ideal for temporary fixtures, prototyping, or flexible layouts where LED strips may need to be adjusted or removed. However, PSAs generally provide lower adhesion strength compared to other types, making them less suitable for permanent installations. B2B buyers should consider PSAs for projects emphasizing flexibility and rapid deployment, particularly in fast-changing retail or event environments.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of led strip adhesive

| Industry/Sector | Specific Application of led strip adhesive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural & Interior Design | Secure mounting of LED strips on diverse surfaces like drywall, wood, and metal | Ensures long-lasting installation with clean aesthetics, reducing maintenance and rework costs | Adhesive must have strong bonding on multiple substrates, resist temperature and humidity variations common in different climates |

| Automotive Manufacturing | Attaching LED strips inside vehicle cabins and exterior trims | Provides durable, vibration-resistant adhesion that withstands automotive environmental stresses | Adhesive needs automotive-grade certifications, UV resistance, and flexibility for curved surfaces |

| Retail & Commercial Display | Fixing LED strips on display cases, signage, and shelving units | Enhances product visibility and customer engagement through reliable lighting | Requires adhesives with clear, residue-free removal and strong adhesion on glass, plastic, and metal |

| Electronics & Appliance Assembly | Integrating LED strips into consumer electronics and appliances | Enables compact, secure lighting solutions that improve product functionality and appeal | Must meet electronic safety standards, be non-corrosive, and maintain adhesion under heat generated by devices |

| Hospitality & Event Management | Temporary and permanent installation of LED lighting in venues | Allows flexible, damage-free installation and repositioning, optimizing ambiance and event aesthetics | Adhesive should allow easy installation/removal without damaging surfaces, and maintain performance under varied environmental conditions |

In the Architectural & Interior Design sector, LED strip adhesive is critical for mounting lighting on a wide variety of surfaces, including drywall, wood, and metal. Buyers from regions such as Europe and South America often face diverse climate conditions, making it essential that adhesives provide strong, durable bonds resistant to humidity and temperature fluctuations. This ensures installations remain secure and visually appealing over time, reducing costly maintenance or replacements.

Illustrative Image (Source: Google Search)

Within Automotive Manufacturing, LED strip adhesives must withstand the unique challenges posed by vehicle environments—vibrations, temperature extremes, and exposure to UV light. Automotive-grade adhesives are indispensable for securely attaching LED strips inside cabins or on exterior trims without failure. For international buyers in markets like the Middle East and Africa, sourcing adhesives compliant with automotive standards ensures product reliability and customer satisfaction.

In Retail & Commercial Display applications, LED strip adhesives play a vital role in securing lighting elements on glass, plastic, and metal surfaces of display cases and signage. The adhesive must offer strong bonding while allowing for residue-free removal or repositioning to accommodate changing retail layouts. This flexibility is especially valuable for businesses in fast-growing markets such as Mexico and Brazil, where visual merchandising agility drives sales performance.

For Electronics & Appliance Assembly, LED strip adhesives are used to integrate lighting within compact consumer devices and appliances. The adhesive must be non-corrosive, maintain strong adhesion despite heat generated by electronics, and comply with safety standards. Buyers from diverse industrial hubs in Europe and South America should prioritize adhesives that support product longevity and compliance with international electronic safety certifications.

Lastly, in Hospitality & Event Management, LED strip adhesives enable both temporary and permanent lighting installations in venues. The ability to install or remove lighting without surface damage is crucial for event spaces that frequently change setups. Adhesives suited for this sector must perform well under varied environmental conditions, a key consideration for buyers operating in the Middle East and Africa where ambient temperatures and humidity can vary widely. This flexibility enhances ambiance control while protecting venue infrastructure.

Related Video: T2C Applycut – Automatic adhesive tape applicator

Strategic Material Selection Guide for led strip adhesive

When selecting adhesives for LED strip applications, material choice critically influences product reliability, installation ease, and long-term performance. International B2B buyers—especially those sourcing for markets in Africa, South America, the Middle East, and Europe—must weigh adhesive properties against environmental conditions, regulatory standards, and cost constraints. Below is an analysis of four common adhesive materials used in LED strip backings, highlighting their technical characteristics and strategic implications for global buyers.

Acrylic Adhesives

Key Properties: Acrylic adhesives are known for their strong bonding strength and excellent resistance to UV light, temperature extremes (typically -40°C to 150°C), and aging. They offer good chemical and corrosion resistance, making them suitable for outdoor and industrial environments.

Pros & Cons: Acrylic adhesives provide durable adhesion with long service life, maintaining stickiness even in humid or hot climates. However, they tend to be more expensive than other adhesives and can be less flexible, which might limit their use on highly curved or flexible LED strip installations.

Impact on Application: Acrylic adhesives are ideal for LED strips installed in demanding environments such as outdoor signage, architectural lighting, or industrial settings where exposure to sunlight and temperature fluctuations is common. Their resistance to corrosion and degradation ensures consistent performance.

Considerations for International Buyers: Buyers from regions like the Middle East and South America, where high temperatures and intense sunlight prevail, will benefit from acrylic adhesives’ UV and heat resistance. Compliance with international standards such as ASTM D1000 (for pressure-sensitive tapes) and DIN EN ISO 9001 quality management is common among premium acrylic adhesive suppliers, ensuring reliability and traceability.

Silicone-Based Adhesives

Key Properties: Silicone adhesives excel in high-temperature resistance (up to 250°C) and flexibility. They maintain adhesion under thermal cycling and resist moisture, chemicals, and oxidation.

Pros & Cons: Their outstanding thermal stability makes silicone adhesives suitable for LED strips used in high-heat applications, such as automotive or industrial machinery. However, silicone adhesives generally have lower initial tack and adhesion strength compared to acrylics and are more costly and complex to manufacture.

Impact on Application: Silicone adhesives are preferred where LED strips are exposed to extreme heat or require flexibility, such as curved surfaces or electronic assemblies with heat dissipation needs. Their chemical inertness also suits harsh chemical environments.

Considerations for International Buyers: For buyers in industrial hubs across Europe and the Middle East, silicone adhesives provide a premium solution for high-performance LED strips. Ensuring suppliers comply with standards like JIS Z 0237 (Japanese Industrial Standard for silicone adhesives) and RoHS directives is crucial to meet local regulations and environmental requirements.

Rubber-Based Adhesives

Key Properties: Rubber adhesives offer strong initial tack and good adhesion to a variety of substrates, including plastics and metals. They function well in moderate temperature ranges (-20°C to 80°C) but have limited resistance to UV exposure and chemical degradation.

Pros & Cons: Rubber adhesives are cost-effective and easy to apply, making them popular for indoor LED strip installations. Their main limitation is reduced durability in outdoor or high-temperature environments, where adhesive failure or peeling can occur.

Impact on Application: Best suited for indoor decorative lighting, retail displays, and temporary installations, rubber adhesives provide sufficient bonding strength while keeping costs low.

Considerations for International Buyers: Buyers targeting markets in Africa and South America, where indoor applications dominate and budget constraints are significant, will find rubber adhesives attractive. However, verifying supplier adherence to ASTM D3330 (peel adhesion test) and local fire safety standards is recommended to avoid quality issues.

Hot Melt Adhesives (Thermoplastic)

Key Properties: Hot melt adhesives solidify quickly upon cooling and offer good adhesion to various surfaces. They provide moderate temperature resistance (up to 120°C) and excellent flexibility.

Pros & Cons: These adhesives enable fast manufacturing cycles and are generally lower cost than silicone or acrylic adhesives. However, they can degrade under prolonged UV exposure and may lose adhesion in very high humidity or heat conditions.

Impact on Application: Hot melt adhesives are suitable for mass production of flexible LED strips intended for indoor use or controlled environments. They allow efficient assembly line processes but may require protective coatings for outdoor use.

Considerations for International Buyers: For buyers in Europe and Mexico focusing on high-volume production with moderate environmental demands, hot melt adhesives offer a cost-efficient option. Compliance with DIN EN 71 (safety of toys, relevant for decorative lighting) and ISO 9001 manufacturing standards helps ensure product consistency.

Summary Table

| Material | Typical Use Case for led strip adhesive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic Adhesives | Outdoor signage, architectural lighting, industrial | Excellent UV and temperature resistance | Higher cost and less flexibility | High |

| Silicone Adhesives | High-heat industrial, automotive, flexible surfaces | Superior thermal stability and flexibility | Lower initial tack, higher cost and complexity | High |

| Rubber Adhesives | Indoor decorative lighting, retail displays | Strong initial tack, cost-effective | Poor UV and chemical resistance | Low |

| Hot Melt Adhesives | Mass production of flexible indoor LED strips | Fast curing, cost-efficient | Limited UV and moisture resistance | Medium |

This guide equips international B2B buyers with a clear understanding of adhesive material options tailored to LED strip applications. By aligning adhesive choice with environmental conditions, regulatory compliance, and cost considerations, buyers can optimize product performance and customer satisfaction across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip adhesive

Manufacturing Processes for LED Strip Adhesive

The production of LED strip adhesive, a critical component ensuring secure and durable attachment of LED strips to various surfaces, involves a series of meticulously controlled stages. Each stage directly impacts the adhesive’s performance, longevity, and suitability for diverse applications—factors that are particularly important for international B2B buyers sourcing for markets in Africa, South America, the Middle East, and Europe.

1. Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. High-quality pressure-sensitive adhesives (PSAs), often acrylic or silicone-based, are chosen for their balance of strong initial tack, temperature resistance, and long-term durability. Fillers, tackifiers, and stabilizers may be blended to tailor adhesive properties such as peel strength and environmental resistance.

Material preparation also involves precise mixing under controlled temperature and humidity conditions to ensure homogeneity and prevent contamination. This step is essential to achieving consistent adhesive performance across production batches.

2. Forming and Coating

Once prepared, the adhesive compound is coated onto a carrier substrate—typically a liner material such as polyester film or paper. This coating process employs advanced techniques like roll-to-roll coating or knife-over-roll coating, enabling uniform adhesive layers with controlled thickness.

Key factors in this stage include:

- Coating uniformity: Ensures consistent adhesion and prevents weak spots.

- Drying and curing: Depending on adhesive chemistry, thermal or UV curing is applied to stabilize the adhesive film.

- Liner quality: The release liner must allow easy application without damaging the adhesive surface.

3. Assembly and Lamination

The adhesive-coated liner is laminated onto the backing material that will directly contact the LED strip or mounting surface. This backing could be flexible plastic films or specialty tapes engineered to withstand mechanical stresses and environmental factors like moisture and UV exposure.

During assembly, tension control and alignment precision are critical to prevent defects such as wrinkles, bubbles, or delamination. Automated inspection systems are often integrated to detect surface irregularities in real-time.

4. Finishing and Conversion

The final stage involves cutting or slitting the adhesive rolls into standardized sizes or custom shapes according to client specifications. Edge finishing techniques ensure clean cuts that facilitate easy handling and installation.

Packaging is also a vital finishing step, designed to protect the adhesive from dust, humidity, and physical damage during international shipping. Protective wraps, moisture barriers, and carton reinforcements are common practices.

Quality Assurance and Control for LED Strip Adhesive

For B2B buyers, especially those operating across diverse regulatory environments, understanding the quality assurance framework behind LED strip adhesive manufacturing is essential. Robust quality control (QC) processes ensure product reliability, compliance, and customer satisfaction.

Relevant International and Industry Standards

- ISO 9001: The foundational quality management system standard ensuring consistent production processes, traceability, and continual improvement.

- CE Marking: Mandatory for products entering the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Important for markets focused on environmental compliance, limiting hazardous chemicals in adhesives.

- UL Certification: Relevant for electrical components, indicating fire safety and electrical performance.

- API Standards: Applicable when adhesives are used in industrial or energy sectors, ensuring chemical resistance and durability.

Buyers should verify suppliers’ certifications to ensure adherence to these standards, which mitigate risks related to product failure or regulatory non-compliance.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC): Raw materials such as adhesive compounds, liners, and backing films undergo rigorous testing for purity, viscosity, and physical properties. This prevents substandard inputs from affecting final product quality.

-

In-Process Quality Control (IPQC): Continuous monitoring during coating, lamination, and curing stages includes thickness measurement, adhesion strength tests, and surface inspection. Automated sensors and inline testers help maintain process consistency.

-

Final Quality Control (FQC): Before shipment, finished adhesive rolls or tapes are subjected to peel adhesion tests, shear strength evaluations, and environmental aging simulations to confirm performance criteria are met.

Common Testing Methods for Adhesive Quality

- Peel Adhesion Test: Measures the force required to peel the adhesive from a substrate, critical for installation reliability.

- Tack Test: Assesses the initial stickiness of the adhesive surface.

- Shear Strength Test: Evaluates the adhesive’s resistance to sliding forces under sustained load.

- Environmental Resistance Testing: Simulates exposure to heat, humidity, UV light, and chemicals to predict long-term durability.

- Thickness and Uniformity Measurement: Ensures consistent application across batches.

How B2B Buyers Can Verify Supplier Quality Control

-

Factory Audits: Onsite inspections or virtual audits assess manufacturing processes, equipment calibration, and worker training. Buyers should request audit reports or conduct third-party inspections to validate claims.

-

Supplier Quality Reports: Request detailed QC data, including batch test results, certificates of analysis, and compliance documentation.

-

Third-Party Testing: Independent laboratories can perform confirmatory tests on adhesive samples to verify performance and certification claims.

-

Sample Evaluation: Procuring samples for in-house testing under actual application conditions helps validate supplier quality before large-scale procurement.

Quality Assurance Nuances for International B2B Buyers

-

Regional Compliance Variations: Buyers from Africa, South America, the Middle East, and Europe must consider local regulatory requirements which may differ significantly. For example, European buyers prioritize CE and RoHS compliance, while Middle Eastern buyers may focus on UL certifications for electrical safety.

-

Climate Adaptability: Adhesives must be suitable for local environmental conditions—high humidity in Brazil, extreme heat in the Middle East, or varying temperatures in Europe. Suppliers should provide data on adhesive performance under these specific conditions.

-

Supply Chain Transparency: Geopolitical and logistical challenges in regions like Africa and South America necessitate transparent supply chains and reliable quality assurance to avoid delays or quality degradation during transit.

-

Customized Solutions: Buyers should engage with suppliers capable of tailoring adhesive formulations to meet specific installation substrates, temperature ranges, and longevity requirements common in their target markets.

Summary for B2B Buyers:

Selecting the right LED strip adhesive involves understanding its complex manufacturing process and stringent quality assurance systems. Prioritize suppliers who demonstrate adherence to international standards, maintain comprehensive QC checkpoints, and offer transparent quality documentation. Engage in supplier audits, request thorough test reports, and conduct in-house sample testing to mitigate risks and ensure product reliability tailored to your regional market conditions. This strategic approach enables buyers across Africa, South America, the Middle East, and Europe to secure adhesive solutions that support durable, safe, and efficient LED strip installations.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip adhesive Sourcing

When sourcing LED strip adhesive, understanding the full cost structure and pricing dynamics is essential for international B2B buyers aiming to optimize procurement efficiency and product performance. The cost components extend beyond the raw adhesive material to encompass a range of factors influencing the final price and total cost of ownership.

Key Cost Components in LED Strip Adhesive Pricing

- Raw Materials: The adhesive’s chemical formulation, such as acrylic, silicone, or rubber-based compounds, significantly affects cost. Premium materials offering superior heat resistance, UV stability, and strong bonding to PCB and substrate surfaces typically command higher prices.

- Labor: Skilled labor costs for mixing, quality control, and application processes vary by manufacturing location. Countries with advanced automation may reduce labor intensity but could have higher wage structures.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines focused on adhesive consistency and curing processes help control overhead.

- Tooling and Equipment: Specialized machinery for coating adhesive layers uniformly on backing materials or reels can influence upfront costs, often amortized over large production runs.

- Quality Control (QC): Rigorous testing for adhesive tackiness, peel strength, temperature tolerance, and aging ensures product reliability. QC efforts add to cost but reduce downstream failure risks.

- Logistics and Shipping: International freight, customs duties, and packaging designed to protect adhesive properties during transit add to the landed cost, especially for buyers in Africa, South America, the Middle East, and Europe.

- Supplier Margin: Manufacturers and distributors set margins based on market demand, exclusivity of formulations, and service levels such as certification support and after-sales service.

Factors Influencing Pricing for LED Strip Adhesive

- Order Volume and Minimum Order Quantity (MOQ): Bulk purchases usually attract lower per-unit prices. Buyers from emerging markets like Mexico and Brazil should negotiate MOQ terms aligned with their project scale to balance inventory costs.

- Specifications and Customization: Adhesives tailored for specific LED strip types (e.g., flexible PCBs, high-temperature strips) or environmental conditions (outdoor, humidity) tend to be costlier due to R&D and formulation complexity.

- Material Quality and Certifications: Adhesives compliant with international standards (e.g., RoHS, REACH, UL) not only command premium pricing but also facilitate smoother customs clearance and market acceptance.

- Supplier Reputation and Location: Established suppliers with proven quality track records might price higher but offer reliability and lower risk. Proximity to supplier hubs or free trade agreements can reduce logistics expenses.

- Incoterms: Terms such as FOB, CIF, or DDP affect who bears shipping, insurance, and customs costs, directly impacting landed cost and cash flow for buyers.

Strategic Tips for International B2B Buyers

- Negotiate Beyond Price: Engage suppliers on payment terms, lead times, and after-sales support. Volume discounts can be combined with flexible delivery schedules to optimize working capital.

- Evaluate Total Cost of Ownership (TCO): Consider adhesive longevity, installation efficiency, and potential failure rates rather than just unit price. A cheaper adhesive with poor bonding can increase warranty claims and maintenance costs.

- Leverage Local Market Insights: Buyers in Africa and South America should assess local climatic challenges—such as high humidity or temperature fluctuations—and specify adhesives accordingly to avoid premature adhesive degradation.

- Understand Pricing Nuances: Be aware of currency fluctuations and inflation impacts in supplier countries. Long-term contracts with price adjustment clauses indexed to raw material costs can provide stability.

- Verify Certification and Compliance: Request documentation to ensure adhesives meet necessary regulatory and environmental standards for your region, reducing import delays and compliance risks.

Indicative Pricing Disclaimer

Pricing for LED strip adhesives varies widely depending on formulation, volume, and supplier capabilities. Buyers should treat quoted prices as indicative and perform due diligence through sample testing and supplier audits before finalizing contracts.

By dissecting cost components and pricing influencers, international B2B buyers can make informed sourcing decisions that align with quality expectations and budgetary constraints, unlocking value in their LED strip adhesive procurement strategies.

Spotlight on Potential led strip adhesive Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip adhesive’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip adhesive

Understanding the technical properties and trade terminology related to LED strip adhesive is crucial for international B2B buyers to ensure product quality, installation reliability, and smooth procurement processes. Below is a detailed overview of key adhesive properties and common industry terms to empower buyers in Africa, South America, the Middle East, and Europe to make informed decisions.

Critical Technical Properties of LED Strip Adhesive

1. Adhesion Strength

This measures how firmly the adhesive bonds the LED strip to various surfaces such as metal, plastic, or wood. Strong adhesion is vital to prevent peeling or detachment over time, especially in environments with temperature fluctuations or humidity. For buyers, selecting adhesives with high adhesion strength guarantees long-lasting installation and reduces maintenance costs.

2. Temperature Resistance

LED strips generate heat during operation, so the adhesive must withstand elevated temperatures without losing its bonding capability or degrading. Typical temperature resistance ranges from -20°C up to +80°C or higher for specialized products. Buyers should verify that the adhesive matches the operational temperature range of their lighting application to ensure durability.

3. Material Compatibility

Not all adhesives work well with every substrate or LED strip backing material (e.g., flexible PCBs). Compatibility ensures the adhesive adheres properly without causing chemical reactions or damaging the strip. For B2B buyers, confirming this compatibility reduces the risk of installation failures and product returns.

4. Thickness and Flexibility

Adhesive thickness affects the overall profile of the LED strip and its flexibility. Thin, flexible adhesives are preferred for curved or irregular surfaces to maintain strip conformity and appearance. Buyers targeting architectural or decorative lighting projects should prioritize adhesives with suitable thickness and elasticity to meet their design needs.

5. UV and Moisture Resistance

In outdoor or high-humidity environments, adhesives must resist UV exposure and moisture to avoid degradation and loss of adhesion. This property is particularly important for buyers in regions with strong sunlight or tropical climates, ensuring the LED strips remain securely mounted and functional over time.

6. Peel and Shear Strength

These mechanical properties describe the adhesive’s resistance to forces trying to pull or slide the strip off the mounting surface. High peel and shear strength contribute to the adhesive’s robustness under mechanical stress, such as vibrations or handling during installation. Buyers should request datasheets specifying these values to assess product reliability.

Common Trade Terminology for LED Strip Adhesive Procurement

OEM (Original Equipment Manufacturer)

Refers to companies that produce the LED strips or adhesives that other brands sell under their own label. Understanding OEM relationships helps buyers source directly from manufacturers or authorized resellers, often leading to better pricing and quality assurance.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs can vary widely based on supplier capabilities and product type. B2B buyers, especially from emerging markets, should negotiate MOQs to optimize inventory costs and cash flow without compromising supplier relationships.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for detailed pricing, delivery terms, and product specifications. Knowing how to craft and respond to RFQs efficiently helps buyers compare offers transparently and select suppliers that meet their technical and commercial requirements.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance between buyers and sellers (e.g., FOB, CIF, DDP). Understanding Incoterms is essential for international buyers to control logistics costs, minimize risks, and comply with local import regulations.

Lead Time

The period between placing an order and receiving the goods. For LED strip adhesive, lead times can vary due to production schedules or shipping constraints. Accurate lead time estimates enable buyers to plan installation projects and manage supply chains effectively.

Certification Compliance

Adhesives used in LED strip applications often require certifications such as RoHS (Restriction of Hazardous Substances) or UL (Underwriters Laboratories) to meet safety and environmental standards. Buyers should verify these certifications to ensure product legality and market acceptance, particularly in Europe and regulated markets.

By focusing on these technical properties and trade terms, international B2B buyers can enhance supplier evaluation, optimize product performance, and navigate global procurement challenges with confidence. Selecting the right LED strip adhesive not only improves installation quality but also contributes to the overall success and longevity of lighting projects across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip adhesive Sector

Market Overview & Key Trends

The global market for LED strip adhesives is experiencing robust growth driven by the expanding adoption of LED strip lighting across residential, commercial, and industrial applications. For international B2B buyers—especially those in emerging and mature markets such as Africa, South America (including Mexico and Brazil), the Middle East, and Europe—the demand for high-performance adhesives tailored to LED strip technology is intensifying. These adhesives must deliver strong bonding on diverse surfaces, withstand heat generated by LED chips and PCBs, and maintain longevity in various environmental conditions.

Key market drivers include the surge in smart lighting solutions, growing infrastructure development, and increased focus on energy-efficient lighting systems. Buyers are prioritizing adhesives that offer not only strong initial tack but also excellent durability against factors like humidity, UV exposure, and thermal cycling. The rise of flexible and addressable LED strips further demands adhesives with enhanced flexibility and resistance to mechanical stress.

Emerging sourcing trends highlight a move toward customized adhesive formulations optimized for specific LED strip types—rigid, flexible, or waterproof variants. Suppliers increasingly offer technical support for selecting adhesives compatible with different substrates such as aluminum, plastics, and glass. Additionally, supply chain resilience has become a critical consideration due to recent disruptions, motivating buyers to diversify sourcing across regions like Southeast Asia, Europe, and the Middle East.

For buyers from Africa and South America, local climatic conditions (high humidity, temperature fluctuations) necessitate adhesives with proven environmental stability. European and Middle Eastern buyers often emphasize compliance with regional regulations and certifications, such as REACH and RoHS, influencing adhesive selection. Strategic partnerships with manufacturers that provide transparent quality control and consistent product performance are increasingly valued to mitigate risks associated with adhesive failure and warranty claims.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the procurement of LED strip adhesives, reflecting broader corporate social responsibility goals and regulatory pressures. Adhesive formulations traditionally involve chemicals that may pose environmental and health risks if not managed properly. For B2B buyers targeting international markets, prioritizing eco-friendly adhesives that minimize volatile organic compounds (VOCs) and hazardous substances is essential.

Ethical sourcing of raw materials—such as polymers, tackifiers, and solvents—ensures supply chain transparency and reduces the environmental footprint. Buyers are increasingly scrutinizing suppliers’ adherence to standards like ISO 14001 (Environmental Management) and certifications for low chemical emissions. Additionally, manufacturers committed to sustainable practices often provide product lifecycle assessments, helping buyers quantify environmental impact and meet green building requirements (e.g., LEED certification).

Green certifications relevant to LED strip adhesives include UL GREENGUARD, Blue Angel, and certifications aligned with EU environmental directives. These labels signal reduced emissions and safer chemical profiles, which are particularly important for indoor lighting applications where air quality is a concern.

For regions like Africa and South America, the push for sustainable adhesives is also linked to local regulatory developments and consumer demand for greener products. European and Middle Eastern buyers frequently require documented compliance with circular economy principles, encouraging suppliers to innovate with recyclable or bio-based adhesive components.

Ultimately, integrating sustainability into sourcing decisions not only mitigates environmental risks but also enhances brand reputation and market access in environmentally conscious regions.

Evolution and Historical Context

The adhesive technology used in LED strip lighting has evolved significantly alongside advancements in LED manufacturing and design. Initially, generic double-sided tapes were employed, often resulting in poor adhesion and early failure due to heat and surface incompatibility. Over time, the industry recognized the need for specialized adhesives engineered to meet the unique challenges of LED strip installation.

Modern LED strip adhesives incorporate silicone, acrylic, or hybrid polymer bases, offering improved heat resistance, UV stability, and substrate versatility. These developments enable secure installation on a variety of surfaces—from smooth glass panels to textured walls—without compromising the LED strip’s performance or lifespan.

This evolution reflects broader trends in electronics assembly and smart lighting, where adhesive innovation supports miniaturization, flexibility, and durability. For international B2B buyers, understanding this history underscores the importance of partnering with suppliers who invest in adhesive R&D and can tailor solutions to the specific demands of contemporary LED strip applications.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip adhesive

-

How can I effectively vet suppliers of LED strip adhesive to ensure quality and reliability?

To vet suppliers, start by requesting detailed product specifications, certifications (such as RoHS, CE), and sample materials for testing adhesion strength and durability under your specific environmental conditions. Verify the supplier’s manufacturing capabilities, quality control processes, and compliance with international standards. Check their track record with references or customer reviews, especially from buyers in similar markets like Africa or South America. Consider visiting factories if possible or using third-party inspection services to confirm production quality and capacity before committing to large orders. -

Is it possible to customize the adhesive properties of LED strip adhesives for different applications?

Yes, many manufacturers offer customization options for LED strip adhesives, including variations in adhesive strength, temperature resistance, and backing material compatibility. This is crucial when your application environment varies widely—such as high humidity in the Middle East or extreme temperatures in Europe. Discuss your project requirements with suppliers early to explore tailored formulations that ensure optimal adhesion without damaging surfaces. Customization may affect lead times and minimum order quantities, so plan accordingly. -

What are typical minimum order quantities (MOQs) and lead times for LED strip adhesive in international B2B trade?

MOQs vary by supplier and adhesive type but generally range from 500 to 5,000 units or more, depending on customization. Lead times typically span 3 to 8 weeks, influenced by order size, customization needs, and current supply chain conditions. For buyers in regions such as Mexico or Brazil, factor in additional shipping and customs clearance time. Early communication with suppliers about your order volume and timelines can help optimize production scheduling and avoid delays. -

Which payment terms are standard when sourcing LED strip adhesive internationally, and how can buyers protect themselves?

Common payment terms include 30% upfront deposit with the balance paid upon shipment or delivery. Letters of credit (LC) and escrow services offer added security for large transactions. For new suppliers, negotiate smaller initial orders or request samples before full payment. Use trade insurance or payment platforms that offer dispute resolution. Building long-term relationships with trusted suppliers often leads to more flexible payment terms over time. -

What quality assurance and certifications should I look for when purchasing LED strip adhesives?

Look for adhesives certified to meet international standards such as RoHS (Restriction of Hazardous Substances), REACH compliance, and ISO 9001 quality management certification. These ensure the adhesive is safe, environmentally friendly, and consistently manufactured. Additionally, inquire about batch testing reports and durability assessments under temperature and humidity extremes. Certifications provide confidence in product consistency, especially important for markets in Europe and the Middle East with strict regulatory environments. -

How should I manage logistics and shipping challenges for LED strip adhesives to regions like Africa or South America?

Due to the adhesive’s chemical composition, classify shipments according to international hazardous materials regulations if applicable. Choose reliable freight forwarders experienced in handling chemical products and customs procedures in your destination countries. Consolidate shipments to reduce costs but avoid excessive delays. Track orders closely and prepare for potential customs inspections. Consider local warehousing partners to expedite distribution once the product arrives in your target region.

Illustrative Image (Source: Google Search)

-

What steps can I take to resolve disputes or quality issues with LED strip adhesive suppliers?

Establish clear contractual terms covering product specifications, delivery timelines, and dispute resolution mechanisms before ordering. If issues arise, document discrepancies with photos and detailed reports. Engage in direct communication with your supplier to seek amicable solutions such as replacement shipments or refunds. Utilize third-party arbitration or mediation if necessary. Maintaining open dialogue and thorough records throughout the transaction reduces misunderstandings and supports effective conflict resolution. -

How can I evaluate the total cost of ownership beyond the adhesive’s purchase price?

Consider factors such as adhesive performance longevity, ease of installation, compatibility with your LED strips, and potential warranty claims. Poor adhesive quality can lead to rework costs, product returns, and damage to your brand reputation. Factor in shipping costs, import duties, and storage requirements, especially for international shipments to regions with complex customs processes. Investing in a slightly higher-cost adhesive with proven durability often results in better ROI by minimizing maintenance and replacement expenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip adhesive

Strategic sourcing of LED strip adhesives is a critical determinant of product performance, installation reliability, and long-term durability. For international B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing adhesives that combine strong bonding strength with environmental resilience ensures optimal outcomes in diverse application environments. High-quality adhesive materials contribute significantly to the overall system’s stability, preventing peeling or degradation that can undermine lighting efficiency and customer satisfaction.

Key takeaways for buyers include:

- Material Compatibility: Select adhesives compatible with various PCB substrates and LED strip materials to maximize adhesion without compromising flexibility or heat dissipation.

- Environmental Durability: Consider adhesives designed to withstand humidity, temperature fluctuations, and UV exposure common in target markets.

- Supplier Reliability: Partner with manufacturers who demonstrate rigorous quality control, certification compliance, and transparency in sourcing to mitigate risks in supply chains.

Looking ahead, the LED strip adhesive market is poised to benefit from ongoing innovations in polymer chemistry and sustainable materials, offering buyers enhanced performance coupled with eco-conscious credentials. As lighting solutions evolve toward more complex and customizable designs, sourcing adhesives that align with these technological advancements will be essential.

For B2B buyers aiming to future-proof their procurement strategies, engaging early with trusted adhesive suppliers and investing in comprehensive testing protocols will unlock competitive advantages in quality and reliability across global markets.