Guide to Led Stairs Strip Lights

- Introduction: Navigating the Global Market for led stairs strip lights

- Understanding led stairs strip lights Types and Variations

- Key Industrial Applications of led stairs strip lights

- Strategic Material Selection Guide for led stairs strip lights

- In-depth Look: Manufacturing Processes and Quality Assurance for led stairs strip lights

- Comprehensive Cost and Pricing Analysis for led stairs strip lights Sourcing

- Spotlight on Potential led stairs strip lights Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led stairs strip lights

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led stairs strip lights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led stairs strip lights

- Strategic Sourcing Conclusion and Outlook for led stairs strip lights

Introduction: Navigating the Global Market for led stairs strip lights

In today’s global construction and design landscape, LED stairs strip lights have emerged as a vital component for enhancing safety, aesthetics, and energy efficiency in both commercial and residential projects. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing these specialized lighting solutions is critical to maintaining competitive advantage and meeting diverse project demands.

This comprehensive guide offers a deep dive into the world of LED stairs strip lights, covering essential aspects such as product types, material quality, manufacturing standards, and rigorous quality control processes. Buyers will gain clarity on identifying reliable suppliers and navigating cost structures that balance affordability with superior performance. Additionally, the guide explores global market trends, regional considerations, and practical FAQs tailored to the unique challenges faced by businesses in regions like Kenya and Brazil.

By integrating expert insights with actionable strategies, this resource empowers procurement managers, distributors, and project developers to make well-informed sourcing decisions. Whether outfitting large-scale commercial developments or smaller architectural installations, understanding the full supply chain—from LED module sourcing through to logistics and after-sales support—ensures seamless project execution and long-term client satisfaction.

For buyers seeking to capitalize on the energy savings, durability, and design flexibility of LED stairs strip lights, this guide serves as an indispensable tool to navigate the complexities of the global market with confidence and precision.

Understanding led stairs strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface-Mounted LED Strips | Mounted directly on stair nosing or adjacent surfaces; visible and easy to install | Commercial buildings, hotels, retail spaces | Pros: Easy installation, cost-effective; Cons: Less protected, may be prone to damage |

| Recessed LED Strip Lights | Installed within stair treads or risers for flush finish; often waterproof | High-end residential, luxury hotels, offices | Pros: Sleek, discreet look, protected from damage; Cons: Higher installation cost, requires precise fitting |

| Waterproof LED Stair Strip Lights | Encased in waterproof silicone or PVC; suitable for outdoor or wet environments | Outdoor stairways, public spaces, stadiums | Pros: Durable in harsh conditions, weather-resistant; Cons: Slightly higher cost, limited flexibility |

| RGB & Color-Changing LED Strips | Multi-color LEDs with remote/app control for dynamic lighting effects | Event venues, entertainment complexes, clubs | Pros: Versatile ambiance control, attractive; Cons: More expensive, requires compatible controllers |

| High-Lumen LED Stair Strip Lights | High brightness output suitable for task lighting and safety | Industrial facilities, hospitals, public buildings | Pros: Enhanced visibility, safety-focused; Cons: Higher energy consumption, may require cooling |

Surface-Mounted LED Strips

These LED strips are the most common and straightforward option for stair lighting. They are affixed directly onto the stair edges or side walls, making installation quick and cost-effective. Ideal for commercial and retail environments where budget and ease of maintenance are priorities. B2B buyers should consider the potential for physical damage in high-traffic areas and may need to select durable housings or protective covers to extend lifespan.

Recessed LED Strip Lights

Recessed strips are installed within the stair structure, providing a seamless and elegant lighting solution. They are favored in luxury hotels, upscale offices, and high-end residential projects where aesthetics are critical. For B2B buyers, installation requires skilled labor and precise measurements, which may increase upfront costs but add value through enhanced design appeal and protection of the lighting elements.

Waterproof LED Stair Strip Lights

Designed for environments exposed to moisture, these strips are sealed with waterproof materials like silicone or PVC. They are essential for outdoor staircases, stadiums, and public spaces in regions with heavy rainfall or humidity, such as parts of Africa and South America. Buyers must verify IP ratings and durability certifications to ensure compliance with local standards and longevity under harsh weather conditions.

RGB & Color-Changing LED Strips

These strips incorporate RGB LEDs controlled via remote or smart apps, allowing dynamic color changes and lighting effects. They are perfect for event venues, entertainment areas, and hospitality businesses seeking to create vibrant atmospheres. B2B purchasers should assess compatibility with existing control systems and factor in higher costs and potential maintenance complexity due to the added electronics.

High-Lumen LED Stair Strip Lights

With enhanced brightness levels, these strips are designed to improve visibility and safety in industrial settings, hospitals, and public buildings. They often consume more power and may require additional heat dissipation solutions. Buyers focusing on safety compliance and regulatory standards will find these strips valuable but must balance energy costs and installation complexity in their procurement decisions.

Related Video: LED STRIP INSTALLATION ON STAIRS

Key Industrial Applications of led stairs strip lights

| Industry/Sector | Specific Application of led stairs strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Real Estate | Staircase illumination in office buildings and malls | Enhances safety and aesthetics, reduces accidents, energy saving | Durability, brightness level, compliance with local safety codes |

| Hospitality & Tourism | Decorative and safety lighting in hotels and resorts | Improves guest experience, highlights architectural features, energy efficiency | Waterproofing, color customization, ease of installation |

| Transportation & Infrastructure | Lighting for public stairways in airports, metro stations | Increases passenger safety, improves visibility, complies with accessibility standards | High durability, anti-slip compatibility, long lifespan |

| Retail & Entertainment | Accent lighting for stairs in shopping centers and theaters | Attracts customers, creates ambiance, enhances brand image | Color options, dimmable features, supplier flexibility |

| Industrial Facilities | Safety lighting on stairways in factories and warehouses | Reduces workplace accidents, meets occupational safety standards | High IP rating, resistance to dust and chemicals, robust build |

Commercial Real Estate

In office buildings and shopping malls across regions like Europe and South America, led stairs strip lights are extensively used to enhance both safety and visual appeal. These lights provide clear visibility on staircases, reducing the risk of falls and accidents, which is crucial for compliance with local safety regulations. For B2B buyers in Kenya or Brazil, sourcing LED strips with appropriate brightness and durability that meet regional electrical standards is essential. Energy efficiency also helps lower operational costs, a significant factor for property managers overseeing large commercial complexes.

Hospitality & Tourism

Hotels and resorts in the Middle East and Africa utilize led stairs strip lights to create inviting atmospheres while ensuring guest safety. These strips are often waterproof and customizable in color, enabling designers to integrate lighting seamlessly with the venue’s branding and décor. For international buyers, it is important to select suppliers offering flexible packaging and customization options to accommodate specific design requirements and installation conditions, especially in humid or outdoor environments.

Transportation & Infrastructure

Public transport hubs such as airports and metro stations in Europe and South America require led stairs strip lights that meet stringent safety and accessibility standards. These lights improve passenger safety by providing consistent illumination and are designed to withstand heavy foot traffic and environmental exposure. Buyers should prioritize products with high durability, anti-slip features, and compliance certifications, ensuring longevity and reliability in demanding infrastructure settings.

Retail & Entertainment

In retail stores and entertainment venues, led stairs strip lights serve a dual purpose of safety and aesthetic enhancement. They help create a dynamic ambiance that attracts customers and highlights key architectural elements. Businesses in regions like the Middle East and Africa benefit from sourcing LED strips with dimmable and color-changing capabilities to tailor lighting effects for different events or seasons. Supplier flexibility in order volume and customization is critical to adapt to evolving marketing needs.

Industrial Facilities

Factories and warehouses across Africa and Europe use led stairs strip lights primarily for safety compliance and accident prevention. These environments demand LED strips with high ingress protection (IP) ratings to resist dust, moisture, and chemical exposure. For B2B buyers, it is vital to source robust, industrial-grade lighting solutions that align with occupational safety standards and can operate reliably under harsh conditions, thereby reducing downtime and enhancing worker safety.

Strategic Material Selection Guide for led stairs strip lights

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, which helps dissipate heat generated by LED strips. It typically withstands temperatures up to 150°C and offers good resistance to moisture and UV exposure, making it suitable for both indoor and outdoor stair applications.

Pros & Cons:

Aluminum’s durability and corrosion resistance make it ideal for long-term installations, especially in humid or coastal environments common in regions like the Middle East and parts of Africa. It is relatively easy to manufacture into extruded profiles or channels for LED strips, allowing for sleek, customizable designs. However, aluminum can be more expensive than plastics and requires anodizing or powder coating for enhanced surface protection and aesthetics.

Impact on Application:

Due to its excellent heat dissipation, aluminum helps maintain LED performance and longevity, which is critical for stair lighting that may operate for extended hours. Its corrosion resistance suits outdoor or semi-outdoor staircases exposed to weather. Aluminum’s rigidity also provides structural support, preventing damage from foot traffic or cleaning processes.

Considerations for International Buyers:

Buyers from Europe and South America should verify compliance with standards such as ASTM B221 (aluminum extrusions) and EN 755. In Africa and the Middle East, corrosion resistance is a priority due to environmental conditions; sourcing anodized aluminum with certifications can ensure durability. Availability of local anodizing services can reduce costs and lead times. Aluminum’s recyclability aligns well with sustainability goals increasingly emphasized in European markets.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance, transparency, and UV stability. It can withstand temperatures up to 135°C and offers good resistance to moisture and chemicals. Its optical clarity makes it an excellent diffuser material for LED stair strips.

Pros & Cons:

Polycarbonate is lightweight and provides excellent protection for LED strips against mechanical impacts and dust ingress, which is crucial for high-traffic stairways. It is easier and cheaper to mold into complex shapes than metals. However, it is less effective at dissipating heat compared to aluminum, potentially affecting LED lifespan if not paired with adequate heat sinks. Polycarbonate can yellow over time if not UV stabilized, which is a concern for outdoor installations in sunny climates like Brazil or Kenya.

Impact on Application:

Ideal for indoor staircases or covered outdoor areas where impact resistance and light diffusion are priorities. Its transparency enhances lighting aesthetics and safety by providing uniform illumination. For outdoor use, UV-resistant grades are recommended to prevent degradation.

Considerations for International Buyers:

Compliance with ISO 7823 (plastics for optical applications) and local fire safety standards (e.g., UL94 V-0 rating) is essential. Buyers in Africa and South America should ensure suppliers provide UV-stabilized polycarbonate to withstand intense sunlight. Polycarbonate’s lower weight reduces shipping costs, a significant factor for importers in remote regions.

Silicone Rubber

Key Properties:

Silicone rubber is flexible, weather-resistant, and can tolerate extreme temperatures ranging from -60°C to 230°C. It offers excellent resistance to UV radiation, moisture, and chemicals, making it highly durable in harsh environments.

Pros & Cons:

Silicone rubber is commonly used as a protective coating or encapsulant for LED strips on stairs, providing waterproofing and shock absorption. Its flexibility allows it to conform to curved or irregular stair profiles. However, silicone is more expensive than standard plastics and can be challenging to process in large-scale manufacturing. It does not provide structural support and is typically used in combination with other materials.

Impact on Application:

Best suited for outdoor or industrial staircases exposed to moisture, dust, and temperature extremes, such as those found in Middle Eastern or African climates. Silicone encapsulation extends LED strip life by preventing ingress of contaminants and mechanical damage.

Considerations for International Buyers:

Buyers should verify compliance with standards like ASTM D2000 for rubber materials and ensure suppliers offer food-grade or medical-grade silicone if required for specific applications. The higher cost may be justified by reduced maintenance and replacement frequency in demanding environments. Logistics considerations include packaging to prevent deformation during transit.

Stainless Steel (304 or 316 grades)

Key Properties:

Stainless steel offers exceptional strength, corrosion resistance, and temperature tolerance (up to 870°C for grade 304). Grades 316 provide enhanced resistance to chlorides and marine environments. Stainless steel is rigid and highly durable.

Pros & Cons:

Its robustness makes stainless steel suitable for stair strip light housings in commercial or industrial settings requiring high mechanical protection. It resists corrosion even in coastal or chemically aggressive environments. However, stainless steel is heavy, expensive, and more complex to fabricate compared to aluminum or plastics. It may also require surface finishing to improve aesthetics and fingerprint resistance.

Impact on Application:

Ideal for high-traffic public staircases or outdoor installations in harsh environments, such as ports or industrial plants in Europe or the Middle East. The material’s longevity reduces replacement cycles but increases upfront costs.

Considerations for International Buyers:

Compliance with EN 10088 or ASTM A240 standards is critical for quality assurance. Buyers in regions with high humidity or salt exposure (e.g., coastal Brazil or Kenya) should prefer grade 316 for better corrosion resistance. The heavier weight impacts shipping costs, so bulk orders and local fabrication can optimize expenses.

Summary Table

| Material | Typical Use Case for led stairs strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Outdoor and indoor staircases requiring heat dissipation and durability | Excellent heat dissipation and corrosion resistance | Higher cost than plastics; requires surface treatment | Medium |

| Polycarbonate | Indoor or covered outdoor staircases needing impact resistance and light diffusion | High impact resistance and optical clarity | Lower heat dissipation; potential UV yellowing | Medium |

| Silicone Rubber | Waterproofing and flexible protection for outdoor or industrial stairs | Extreme temperature tolerance and weather resistance | Higher cost; no structural support | High |

| Stainless Steel | High-traffic or industrial staircases needing maximum durability | Superior strength and corrosion resistance | Heavy, expensive, complex fabrication | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led stairs strip lights

Manufacturing Processes of LED Stairs Strip Lights

The production of LED stairs strip lights involves a series of carefully coordinated stages designed to ensure durability, performance, and aesthetic appeal. For international B2B buyers—especially those operating in markets like Kenya, Brazil, the Middle East, and Europe—understanding these manufacturing stages is crucial for selecting reliable suppliers and ensuring product quality.

1. Material Preparation

The manufacturing process begins with sourcing and preparing high-quality raw materials, including flexible printed circuit boards (PCBs), LED chips, resistors, connectors, and adhesives. The selection of LED chips, often from reputable manufacturers, directly impacts the brightness, energy efficiency, and lifespan of the final product. Materials must also meet specific fire-retardant and waterproof standards relevant to stair lighting applications.

2. PCB Forming and Circuit Integration

Flexible PCBs are cut and shaped to fit stair dimensions and design requirements. This stage includes precise soldering of LED chips and electrical components onto the PCB using automated surface-mount technology (SMT) lines. Advanced manufacturers employ pick-and-place machines for accuracy and consistency. The flexible nature of the PCB allows strips to conform to stair edges and corners seamlessly.

3. Assembly

After circuit integration, the LED strips undergo assembly processes, which include adding protective coatings or encapsulation layers to enhance water resistance and mechanical protection. For stairs, IP65 to IP67 waterproof ratings are common, achieved by applying silicone or epoxy resin coatings. Connectors and power supply units are attached according to the product design, ensuring easy installation and compatibility with existing electrical systems.

4. Finishing and Packaging

Final finishing involves cutting the strips to standardized or customized lengths, quality marking, and applying branding labels if required. Packaging is designed to protect products during international shipping, often using anti-static bags and cushioned boxes to prevent damage. Custom packaging options may also be offered to align with buyer branding and retail requirements.

Quality Assurance and Control Framework

Quality assurance (QA) and quality control (QC) are paramount in the production of LED stairs strip lights to guarantee safety, performance, and regulatory compliance. B2B buyers should prioritize suppliers who implement robust QA/QC systems aligned with international standards.

Relevant International and Industry Standards

– ISO 9001: The global benchmark for quality management systems, ensuring consistent manufacturing processes and continuous improvement. Suppliers certified with ISO 9001 demonstrate strong process control and customer focus.

– CE Marking (Europe): Indicates compliance with European Union safety, health, and environmental protection standards. CE certification is mandatory for LED products sold in Europe.

– RoHS Compliance: Restricts hazardous substances in electronic products, critical for markets enforcing environmental regulations.

– IP Ratings (Ingress Protection): Defines water and dust resistance levels, essential for LED strips used on stairs exposed to moisture or outdoor conditions.

– UL Certification (North America) and API Standards (where applicable): While UL is less common outside North America, some buyers in the Middle East and South America may require similar certifications for electrical safety.

Key Quality Control Checkpoints

A comprehensive QC system typically includes several inspection stages, each serving to detect and eliminate defects early in the production cycle:

- Incoming Quality Control (IQC): Verification of raw materials and components such as LED chips, PCBs, and connectors. IQC prevents defective materials from entering production, reducing downstream failures.

- In-Process Quality Control (IPQC): Continuous monitoring during PCB assembly and soldering processes. IPQC focuses on solder joint integrity, LED placement accuracy, and electrical continuity tests to catch faults immediately.

- Final Quality Control (FQC): Thorough testing of finished LED strips, including visual inspection, functional testing, and packaging verification. FQC ensures products meet specifications before shipment.

Common Testing Methods for LED Stairs Strip Lights

To assure product quality and reliability, manufacturers perform multiple tests:

- Electrical Testing: Includes voltage, current, and power consumption verification to ensure LEDs operate within specified ranges.

- Light Output Measurement: Using spectrometers or lux meters to verify brightness levels, color temperature, and uniformity across the strip.

- Waterproof and Dustproof Tests: Simulating environmental conditions to confirm IP rating claims. This may involve water immersion or dust chamber testing.

- Thermal Testing: Assesses heat dissipation capabilities to prevent overheating during prolonged use on stairs.

- Durability and Flexibility Tests: Evaluates the strip’s ability to bend without damaging the circuitry, critical for stair installations with curves or edges.

- Aging Tests: Prolonged operation under controlled conditions to predict lifespan and identify early failures.

How B2B Buyers Can Verify Supplier Quality Control

Ensuring supplier QC integrity is essential for international buyers who often cannot inspect products physically before shipment. Recommended verification strategies include:

- Factory Audits: Conduct on-site or third-party audits to assess manufacturing processes, quality control systems, and compliance with certifications like ISO 9001. Audits provide insight into supplier capabilities and operational standards.

- Review of QC Documentation: Request detailed quality reports, including test results, inspection records, and certification copies. Transparent documentation reflects supplier confidence and traceability.

- Third-Party Inspections: Engage independent quality inspection agencies to perform pre-shipment inspections (PSI) or in-line inspections (ILI). These inspections verify product conformity, packaging, and labeling accuracy.

- Sample Testing: Obtain product samples for laboratory testing in the buyer’s country or region to verify performance and compliance with local regulations before placing large orders.

- Supplier Performance Monitoring: Establish ongoing communication channels and performance metrics, including defect rates and delivery punctuality, to maintain quality over time.

QC and Certification Nuances for International B2B Buyers

Africa and Middle East:

Buyers in countries like Kenya and the UAE should emphasize compliance with IEC standards and CE marking, as many import regulations align with European norms. Additionally, waterproof ratings and electrical safety certifications are critical due to variable environmental conditions.

South America:

In markets such as Brazil, buyers must consider local certification requirements like INMETRO, which governs electrical product safety and quality. Ensuring suppliers provide compliant documentation can ease customs clearance and market acceptance.

Europe:

European buyers demand strict adherence to CE and RoHS standards, with particular attention to energy efficiency and environmental impact. Suppliers with ISO 9001 and additional environmental certifications (e.g., ISO 14001) are preferred for sustainability-conscious projects.

General Considerations:

– Customs and import regulations vary by country; buyers should verify that LED stairs strip lights meet local electrical safety and environmental standards to avoid shipment delays or rejections.

– Language and cultural differences may affect communication; choosing suppliers with multilingual support and clear documentation helps mitigate misunderstandings.

– Payment terms and warranty policies should be clearly negotiated to protect buyers in case of quality issues.

Conclusion

For international B2B buyers targeting LED stairs strip lights, a deep understanding of the manufacturing processes and quality assurance practices is indispensable. Partnering with manufacturers who implement rigorous material preparation, precise assembly techniques, and comprehensive QC checkpoints ensures reliable, high-performing products suitable for diverse markets. By leveraging certifications, factory audits, and third-party inspections, buyers in Africa, South America, the Middle East, and Europe can confidently source LED stairs strip lights that meet their technical requirements and regulatory demands, enabling successful project execution and long-term business growth.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led stairs strip lights Sourcing

Understanding the cost and pricing dynamics of LED stairs strip lights is essential for international B2B buyers aiming to optimize procurement budgets while securing quality products. The pricing structure reflects multiple components and market factors, especially relevant for buyers in regions such as Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Stairs Strip Lights

- Materials: The primary cost driver includes LED chips, flexible PCB substrates, resistors, adhesives, and protective coatings. High-quality LEDs and waterproof materials increase costs but ensure durability and performance, critical for stair installations.

- Labor and Manufacturing Overhead: Assembly, soldering, and quality control labor costs vary by manufacturing location. Factories with automated processes often offer better economies of scale, reducing unit costs.

- Tooling and Customization: Custom lengths, colors, or packaging require specific tooling setups, which add upfront costs. However, these can be amortized over large order volumes.

- Quality Control (QC): Rigorous QC processes, including testing for brightness uniformity, waterproofing, and electrical safety, contribute to higher production costs but reduce returns and warranty claims.

- Logistics and Shipping: Freight, customs duties, and insurance significantly affect landed costs, especially for buyers in Africa and South America where shipping routes may be longer and customs procedures more complex.

- Supplier Margin: Wholesalers and manufacturers include profit margins that reflect market demand, brand positioning, and service levels such as after-sales support and warranty terms.

Influencing Factors on Pricing

- Order Volume and Minimum Order Quantities (MOQ): Larger orders typically benefit from volume discounts. Buyers in emerging markets should negotiate MOQs carefully to balance inventory costs against price savings.

- Product Specifications and Customization: Features such as RGB color options, dimmability, smart controls, and waterproof ratings (IP65 or higher) impact costs. Customized branding or packaging also raises prices but can enhance market differentiation.

- Material Quality and Certifications: LED strips with certifications like CE, RoHS, or UL command premium prices but are essential for compliance and safety in European and Middle Eastern markets.

- Supplier Reliability and Location: Established suppliers with proven quality track records may charge higher prices but reduce risks of defects and delays. Proximity to supplier hubs in Asia can influence shipping costs and lead times.

- Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears shipping and customs costs, impacting the total purchase price. Flexible payment terms can also improve cash flow management.

Practical Tips for Buyers from Africa, South America, the Middle East, and Europe

- Negotiate Beyond Unit Price: Engage suppliers in discussions about payment terms, shipping options, and after-sales service to optimize overall procurement costs.

- Evaluate Total Cost of Ownership (TCO): Consider warranty, expected product lifespan, and energy efficiency. Investing slightly more upfront in higher-quality LED strips can reduce maintenance and replacement expenses.

- Request Samples Before Bulk Orders: Samples help verify product quality, color accuracy, and compatibility with local electrical standards, minimizing costly returns.

- Leverage Consolidated Shipping: Combining multiple orders or sourcing from suppliers offering consolidated freight can reduce logistics expenses.

- Understand Local Import Regulations: Be aware of import duties, taxes, and certification requirements in your country to avoid unexpected costs or shipment delays.

- Use Technology for Transparency: Employ supply chain management tools or platforms that offer real-time tracking and inventory insights to improve ordering accuracy and reduce stockouts.

Indicative Pricing Disclaimer

Prices for LED stairs strip lights vary widely based on specifications, volumes, and supplier terms. Typical wholesale prices may range from $3 to $15 per meter, influenced by factors such as LED density, waterproof rating, and smart features. Buyers should treat these figures as indicative and conduct direct supplier inquiries for precise quotations.

By comprehensively analyzing cost components and price influencers, international B2B buyers can make informed sourcing decisions that balance quality, cost-efficiency, and supply reliability in the competitive LED stairs strip lights market.

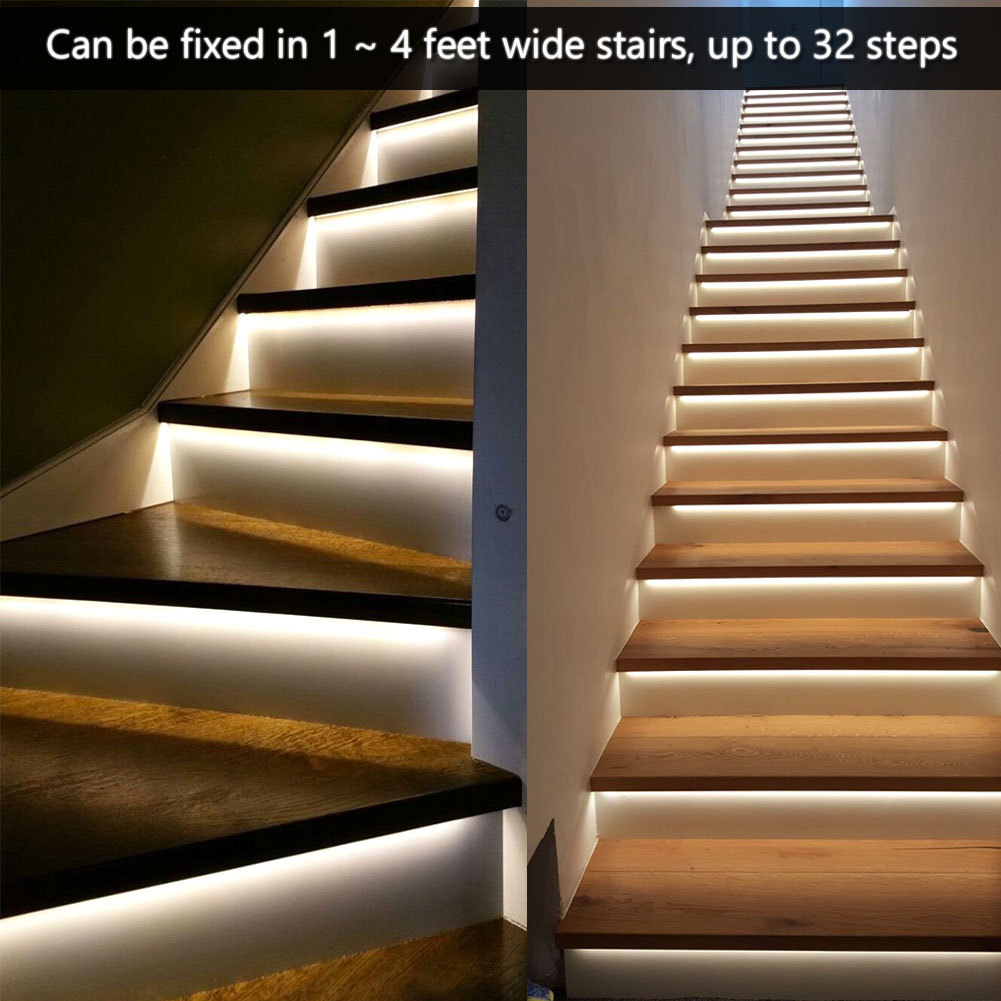

Illustrative Image (Source: Google Search)

Spotlight on Potential led stairs strip lights Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led stairs strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led stairs strip lights

Understanding the critical technical properties and common trade terminology associated with LED stairs strip lights empowers international B2B buyers to make informed procurement decisions. This knowledge is especially valuable for buyers in Africa, South America, the Middle East, and Europe, where diverse project requirements and supply chain nuances demand clarity and precision.

Key Technical Properties of LED Stairs Strip Lights

1. Material Grade and Build Quality

The material composition, typically high-grade flexible PCB (Printed Circuit Board) and durable silicone or PVC coatings, determines the strip’s longevity and resistance to wear. For stair lighting, materials must withstand foot traffic, moisture, and potential impacts. High material grade ensures safety, reduces maintenance costs, and guarantees consistent lighting performance—critical for public or commercial staircases.

2. IP Rating (Ingress Protection)

IP rating classifies the strip’s resistance to dust and water. For stairs, especially outdoor or semi-exposed ones, an IP65 rating or higher is preferred, indicating protection against water jets and dust ingress. Buyers should prioritize IP ratings that match their installation environments to avoid premature failures and costly replacements.

3. Luminous Intensity (Brightness) and Color Temperature

Measured in lumens and Kelvin respectively, these specs define how bright the strip lights are and the light hue they emit (warm, neutral, or cool white). Stair lighting requires sufficient brightness for safety without glare. Selecting the correct color temperature enhances aesthetics and user comfort, vital in hospitality or commercial settings.

4. Power Consumption and Voltage

LED strip lights commonly operate at 12V or 24V DC, with power consumption measured in watts per meter. Efficient power use reduces operational costs and simplifies power supply requirements. Buyers should confirm compatibility with existing electrical systems and consider energy efficiency certifications to optimize total cost of ownership.

5. Cuttable and Flexible Design

LED strips must be easily cut to custom lengths and flexible enough to fit stair contours and corners. This adaptability reduces installation complexity and material waste. For large-scale projects, suppliers offering pre-cut or customized lengths can enhance project scalability and speed.

6. Color Rendering Index (CRI)

CRI measures how accurately a light source reveals colors compared to natural light, rated on a scale up to 100. A CRI of 80 or above is desirable for stair lighting to ensure safety and visual clarity, helping users distinguish edges and textures clearly.

Common Trade Terminology for LED Stairs Strip Lights

1. OEM (Original Equipment Manufacturer)

OEM refers to products manufactured by one company to be rebranded and sold by another. For B2B buyers, choosing OEM suppliers can offer customization options and cost advantages but requires due diligence on quality and warranty terms.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory, negotiate pricing, and manage cash flow, especially critical when balancing budget constraints with project scale.

3. RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers asking for price, lead time, and terms for specific products. It initiates the procurement process and allows buyers to compare offers, ensuring they secure competitive pricing and favorable conditions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms like FOB (Free On Board) and CIF (Cost, Insurance, Freight) affect cost structure and risk allocation. Understanding these is essential for international buyers to avoid unexpected expenses and delays.

5. Bin Code

This is a code indicating the LED’s color and brightness binning category, reflecting consistency in light output. Buyers aiming for uniform lighting across installations should verify bin codes to ensure batch-to-batch consistency.

6. Dimmable

Indicates whether the LED strips can be adjusted for brightness levels. Dimmable strips add flexibility for ambiance control and energy savings, important in commercial venues or upscale residential projects.

By mastering these technical specifications and trade terms, B2B buyers can confidently evaluate suppliers, negotiate better deals, and select LED stairs strip lights that meet both performance and budgetary requirements across diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led stairs strip lights Sector

Market Overview & Key Trends

The global market for LED stairs strip lights is expanding rapidly, driven by increasing demand for energy-efficient, customizable, and aesthetically appealing lighting solutions in commercial, residential, and public infrastructure sectors. This growth is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where urbanization and modernization of building projects fuel the need for innovative lighting technologies.

Key Market Drivers:

- Energy Efficiency & Cost Savings: With rising energy costs and environmental regulations, LED technology’s low power consumption and long lifespan are major selling points. Businesses in Kenya, Brazil, and the UAE, for example, are prioritizing LED stairs strip lights to reduce operational expenses and carbon footprints.

- Urban Development & Safety Regulations: Many governments are enforcing stricter safety and accessibility standards, including illuminated stairways in public and commercial buildings, which propels demand for high-quality, durable LED strips.

- Aesthetic & Functional Versatility: LED stairs strip lights offer customizable colors, brightness levels, and designs, allowing architects and interior designers to create visually striking environments that also enhance user safety.

Emerging B2B Sourcing Trends:

- Customization & Smart Integration: Buyers increasingly seek suppliers who can provide tailor-made solutions such as specific lengths, colors, and smart control features (e.g., app-controlled dimming or color changes) to meet unique project requirements.

- Direct Sourcing & Supplier Diversification: To mitigate supply chain risks and reduce costs, businesses are sourcing directly from manufacturers or multiple LED module suppliers, especially in regions where import delays and tariffs are common.

- Digital Procurement Platforms: Online wholesale marketplaces and B2B portals facilitate faster sourcing, transparent pricing, and access to the latest LED technologies, benefiting buyers across continents.

Market Dynamics for International Buyers:

For international B2B buyers in emerging markets, understanding local infrastructure challenges, import regulations, and supplier reliability is critical. Establishing partnerships with suppliers offering comprehensive warranties, after-sales support, and logistics solutions ensures smoother project execution. Additionally, bulk purchasing strategies and consolidated shipments can optimize costs and inventory management.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to procurement decisions in the LED stairs strip lights sector. The environmental impact of lighting products—spanning raw material extraction, manufacturing, usage, and end-of-life disposal—has prompted buyers to prioritize green and ethical sourcing.

Environmental Impact Considerations:

- LED technology inherently reduces energy consumption compared to traditional lighting, but the sourcing of raw materials like rare earth elements and electronic components can have significant ecological footprints.

- Responsible disposal and recycling of LED strips are vital to prevent electronic waste accumulation, particularly in regions with limited recycling infrastructure.

Ethical Supply Chains:

- International buyers are demanding transparency across the supply chain to ensure compliance with labor standards, fair wages, and safe working conditions.

- Partnering with suppliers who adhere to internationally recognized certifications such as ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and Energy Star ensures product safety and environmental responsibility.

- Green certifications and eco-labels signal commitment to sustainable manufacturing practices, including reduced carbon emissions and use of recyclable or biodegradable materials.

Actionable Insights for Buyers:

- Incorporate sustainability criteria into supplier evaluation and selection processes.

- Favor LED strip lights that use non-toxic materials and offer modular designs to extend product lifespan and facilitate repair or upgrades.

- Engage with suppliers who provide lifecycle assessments and support take-back or recycling programs.

By embedding sustainability into procurement strategies, B2B buyers not only comply with evolving regulations but also enhance brand reputation and meet growing consumer demand for environmentally conscious products.

Evolution of LED Stairs Strip Lights

The evolution of LED stairs strip lights reflects broader advances in LED technology and lighting design. Initially, LED strips were simple, fixed-color light sources primarily used for decorative purposes. Over the past decade, innovations have transformed them into versatile, smart lighting solutions tailored for safety, energy efficiency, and aesthetics in architectural spaces.

Early models lacked flexibility in customization and durability, limiting their use in high-traffic environments. Today’s LED stairs strip lights feature waterproof coatings, high lumen output, and integrated control systems, enabling dynamic lighting scenarios and seamless integration with building automation.

For B2B buyers, understanding this progression highlights the importance of selecting suppliers who stay abreast of technological developments and can deliver state-of-the-art products that align with modern construction and design standards. This evolution underscores the sector’s shift from basic illumination to sophisticated, sustainable lighting solutions that meet diverse commercial needs globally.

Related Video: Perform Like a Pro: LED Stair Lights

Frequently Asked Questions (FAQs) for B2B Buyers of led stairs strip lights

-

How can I effectively vet LED stairs strip lights suppliers for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications such as ISO or CE marks to ensure compliance with international standards. Request detailed product specifications and third-party test reports to confirm quality. Check customer reviews and ask for references, especially from buyers in your region (Africa, South America, Middle East, Europe). Visit supplier facilities if possible or hire third-party inspection agencies for factory audits. Establish clear communication channels to assess responsiveness and transparency, which are critical for successful long-term partnerships. -

What customization options are typically available for LED stairs strip lights in bulk orders?

Most wholesale suppliers offer customization in length, color temperature, LED density, waterproof ratings, and packaging. You can also request specific voltage options or smart control compatibility (e.g., app-controlled RGB). Custom branding on packaging or product labels is often feasible, supporting your market differentiation. For international buyers, ensure customization requests comply with local electrical standards and certifications. Early discussions about customization can reduce lead times and ensure the product fits your exact project requirements and customer preferences. -

What are common Minimum Order Quantities (MOQs), lead times, and payment terms for international B2B orders?

MOQs vary widely depending on supplier and product complexity but typically range from 500 to 2000 meters per SKU for LED stairs strip lights. Lead times usually span 3 to 6 weeks, including customization and quality checks. Payment terms often require a 30%-50% deposit upfront, with balance paid before shipment or upon delivery. For buyers in Africa, South America, and the Middle East, negotiating payment terms such as Letters of Credit or escrow services can enhance security and trust. Always clarify these terms in your contract to avoid surprises. -

Which quality assurance certifications should I prioritize when sourcing LED stairs strip lights internationally?

Focus on internationally recognized certifications such as CE (Europe), RoHS (restriction on hazardous substances), UL or ETL (North America), and IEC standards. For buyers in regions with specific regulations, confirm compliance with local certifications (e.g., INMETRO in Brazil, SASO in Saudi Arabia). Quality assurance also involves supplier adherence to ISO 9001 for manufacturing processes. Request product test reports for photometric performance, waterproof ratings (IP65/IP67), and electrical safety to ensure the strips meet your performance and durability expectations. -

How can I optimize logistics and shipping for bulk LED stairs strip lights to regions like Kenya or Brazil?

Choose suppliers with experience shipping to your region to avoid customs delays and unexpected duties. Opt for consolidated shipping to reduce freight costs and minimize handling damage. Consider incoterms carefully; DDP (Delivered Duty Paid) is ideal for buyers unfamiliar with import procedures, while FOB or EXW may reduce upfront costs but require more import expertise. Work with freight forwarders knowledgeable in regional regulations and ensure packaging is robust to protect sensitive LED strips during transit, especially for long shipping routes. -

What steps should I take if I encounter disputes or product defects upon receiving LED stairs strip lights?

First, document all discrepancies with photos and detailed descriptions. Review your purchase agreement for warranty and return policies. Contact the supplier promptly, providing evidence and requesting resolution—repair, replacement, or refund. For international transactions, use formal communication channels and maintain records. If disputes escalate, consider mediation services or trade bodies like chambers of commerce relevant to your country or supplier’s. Building strong supplier relationships and clear contracts with quality clauses can minimize such risks upfront. -

Are there specific considerations for electrical standards when importing LED stairs strip lights to different regions?

Yes, electrical standards vary significantly across continents. For example, Europe uses 220-240V at 50Hz, while South America and Africa have mixed standards (Brazil uses both 127V and 220V). The Middle East often follows European or American standards depending on the country. Ensure your supplier can provide LED strips compatible with your region’s voltage and frequency to avoid costly modifications. Additionally, check plug and connector types for compatibility or request adapters. Compliance with local electrical safety regulations is mandatory to avoid import restrictions.

- How can I ensure scalability and consistent quality when ordering large quantities for multi-site projects?

Partner with suppliers who demonstrate robust quality control processes and have scalable manufacturing capabilities. Request batch consistency guarantees and conduct pre-shipment inspections or third-party quality audits regularly. Establish clear specifications and sample approvals before mass production. For multi-site projects across different countries, coordinate logistics to deliver consistent product versions to each location, minimizing variation. Maintaining open communication channels with your supplier ensures they understand your volume growth plans and can allocate resources accordingly, reducing risk of delays or quality fluctuations.

Strategic Sourcing Conclusion and Outlook for led stairs strip lights

Strategic sourcing of LED stairs strip lights is essential for international B2B buyers aiming to optimize cost-efficiency, quality, and supply chain reliability. Key takeaways include the importance of partnering with reputable suppliers who offer customizable, high-performance LED modules tailored to specific project requirements. Bulk purchasing not only reduces unit costs but also ensures consistency across large-scale installations, critical for commercial and infrastructural applications prevalent in markets like Kenya, Brazil, and the Middle East.

Effective supply chain management—encompassing supplier diversification, inventory control, and efficient logistics—further enhances resilience against market fluctuations and delivery delays. Leveraging technology and maintaining strong relationships with LED module manufacturers empower buyers to access the latest innovations, such as smart and waterproof strips, thereby future-proofing their lighting solutions.

Looking ahead, buyers across Africa, South America, the Middle East, and Europe should prioritize strategic sourcing as a driver of competitive advantage. By adopting a proactive, informed procurement approach, businesses can capitalize on emerging trends and evolving technologies in LED lighting. Now is the time to engage trusted suppliers, request samples for quality validation, and integrate advanced supply chain practices to ensure sustainable growth and superior project outcomes in the LED stairs strip lights market.