Guide to Led Rv Light Strips

- Introduction: Navigating the Global Market for led rv light strips

- Understanding led rv light strips Types and Variations

- Key Industrial Applications of led rv light strips

- Strategic Material Selection Guide for led rv light strips

- In-depth Look: Manufacturing Processes and Quality Assurance for led rv light strips

- Comprehensive Cost and Pricing Analysis for led rv light strips Sourcing

- Spotlight on Potential led rv light strips Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led rv light strips

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led rv light strips Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led rv light strips

- Strategic Sourcing Conclusion and Outlook for led rv light strips

Introduction: Navigating the Global Market for led rv light strips

LED RV light strips have emerged as a pivotal component in enhancing the functionality, aesthetics, and energy efficiency of recreational vehicles worldwide. For international B2B buyers, particularly from dynamic markets in Africa, South America, the Middle East, and Europe—including rapidly growing hubs like Mexico and the UAE—understanding the nuances of this product category is essential for making strategic sourcing decisions. These LED strips not only offer versatile lighting solutions but also contribute significantly to reducing power consumption and improving user experience in mobile environments.

This comprehensive guide delves into every critical aspect of LED RV light strips, starting with an overview of the various types available—from waterproof and flexible strips to customizable RGB options tailored for diverse installation needs. It explores the importance of high-quality materials such as premium LED chips, advanced PCBs, and durable adhesive backings that ensure longevity and superior performance. Detailed insights into the manufacturing and quality control processes reveal how rigorous testing and international compliance certifications guarantee product reliability and safety.

For B2B buyers, the guide also addresses how to identify reputable suppliers, evaluate cost structures including wholesale pricing benefits, and navigate logistics challenges unique to cross-border procurement. Additionally, it highlights market trends, emerging technologies, and practical FAQs to empower buyers with actionable knowledge. By equipping businesses with this in-depth understanding, the guide facilitates confident purchasing decisions that align with operational goals and market demands across diverse global regions.

Understanding led rv light strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard White LED Strips | Single-color white LEDs, varying brightness levels | Interior RV lighting, task lighting | Pros: Cost-effective, energy-efficient; Cons: Limited color options |

| RGB LED Strips | Multi-color LEDs with remote/app control capabilities | Ambient and accent lighting, customizable environments | Pros: Versatile, visually appealing; Cons: Higher cost, requires controllers |

| Waterproof LED Strips | Encased in silicone or epoxy for moisture resistance | Exterior RV lighting, undercarriage, outdoor use | Pros: Durable, weather-resistant; Cons: Slightly bulkier, higher price |

| Flexible vs. Rigid LED Strips | Flexible strips bend for curved surfaces; rigid strips are firm and durable | Custom installations, tight spaces (flexible); structural lighting (rigid) | Pros: Flexible for complex layouts; rigid offers better heat dissipation; Cons: Flexible may have shorter lifespan |

| High Lumen LED Strips | High brightness output with premium LED chips | Task lighting, security lighting, commercial RV setups | Pros: Superior illumination, long-lasting; Cons: Higher power consumption, costlier |

Standard White LED Strips are the most common choice for RV interiors, providing consistent white light suitable for general illumination and task lighting. They are cost-effective and energy-efficient, making them ideal for large volume purchases where budget constraints are important. Buyers should verify brightness levels (measured in lumens) and ensure compliance with international standards like CE or RoHS, especially when sourcing for multiple regions.

RGB LED Strips offer dynamic color-changing capabilities controlled via remotes or smartphone apps. These strips are perfect for creating customizable ambient lighting inside RVs, enhancing user experience. For B2B buyers targeting hospitality or premium RV markets in regions like Europe and the Middle East, offering RGB options adds value but requires understanding of controller compatibility and potential higher costs.

Waterproof LED Strips are designed with protective coatings or silicone casings to withstand moisture, dust, and outdoor conditions. These are essential for exterior RV lighting applications such as awnings, undercarriage illumination, or outdoor steps. Buyers from regions with high humidity or rainy climates (e.g., parts of Africa and South America) should prioritize waterproof ratings (IP65 and above) to ensure product durability.

Flexible vs. Rigid LED Strips cater to different installation needs. Flexible strips are thin and bendable, ideal for curved or irregular surfaces inside RVs, enabling creative lighting designs. Rigid strips, often aluminum-backed, provide enhanced heat dissipation and structural integrity, suitable for fixed installations requiring longevity. B2B buyers should assess the installation environment and balance flexibility with durability requirements.

High Lumen LED Strips utilize premium LED chips to deliver brighter light output, suitable for task-intensive areas or security lighting in commercial or luxury RVs. These strips consume more power but provide superior illumination and longer lifespans. Buyers targeting commercial fleets or high-end markets should consider these for enhanced performance but weigh energy usage and cost implications carefully.

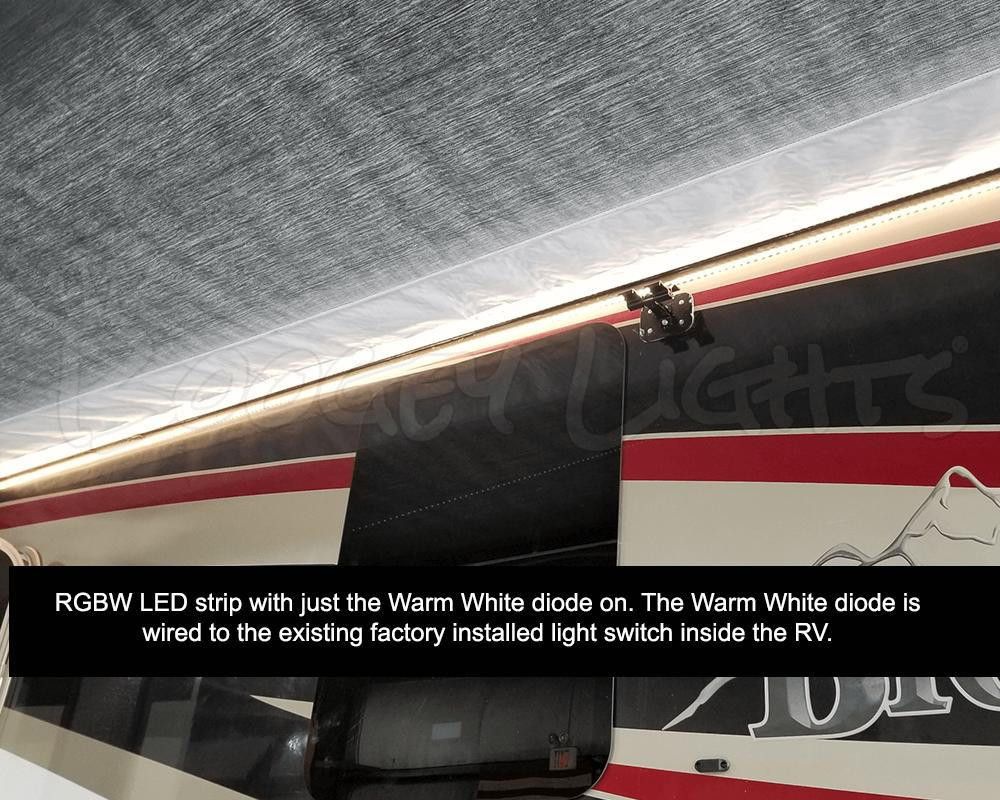

Related Video: RV LED AWNING LIGHT INSTALLATION | STEP BY STEP GUIDE

Key Industrial Applications of led rv light strips

| Industry/Sector | Specific Application of led rv light strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Recreational Vehicle Manufacturing | Interior ambient and task lighting in RV cabins | Enhances user comfort and energy efficiency; lightweight and flexible design reduces installation time and cost | Compliance with automotive and international safety standards; durability under vibration and temperature variations |

| Hospitality & Tourism | Lighting for mobile hotel units and luxury camper vans | Creates appealing, customizable lighting environments that improve guest experience and brand differentiation | Customizable color options; waterproof and dustproof ratings; consistent quality for bulk orders |

| Transportation & Logistics | Cargo area illumination in transport trucks and trailers | Improves visibility, safety, and operational efficiency during loading/unloading | Robust adhesive backing for vibration resistance; energy efficiency for extended battery life; ease of installation |

| Outdoor & Event Management | Temporary lighting for outdoor events and mobile exhibitions | Provides flexible, portable lighting solutions that enhance event aesthetics and safety | Weatherproofing (IP65+); ease of cutting and joining strips; compatibility with dimmers and controllers |

| Retail & Commercial Spaces | Accent and display lighting in mobile retail units and pop-up shops | Attracts customer attention, highlights products, and creates dynamic retail environments | Uniform brightness; color rendering index (CRI) for product display; scalability for large installations |

Recreational Vehicle Manufacturing

In the RV manufacturing sector, LED RV light strips serve as an essential component for interior ambient and task lighting. These strips offer a lightweight, flexible solution that fits the compact and often curved spaces within RV cabins. They solve common problems such as high energy consumption and limited installation space. For international buyers, especially from regions like Africa, South America, and the Middle East, sourcing LED strips compliant with automotive safety standards and capable of withstanding vibration and temperature fluctuations is crucial. High durability and consistent performance ensure long-term customer satisfaction and reduce maintenance costs.

Hospitality & Tourism

Mobile hotel units and luxury camper vans in the hospitality sector benefit significantly from LED RV light strips. They provide customizable lighting options that enhance the ambiance and overall guest experience, a key differentiator in competitive markets like Europe and the UAE. The ability to offer various colors and dimming capabilities allows businesses to tailor environments to different moods and themes. For B2B buyers, waterproof and dustproof features are critical to ensure reliability in diverse climatic conditions, while bulk purchasing options with consistent quality support large fleet outfitting.

Transportation & Logistics

LED RV light strips are increasingly used to illuminate cargo areas within transport trucks and trailers, improving safety and operational efficiency during loading and unloading, particularly in low-light conditions. For logistics companies operating in Africa and South America, where night-time operations are common, these lighting solutions reduce accidents and enhance productivity. Buyers must focus on sourcing strips with strong adhesive backing to withstand vibrations and shocks, alongside energy-efficient models that extend battery life in vehicles with limited power availability.

Outdoor & Event Management

In outdoor event management and mobile exhibitions, LED RV light strips offer versatile, portable lighting that can be easily installed and reconfigured. Their flexibility and weather resistance make them ideal for temporary setups in diverse environments, from the deserts of the Middle East to European outdoor festivals. Buyers should prioritize waterproof (IP65 or higher) and UV-resistant strips that maintain brightness and color integrity under harsh conditions. Compatibility with dimmers and controllers is also important to create dynamic lighting effects that enhance event appeal.

Retail & Commercial Spaces

Mobile retail units and pop-up shops leverage LED RV light strips for accent and display lighting to draw customer attention and showcase products effectively. These strips provide uniform brightness and high color rendering, ensuring merchandise is presented in the best light. For B2B buyers in Europe and Mexico, sourcing LED strips with scalability for large installations and consistency across batches is critical to maintain brand image and operational efficiency. Additionally, ease of installation and maintenance supports quick setup and turnover in fast-paced retail environments.

Strategic Material Selection Guide for led rv light strips

When selecting materials for LED RV light strips, understanding the properties, advantages, and limitations of each component is crucial for international B2B buyers. This ensures the final product meets performance expectations, regulatory requirements, and market preferences across diverse regions such as Africa, South America, the Middle East, and Europe.

1. Flexible Printed Circuit Board (FPCB) Material

Key Properties:

FPCBs are typically made from polyimide or polyester films, offering excellent flexibility, high-temperature resistance (up to 200°C for polyimide), and good electrical insulation. They support tight bending radii, which is essential for curved or irregular RV interior surfaces.

Pros & Cons:

– Pros: Enables versatile installation in confined or curved spaces; good thermal stability; lightweight.

– Cons: Higher cost compared to rigid PCBs; more complex manufacturing process; sensitive to mechanical damage if improperly handled.

Impact on Application:

Flexible PCBs allow LED strips to conform to RV contours, improving aesthetic integration and installation ease. They are ideal for dynamic lighting setups requiring bends or folds.

Considerations for International Buyers:

Regions with high ambient temperatures, such as the Middle East and parts of Africa, benefit from polyimide-based FPCBs due to their heat resistance. Buyers should verify compliance with IEC and UL standards for electrical safety and durability. European buyers often prefer materials compliant with RoHS and REACH regulations to ensure environmental safety.

2. LED Chips (Semiconductor Material)

Key Properties:

LED chips are primarily made from gallium arsenide (GaAs) or gallium nitride (GaN), offering high luminous efficacy, long lifespan (up to 50,000 hours), and low power consumption. They operate efficiently within a temperature range of -40°C to +85°C.

Pros & Cons:

– Pros: High brightness with low energy use; long operational life; minimal heat generation.

– Cons: Sensitive to electrostatic discharge (ESD); performance can degrade under extreme heat without proper heat dissipation.

Impact on Application:

High-quality LED chips ensure consistent brightness and color rendering, critical for RV lighting aesthetics and functionality. Proper thermal management materials must accompany these chips to prevent premature failure.

Considerations for International Buyers:

Buyers in humid or dusty environments (e.g., parts of South America and Africa) should prioritize LED chips with protective coatings or encapsulation to resist corrosion. Compliance with international certifications like CE and UL is essential to assure product reliability and safety.

3. Adhesive Backing (Material for Mounting)

Key Properties:

Common adhesives include 3M VHB (Very High Bond) tapes or acrylic-based adhesives. These provide strong adhesion to various RV interior surfaces, resist temperature fluctuations (-40°C to +120°C), and offer moisture resistance.

Pros & Cons:

– Pros: Simplifies installation; durable bond under vibration and temperature changes; moisture and UV resistant variants available.

– Cons: Adhesive strength can degrade on textured or oily surfaces; removal may damage surfaces or leave residue.

Impact on Application:

A reliable adhesive backing ensures the LED strip remains securely mounted despite RV movement and environmental changes. This is particularly important for buyers supplying to markets with rough terrain or high humidity.

Considerations for International Buyers:

In regions like the Middle East and South America, where heat and humidity are prevalent, selecting adhesives with proven resistance to UV and moisture is critical. Buyers should check for compliance with ASTM D3330 (adhesion testing) and ISO standards to guarantee performance.

4. Silicone or Polyurethane Coating (Protective Layer)

Key Properties:

Silicone and polyurethane coatings provide waterproofing (IP65 to IP68 ratings), UV resistance, and mechanical protection. Silicone is more flexible and heat resistant, while polyurethane offers superior abrasion resistance.

Pros & Cons:

– Pros: Enhances durability in outdoor or wet environments; protects against dust and mechanical wear; extends LED strip lifespan.

– Cons: Silicone coatings can be more expensive; polyurethane may yellow over time under UV exposure.

Impact on Application:

Protective coatings enable LED RV light strips to be used in exterior or high-moisture areas, such as awnings or undercarriage lighting. This expands product versatility for diverse climates.

Considerations for International Buyers:

Buyers targeting European and Middle Eastern markets should ensure coatings meet IP and EN standards for ingress protection. In Africa and South America, where outdoor exposure is common, UV resistance and waterproofing are decisive factors for material selection.

Summary Table of Materials for LED RV Light Strips

| Material | Typical Use Case for led rv light strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Board (FPCB) | Flexible mounting on curved or irregular RV surfaces | High flexibility and heat resistance | Higher cost and manufacturing complexity | High |

| LED Chips (GaN/GaAs semiconductor) | Light emission source with high brightness and efficiency | Long lifespan and energy-efficient | Sensitive to heat and ESD without proper handling | High |

| Adhesive Backing (3M VHB/Acrylic) | Secure mounting on various RV interior surfaces | Strong adhesion, moisture and temperature resistant | May degrade on textured/oily surfaces; residue on removal | Medium |

| Silicone/Polyurethane Coating | Protective waterproof and UV-resistant layer for outdoor use | Excellent environmental protection | Silicone is costly; polyurethane may yellow over time | Medium |

This guide equips international B2B buyers with critical insights to select materials that optimize performance, durability, and compliance for LED RV light strips tailored to diverse regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for led rv light strips

The manufacturing of LED RV light strips is a sophisticated process that blends precision engineering with rigorous quality assurance to meet the demanding requirements of mobile environments. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding these processes and quality protocols is critical for sourcing reliable, high-performance products. Below is a detailed exploration of the typical manufacturing stages, quality control frameworks, and best practices for verifying supplier compliance.

Manufacturing Process Overview for LED RV Light Strips

The production of LED RV light strips involves several carefully controlled stages, each essential for ensuring durability, efficiency, and safety in the variable conditions of recreational vehicles.

1. Material Preparation and Sourcing

High-quality raw materials form the foundation of superior LED strips. This includes:

- LED Chips: Sourced from premium manufacturers to guarantee brightness, longevity, and energy efficiency. The choice of chips directly impacts the luminous efficacy and reliability of the final product.

- Printed Circuit Boards (PCBs): Flexible or rigid PCBs are fabricated with materials that provide excellent heat dissipation, crucial for preventing overheating in confined RV spaces.

- Adhesive Backing: Industrial-grade adhesives suitable for varying temperatures and surface types found in RV interiors.

For international buyers, verifying that suppliers source components compliant with regional environmental regulations (such as RoHS in Europe) ensures smooth customs clearance and market acceptance.

2. PCB Fabrication and LED Mounting

The fabrication of PCBs is a critical step where the circuit board is designed to accommodate the specific layout of LED chips and connectors:

- PCB Manufacturing: Includes layering, etching, and applying conductive traces with materials like copper to optimize electrical performance and heat management.

- Surface Mount Technology (SMT): LED chips are precisely soldered onto the PCB using automated pick-and-place machines to ensure consistent placement and soldering quality.

This stage demands stringent process control to avoid defects like cold solder joints or misalignment, which can cause premature failure.

3. Assembly and Integration

Once PCBs with LEDs are prepared, the assembly process involves:

- Encapsulation: Applying protective coatings or silicone layers to shield LEDs from moisture, dust, and mechanical damage, essential for the variable environments in RVs.

- Cutting and Connecting: Strips are cut into standard or customized lengths and fitted with connectors or wiring harnesses compatible with RV electrical systems.

- Packaging: Final products are carefully packaged with anti-static and cushioning materials to prevent damage during international shipping.

Customization options at this stage—such as specific voltage ratings or waterproof ratings (IP65/IP67)—are often requested by B2B buyers to meet regional installation standards.

4. Finishing and Labeling

The finishing touches include labeling for traceability, branding, and certification marks. Accurate product information and compliance labels (CE, UL, RoHS) facilitate import/export processes and reassure buyers of product authenticity.

Quality Assurance and Control in LED RV Light Strip Production

Quality control (QC) in LED strip manufacturing is a multi-tiered system designed to detect and prevent defects at every production stage. International buyers should look for suppliers that implement recognized standards and transparent QC practices.

Relevant International Standards and Certifications

- ISO 9001: This quality management system standard ensures the supplier maintains consistent production quality and continuous improvement protocols.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- UL and ETL Listings: Commonly required in North America and increasingly recognized in other regions, these certifications attest to electrical safety.

- RoHS Compliance: Restricts hazardous substances, vital for environmental regulations in Europe and many other countries.

- IP Ratings (Ingress Protection): Critical for RV applications, IP65 or higher ratings confirm resistance to dust and water.

B2B buyers in regions like the Middle East or South America should verify if local import regulations require additional certifications or testing.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components before production begins to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including solder joint inspections, LED alignment, and PCB integrity.

- Final Quality Control (FQC): Comprehensive testing of finished strips, including visual inspection, functional tests, and packaging verification.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and resistance parameters to ensure safe operation within RV power systems.

- Luminous Intensity and Color Consistency: Measures brightness and color uniformity to meet design specifications.

- Thermal Testing: Assesses heat dissipation under typical operating conditions to prevent failure.

- Environmental Stress Testing: Includes moisture, vibration, and temperature cycling tests simulating RV environments to ensure durability.

- Adhesion Testing: Ensures adhesive backing maintains strong bonds on typical RV interior surfaces under varying conditions.

How B2B Buyers Can Verify Supplier Quality Control

For buyers from Africa, South America, the Middle East, and Europe, verifying supplier QC beyond certifications is critical to mitigate risks associated with long-distance procurement.

Supplier Audits

- Factory Audits: Conduct on-site or third-party audits to review manufacturing capabilities, process controls, and worker training.

- Process Audits: Focus on specific production stages such as PCB fabrication or LED mounting for compliance with best practices.

Documentation and Reporting

- Quality Control Reports: Request detailed inspection and testing reports for each batch.

- Certificates of Conformity: Ensure all products come with up-to-date certifications relevant to the buyer’s region.

- Sample Testing: Prior to large orders, obtain samples to independently verify performance and durability.

Third-Party Inspection Services

Engaging independent inspection agencies to perform random batch testing and factory audits provides an unbiased assessment of product quality and supplier reliability. This is particularly important for buyers in emerging markets where local enforcement of standards may vary.

Quality Assurance Nuances for International B2B Buyers

- Regional Compliance Variations: Buyers in Europe must prioritize CE and RoHS certifications, while those in the Middle East and Mexico might focus on UL or local standards. Understanding these nuances helps avoid regulatory delays.

- Climate Considerations: Buyers from hot or humid regions should specify higher IP ratings and robust adhesive qualities suited for those environments.

- After-Sales Support: Ensure suppliers offer warranties and clear return policies tailored for international shipping challenges.

- Customs and Import Regulations: Verify that packaging and labeling meet the import requirements of the destination country to prevent clearance issues.

Summary

For international B2B buyers sourcing LED RV light strips, a comprehensive understanding of the manufacturing process and quality assurance protocols is essential. High-quality raw materials, precise PCB fabrication, and meticulous assembly form the backbone of reliable products. Equally important is adherence to international and regional standards, robust QC checkpoints, and transparent supplier verification methods. By leveraging audits, third-party inspections, and sample testing, buyers in Africa, South America, the Middle East, and Europe can confidently procure LED RV light strips that deliver consistent performance, durability, and compliance across diverse markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led rv light strips Sourcing

When sourcing LED RV light strips for international B2B needs, understanding the detailed cost structure and pricing dynamics is essential to make informed procurement decisions. Various factors contribute to the final price, and being aware of these components helps buyers negotiate effectively and optimize total cost of ownership.

Key Cost Components in LED RV Light Strip Production

-

Materials: The primary cost driver includes high-quality LED chips, printed circuit boards (PCBs), adhesive backing, and protective coatings. Premium LED chips improve brightness and lifespan but come at a higher cost. PCB quality influences heat dissipation and durability, affecting long-term performance.

-

Labor: Skilled labor is required for precise LED chip mounting, soldering, and assembly. Labor costs vary significantly by manufacturing location, impacting overall pricing, especially when sourcing from regions with higher wages.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines and automation can reduce overhead, enabling competitive pricing.

-

Tooling and Setup: Initial tooling for custom designs or specific strip configurations adds upfront costs, which are amortized over the production volume.

-

Quality Control (QC): Rigorous testing for performance, durability, and compliance with certifications (e.g., CE, RoHS) ensures product reliability but adds to cost. QC processes help reduce returns and warranty claims.

-

Logistics and Shipping: Freight costs depend on shipment size, weight, and mode (air, sea, or land). International buyers from Africa, South America, the Middle East, and Europe must factor in customs duties, taxes, and potential delays.

-

Supplier Margin: Profit margins vary by supplier scale, brand reputation, and value-added services such as packaging customization or after-sales support.

Critical Price Influencers for B2B Buyers

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically secure lower unit prices due to economies of scale. Some manufacturers require MOQs that may affect upfront investment, so aligning order size with budget and storage capacity is vital.

-

Product Specifications and Customization: Features such as waterproofing (IP ratings), RGB color capabilities, flexible vs. rigid PCBs, and custom lengths or packaging influence cost. Custom orders usually incur higher tooling and setup fees.

-

Material Quality and Certifications: LED strips with certified components and compliance to international standards command premium prices but reduce risks related to safety and regulatory issues.

-

Supplier Location and Reliability: Suppliers closer to the buyer or with established logistics networks may offer better shipping terms and faster delivery, impacting overall costs.

-

Incoterms: Understanding shipping terms like FOB, CIF, or DDP affects who bears transportation risk and costs, influencing landed price.

Practical Tips for International B2B Buyers

-

Negotiate Based on Volume and Repeat Orders: Leverage potential for recurring business to negotiate better pricing, payment terms, or added services.

-

Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also warranty, energy efficiency, lifespan, and maintenance costs. High-quality LED strips might have a higher upfront cost but lower operational expenses.

-

Request Samples and Audit Quality: Testing samples prior to bulk purchase mitigates risks. For buyers in emerging markets, verifying certifications and supplier credibility is crucial.

-

Consolidate Shipments: Combining orders or sourcing multiple product types from a single supplier can reduce shipping costs and customs complexity.

-

Understand Regional Import Regulations: Buyers in Africa, South America, the Middle East, and Europe should factor in import duties, VAT, and compliance with local standards to avoid unexpected expenses.

-

Clarify Payment and Delivery Terms: Transparent agreements on payment methods and delivery timelines help avoid disputes and cash flow issues.

Disclaimer: Pricing for LED RV light strips varies widely based on specifications, volumes, and supplier agreements. The information provided serves as a general guide and should be supplemented with direct supplier quotations and market research tailored to your specific sourcing context.

Spotlight on Potential led rv light strips Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led rv light strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led rv light strips

Critical Technical Properties of LED RV Light Strips

Understanding the technical specifications of LED RV light strips is essential for making informed purchasing decisions, especially when sourcing internationally for diverse markets like Africa, South America, the Middle East, and Europe. Here are the key properties to evaluate:

-

LED Chip Quality and Luminous Efficacy

The LED chips are the core light source. High-quality chips deliver greater luminous efficacy, meaning more brightness per watt of power consumed. For B2B buyers, this translates into energy-efficient lighting solutions that reduce operational costs and improve customer satisfaction through longer-lasting products. -

PCB Type and Material Grade

The printed circuit board (PCB) supports and connects the LEDs. Flexible PCBs allow installation in curved or irregular spaces typical in RV interiors, while rigid PCBs offer sturdiness for fixed installations. The material grade affects heat dissipation, which is critical to prevent premature LED failure and maintain consistent brightness over time. -

Waterproof Rating (IP Rating)

For RV applications, where exposure to moisture or outdoor conditions is common, the ingress protection (IP) rating is vital. Ratings such as IP65 or IP67 indicate resistance to dust and water jets or immersion, respectively. Selecting the right waterproof level ensures durability and safety in various climates and terrains. -

Voltage and Power Consumption

Common LED RV strips operate at 12V or 24V DC, compatible with typical RV electrical systems. Understanding voltage requirements avoids compatibility issues. Additionally, power consumption per meter influences battery load and energy management, critical for mobile environments. -

Adhesive Backing Quality

The adhesive used on the strip’s backside affects installation ease and longevity. High-grade adhesives prevent peeling or displacement caused by vibrations and temperature fluctuations during travel, reducing maintenance costs and ensuring consistent lighting performance. -

Cutting and Length Tolerance

LED strips come in standard lengths but should allow precise cutting at designated intervals without damaging circuitry. Accurate length tolerance is important for custom installations, minimizing waste, and optimizing fit in confined RV spaces.

Common Trade Terminology in LED RV Light Strip Procurement

Navigating international B2B transactions requires familiarity with industry-specific terms that impact sourcing, pricing, and logistics. Here are essential terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that can be rebranded or customized by buyers. Partnering with OEMs allows businesses to offer unique products under their brand name, enhancing market differentiation. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. Understanding MOQs helps buyers plan inventory and manage cash flow, especially important for startups or businesses entering new markets with limited upfront investment. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, availability, and terms for specific products. RFQs streamline supplier comparisons and ensure buyers receive competitive offers tailored to their exact specifications. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowing these terms clarifies cost allocation and risk during transit, crucial for smooth cross-border procurement. -

Lead Time

The total time from placing an order to receiving the goods. Lead time affects project scheduling and inventory management, making it important to confirm with suppliers upfront to avoid delays. -

Batch Consistency

Refers to uniform quality and performance across production batches. For large-scale projects, consistent batches ensure reliable lighting results and reduce issues related to color variation or brightness differences.

By focusing on these technical properties and mastering relevant trade terminology, international B2B buyers can confidently source LED RV light strips that meet both quality and logistical requirements, ensuring successful procurement and customer satisfaction across diverse regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led rv light strips Sector

Market Overview & Key Trends

The global LED RV light strips market is experiencing robust growth driven by the increasing demand for energy-efficient, customizable lighting solutions in recreational vehicles. Key market drivers include the rising popularity of RV travel and outdoor lifestyles, especially in regions such as Europe and North America, which subsequently influences international B2B demand from Africa, South America, the Middle East, and Europe. Buyers in countries like Mexico and the UAE are increasingly seeking LED RV light strips that combine durability with innovative features to withstand diverse climates and usage conditions.

From a sourcing perspective, there is a clear shift toward suppliers offering advanced LED technologies such as smart, app-controlled strips and high-lumen, low-power consumption variants. Flexibility and modularity in design are critical, allowing buyers to customize lengths, colors, and functionalities to meet specific project needs. Wholesale purchasing remains a dominant trend, favored for cost efficiencies and supply chain simplification, especially for large-scale commercial projects and OEM partnerships.

Market dynamics also highlight a growing preference for suppliers who provide comprehensive quality assurance, including international certifications (CE, RoHS, UL) and rigorous testing protocols. This is particularly important for buyers in emerging markets where regulatory frameworks are evolving, and product reliability is paramount. Additionally, the proliferation of e-commerce platforms and direct manufacturer shipments has enhanced accessibility and reduced lead times, enabling faster market response for B2B buyers globally.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone for B2B buyers in the LED RV light strips sector, with environmental impact and ethical sourcing gaining unprecedented attention. LED technology inherently offers energy efficiency benefits by reducing power consumption and extending product lifespan, thus lowering the carbon footprint of lighting solutions. However, the sourcing of raw materials such as LED chips, PCBs, and adhesives must also align with green standards to ensure holistic sustainability.

Ethical supply chains are increasingly scrutinized, especially by buyers in Europe and the Middle East, who prioritize transparency and compliance with international labor and environmental standards. Certifications like RoHS (Restriction of Hazardous Substances) and CE (Conformité Européenne) are not only regulatory requirements but also signals of responsible manufacturing practices. More progressive suppliers are adopting eco-friendly materials, such as lead-free solder and recyclable packaging, to meet these demands.

For international B2B buyers, partnering with manufacturers who demonstrate a commitment to reducing waste, minimizing hazardous materials, and implementing circular economy principles can enhance brand reputation and meet growing consumer expectations. Additionally, verifying supplier adherence to environmental standards through audits or third-party certifications can mitigate risks associated with greenwashing and supply chain disruptions.

Brief Evolution and Historical Context

The evolution of LED RV light strips mirrors broader advancements in LED lighting technology over the past two decades. Initially, LED strips were simple, rigid circuits with limited color options and low brightness. The introduction of flexible PCBs and high-efficiency LED chips revolutionized their application in RVs, where adaptability and durability are critical.

Over time, integration with smart technologies and improvements in luminous efficacy have transformed LED strips into multifunctional lighting solutions that cater to aesthetic, safety, and energy-saving needs. For B2B buyers, understanding this evolution is essential to appreciate the value of newer products that offer enhanced performance, longer lifespans, and better integration capabilities. This historical perspective also underscores the importance of sourcing from suppliers who invest in continuous innovation and quality assurance to remain competitive in the global market.

Related Video: What Is International Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led rv light strips

-

How can I effectively vet suppliers of LED RV light strips for international trade?

To vet suppliers, start by verifying their business licenses and certifications such as CE, RoHS, or UL, which indicate compliance with international safety and quality standards. Request detailed product specifications, samples, and references from other B2B clients, especially those in your region. Evaluate their production capacity, lead times, and after-sales support responsiveness. Utilize third-party inspection services or audits to assess manufacturing facilities. Checking for transparent communication, documented quality control processes, and willingness to provide test reports will help ensure you partner with a reliable supplier suited for your market in Africa, South America, the Middle East, or Europe. -

What customization options are typically available for LED RV light strips when ordering wholesale?

Wholesale suppliers often offer customization in length, color temperature, LED density, waterproofing levels, and adhesive backing types to suit diverse installation environments. Many also provide options for custom packaging, branding, or connector types to align with your market or client preferences. For B2B buyers targeting specific regions, requesting features such as voltage compatibility (12V/24V), dimmable controls, or color-changing RGB capabilities can add value. Engaging suppliers early about your customization needs helps secure tailored products that differentiate your offerings and meet regulatory or functional requirements in your target markets. -

What are the typical minimum order quantities (MOQs), lead times, and payment terms for international buyers of LED RV light strips?

MOQs vary widely depending on supplier scale and customization, ranging from a few hundred to several thousand meters per order. Lead times generally span 3–6 weeks, factoring in production, quality testing, and international shipping. Payment terms often include a 30% deposit upfront with the balance paid before shipment or upon delivery. For new buyers, suppliers may request full payment or use secure payment methods like letters of credit. Negotiating MOQs and payment terms upfront helps manage cash flow and inventory, especially for buyers in emerging markets like Africa or South America where import cycles can be longer. -

How can I ensure the quality and safety of LED RV light strips for my international customers?

Demand products with internationally recognized certifications such as CE, RoHS, UL, or ETL to guarantee compliance with safety and environmental standards. Request detailed quality assurance documentation including material sourcing, PCB fabrication, LED chip brand, and adhesive quality. Insist on rigorous pre-shipment inspections and test reports covering brightness, durability, water resistance, and electrical safety. Sampling and pilot orders can validate product performance in your specific climate or usage conditions. Partnering with suppliers who maintain transparent quality control processes reduces risk of defects, returns, and reputational damage in your target markets. -

What logistics considerations should international B2B buyers of LED RV light strips keep in mind?

Plan for shipping methods that balance cost, speed, and product safety—sea freight is economical for large orders but slower, while air freight offers faster delivery at higher costs. Confirm that suppliers use robust packaging to prevent damage during transit, especially for fragile LED components. Understand import duties, taxes, and customs clearance procedures specific to your country (e.g., UAE, Mexico, South Africa) to avoid delays. Coordinate with freight forwarders experienced in handling electronic goods and negotiate consolidated shipments to optimize costs. Tracking shipments and maintaining clear communication with suppliers ensures smooth delivery and inventory management. -

How should I handle disputes or quality issues with LED RV light strip suppliers?

Establish clear contractual terms before ordering, specifying quality standards, inspection rights, delivery timelines, and dispute resolution mechanisms. If issues arise, document defects with photos and test data, then communicate promptly and professionally with the supplier. Most reputable suppliers offer warranties and replacement policies. Escalate disputes through mediation or arbitration clauses if necessary. Maintaining good supplier relationships and transparent communication often leads to amicable resolutions. For high-value or recurring purchases, consider third-party quality inspections and escrow payment arrangements to mitigate risks. -

Are there regional compliance or certification differences I should be aware of when sourcing LED RV light strips?

Yes. Different regions have distinct regulatory requirements. For example, the European Union mandates CE marking and RoHS compliance to restrict hazardous substances, while the UAE and other Middle Eastern countries may require additional local certifications or conformity assessments. South American countries might have varying import regulations and safety standards. It’s vital to verify that your supplier’s products meet all applicable certifications for your target markets to ensure legal importation and customer safety. Collaborating with suppliers familiar with regional standards helps streamline compliance and market entry. -

What are best practices for negotiating pricing and terms with LED RV light strip suppliers for international B2B purchases?

Begin by clearly defining your order volume, customization needs, and delivery timelines to receive accurate quotes. Compare multiple suppliers to benchmark pricing and service levels. Leverage bulk order potential to negotiate discounts, flexible MOQs, or better payment terms. Clarify shipping responsibilities (Incoterms) to understand cost allocation. Request sample orders to verify quality before committing to large purchases. Building long-term relationships through transparent communication and reliability often leads to improved pricing and priority service. Being well-informed about supplier capabilities and market standards empowers you to negotiate effectively and secure favorable deals.

Strategic Sourcing Conclusion and Outlook for led rv light strips

In navigating the dynamic market of LED RV light strips, strategic sourcing remains paramount for international B2B buyers. Prioritizing suppliers who demonstrate rigorous quality control, use premium LED chips, and adhere to global certifications ensures durable, efficient, and compliant products that meet diverse regional standards. Leveraging wholesale opportunities not only reduces costs but also provides access to a broad spectrum of customizable options, enabling businesses to tailor solutions to unique project demands across Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Key considerations include verifying supplier reliability, requesting product samples, and assessing warranty and after-sales support to mitigate risks and enhance supply chain resilience. Additionally, understanding the critical role of material quality—from PCB fabrication to adhesive backing—empowers buyers to make informed decisions that safeguard product longevity and customer satisfaction.

Illustrative Image (Source: Google Search)

Looking ahead, the LED RV lighting sector is poised for innovation with smart, energy-efficient technologies and expanding customization capabilities. International buyers are encouraged to cultivate strong supplier partnerships and stay abreast of emerging trends to capitalize on evolving market demands. By adopting a proactive, well-informed sourcing strategy, businesses can secure competitive advantages and drive sustainable growth in their lighting portfolios worldwide.