Guide to Led Light Strip Tape

- Introduction: Navigating the Global Market for led light strip tape

- Understanding led light strip tape Types and Variations

- Key Industrial Applications of led light strip tape

- Strategic Material Selection Guide for led light strip tape

- In-depth Look: Manufacturing Processes and Quality Assurance for led light strip tape

- Comprehensive Cost and Pricing Analysis for led light strip tape Sourcing

- Spotlight on Potential led light strip tape Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led light strip tape

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led light strip tape Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led light strip tape

- Strategic Sourcing Conclusion and Outlook for led light strip tape

Introduction: Navigating the Global Market for led light strip tape

The global demand for LED light strip tape continues to surge as industries across Africa, South America, the Middle East, and Europe embrace energy-efficient, versatile lighting solutions. For international B2B buyers, mastering the complexities of this dynamic market is essential to securing quality products that align with project specifications, budget constraints, and regulatory standards. LED strip tapes offer unparalleled flexibility for commercial, architectural, retail, and industrial applications—making them a critical component in modern lighting design and infrastructure.

This comprehensive guide serves as your strategic resource, delivering in-depth insights into the diverse types and materials of LED strip tapes, advanced manufacturing and quality control processes, and trusted supplier networks worldwide. Buyers will benefit from detailed analyses of cost structures, emerging market trends, and regional considerations to optimize procurement strategies. Additionally, practical FAQs and sourcing tips are provided to address common challenges faced by buyers in emerging and established markets such as Italy and Germany.

By leveraging this knowledge, B2B buyers can confidently navigate supplier selection, negotiate favorable terms, and ensure product compliance and performance. Whether outfitting large-scale commercial projects or stocking retail inventories, this guide empowers decision-makers to unlock value and drive long-term success in the evolving global LED strip tape marketplace.

Understanding led light strip tape Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color LED Strip | Emits a fixed, single color light; available in various brightness levels | Retail displays, signage, architectural lighting | Pros: Cost-effective, simple installation; Cons: Limited design flexibility |

| RGB LED Strip | Capable of producing multiple colors via red, green, blue LEDs, often with controller compatibility | Hospitality, event lighting, dynamic retail environments | Pros: Versatile color options, customizable effects; Cons: Higher cost, requires controllers |

| Waterproof LED Strip | Encased in silicone or epoxy for moisture resistance | Outdoor lighting, industrial settings, wet areas | Pros: Durable, weather-resistant; Cons: Slightly bulkier, higher price |

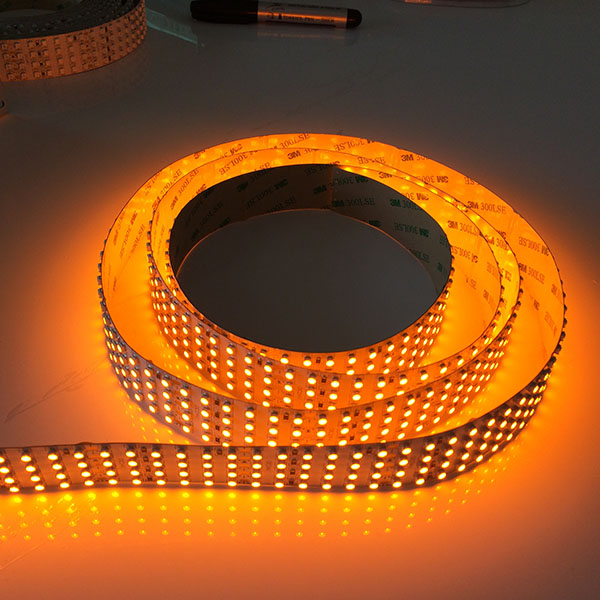

| High-Density LED Strip | Higher LED count per meter for brighter, uniform illumination | Task lighting, commercial spaces, photography studios | Pros: Superior brightness and uniformity; Cons: Increased power consumption, cost |

| Flexible LED Strip Tape | Highly bendable and cuttable, suitable for irregular shapes and tight spaces | Custom installations, automotive, architectural accents | Pros: Easy to install in complex spaces; Cons: May require specialized connectors |

Single-Color LED Strip

Single-color LED strips are the most straightforward type, emitting a consistent light color such as warm white or cool white. They are highly cost-effective and ideal for businesses focused on functional lighting like retail shelving or architectural accent lighting. When purchasing in bulk, buyers should consider the required brightness level and ensure compatibility with existing power supplies. This type suits buyers seeking simplicity and reliability without the need for color variation.

RGB LED Strip

RGB LED strips offer dynamic color-changing capabilities by combining red, green, and blue LEDs controlled via remote or smart systems. This versatility makes them popular for hospitality venues, event spaces, and retail environments aiming to create engaging atmospheres. B2B buyers should evaluate controller compatibility, ease of integration with smart systems, and the supplier’s ability to provide customization options, such as specific color presets or branding colors.

Waterproof LED Strip

Encased with protective silicone or epoxy coatings, waterproof LED strips are designed to withstand moisture, dust, and harsh environmental conditions. These are essential for outdoor applications, industrial zones, or wet areas like kitchens and bathrooms. Buyers targeting markets in regions with high humidity or outdoor lighting needs should prioritize IP ratings (e.g., IP65, IP67) and confirm supplier testing standards to ensure durability and compliance with local regulations.

High-Density LED Strip

High-density strips feature a greater number of LEDs per meter, delivering brighter and more uniform lighting. They are well-suited for commercial task lighting, photography studios, or any application requiring intense illumination without hotspots. For B2B buyers, assessing the power requirements and heat dissipation solutions is critical to avoid premature failure. Partnering with suppliers that offer integrated heat management solutions can enhance product longevity.

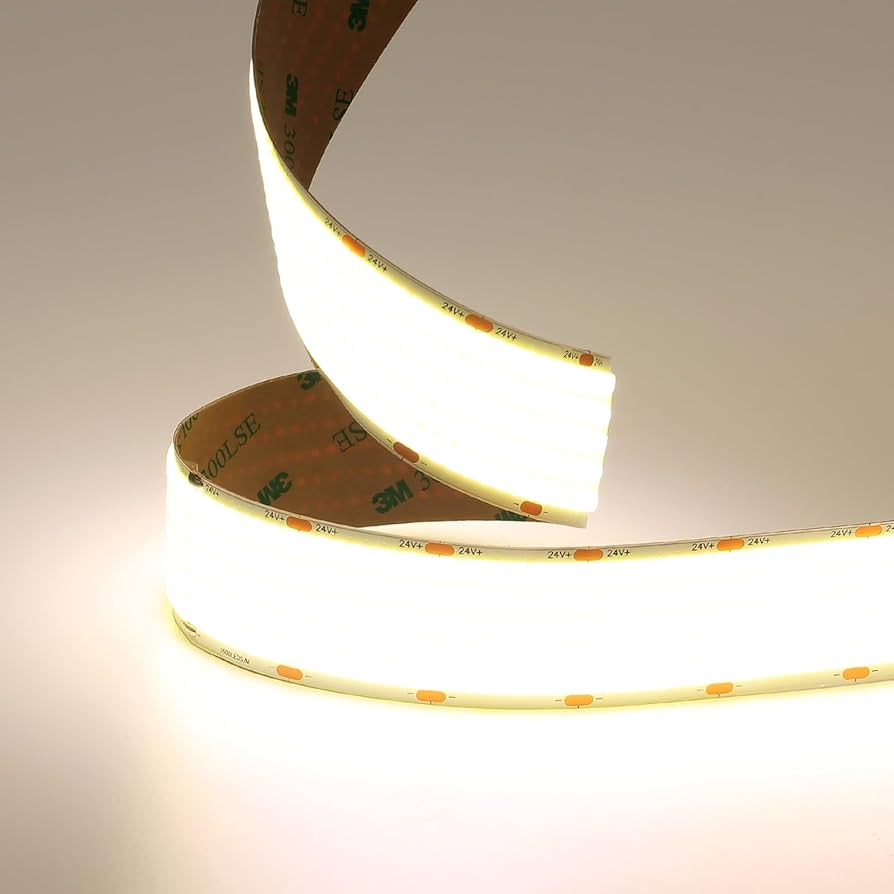

Flexible LED Strip Tape

Flexible LED strip tapes are designed for complex installations requiring bends, curves, or irregular shapes. Their adaptability makes them ideal for custom architectural projects, automotive lighting, or creative retail displays. Buyers should consider the quality of connectors and the ease of cutting and rejoining the strips. Evaluating supplier support for custom lengths and compatibility with various mounting accessories is important for seamless project execution and scalability.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Key Industrial Applications of led light strip tape

| Industry/Sector | Specific Application of led light strip tape | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in stores and showrooms | Enhances product visibility, attracts customers, and boosts sales | Quality of color rendering, customizable lengths, durability |

| Hospitality & Leisure | Ambient and decorative lighting in hotels and restaurants | Creates inviting atmospheres, supports brand aesthetics, energy savings | Waterproof ratings, dimmability, ease of installation |

| Automotive & Transportation | Interior cabin and exterior accent lighting | Improves safety, aesthetic appeal, and brand differentiation | Flexibility for curved surfaces, vibration resistance, certifications |

| Architectural & Interior Design | Cove and recessed lighting in offices and residential buildings | Provides seamless, modern lighting solutions, energy efficiency | Heat dissipation capability, diffuser quality, compatibility with control systems |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Enhances worker safety, increases productivity, reduces energy costs | Robustness, IP rating for dust/moisture, long lifespan |

Retail & Commercial Lighting

LED light strip tape is widely used in retail environments for accentuating product displays, shelving, and signage. It provides uniform, vibrant illumination that draws customer attention and highlights merchandise details, crucial for competitive markets in Europe and South America where visual merchandising is a key sales driver. Buyers must prioritize strips with high color rendering index (CRI) and customizable lengths to fit diverse store layouts. Durable, consistent lighting solutions reduce maintenance costs and downtime, essential for large retail chains sourcing in bulk.

Hospitality & Leisure Environments

In the hospitality sector, LED strip tapes create dynamic and customizable ambient lighting in hotel lobbies, restaurants, and bars. These strips support brand identity through color options and dimmable features, enhancing guest experience while reducing energy consumption. For buyers in regions like the Middle East and Africa, waterproof and dustproof LED strips are critical due to environmental conditions. Easy installation and remote control compatibility are also valued for quick updates to lighting schemes without disrupting operations.

Automotive & Transportation Applications

Within automotive manufacturing and transportation, LED strip tapes serve both functional and decorative roles—illuminating interiors, dashboards, and exterior accents. Their flexibility allows integration into curved surfaces and tight spaces, meeting stringent European standards for safety and quality. Buyers must ensure vibration resistance and certifications (e.g., ECE compliance) to guarantee durability and compliance. These features help manufacturers and fleet operators improve vehicle aesthetics while maintaining operational safety.

Architectural & Interior Design

Architects and interior designers rely on LED strip tape for elegant cove, recessed, and under-cabinet lighting that offers seamless, glare-free illumination. This is especially relevant in upscale European and Middle Eastern markets where design sophistication is paramount. Buyers should focus on products with excellent heat dissipation and high-quality diffusers to avoid hotspots and prolong lifespan. Integration with smart lighting controls is increasingly important for energy management and user convenience in commercial and residential projects.

Manufacturing & Warehousing

In industrial settings, LED strip tapes provide bright, reliable task lighting along production lines and storage racks, improving worker safety and operational efficiency. For B2B buyers in Africa and South America, robustness against dust and moisture is essential, necessitating IP-rated strips. Long lifespan and energy efficiency reduce replacement frequency and utility costs, critical for large-scale facilities. Buyers should also consider ease of installation and maintenance to minimize downtime in fast-paced manufacturing environments.

Related Video: How to Use Solderless LED Strip Light Connectors

Strategic Material Selection Guide for led light strip tape

When selecting materials for LED light strip tape, B2B buyers must consider factors such as durability, thermal management, environmental resistance, and compliance with international standards. The choice of material directly impacts the product’s performance, longevity, and suitability for specific applications, especially in diverse climates and regulatory environments across Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used polymer for LED strip tape insulation and housing. It offers good flexibility, moderate heat resistance (typically up to 60-70°C), and basic moisture resistance. PVC is chemically stable but can degrade under prolonged UV exposure unless specially treated.

Pros & Cons:

PVC is cost-effective and easy to manufacture, making it a popular choice for large-scale production. However, it has limited high-temperature tolerance and can become brittle in very cold environments. It also has moderate environmental resistance, which may require additional coatings or additives for outdoor use.

Impact on Application:

PVC-based LED strips are suitable for indoor applications such as residential and commercial lighting where temperature extremes and UV exposure are limited. For outdoor or industrial environments, PVC may require protective channels or covers.

International B2B Considerations:

Buyers in Europe (e.g., Germany, Italy) often require compliance with RoHS and REACH regulations restricting hazardous substances in PVC. In regions like the Middle East and Africa, PVC’s flame retardancy ratings (UL94 V-0 or equivalent) are critical due to safety standards. South American markets may prioritize cost-efficiency but increasingly demand eco-friendly materials, influencing PVC formulations.

Silicone Rubber

Key Properties:

Silicone rubber offers excellent thermal stability (operating temperatures from -60°C to 200°C), superior flexibility, and outstanding resistance to UV radiation, ozone, and moisture. It is inherently flame retardant and chemically inert.

Pros & Cons:

Silicone’s durability and weather resistance make it ideal for harsh environments, including outdoor and industrial applications. The main downside is higher material and manufacturing costs compared to PVC. Silicone extrusion and bonding require specialized equipment and expertise.

Impact on Application:

Silicone-encapsulated LED strip tapes excel in outdoor lighting, marine environments, and areas with extreme temperature fluctuations. Their flexibility also suits curved or irregular surfaces.

International B2B Considerations:

European buyers favor silicone for premium, long-lasting installations, aligning with strict environmental and safety standards (e.g., DIN EN 60598). In the Middle East and Africa, silicone’s heat resistance is advantageous for hot climates. South American buyers may weigh cost versus performance but recognize silicone’s value in premium commercial projects.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a rigid, transparent thermoplastic often used for LED strip diffusers or protective covers. It has high impact resistance, good thermal stability (up to ~130°C), and excellent optical clarity.

Pros & Cons:

PC provides superior mechanical protection and light diffusion, enhancing LED strip aesthetics and lifespan. It is more expensive and less flexible than PVC or silicone, and can yellow over time if not UV-stabilized.

Impact on Application:

PC is ideal for LED strips requiring robust protection and uniform light output, such as architectural lighting, retail displays, and outdoor signage. It is typically paired with aluminum profiles for enhanced heat dissipation.

International B2B Considerations:

European markets often mandate PC materials comply with stringent fire safety and optical standards (e.g., EN 13501-1). In Africa and South America, PC’s durability supports installations in public and commercial spaces. The Middle East benefits from PC’s UV resistance when properly treated.

Aluminum (for LED Channels and Backing)

Key Properties:

Aluminum is a metal used primarily for LED strip tape backing or housing profiles. It offers excellent thermal conductivity, corrosion resistance (especially anodized variants), and structural strength.

Pros & Cons:

Aluminum effectively dissipates heat, extending LED lifespan and maintaining brightness. It adds rigidity and mechanical protection but increases weight and cost. Manufacturing requires precision extrusion and finishing processes.

Impact on Application:

Aluminum-backed LED strips or profiles are essential for commercial, architectural, and outdoor applications where heat management and durability are critical. They also enable sleek, professional installations with integrated diffusers.

International B2B Considerations:

European buyers expect aluminum profiles to meet DIN or EN standards for corrosion resistance and mechanical properties. In hot and humid climates of Africa and the Middle East, anodized or powder-coated aluminum resists corrosion. South American markets appreciate aluminum for its longevity despite higher upfront costs.

| Material | Typical Use Case for led light strip tape | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Indoor residential and commercial lighting | Cost-effective, flexible, easy to manufacture | Limited heat and UV resistance; less durable outdoors | Low |

| Silicone Rubber | Outdoor, industrial, and harsh environment installations | Excellent heat, UV, and moisture resistance | Higher cost and manufacturing complexity | High |

| Polycarbonate (PC) | Protective covers and diffusers for architectural lighting | High impact resistance and optical clarity | Rigid, can yellow without UV stabilization | Medium |

| Aluminum | Backing and housing profiles for heat dissipation and protection | Superior thermal management and mechanical strength | Adds weight and cost; requires precise manufacturing | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led light strip tape

Understanding the manufacturing and quality assurance processes behind LED light strip tape is crucial for international B2B buyers aiming to secure reliable, high-performance products. This knowledge helps buyers from regions such as Africa, South America, the Middle East, and Europe (including markets like Italy and Germany) make informed sourcing decisions, ensuring compliance with local and international standards while optimizing cost-efficiency and product longevity.

Manufacturing Process of LED Light Strip Tape

The production of LED strip tape involves several carefully controlled stages, each critical to achieving consistent quality and performance. Below is a breakdown of the primary manufacturing phases:

1. Material Preparation

- Substrate Selection: The base material typically consists of flexible printed circuit boards (FPC), often made from polyimide or PET films. These substrates must be heat-resistant and flexible to accommodate various installation needs.

- LED and Component Sourcing: High-quality LEDs, resistors, and copper conductors are sourced, with a preference for components meeting recognized certifications (e.g., RoHS compliance).

- Raw Material Inspection: Incoming materials undergo initial quality checks to ensure they meet electrical, mechanical, and environmental specifications.

2. Circuit Forming

- Copper Foil Lamination: Copper layers are laminated onto the substrate to form the conductive pathways.

- Photolithography and Etching: Circuit patterns are created by applying photoresist and etching away unwanted copper, defining the LED pads and traces.

- Solder Mask Application: A protective solder mask is applied to prevent short circuits and enhance durability.

Illustrative Image (Source: Google Search)

3. Assembly

- LED Placement: Automated pick-and-place machines accurately position LEDs and other surface-mounted components onto the PCB.

- Soldering: Reflow soldering techniques secure components to the board, ensuring strong electrical connections.

- Protective Coating: To improve moisture resistance and mechanical protection, a layer of silicone or epoxy resin is often applied, especially for outdoor or waterproof variants.

4. Finishing and Packaging

- Cutting and Sectioning: The continuous LED tape is cut into standard or customized lengths, with designated cutting marks.

- Adhesive Backing Application: A strong adhesive layer is applied to the reverse side, facilitating easy installation.

- Labeling and Packaging: Strips are labeled with batch numbers, certifications, and handling instructions before being packed in protective reels or boxes designed to prevent damage during transport.

Quality Assurance Framework

Robust quality assurance (QA) is vital to guarantee that LED strip tapes perform reliably across diverse environments and meet international compliance requirements. QA in LED strip tape manufacturing typically aligns with both general management standards and industry-specific certifications.

Key International and Industry Standards

- ISO 9001: This globally recognized quality management system standard ensures that suppliers maintain consistent manufacturing processes, continuous improvement, and customer satisfaction.

- CE Marking: Essential for products entering the European market, CE certification verifies conformity with EU safety, health, and environmental protection requirements.

- RoHS Compliance: Restricts hazardous substances in electronic components, critical for environmental and health safety.

- UL and ETL Listings: These North American safety certifications may also be relevant for international buyers targeting global markets.

- IP Ratings (Ingress Protection): Defines the water and dust resistance level, crucial for outdoor or industrial applications.

- Other Regional Standards: Buyers in the Middle East or South America should verify compliance with local standards such as SASO (Saudi Arabia) or INMETRO (Brazil) as applicable.

Quality Control Checkpoints

Quality control (QC) is integrated at multiple stages of manufacturing to detect defects early and ensure the final product meets specifications.

- Incoming Quality Control (IQC): Inspection of raw materials and components for compliance with technical requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection and LED placement accuracy.

- Final Quality Control (FQC): Comprehensive testing of finished products, including electrical functionality, physical inspection, and packaging integrity.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and luminous efficacy to ensure LED strips meet design specifications.

- Thermal Testing: Assesses heat dissipation to prevent premature LED failure.

- Durability Testing: Includes bending, tensile strength, and environmental exposure tests (humidity, temperature cycling) to simulate real-world conditions.

- Optical Testing: Measures color consistency (using spectrometers) and brightness uniformity.

- Waterproof Testing: For IP65 and above rated strips, immersion or spray tests confirm water resistance.

- Safety Testing: Ensures insulation resistance and absence of electrical hazards.

Verifying Supplier Quality Controls for B2B Buyers

For buyers across Africa, South America, the Middle East, and Europe, ensuring supplier reliability is essential due to varying regional regulatory environments and market expectations.

Supplier Audits and Inspections

- On-site Audits: Conducting factory visits or commissioning third-party inspection agencies to review manufacturing processes, quality management systems, and worker training.

- Process Audits: Evaluating adherence to ISO 9001 and other certifications through documented evidence and operational observations.

- Random Sampling: Independent testing of product samples in accredited laboratories to validate supplier claims on performance and certifications.

Documentation and Traceability

- Request comprehensive Certificates of Conformity (CoC) and Test Reports for each batch.

- Verify Material Safety Data Sheets (MSDS) and RoHS compliance certificates.

- Ensure traceability through batch numbers and production records to facilitate warranty claims and quality tracking.

Key Considerations for International Buyers

- Certification Nuances: European buyers, especially from Germany and Italy, prioritize CE and RoHS certifications, while buyers in the Middle East may require additional local conformity marks (e.g., SASO). African and South American buyers should confirm compliance with import regulations and electrical safety standards relevant to their countries.

- Customs and Import Regulations: Verify that suppliers provide all necessary documentation to avoid customs clearance delays.

- After-Sales Support: Confirm supplier commitment to warranty service, technical support, and replacement policies, which are vital for large-scale or ongoing projects.

- Communication and Lead Times: Consider suppliers’ ability to provide clear communication in multiple languages and reliable delivery schedules, which impact project planning and cost management.

By understanding the detailed manufacturing stages and comprehensive quality assurance protocols, international B2B buyers can confidently evaluate LED strip tape suppliers. Prioritizing suppliers with robust ISO-certified processes, recognized product certifications, and transparent QC practices ensures procurement of durable, efficient, and compliant LED lighting solutions tailored to diverse regional market demands.

Related Video: Inspire LED Tape Light Manufacturing Process

Comprehensive Cost and Pricing Analysis for led light strip tape Sourcing

Understanding Cost Components in LED Light Strip Tape Sourcing

When sourcing LED light strip tape for B2B purposes, especially across diverse international markets such as Africa, South America, the Middle East, and Europe, understanding the underlying cost structure is essential to making informed purchasing decisions.

- Materials: The core cost driver is the raw materials used, including LED chips, flexible circuit boards, resistors, adhesives, and protective coatings. Higher-grade LEDs (e.g., SMD 2835 or 5050) and premium waterproofing materials increase costs but improve longevity and performance.

- Labor and Manufacturing Overhead: Labor intensity varies by region and production complexity. Automated assembly lines reduce labor costs but increase initial capital expenditure. Overhead includes factory utilities, maintenance, and indirect labor.

- Tooling and Setup: Custom lengths, unique PCB designs, or specialized packaging require tooling investments. These are often amortized over large order volumes but can significantly impact pricing for smaller runs or customized batches.

- Quality Control (QC): Rigorous testing protocols—such as color consistency, brightness uniformity, and waterproof certification—add to costs but reduce defective returns and warranty claims.

- Logistics and Shipping: Freight charges, customs duties, import taxes, and insurance vary widely depending on origin, destination, and shipping terms. For buyers in Africa, South America, and the Middle East, port handling fees and inland transport must be factored into total landed costs.

- Supplier Margin: Wholesale suppliers incorporate a margin that reflects their service level, reliability, and product exclusivity. Established suppliers with strong brand reputations may charge a premium.

Key Pricing Influencers for Bulk LED Strip Tape Purchases

Several factors influence the final price of LED light strip tapes in a B2B context:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders usually benefit from significant price breaks. Negotiating MOQ flexibility can be critical for businesses with constrained storage or cash flow.

- Product Specifications and Customization: Customized color temperatures, waterproof ratings (IP65, IP67), and integrated smart features (e.g., app control, dimmability) increase unit costs. Balancing feature needs against budget constraints is vital.

- Material Quality and Certifications: Products with certifications such as CE, RoHS, UL, or ETL command higher prices but assure compliance with international standards, crucial for European buyers and those targeting regulated markets.

- Supplier Reputation and Location: Established suppliers in manufacturing hubs like China or South Korea may offer competitive pricing but require careful vetting. Local or regional suppliers might offer better logistical advantages and after-sales support.

- Incoterms and Payment Terms: Shipping terms (FOB, CIF, DDP) significantly impact total costs. Buyers should evaluate who bears freight, insurance, and customs duties to avoid unexpected expenses.

Practical Tips for B2B Buyers to Optimize Cost Efficiency

For international buyers, especially those operating in emerging and diverse markets, optimizing procurement costs involves strategic negotiation and comprehensive cost analysis:

- Negotiate Beyond Unit Price: Engage suppliers on payment terms, shipping arrangements, warranty periods, and after-sales support. For instance, extended payment terms or supplier-managed logistics can reduce upfront capital needs.

- Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation costs, energy consumption, maintenance frequency, and expected lifespan. Higher initial costs may be justified by lower operating expenses and longer durability.

- Leverage Sample Testing: Request samples to verify quality and compatibility, avoiding costly returns or rework. This step is especially critical when dealing with new suppliers or innovative product variants.

- Consolidate Orders for Volume Discounts: Buyers from regions with higher import tariffs or logistical challenges (e.g., African and South American countries) should consider consolidating orders or partnering with regional distributors to minimize per-unit shipping costs.

- Stay Updated on Market Trends: Technological advancements such as improved LED efficacy or integrated smart controls can shift pricing dynamics. Buyers in technologically advanced markets like Germany or Italy should balance innovation adoption with cost management.

- Factor in Exchange Rate Fluctuations: For buyers transacting in multiple currencies, currency volatility can affect landed costs. Hedging or negotiating fixed exchange rates with suppliers may reduce financial risks.

Indicative Pricing Disclaimer

Prices for LED light strip tape can vary widely based on specifications, order size, supplier location, and prevailing market conditions. The guidance above is indicative and intended to support strategic sourcing decisions. Buyers are encouraged to obtain detailed quotations and conduct due diligence tailored to their specific project requirements and regional considerations.

Spotlight on Potential led light strip tape Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led light strip tape’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led light strip tape

Understanding the technical properties and trade terminology related to LED light strip tape is crucial for international B2B buyers aiming to make informed purchasing decisions. This knowledge helps ensure product compatibility, quality assurance, and smooth procurement processes, particularly for buyers across Africa, South America, the Middle East, and Europe.

Critical Technical Properties of LED Light Strip Tape

1. Material Grade and Flexibility

LED strip tapes are typically manufactured on flexible printed circuit boards (FPCBs) made from materials like polyimide or polyester. The material grade affects the strip’s durability, heat resistance, and flexibility. High-grade materials ensure better performance in curved or confined installations and reduce the risk of damage during handling or installation. For B2B buyers, selecting the right material grade means fewer returns and longer-lasting installations, especially in environments with temperature fluctuations.

2. IP Rating (Ingress Protection)

The IP rating indicates the level of protection against dust and water. For example, IP20 is suitable for indoor use where no moisture is present, while IP65 or higher ratings are essential for outdoor or wet-area applications. Understanding IP ratings is critical for buyers planning installations in diverse climates or harsh environments common in regions like the Middle East or coastal parts of Europe and South America.

3. LED Density (LEDs per Meter)

LED density refers to the number of LED chips placed per meter of strip tape. Higher density (e.g., 120 LEDs/m) means brighter, more uniform light, suitable for applications requiring high illumination levels. Lower density strips are more energy-efficient and cost-effective for ambient lighting. Buyers must align LED density with project requirements to balance brightness, energy consumption, and budget.

4. Voltage and Power Consumption

Common operating voltages for LED strips are 12V and 24V DC. Power consumption, measured in watts per meter, impacts energy efficiency and heat generation. Choosing the correct voltage and power rating is important for system compatibility and long-term operational costs. For large-scale projects, such as commercial or architectural lighting in Europe or Africa, understanding power requirements helps optimize electrical infrastructure and reduce energy expenses.

5. Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvin) defines the light’s warmth or coolness, ranging from warm white (2700K) to daylight (6500K). CRI measures how accurately the light renders colors compared to natural light, with values above 80 considered good for most applications. For buyers in retail or hospitality sectors, especially in Europe and the Middle East, selecting LED strips with appropriate color temperature and high CRI enhances visual appeal and customer experience.

6. Tolerance and Cut Points

LED strip tapes come with defined cut points, allowing customization of length without damaging the circuit. Tolerance indicates allowable variations in brightness or color between batches. Buyers should request clear specifications on cut points and tolerance to ensure consistent lighting quality and ease of installation, especially when sourcing from multiple suppliers or for projects requiring precise light layout.

Common Trade Terminology for LED Light Strip Tape Procurement

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce LED strip tapes that can be branded or customized by the buyer. OEM options are important for businesses seeking private label products or specific technical modifications to meet local market preferences, common in European and Middle Eastern markets.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ helps buyers, especially from emerging markets in Africa and South America, plan inventory and cash flow effectively. Negotiating MOQ can enable smaller buyers to enter the market without overstocking.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, specifications, and terms for a defined quantity of LED strip tape. RFQs are essential for comparing offers, especially when dealing with multiple international suppliers and ensuring transparency in costs and delivery conditions.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyers and sellers during shipment (e.g., FOB, CIF, DDP). Knowledge of Incoterms is vital for managing logistics and customs across continents, ensuring buyers from Africa, South America, and Europe understand who handles freight, insurance, and import duties.

Lead Time

The period between placing an order and receiving the goods. Lead times can vary widely depending on supplier location and production schedules. B2B buyers must factor lead time into project planning to avoid delays, especially for large-scale or time-sensitive installations.

Cuttable Length

The specific segment length at which an LED strip can be safely cut without damaging functionality. This term is critical for buyers to plan installations accurately and minimize waste, particularly in custom architectural or retail lighting projects.

By mastering these technical properties and trade terms, international B2B buyers can confidently navigate the LED strip tape market, optimize procurement, and ensure successful project outcomes across diverse regional demands and conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led light strip tape Sector

Market Overview & Key Trends

The global LED light strip tape sector is experiencing robust growth, driven by increasing demand for energy-efficient and versatile lighting solutions across commercial, industrial, and residential applications. Key markets such as Europe—particularly Germany and Italy—along with emerging economies in Africa, South America, and the Middle East, are adopting LED strip lighting for its flexibility, long lifespan, and cost-effectiveness. The rise of smart lighting technologies, including app-controlled and color-changing LED strips, is reshaping B2B sourcing preferences, enabling businesses to offer more customizable and integrated lighting solutions.

For international buyers, market dynamics emphasize the importance of supplier reliability, product quality, and innovation. European buyers often prioritize certifications such as CE and RoHS compliance, reflecting stringent regulatory requirements and sustainability commitments. Meanwhile, B2B buyers in Africa and South America are increasingly focusing on cost efficiency and durability, favoring suppliers who offer robust warranty terms and technical support.

Sourcing trends reveal a growing preference for suppliers who provide comprehensive product ranges—including waterproof, high-lumen, and RGB LED strips—and complementary accessories like aluminum mounting channels for heat dissipation and protection. Bulk purchasing remains a strategic approach, offering significant price advantages and ensuring consistent product quality across large projects such as retail stores, hospitality venues, and office buildings.

Additionally, digital sourcing platforms and direct manufacturer relationships are becoming more prevalent, reducing lead times and enabling transparent pricing. Buyers are also leveraging product samples and third-party testing to verify quality before committing to large orders, mitigating supply chain risks.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical factor in the procurement of LED light strip tape, with businesses across Africa, South America, the Middle East, and Europe seeking environmentally responsible products and supply chains. LED strips inherently offer energy savings compared to traditional lighting, but the sector is now pushing further toward eco-friendly materials, improved recyclability, and reduced hazardous substances.

Ethical sourcing involves ensuring that manufacturers adhere to fair labor practices and environmentally sound production methods. Buyers increasingly demand transparency regarding the origin of components such as LED chips, flexible PCBs, and aluminum profiles. Certifications like Energy Star, RoHS, and REACH are vital indicators of compliance with environmental and safety standards, particularly for European markets where regulatory scrutiny is rigorous.

Material innovations such as lead-free solder, halogen-free wiring, and biodegradable packaging are gaining traction. Aluminum channels, commonly used with LED strips, also contribute to sustainability by enhancing product longevity and enabling easier recycling. Furthermore, some suppliers are adopting circular economy principles, offering take-back programs or modular designs that facilitate repair and upgrade rather than replacement.

For B2B buyers, integrating sustainability criteria into vendor selection not only mitigates environmental impact but also aligns with growing customer expectations and regulatory mandates. This approach supports long-term brand value and opens access to markets with strict green procurement policies.

Evolution and Historical Context

The LED light strip tape industry has evolved significantly since its inception in the late 20th century. Early LED strips were limited in brightness, color options, and flexibility, primarily used for indicator lighting or simple decorative effects. Advances in semiconductor technology and flexible circuit manufacturing in the 2000s enabled the development of high-density, multi-color LED strips with improved energy efficiency and durability.

As urbanization and smart building trends accelerated globally, LED strip lighting transitioned from a niche decorative product to a mainstream lighting solution for architectural, retail, and industrial applications. The integration of smart controls and IoT connectivity in recent years has further expanded the sector’s potential, enabling dynamic lighting scenes and energy management capabilities.

Today, the LED strip tape market represents a mature yet innovative segment where continuous improvements in materials, thermal management (such as aluminum channels), and customization options cater to diverse international B2B needs. Understanding this evolution helps buyers appreciate the technological maturity and scalability of LED strip solutions for their projects.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led light strip tape

-

How can I effectively vet LED light strip tape suppliers for international B2B purchases?

To vet suppliers, prioritize those with established reputations, verified business licenses, and positive customer reviews—especially from buyers in your region (Africa, South America, Middle East, Europe). Request product samples to assess quality firsthand. Confirm that suppliers provide clear warranty terms and after-sales support. Use platforms offering trade assurance or escrow services to mitigate risks. Additionally, inquire about their production capacity and compliance with international standards like CE or RoHS to ensure consistent quality for large orders. -

What customization options are typically available when ordering LED strip tape in bulk?

Most wholesale suppliers offer customization in length, color temperature, brightness, and packaging. Some can tailor LED density per meter or provide RGB and smart lighting features. Custom branding on packaging and product labeling is common, helping buyers differentiate their offerings. For complex requirements, discuss technical specifications upfront to align on feasibility and pricing. Custom orders may require higher minimum quantities and longer lead times, so plan accordingly to integrate these features smoothly into your product lineup. -

What are the typical minimum order quantities (MOQs) and lead times for wholesale LED strip tape?

MOQs vary widely depending on supplier and customization level but generally range from 100 to 500 meters per order. Standard, non-customized products often have lower MOQs. Lead times typically span 2 to 6 weeks, influenced by order size, customization, and shipping method. Buyers from Africa or South America should factor in additional transit time due to logistics complexities. Early communication with suppliers about production schedules and shipping timelines is crucial to avoid project delays.

Illustrative Image (Source: Google Search)

-

Which payment methods are safest and most commonly accepted for international LED strip tape orders?

Secure payment methods include Letters of Credit (LC), PayPal (for smaller orders), and escrow services offered by B2B platforms. Bank wire transfers (T/T) are widely accepted but carry higher risk if the supplier is unverified. For first-time orders, consider partial upfront payment with balance upon delivery or inspection. Always confirm payment terms in the contract and avoid full prepayment unless dealing with highly reputable suppliers. Using trade assurance services can add a layer of protection for buyers in emerging markets. -

What quality assurance certifications should I look for when sourcing LED strip tape?

Look for internationally recognized certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and ISO 9001 quality management certification. These ensure compliance with safety, environmental, and quality standards critical for European, Middle Eastern, and other global markets. Additionally, suppliers offering product testing reports (e.g., LM-80 for LED lifespan) and warranty guarantees provide greater confidence in product reliability and longevity. -

How should I plan logistics and shipping for bulk LED strip tape orders to Africa, South America, or the Middle East?

Choose suppliers with experience exporting to your region to leverage optimized shipping routes and customs clearance processes. Sea freight is cost-effective for large volumes but slower; air freight suits urgent orders but at higher cost. Consolidate shipments where possible to reduce freight charges. Ensure the supplier provides proper export documentation (commercial invoice, packing list, certificate of origin) to prevent customs delays. Partnering with reliable freight forwarders familiar with your destination’s import regulations can streamline delivery. -

What are common challenges in international B2B transactions for LED strip tape and how can I resolve disputes?

Challenges include product quality discrepancies, delayed shipments, and miscommunication on specifications. Mitigate risks by clearly documenting all terms in purchase agreements, including quality standards, delivery schedules, and penalty clauses. Request inspection reports or third-party quality audits before shipment. In case of disputes, first seek amicable resolution through supplier communication. If unresolved, use arbitration clauses or mediation services as specified in the contract. Maintaining thorough records of correspondence and contracts supports your position. -

How can I ensure consistent product quality across multiple LED strip tape orders over time?

Establish a strong relationship with your supplier and develop standardized product specifications documented in quality agreements. Regularly request samples from production batches for quality checks. Implement periodic factory audits or hire third-party inspection agencies to verify compliance with agreed standards. Consider signing long-term contracts with clauses for continuous quality monitoring. Consistency is especially critical for European and Middle Eastern markets where regulatory compliance and customer expectations are stringent.

Strategic Sourcing Conclusion and Outlook for led light strip tape

Strategic sourcing of LED light strip tape offers international B2B buyers a powerful opportunity to optimize cost, quality, and innovation. By leveraging wholesale purchasing, businesses can access competitive pricing, broad product varieties—including customizable and technologically advanced options—and streamlined supply chains essential for large-scale or diverse projects. Prioritizing suppliers with robust warranties, transparent return policies, and sample availability ensures procurement confidence and product reliability.

Incorporating complementary components like LED tape light channels further enhances product performance and installation quality, underscoring the importance of a holistic sourcing strategy that considers both functional and aesthetic requirements. For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics and supplier capabilities is key to securing products that meet local standards and end-user expectations.

Looking ahead, the LED strip tape market is poised for continued innovation, with smart lighting and energy-efficient solutions gaining traction globally. Forward-thinking buyers are encouraged to cultivate partnerships with suppliers who prioritize sustainability, technological advancement, and responsive service. Embracing these strategic sourcing principles will not only drive competitive advantage but also enable businesses to deliver cutting-edge lighting solutions that resonate across diverse international markets.