Introduction: Navigating the Global Market for led strip 12v auto

The global demand for 12V LED strip lights designed specifically for automotive applications is surging, driven by their unmatched combination of energy efficiency, durability, and design flexibility. For B2B buyers across Africa, South America, the Middle East, and Europe—regions experiencing rapid automotive sector growth and infrastructure development—understanding this market is critical to securing competitive, high-quality lighting solutions that meet local and international standards.

This guide offers a comprehensive roadmap to mastering the complexities of sourcing led strip 12v auto products. It covers the full spectrum—from differentiating between types such as single-color, RGB, and flexible strips, to dissecting the importance of premium materials like LED chips, PCB substrates, and adhesive backings that directly impact performance and longevity. We delve into manufacturing processes and rigorous quality control measures that ensure compliance with global certifications, reducing risks and boosting reliability.

In addition, you will find detailed insights into evaluating suppliers, benchmarking costs, and navigating market dynamics tailored to diverse regional demands. Practical FAQs address common sourcing challenges and technical considerations to empower your procurement strategy.

By leveraging this guide, international B2B buyers—whether based in Nairobi, São Paulo, Dubai, or Berlin—will be equipped to make informed, strategic decisions that optimize value, enhance product quality, and support sustainable growth in their automotive lighting offerings. Unlock the potential of 12V LED strip lights and illuminate your path to successful global partnerships.

Understanding led strip 12v auto Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Color 12V LED Strip | Monochromatic LEDs, typically white or warm white; simple control | Automotive ambient lighting, dashboard illumination, accent lighting | Pros: Cost-effective, easy installation, reliable performance; Cons: Limited color options, less dynamic lighting |

| RGB 12V LED Strip | Multi-color LEDs with red, green, blue chips; color-changing via controller | Vehicle interior/exterior customization, commercial signage, event lighting | Pros: Versatile color options, dynamic effects; Cons: Higher cost, requires controller and wiring complexity |

| Waterproof 12V LED Strip | Encapsulated with silicone or epoxy coating for water resistance | Exterior automotive lighting, off-road vehicles, marine applications | Pros: Durable in harsh environments, extended lifespan; Cons: Slightly higher price, potential heat dissipation challenges |

| Flexible 12V LED Strip | Bendable PCB allowing installation on curved or irregular surfaces | Custom automotive designs, tight spaces, retrofit projects | Pros: Highly adaptable, easy to install in complex shapes; Cons: May have lower heat tolerance, needs careful handling |

| High-Density 12V LED Strip | Increased LED count per meter for brighter illumination | Task lighting, automotive work lights, commercial vehicle lighting | Pros: Superior brightness, uniform light output; Cons: Higher power consumption, requires robust power supply |

Single Color 12V LED Strip

Single color 12V LED strips are the most straightforward option, offering a consistent light output in a single hue, typically white or warm white. Their simplicity makes them a cost-effective choice for B2B buyers focusing on automotive ambient lighting or dashboard illumination. These strips are easy to install and maintain, suitable for large volume orders where budget and reliability are priorities. However, buyers should consider the limited design flexibility due to the absence of color-changing capabilities.

RGB 12V LED Strip

RGB LED strips integrate red, green, and blue LEDs allowing a broad spectrum of colors through electronic controllers. This type is ideal for businesses targeting automotive customization markets or commercial signage where dynamic lighting effects attract attention. While the upfront cost and installation complexity are higher, the ability to tailor lighting moods and colors provides a competitive edge. Buyers must ensure compatibility with controllers and power supplies to maximize product performance.

Waterproof 12V LED Strip

Designed for durability, waterproof 12V LED strips feature protective coatings that make them resistant to moisture, dust, and environmental wear. These are essential for automotive applications exposed to rain, dust, or marine conditions. For B2B buyers in regions with harsh climates—such as parts of Africa or the Middle East—this variant ensures longevity and reduces maintenance costs. The trade-off includes a slightly higher price and potential considerations for heat dissipation during extended use.

Flexible 12V LED Strip

Flexible LED strips use bendable PCBs allowing installation on curved surfaces or inside confined automotive spaces. This adaptability is crucial for custom vehicle designs or retrofit projects where standard rigid strips cannot fit. Buyers should assess the flexibility requirements of their applications and ensure proper handling to avoid damage. Flexible strips typically require careful heat management and may have specific adhesive needs based on the installation environment.

High-Density 12V LED Strip

High-density LED strips pack more LEDs per meter, delivering brighter and more uniform illumination. These are favored in B2B scenarios requiring task lighting or enhanced visibility such as commercial vehicle lighting or automotive work lights. While offering superior brightness, they demand more robust power supplies and effective thermal management. Buyers should balance the need for illumination intensity against energy consumption and system complexity to optimize operational efficiency.

Related Video: Mercedes Models Explained (2020 model range) | Let Me Explain

Key Industrial Applications of led strip 12v auto

| Industry/Sector | Specific Application of led strip 12v auto | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior ambient lighting and dashboard illumination | Enhances vehicle aesthetics and driver experience; energy-efficient lighting reduces power draw | High durability, heat resistance, compliance with automotive standards (e.g., ISO, RoHS), flexible PCB options for curved surfaces |

| Commercial Transportation | Bus and truck cabin lighting and external accent lighting | Improves passenger comfort and vehicle visibility; lowers maintenance costs due to long lifespan | Waterproof and vibration-resistant strips, stable 12V operation, sourcing from certified suppliers with proven quality control |

| Retail and Display | Illuminated display cases and shelving in stores | Attracts customer attention, highlights products, and increases sales conversion | Customizable brightness and color temperature, ease of installation, adhesive quality suited for various surfaces |

| Hospitality & Tourism | Accent lighting in hotel rooms, restaurants, and lounges | Creates ambiance, enhances guest experience, and reduces energy costs | Compliance with international safety standards, dimmable features, sourcing from manufacturers offering warranty and support |

| Marine and Offshore | Cabin and deck lighting on boats and offshore platforms | Provides reliable, low-voltage lighting in harsh environments; improves safety and operational efficiency | Waterproof ratings (IP65+), corrosion-resistant materials, flexible design for tight spaces, and supplier experience with marine-grade products |

Automotive Manufacturing

In the automotive sector, 12V LED strip lights are extensively used for interior ambient lighting, dashboard illumination, and accent lighting. These strips provide a sleek, modern look while consuming less power compared to traditional bulbs, which is critical for electric and hybrid vehicles. For international B2B buyers in regions like Africa and South America, sourcing LED strips that meet stringent automotive standards and can withstand temperature fluctuations is essential. Flexible PCBs are often required to fit complex interior shapes, making supplier expertise in customization a key factor.

Commercial Transportation

LED strip lights are vital in buses, trucks, and other commercial vehicles for both cabin lighting and external decorative purposes. They improve passenger comfort by providing consistent, glare-free illumination and enhance vehicle visibility, contributing to road safety. Buyers from the Middle East and Europe should prioritize LED strips with robust waterproof and vibration resistance features to endure rough road conditions and climate extremes. Reliable suppliers offering certified products with stable voltage operation help minimize downtime and maintenance costs.

Retail and Display

Retail environments leverage 12V LED strip lights to illuminate display cases, shelves, and signage, significantly boosting product visibility and consumer engagement. The ability to customize brightness and color temperature allows retailers to create inviting atmospheres tailored to their brand identity. For B2B buyers in emerging markets like Kenya and Nigeria, adhesive quality and ease of installation are crucial to ensure longevity and reduce installation time. Partnering with manufacturers who provide flexible length options and consistent color rendering enhances retail presentation.

Hospitality & Tourism

Hotels, restaurants, and lounges utilize 12V LED strip lighting to craft appealing ambiances that elevate guest experiences while optimizing energy consumption. Dimmable features and precise color control enable dynamic lighting schemes that adapt to different moods and times of day. International buyers should focus on LED strips that comply with global safety certifications and come with reliable warranty support. This ensures both compliance with local regulations and peace of mind regarding product performance in diverse environments.

Marine and Offshore

In marine and offshore industries, 12V LED strip lights are essential for cabin and deck lighting where safety and durability are paramount. These environments demand LED strips with high waterproof ratings and corrosion-resistant materials to withstand saltwater exposure and humidity. Buyers from Europe and the Middle East should seek suppliers with proven experience in marine-grade lighting solutions that offer flexible designs for confined spaces onboard vessels and platforms. Such sourcing decisions directly impact operational reliability and crew safety.

Related Video: How To Rig LED Strip Lights To 12V Battery

Strategic Material Selection Guide for led strip 12v auto

When selecting materials for 12V LED strip lights used in automotive applications, understanding the interplay between material properties and environmental demands is critical. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, must consider factors like temperature extremes, humidity, corrosion, and compliance with regional standards to ensure product longevity and performance.

1. Flexible Printed Circuit Boards (FPC) – Polyimide and PET Substrates

Key Properties:

Flexible PCBs made from polyimide or polyethylene terephthalate (PET) substrates provide excellent flexibility, heat resistance (polyimide up to ~260°C, PET up to ~150°C), and electrical insulation. Polyimide offers superior thermal stability and chemical resistance compared to PET.

Pros & Cons:

– Pros: Enables installation in curved or confined automotive spaces; high thermal endurance (polyimide); lightweight; good electrical insulation.

– Cons: Polyimide is more expensive; PET has lower heat resistance and can degrade faster under harsh conditions. Manufacturing complexity is moderate due to flexible assembly processes.

Impact on Application:

Ideal for automotive interiors and accent lighting where bending and shaping around contours are necessary. Polyimide FPCs are preferred in engine bays or areas exposed to higher temperatures.

Considerations for B2B Buyers:

Buyers in hot climates like the Middle East or parts of Africa should prioritize polyimide-based FPCs to avoid thermal degradation. Compliance with international standards such as IPC-6013 (flexible PCBs) and regional certifications (e.g., CE for Europe, SABS for South Africa) ensures quality and acceptance. Cost sensitivity in emerging markets may drive PET-based options for less demanding applications.

2. LED Chips – High-Quality SMD (Surface-Mounted Device) Components (e.g., SMD 5050, 3528)

Key Properties:

LED chips determine luminous efficacy, power consumption, and lifespan. High-quality SMD chips offer stable light output, low heat generation, and resistance to voltage fluctuations.

Pros & Cons:

– Pros: Enhanced brightness and energy efficiency; longer operational life; consistent color rendering.

– Cons: Premium chips increase BOM cost; lower-quality chips risk early failure and color inconsistency.

Impact on Application:

Automotive lighting demands reliable, bright LEDs capable of withstanding vibration and temperature changes. SMD 5050 chips are popular for their brightness and multi-color capabilities, while SMD 3528 suits simpler single-color applications.

Considerations for B2B Buyers:

Buyers from regions with variable power supply quality (e.g., parts of Africa and South America) should insist on LED chips with robust voltage tolerance and certifications like RoHS and CE. Establishing supplier traceability to reputable chip manufacturers reduces risk. European buyers may demand adherence to strict EU environmental and safety directives.

3. Adhesive Backing – High-Temperature Resistant Acrylic Adhesive

Key Properties:

Adhesive backing secures the LED strip to automotive surfaces and must resist heat, vibration, and humidity. Acrylic adhesives typically withstand temperatures up to 120°C and offer strong bonding on metals and plastics.

Pros & Cons:

– Pros: Strong adhesion on diverse substrates; good resistance to automotive environmental stresses; easy installation.

– Cons: Some adhesives may degrade under prolonged UV exposure; removal can leave residue or damage surfaces.

Impact on Application:

Critical for maintaining strip placement in vehicles subjected to temperature fluctuations and movement. Acrylic adhesives are preferred for their balance of durability and ease of use.

Considerations for B2B Buyers:

In regions with intense sunlight (Middle East, parts of Africa), UV-resistant adhesive formulations are advisable. Buyers should verify adhesive certifications and conduct peel tests under local climate simulations. Cost-effective adhesive solutions may be prioritized in price-sensitive markets but should not compromise durability.

4. Protective Silicone or PVC Coating (Encapsulation)

Key Properties:

Encapsulation materials protect LED strips from moisture, dust, and mechanical damage. Silicone coatings offer excellent flexibility and high-temperature resistance (~200°C), while PVC coatings are more rigid and cost-effective but less heat tolerant.

Pros & Cons:

– Pros: Silicone provides superior waterproofing and UV resistance; PVC is economical and easy to manufacture.

– Cons: Silicone coatings increase product cost; PVC may yellow or crack under UV exposure and heat.

Impact on Application:

For automotive exterior or engine compartment lighting, silicone encapsulation ensures longevity against harsh environmental factors. PVC coatings suit interior or protected areas where cost is a concern.

Considerations for B2B Buyers:

Buyers from humid or coastal regions (e.g., Nigeria, Kenya) should prioritize silicone encapsulation to prevent corrosion and electrical failures. Compliance with IP ratings (e.g., IP65 or higher) and relevant automotive standards (ISO 16750) is essential. European buyers may require REACH compliance for encapsulation materials.

Summary Table

| Material | Typical Use Case for led strip 12v auto | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible PCB (Polyimide/PET) | Flexible mounting in automotive interiors and engine bays | High thermal resistance (polyimide), flexibility | Polyimide costly; PET lower heat tolerance | Polyimide: High; PET: Medium |

| High-Quality SMD LED Chips | Primary light source for brightness and color accuracy | Superior luminous efficacy and durability | Higher BOM cost for premium chips | Medium to High |

| Acrylic Adhesive Backing | Securing strips on various automotive surfaces | Strong adhesion, heat and vibration resistant | Potential UV degradation; residue on removal | Low to Medium |

| Silicone/PVC Encapsulation | Protection against moisture and mechanical damage | Silicone: excellent waterproofing and UV resistance | Silicone costly; PVC less heat and UV resistant | Silicone: High; PVC: Low |

This guide empowers international B2B buyers to make informed material choices for 12V LED strip lights in automotive applications, balancing performance, durability, and cost while considering regional environmental and regulatory factors.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip 12v auto

Manufacturing and Quality Assurance of 12V LED Auto Strip Lights: A Comprehensive Overview

Understanding the manufacturing and quality assurance processes behind 12V LED strip lights designed for automotive use is essential for international B2B buyers. This knowledge ensures that the products you source meet durability, safety, and performance requirements tailored to demanding automotive environments. Below, we detail the typical manufacturing stages, critical quality control measures, and actionable insights for verifying supplier reliability—especially relevant for buyers from Africa, South America, the Middle East, and Europe.

Key Manufacturing Stages for 12V LED Auto Strip Lights

The production of 12V LED strips for automotive applications involves several precise stages, each contributing to the product’s overall quality and longevity.

-

Material Preparation

– Sourcing High-Quality Components: Premium LED chips (often SMD 5050 or 3528 for automotive), flexible or rigid PCBs with excellent heat dissipation properties, durable adhesives, and protective coatings are sourced. The choice of materials directly impacts product lifespan and performance.

– Pre-Inspection: Incoming materials undergo initial quality checks to verify specifications such as chip brightness, PCB thickness, and adhesive strength. -

PCB Fabrication and Forming

– Flexible PCB Production: Flexible PCBs are preferred in automotive LED strips to accommodate curved surfaces. Manufacturers use copper-clad laminates with thermal conductive layers.

– Circuit Patterning: Photolithography or etching techniques create precise conductive pathways, ensuring efficient electrical flow and heat management.

– Protective Coating Application: A conformal coating or silicone encapsulation is applied to protect against moisture, dust, and vibration typical in automotive environments. -

LED Chip Mounting and Assembly

– Surface Mount Technology (SMT): Automated SMT machines place LED chips onto the PCB with micron-level accuracy, crucial for uniform light output.

– Soldering: Reflow soldering secures LED chips electrically and mechanically, minimizing cold joints and ensuring durability under vibration.

– Integration of Resistors and Drivers: Resistors for current regulation and integrated circuit drivers are added to stabilize voltage and prevent damage from automotive power fluctuations. -

Finishing and Packaging

– Adhesive Backing Application: High-strength, automotive-grade adhesives (often 3M VHB tapes) are applied to ensure the strip remains affixed despite heat cycles and vibrations.

– Cutting and Customization: Strips are cut to standard or custom lengths, with clear markings for easy installation.

– Protective Packaging: Anti-static, moisture-resistant packaging protects LED strips during international shipping, reducing risk of damage.

Quality Control (QC) Frameworks and Standards

Robust QC processes safeguard product reliability and compliance with international and regional regulations. For automotive LED strips, quality extends beyond visual inspection to include electrical, mechanical, and environmental testing.

International and Industry-Specific Standards

- ISO 9001: Quality management system standard ensuring consistent manufacturing processes.

- CE Marking: Compliance with European health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Limits use of hazardous materials, important for European and Middle Eastern markets.

- UL Certification: Ensures electrical safety, often critical for North American and some Middle Eastern buyers.

- Automotive-Specific Standards (e.g., ISO/TS 16949): Quality management tailored for automotive suppliers, relevant for buyers seeking high-end automotive applications.

- IP Ratings (Ingress Protection): Ratings like IP65 or IP67 confirm resistance to dust and water, vital for automotive exterior use.

QC Checkpoints

-

Incoming Quality Control (IQC)

– Verification of raw materials and components against specifications.

– Sampling and testing LED chips for luminous intensity and color consistency.

– PCB integrity checks for thickness, flexibility, and conductivity. -

In-Process Quality Control (IPQC)

– Monitoring SMT placement accuracy and soldering quality through automated optical inspection (AOI).

– Thermal cycling tests on assembled strips to simulate automotive temperature fluctuations.

– Adhesive strength tests ensuring strips maintain adhesion under stress. -

Final Quality Control (FQC)

– Electrical Testing: Continuity, voltage, and current draw tests to verify performance.

– Functional Testing: Full illumination and color uniformity tests.

– Environmental Testing: Exposure to humidity, vibration, and UV light to simulate real-world conditions.

– Packaging Inspection: Ensures correct labeling, packaging integrity, and inclusion of installation instructions.

Common Testing Methods

- Lumen Output and Color Temperature Measurement: Using spectrometers to ensure consistent brightness and color.

- Thermal Imaging: Detects hotspots that could indicate poor heat dissipation.

- Accelerated Aging Tests: Simulates prolonged use to predict lifespan.

- Vibration and Shock Testing: Ensures durability under automotive road conditions.

- Adhesive Peel Tests: Measures bonding strength on various automotive surfaces.

How B2B Buyers Can Verify Supplier QC Practices

For buyers in Africa, South America, the Middle East, and Europe, verifying supplier QC is crucial to mitigate risks associated with quality, shipment delays, and compliance.

- Factory Audits: Conduct or commission on-site inspections to assess manufacturing capabilities, QC processes, and working conditions. Focus on certifications, equipment, and staff expertise.

- Review QC Documentation: Request detailed inspection reports, test certificates, and compliance documentation (e.g., RoHS, CE).

- Third-Party Inspections: Engage independent testing laboratories or inspection agencies to perform random sampling and testing before shipment.

- Sample Testing: Obtain product samples for in-house testing under your operating conditions.

- Supplier Quality Agreements: Define quality expectations, testing procedures, and penalties for non-compliance contractually.

QC and Certification Nuances for International Buyers

- Regional Compliance Variations: CE and RoHS are essential for Europe and increasingly recognized in Middle Eastern markets, while UL and API certifications may be more relevant for certain South American or Middle Eastern buyers.

- Environmental and Climatic Considerations: Buyers from Africa and the Middle East should prioritize IP ratings and thermal resistance due to hot, dusty conditions.

- Supply Chain Transparency: Demand traceability of components to avoid counterfeit or substandard LED chips, especially important in markets with limited local manufacturing.

- After-Sales Support and Warranty: Ensure suppliers offer clear warranty policies and responsive customer service to handle potential quality issues post-purchase.

Summary for B2B Buyers:

When sourcing 12V LED auto strip lights, prioritize suppliers who demonstrate stringent material selection, advanced manufacturing techniques (such as SMT and thermal management), and comprehensive QC protocols aligned with international standards. Verify certifications relevant to your regional market and insist on transparency through audits and third-party inspections. This approach reduces risk, ensures compliance, and secures high-performance products tailored for demanding automotive environments across Africa, South America, the Middle East, and Europe.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip 12v auto Sourcing

Understanding the cost and pricing dynamics for sourcing 12V LED strips for automotive applications is critical for international B2B buyers aiming to optimize procurement strategies. The pricing landscape is influenced by multiple cost components and market variables, which must be carefully analyzed to make informed purchasing decisions.

Key Cost Components in LED Strip 12V Auto Manufacturing

-

Materials

The primary cost driver is the quality and type of materials used. This includes LED chips (commonly SMD 5050 or 2835), printed circuit boards (PCBs), adhesive backings, resistors, and protective coatings. Premium LED chips with higher luminous efficacy and longer lifespan increase costs but improve product reliability and energy efficiency. High-grade PCBs ensure better heat dissipation, directly impacting durability and performance. -

Labor and Manufacturing Overhead

Labor costs vary significantly depending on the manufacturing location. Countries with well-established LED manufacturing hubs often offer competitive labor rates. Overhead includes factory utilities, equipment depreciation, and indirect labor associated with assembly, testing, and packaging. -

Tooling and Equipment

Initial tooling investments for PCB fabrication, soldering machines, and automated assembly lines impact per-unit costs, especially for smaller orders. Custom tooling for specific automotive specifications or unique designs may add to upfront expenses. -

Quality Control (QC) and Testing

Rigorous QC processes—including electrical testing, stress testing, and compliance checks for certifications like CE, RoHS, and UL—are essential. These processes add to cost but reduce the risk of defective products and returns, which is critical for maintaining brand reputation and ensuring safety standards. -

Logistics and Shipping

International logistics costs depend on shipment size, mode (air vs. sea freight), and destination. Import duties, taxes, and customs clearance fees in regions such as Africa (Kenya, Nigeria), South America, the Middle East, and Europe must be factored into landed costs. -

Supplier Margin

Suppliers set margins based on order volume, market demand, and competitive positioning. Margins tend to decrease with higher order quantities due to economies of scale.

Influential Factors Affecting Final Pricing

-

Order Volume and Minimum Order Quantities (MOQ)

Larger volume orders typically attract better unit prices. MOQ requirements vary by supplier and can range from a few hundred meters to thousands, influencing total procurement cost and inventory planning. -

Customization and Technical Specifications

Custom lengths, color temperatures, waterproof ratings (IP65/IP67), and integration with automotive control systems raise costs. Buyers should balance customization needs against budget constraints. -

Material Grade and Certification Compliance

LED strips with internationally recognized certifications command higher prices but ensure safety, performance, and regulatory compliance—especially important for automotive applications in regulated markets. -

Supplier Location and Reliability

Suppliers from China dominate global LED strip manufacturing, often offering competitive pricing but requiring diligence in supplier vetting. Local or regional suppliers may provide advantages in shipping time and communication but may have higher costs. -

Incoterms and Payment Terms

Incoterms such as FOB, CIF, or DDP impact who bears logistics risk and cost. Buyers should negotiate terms that optimize cash flow and reduce exposure to unforeseen shipping expenses.

Practical Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO)

Focus on long-term value rather than just unit price. High-quality LED strips reduce maintenance and replacement costs, offering better ROI. -

Leverage Volume Consolidation

Pool orders with partners or across projects to meet MOQ thresholds and access volume discounts. -

Clarify Specifications Upfront

Avoid costly last-minute changes by finalizing technical requirements and certification needs early in supplier discussions. -

Factor in After-Sales Support and Warranty

Prioritize suppliers offering robust warranties and responsive customer service to mitigate risks. -

Understand Regional Import Regulations and Duties

Engage local customs experts to anticipate taxes and compliance requirements, particularly in Africa and South America, where import procedures may be complex. -

Beware of Pricing Traps

Extremely low prices may signal inferior materials or lack of certification, which can lead to failures and increased operational costs.

Indicative Pricing Disclaimer

Pricing for 12V LED strips varies widely based on order size, specifications, and supplier. Buyers should request detailed quotations including all cost components and confirm current market conditions. The information herein is indicative and intended to guide procurement strategy rather than serve as exact price references.

By carefully analyzing these cost elements and market factors, international B2B buyers can optimize sourcing decisions for 12V LED strip lights tailored for automotive use—ensuring a balance of cost-efficiency, quality, and compliance suitable for diverse global markets.

Spotlight on Potential led strip 12v auto Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip 12v auto’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip 12v auto

Understanding Critical Technical Properties of 12V LED Strip Lights

When sourcing 12V LED strip lights for automotive or industrial use, grasping key technical specifications is essential for ensuring product suitability and reliability across diverse markets such as Africa, South America, the Middle East, and Europe.

-

Material Grade (LED Chips and PCB Quality):

High-grade LED chips (e.g., SMD 5050 or 2835) and premium PCB materials directly influence light output, energy efficiency, and lifespan. For B2B buyers, specifying material grade ensures durability under varying environmental conditions, particularly important in regions with high temperatures or humidity. -

Voltage Tolerance and Stability:

Although designed for 12V DC, LED strips must tolerate slight voltage fluctuations common in automotive electrical systems. A tolerance range of ±5% or better minimizes risks of premature LED failure, flickering, or dimming. Buyers should verify this spec to reduce warranty claims and downtime. -

IP Rating (Ingress Protection):

The IP rating, such as IP65 or IP67, indicates resistance to dust and water ingress. For automotive applications, a minimum of IP65 is typically required to withstand rain, dust, and road debris. Selecting the appropriate IP rating protects investment and enhances product lifespan in harsh environments. -

Luminous Efficacy (Brightness per Watt):

Measured in lumens per watt (lm/W), this property reflects energy efficiency and brightness quality. Higher luminous efficacy means brighter illumination with lower power consumption—crucial for energy-conscious buyers aiming to balance performance and operating costs. -

Cutting and Soldering Segments:

LED strips are divided into segments (often every 3, 6, or 12 LEDs) that can be cut to length. Understanding segment size and soldering points is vital for customization and installation flexibility, especially in complex automotive or architectural projects. -

Adhesive Backing Quality:

The type and strength of adhesive backing (usually 3M tapes) affect installation ease and long-term adhesion. Buyers should ensure the adhesive suits the target application surface, considering temperature variations and exposure to vibration in vehicles.

Key Industry and Trade Terms for Smooth Procurement

Navigating international LED strip light procurement requires familiarity with common B2B trade terminology that impacts negotiation, logistics, and compliance.

-

OEM (Original Equipment Manufacturer):

Refers to suppliers who produce LED strips that can be branded or customized for the buyer. Choosing OEM partners allows buyers to tailor product specifications, branding, and packaging, which is essential for differentiation in competitive markets. -

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and budget effectively. For emerging markets, negotiating flexible MOQs can facilitate market entry without excessive capital outlay. -

RFQ (Request for Quotation):

A formal inquiry sent to suppliers detailing product requirements to obtain pricing and terms. Precise RFQs reduce misunderstandings and accelerate sourcing cycles, especially when dealing with multiple international suppliers. -

Incoterms (International Commercial Terms):

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs clearance. Mastery of Incoterms ensures buyers manage costs, risks, and delivery expectations efficiently, which is critical for cross-border shipments. -

Lead Time:

The period between order placement and product delivery. Accurate knowledge of lead times is crucial for supply chain planning and meeting market demand, particularly in regions with longer shipping durations. -

RoHS and CE Certifications:

Compliance marks indicating adherence to safety and environmental standards (e.g., restriction of hazardous substances, European conformity). Verifying certifications safeguards buyers from regulatory issues and enhances product acceptance in global markets.

By prioritizing these technical properties and mastering essential trade terminology, international B2B buyers can confidently source high-quality 12V LED strip lights optimized for automotive and commercial applications, ensuring operational excellence and customer satisfaction across diverse regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip 12v auto Sector

Market Overview & Key Trends

The global market for 12V LED strip lights in automotive applications is rapidly expanding, driven by increasing demand for energy-efficient, customizable, and durable lighting solutions. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging economies like Kenya and Nigeria—are capitalizing on this growth to enhance vehicle aesthetics, safety, and functionality. The automotive sector’s shift towards electric vehicles (EVs) and smart vehicle technologies further fuels demand for advanced LED strips that offer low power consumption and seamless integration with vehicle electronics.

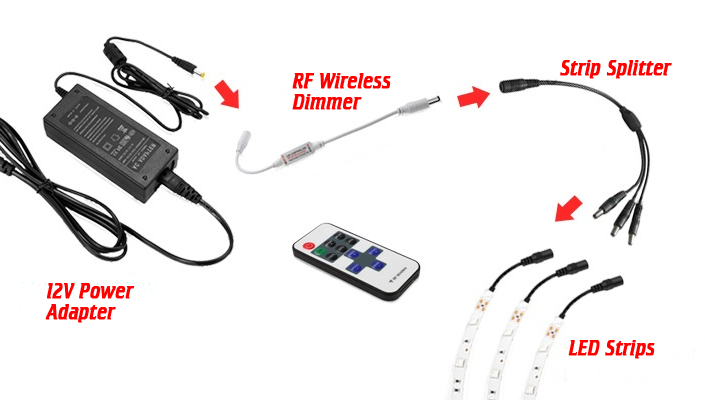

Illustrative Image (Source: Google Search)

Key market drivers include the rising adoption of LED technology over traditional halogen or incandescent lighting due to superior lifespan, reduced heat emission, and enhanced design flexibility. Additionally, the versatility of 12V LED strips allows their use in interior ambient lighting, exterior accent lighting, and functional components such as turn signals and brake lights. This versatility appeals to automotive manufacturers and aftermarket suppliers alike.

In terms of sourcing trends, buyers are increasingly prioritizing suppliers who can offer high-quality components—particularly premium LED chips and robust PCBs—that guarantee durability and performance under automotive conditions. Flexible PCB substrates and strong adhesive backings tailored for vibration and temperature fluctuations are becoming standard expectations. Additionally, there is a growing preference for suppliers offering modular, customizable LED strip solutions to meet diverse vehicle specifications.

Emerging technologies such as smart LED strips with integrated sensors and IoT connectivity are gaining traction in sophisticated automotive markets. For B2B buyers in developing regions, this trend presents opportunities to partner with manufacturers offering scalable solutions that balance innovation with cost-effectiveness. Furthermore, regional trade agreements and improving logistics infrastructure in Africa, South America, and the Middle East are easing import complexities, enabling more competitive pricing and faster delivery times.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor influencing procurement decisions in the 12V LED strip automotive sector. With increasing regulatory pressure and consumer awareness globally, B2B buyers are demanding products that minimize environmental impact across their lifecycle—from raw material extraction to manufacturing, usage, and disposal.

Ethical sourcing of materials such as LED chips and PCBs is essential to ensure compliance with international standards and avoid supply chain risks associated with conflict minerals or hazardous substances. Certifications like RoHS (Restriction of Hazardous Substances), CE (Conformité Européenne), and UL (Underwriters Laboratories) serve as critical benchmarks for ensuring that LED strip products meet stringent environmental and safety requirements.

Many leading manufacturers are now incorporating recycled and eco-friendly materials in their PCBs and packaging, reducing carbon footprints and waste generation. Additionally, energy-efficient LED chips contribute to lower power consumption in vehicles, supporting broader sustainability goals such as reduced greenhouse gas emissions.

For international buyers, especially in regions with emerging environmental regulations, partnering with suppliers who demonstrate transparent supply chains and commitment to green manufacturing practices can enhance brand reputation and market access. Ethical certifications and adherence to corporate social responsibility (CSR) standards not only mitigate reputational risks but also align with the growing global emphasis on sustainable development.

Brief Evolution and Historical Context

The development of 12V LED strip lights for automotive use has evolved significantly over the past two decades. Initially, LED strips were primarily used for decorative interior lighting due to their low power requirements and compact form factor. As LED technology advanced, improvements in chip efficiency, PCB design, and adhesive materials enabled their broader adoption for exterior automotive lighting applications.

The shift from 24V to 12V systems in many vehicles standardized the voltage requirement, simplifying integration and expanding the global market. Over time, manufacturers introduced features such as waterproof coatings, flexible substrates, and smart control systems, which greatly enhanced the reliability and functionality of LED strips in automotive environments.

Today, 12V LED strips are integral to modern automotive design, offering manufacturers and aftermarket suppliers a versatile lighting solution that combines aesthetics, safety, and sustainability. This evolution underscores the importance of selecting suppliers with proven expertise and innovation capabilities to meet the increasingly complex demands of the global automotive lighting market.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip 12v auto

-

How can I effectively vet suppliers of 12V LED strip lights for automotive applications?

Start by verifying the supplier’s certifications such as CE, RoHS, UL, or equivalent international standards to ensure product safety and compliance. Request detailed product specifications and samples to assess quality firsthand. Investigate the supplier’s manufacturing capabilities, quality control processes, and client references, especially from your region (Africa, South America, Middle East, Europe). Utilize third-party factory audits or inspections to validate production standards. Transparent communication and willingness to provide documentation and certifications are key indicators of a reliable supplier. -

Is customization available for 12V LED strip lights, and how does it impact pricing and lead times?

Most reputable manufacturers offer customization options including length, color temperature, IP rating, adhesive backing, and connectors tailored to automotive needs. Customization typically requires a higher minimum order quantity (MOQ) and may extend lead times by 2–4 weeks depending on complexity. Pricing will vary based on materials, design changes, and tooling requirements. Engage suppliers early to discuss your specific requirements and negotiate MOQ and delivery schedules. Clear specifications and prototype approvals can prevent costly delays. -

What are typical MOQs and payment terms for international orders of 12V LED strip lights?

MOQs vary by supplier but generally range from 500 to 2000 meters per order for automotive LED strips. Some suppliers may offer flexible MOQs for new buyers or trial orders, especially if you agree to longer payment terms. Common payment terms include 30% deposit upfront with balance upon shipment or letter of credit (L/C) for larger orders. Payment methods such as T/T, PayPal, or escrow services are preferred for security. Negotiate terms that balance your cash flow with supplier trustworthiness. -

How do I ensure quality assurance (QA) and product certifications meet international standards?

Request copies of third-party test reports and compliance certificates (CE, RoHS, UL) before purchase. Confirm that the supplier conducts in-house quality control tests including LED chip performance, waterproofing, adhesion strength, and electrical safety. Ask for batch-specific QA documentation and consider arranging pre-shipment inspections by independent agencies. For automotive use, ensure products meet relevant automotive-grade durability and vibration standards. Maintaining open communication about QA processes helps mitigate risks of defective shipments. -

What logistics considerations should I be aware of when importing 12V LED strip lights internationally?

Consider shipping modes—air freight for urgent, smaller shipments; sea freight for bulk orders to reduce costs. Account for customs duties, import taxes, and compliance with local regulations in your country. Packaging should protect delicate LED components from moisture and damage during transit. Work with freight forwarders experienced in electronics to handle documentation and customs clearance efficiently. Also, factor in potential delays due to seasonal demand spikes or geopolitical issues affecting key ports. -

How can disputes with suppliers regarding product quality or delivery be effectively managed?

Mitigate disputes by having clear contracts specifying product specifications, quality standards, delivery timelines, and penalties for non-compliance. Use purchase orders and written agreements to document terms. If issues arise, initiate resolution through direct supplier communication, providing photographic or video evidence. Escalate unresolved disputes by engaging third-party arbitration or trade mediation services, especially if contracts include arbitration clauses. Building strong supplier relationships and clear communication channels reduces the likelihood of conflicts. -

Are there specific considerations for sourcing 12V LED strip lights suitable for automotive use in African and South American markets?

Yes, environmental factors such as high temperatures, humidity, and dust prevalent in these regions demand LED strips with robust IP65 or higher waterproof ratings and durable adhesive backing. Suppliers must provide products tested for vibration resistance and temperature fluctuations common in automotive applications. Additionally, consider local power supply compatibility and voltage stability. Working with suppliers familiar with these regional challenges ensures product longevity and customer satisfaction in your target markets. -

What after-sales support can I expect from reputable 12V LED strip light manufacturers?

Top manufacturers provide technical support, warranty services (typically 1–3 years), and replacement policies for defective products. They may offer installation guidance, troubleshooting, and sometimes customized training for your technical team. After-sales responsiveness is crucial for maintaining your own customer satisfaction. Verify support availability in your time zone and preferred language. Establishing a service-level agreement (SLA) during contract negotiation can formalize expectations and improve cooperation post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip 12v auto

The strategic sourcing of 12V LED strip lights for automotive applications demands a nuanced understanding of quality, compliance, and supplier capabilities. Key factors such as premium LED chip selection, robust PCB fabrication, and reliable adhesive backing directly influence product longevity and performance—critical criteria for B2B buyers aiming to satisfy diverse market needs across Africa, South America, the Middle East, and Europe. Prioritizing suppliers with rigorous quality control processes and recognized certifications ensures compliance with international standards, reducing risks associated with product failures and regulatory setbacks.

For international buyers, fostering strong partnerships with manufacturers who emphasize innovation, transparency, and sustainability can unlock competitive advantages. This is especially vital in emerging markets like Kenya and Nigeria, where demand for energy-efficient automotive lighting solutions is rapidly growing. Leveraging strategic sourcing to balance cost, quality, and delivery timelines will empower businesses to meet evolving consumer expectations and regulatory requirements.

Illustrative Image (Source: Google Search)

Looking ahead, the LED strip 12V auto segment is poised for continued growth fueled by smart lighting integration and eco-conscious design trends. Buyers are encouraged to engage proactively with suppliers offering customization and after-sales support to future-proof their investments. By adopting a strategic sourcing mindset, businesses can confidently navigate market complexities and capitalize on emerging opportunities in this dynamic sector.