Introduction: Navigating the Global Market for led light strip connectors 2 pin

The global demand for 2-pin LED light strip connectors is rapidly expanding as LED lighting solutions become integral to commercial, industrial, and architectural projects worldwide. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding the nuances of these connectors is essential to secure reliable, high-performance components that meet specific project requirements and regional standards.

These compact yet crucial connectors ensure seamless electrical connections between LED strip segments, enabling quick installation and maintenance while preserving waterproof integrity in outdoor or harsh environments. Their role extends beyond simple connectivity; they influence overall system longevity, safety, and energy efficiency, factors highly scrutinized in professional installations across varying climates and regulatory landscapes.

This guide delivers a comprehensive exploration tailored for B2B procurement specialists and technical buyers. Key areas covered include:

- Varieties of 2-pin connectors and their material compositions

- Manufacturing processes and quality control benchmarks

- Global supplier landscapes with insights into sourcing from emerging and established markets

- Cost structures and value analysis for bulk purchasing

- Market trends and future outlooks relevant to international trade

- Practical FAQs addressing installation, compatibility, and certification concerns

By distilling complex technical details and market intelligence into actionable insights, this resource empowers buyers in France, Colombia, Nigeria, UAE, and beyond to make informed sourcing decisions. Whether upgrading existing LED systems or launching new lighting projects, readers will gain the confidence to select connectors that optimize performance, comply with local regulations, and deliver cost-effective solutions—driving success in competitive global markets.

Understanding led light strip connectors 2 pin Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

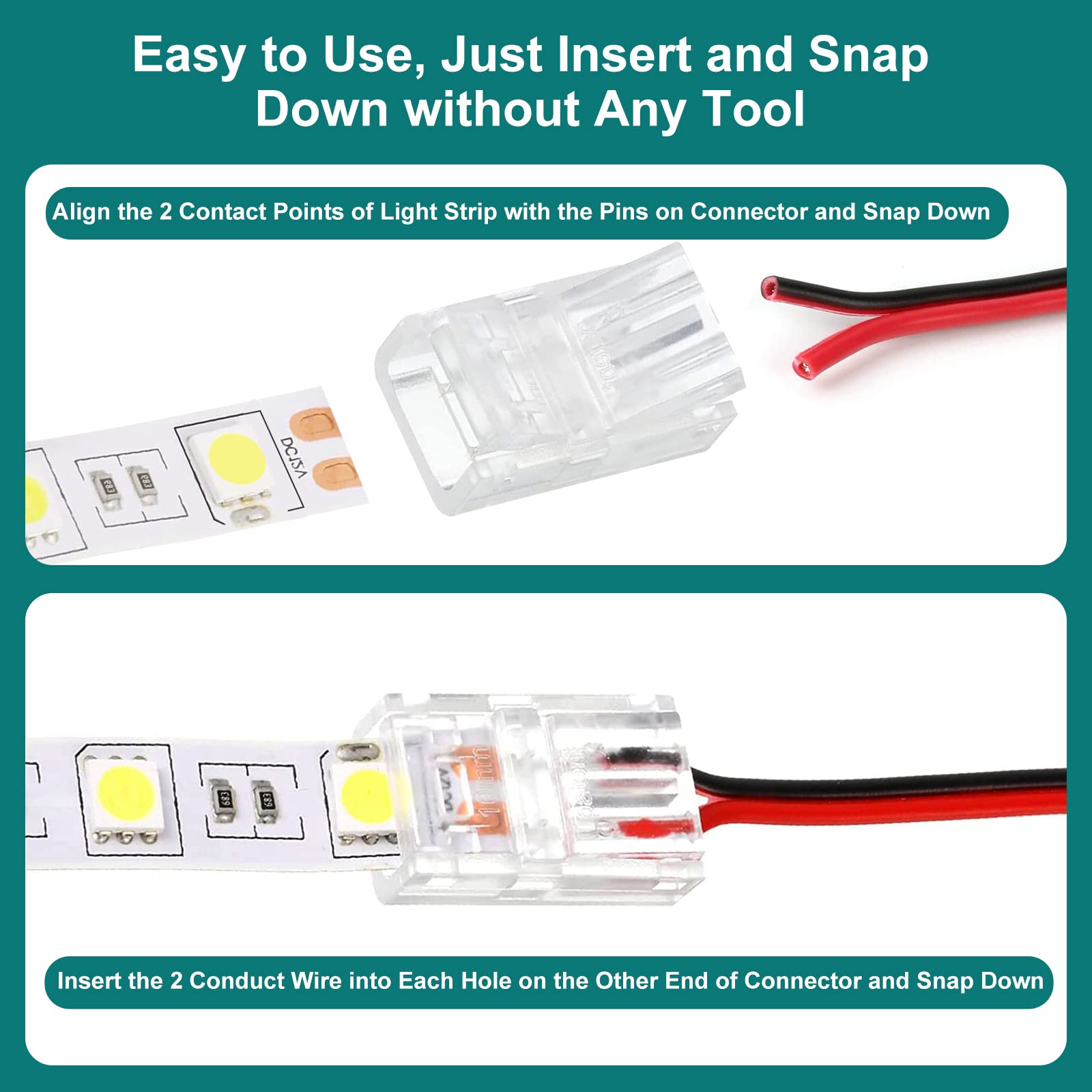

| Clip-On 2-Pin Connectors | Simple snap-on mechanism, no soldering needed | Quick installations, prototyping, retail display | + Easy to use, no tools required – Limited waterproofing |

| Waterproof 2-Pin Connectors | Sealed design with silicone or rubber gaskets, IP65+ rated | Outdoor lighting, industrial, harsh environment | + Durable, weather-resistant – Higher cost, bulkier |

| Solderless 2-Pin Connectors | Tool-free insertion with locking clips, flexible positioning | Modular LED systems, commercial lighting | + Fast assembly, reusable – May have lower current capacity |

| PCB Terminal Block Connectors | Screw terminal connection on PCB, secure and robust | Custom LED strip assemblies, OEM applications | + Reliable, strong contact – Requires tools, assembly time |

| Magnetic 2-Pin Connectors | Magnetic coupling for quick connect/disconnect | Temporary setups, exhibition lighting | + Fast connect/disconnect – Limited load capacity, less secure |

Clip-On 2-Pin Connectors

These connectors feature a snap-on design allowing LED strips to be connected quickly without soldering. Ideal for rapid prototyping or retail display setups, they facilitate easy installation and replacement. For B2B buyers, they offer cost-effective solutions for short-term or indoor projects but are less suitable for environments requiring moisture resistance or long-term durability.

Waterproof 2-Pin Connectors

Designed with sealed housings and high ingress protection ratings (IP65 and above), these connectors are tailored for outdoor and industrial applications where exposure to water, dust, or chemicals is common. Buyers from sectors such as construction, landscaping, or outdoor advertising will find these connectors essential despite their higher price point, as they ensure system reliability and reduce maintenance costs.

Illustrative Image (Source: Google Search)

Solderless 2-Pin Connectors

Solderless connectors use locking clips to secure LED strips without the need for soldering, enabling modular and flexible configurations. This type suits commercial lighting projects requiring frequent reconfiguration or upgrades. B2B buyers benefit from reduced labor time and minimized skill requirements, though they should verify current ratings to match power needs and avoid performance issues.

PCB Terminal Block Connectors

These connectors attach directly to LED strip PCBs via screw terminals, offering a robust and secure electrical connection. They are favored in OEM and custom lighting solutions where reliability and durability are paramount. Buyers investing in large-scale or specialized lighting systems should consider these connectors for their strong mechanical and electrical properties, though assembly time and tooling requirements are higher.

Magnetic 2-Pin Connectors

Magnetic connectors provide an innovative solution for quick, tool-free connection and disconnection of LED strips, ideal for temporary installations such as exhibitions or events. While they offer unparalleled convenience, B2B buyers must assess their limited current capacity and mechanical security, making them less suitable for permanent or high-load applications.

Related Video: How to use LED Strip Light wire-to-tape light connectors

Key Industrial Applications of led light strip connectors 2 pin

| Industry/Sector | Specific Application of led light strip connectors 2 pin | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Seamless lighting integration for display shelving and signage | Enhances product visibility and customer experience; quick installation reduces downtime | Waterproof and dustproof connectors for durability; compatibility with different LED strip voltages; compliance with local electrical standards |

| Hospitality & Leisure | Ambient and accent lighting in hotels, restaurants, and lounges | Creates customizable mood lighting; energy-efficient and easy maintenance | Connector IP rating for humid environments; flexibility for curved or irregular installations; supplier support for bulk orders and logistics |

| Automotive & Transportation | Interior vehicle lighting and dashboard illumination | Improves aesthetic appeal and safety; facilitates modular upgrades | High vibration resistance; connectors suitable for 12V automotive systems; adherence to automotive quality certifications |

| Industrial & Manufacturing | Machine and workstation lighting for improved visibility | Enhances worker safety and productivity; reduces maintenance costs | Robust connector design for harsh environments; reliable electrical contact under frequent vibration; sourcing connectors with high temperature tolerance |

| Architectural & Outdoor | Façade and landscape lighting requiring waterproof connections | Long-lasting, weather-resistant installations; supports complex lighting designs | IP67 or higher waterproof connectors; UV-resistant materials; availability of local technical support and certification compliance |

Retail & Commercial Spaces

In retail environments, 2 pin LED light strip connectors are essential for integrating lighting into display shelving and signage. These connectors enable fast, solderless connections, allowing retailers to quickly update or reconfigure lighting layouts to highlight products effectively. For international buyers, especially in markets like France and Colombia, sourcing connectors with waterproof and dustproof ratings ensures durability in diverse store conditions. Compatibility with various LED strip voltages and adherence to regional electrical safety standards is critical for smooth installation and compliance.

Hospitality & Leisure

Hotels, restaurants, and lounges rely on 2 pin LED strip connectors to create ambient and accent lighting that enhances guest experience. The connectors’ ease of use supports flexible lighting designs, including curved and irregular surfaces typical in interior décor. Buyers from the Middle East and Africa should prioritize connectors with IP-rated protection against humidity and dust, ensuring longevity in tropical or desert climates. Additionally, suppliers offering support for large volume orders and logistics simplify procurement for large-scale hospitality projects.

Automotive & Transportation

Automotive manufacturers and aftermarket suppliers use 2 pin LED connectors for interior vehicle lighting such as dashboard illumination and ambient cabin lights. These connectors must withstand constant vibration and operate reliably on 12V systems typical in vehicles. For B2B buyers across South America and Europe, sourcing connectors with automotive-grade certifications and robust mechanical stability guarantees long-term performance and safety compliance. Modular connector designs also facilitate easy upgrades or repairs without extensive rewiring.

Industrial & Manufacturing

In industrial settings, 2 pin LED strip connectors are used for machine lighting and workstation illumination, improving visibility and worker safety. These environments demand connectors that endure harsh conditions including vibration, dust, and elevated temperatures. Buyers in regions with heavy manufacturing sectors, such as parts of Europe and South Africa, should focus on sourcing connectors with reinforced electrical contacts and high temperature tolerance. Reliable connections reduce maintenance frequency and downtime, translating to cost savings.

Architectural & Outdoor

Architectural lighting projects, including building façades and landscape illumination, require 2 pin LED connectors that are waterproof and UV resistant to withstand outdoor exposure. International buyers from Europe and the Middle East benefit from connectors rated IP67 or higher, ensuring weatherproof installations that maintain performance over time. Availability of local technical support and compliance with regional certification standards are key considerations to ensure smooth project execution and adherence to safety regulations.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for led light strip connectors 2 pin

When selecting materials for 2-pin LED light strip connectors, international B2B buyers must carefully evaluate the physical and chemical properties that influence performance, durability, cost, and regulatory compliance. This is especially critical for buyers from diverse regions such as Africa, South America, the Middle East, and Europe, where environmental conditions, installation standards, and market expectations vary significantly.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance, excellent dimensional stability, and good electrical insulation properties. It withstands temperatures typically up to 120°C and offers moderate resistance to UV radiation and chemicals.

Pros & Cons:

Polycarbonate connectors are durable and lightweight, making them easy to handle and install. Their electrical insulation and flame-retardant grades enhance safety in LED lighting applications. However, PC is more expensive than basic plastics and can degrade under prolonged UV exposure unless specially treated.

Impact on Application:

Ideal for indoor and semi-outdoor LED strip installations where moderate exposure to heat and mechanical stress is expected. Its electrical insulation properties make it suitable for connectors in residential and commercial lighting. However, in harsh outdoor environments, additional UV protection or alternative materials may be preferred.

Regional Considerations:

European buyers, particularly in France, often require compliance with stringent standards such as IEC 60695 (flammability) and RoHS directives, which PC materials can meet with proper certification. In the Middle East and Africa, where ambient temperatures can be high, polycarbonate’s thermal limits must be considered carefully. South American markets may prioritize cost-effectiveness, so PC connectors are often reserved for premium installations.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a flexible, chemically resistant plastic with good electrical insulation and flame retardancy. It typically withstands temperatures up to 70-80°C and offers excellent resistance to moisture and many chemicals.

Pros & Cons:

PVC connectors are cost-effective and widely available, making them attractive for large-scale, budget-sensitive projects. Their flexibility aids in easy installation and reduces mechanical stress on connections. However, PVC has lower heat resistance and mechanical strength compared to polycarbonate, limiting its use in high-temperature or heavy-duty environments.

Impact on Application:

Best suited for indoor LED strip lighting in controlled environments such as office buildings or retail spaces. PVC connectors may not be ideal for outdoor or industrial applications due to lower thermal and UV resistance.

Regional Considerations:

In South America and Africa, where cost constraints are significant, PVC connectors are popular for mass-market LED lighting. However, buyers should verify compliance with local fire safety standards, such as ASTM E84 or equivalent regional norms. The Middle East’s hotter climates may require careful assessment of PVC’s thermal limits to avoid premature failure.

Nylon (Polyamide)

Key Properties:

Nylon is a strong, wear-resistant polymer with excellent chemical resistance and a higher melting point (up to 220°C). It offers good electrical insulation and is naturally resistant to abrasion and impact.

Pros & Cons:

Nylon connectors provide superior mechanical strength and durability, suitable for demanding installations. They resist deformation under heat and mechanical load better than PVC or polycarbonate. On the downside, nylon is relatively more expensive and can absorb moisture, which may affect dimensional stability if not properly stabilized.

Impact on Application:

Highly recommended for outdoor or industrial LED strip installations requiring robustness against mechanical stress, vibration, and temperature fluctuations. Nylon’s resistance to oils and chemicals also makes it suitable for harsh environments such as manufacturing facilities.

Regional Considerations:

European buyers often favor nylon connectors for industrial-grade lighting solutions due to compliance with DIN and IEC standards. In the Middle East and Africa, nylon’s heat resistance is advantageous, but moisture absorption must be managed. South American buyers may find nylon connectors suitable for premium outdoor projects despite the higher cost.

Silicone (for Connector Seals and Waterproofing)

Key Properties:

Silicone is a flexible, rubber-like material with excellent thermal stability (-60°C to 230°C), outstanding UV and weather resistance, and superior waterproofing capabilities.

Pros & Cons:

While not typically used for the connector housing itself, silicone is critical for gaskets and seals in waterproof 2-pin LED strip connectors. It ensures ingress protection (IP65 and above), extending product life in outdoor and humid environments. Silicone’s flexibility and durability are unmatched, but it adds complexity and cost to manufacturing.

Impact on Application:

Essential for outdoor, marine, or industrial LED strip installations where moisture, dust, and temperature extremes are concerns. Silicone seals enable connectors to meet international waterproofing standards, enhancing reliability.

Regional Considerations:

Buyers from regions with high humidity or outdoor exposure, such as coastal areas in South America and the Middle East, should prioritize connectors with silicone sealing. European markets, with strict IP rating requirements, also demand silicone-based waterproofing solutions. In Africa, the balance between cost and durability will dictate the extent of silicone use.

Summary Table

| Material | Typical Use Case for led light strip connectors 2 pin | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor and semi-outdoor lighting with moderate heat and mechanical stress | High impact resistance and electrical insulation | Higher cost and UV degradation without treatment | Medium |

| Polyvinyl Chloride (PVC) | Budget indoor lighting in controlled environments | Cost-effective and flexible | Lower heat resistance and mechanical strength | Low |

| Nylon (Polyamide) | Outdoor, industrial, and high-stress environments | Superior mechanical strength and heat resistance | Moisture absorption affecting stability | High |

| Silicone (Seals) | Waterproofing for outdoor and harsh environment connectors | Excellent thermal stability and waterproofing | Adds manufacturing complexity and cost | Medium |

This material selection guide enables B2B buyers to align their purchasing decisions with project requirements, environmental conditions, and regional compliance standards, ensuring optimal performance and cost-efficiency for 2-pin LED light strip connectors.

In-depth Look: Manufacturing Processes and Quality Assurance for led light strip connectors 2 pin

The manufacturing and quality assurance of 2-pin LED light strip connectors are critical factors that determine product reliability, safety, and long-term performance—key concerns for international B2B buyers. Understanding the typical production workflow, quality control (QC) protocols, and compliance requirements helps buyers from Africa, South America, the Middle East, and Europe make informed sourcing decisions and ensure smooth project execution.

Manufacturing Process Overview

The production of 2-pin LED strip connectors generally involves several precise stages designed to ensure electrical integrity, mechanical durability, and environmental protection.

1. Material Preparation

- Raw Materials: High-grade copper or copper alloy is selected for conductive parts due to excellent electrical conductivity. The plastic housing is typically made from flame-retardant, UV-resistant polycarbonate or nylon to endure heat and outdoor exposure.

- Surface Treatment: Copper pins undergo plating (commonly tin or nickel) to improve corrosion resistance and solderability. This step is crucial for connectors intended for humid or outdoor environments, often seen in African and Middle Eastern markets.

2. Forming and Stamping

- Metal Stamping: Conductive pins are precision-stamped from metal sheets using dies that ensure exact dimensions and consistent contact force.

- Injection Molding: The plastic housing is formed via injection molding, allowing complex shapes with integrated locking mechanisms and waterproof seals (e.g., silicone gaskets for IP65 or higher ratings).

- Key Techniques: Automated CNC stamping and molding machines are used to maintain tight tolerances and reduce defects.

3. Assembly

- Pin Insertion: Conductive pins are press-fitted or ultrasonically welded into the molded housing to ensure secure mechanical and electrical connections.

- Sealing: For waterproof connectors, sealing components (gaskets, O-rings) are added during assembly, and the housing may be ultrasonically welded or clipped.

- Automation vs. Manual: Larger manufacturers employ robotic assembly lines for consistency, while smaller producers may rely on skilled manual assembly, impacting scalability and lead time.

4. Finishing and Packaging

- Cleaning: Connectors undergo ultrasonic cleaning to remove residues and ensure optimal electrical contact.

- Marking: Laser or inkjet marking adds part numbers, batch codes, and certification marks.

- Packaging: Connectors are packaged in moisture-proof, anti-static bags with batch traceability to protect during shipping and storage.

Quality Assurance and Control Framework

Robust QC systems aligned with international standards are vital to guarantee that 2-pin LED strip connectors meet the demanding requirements of diverse global markets.

International and Industry Standards

- ISO 9001: The foundational quality management system standard ensuring consistent manufacturing and continual improvement.

- CE Marking (Europe): Demonstrates compliance with EU safety, health, and environmental protection directives.

- RoHS Compliance: Restricts hazardous substances, essential for European and increasingly for South American and Middle Eastern buyers.

- IP Rating Standards (IEC 60529): Specifies waterproof and dustproof levels critical for outdoor and industrial applications.

- Additional Certifications: Some suppliers obtain UL certification or industry-specific approvals for enhanced credibility.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components, including:

- Material composition verification (e.g., copper purity)

- Dimensional checks of pins and plastic parts

- Plating thickness measurement

- In-Process Quality Control (IPQC): Monitors manufacturing stages to detect defects early:

- Stamping die condition and precision

- Injection molding integrity (no warping, voids, or cracks)

- Assembly fit and locking mechanism testing

- Final Quality Control (FQC): Comprehensive testing of finished products, including:

- Electrical continuity and resistance measurements

- Mechanical durability tests (tensile strength of pins, housing robustness)

- Waterproof performance (pressure or immersion tests for IP-rated connectors)

- Visual inspections for surface finish and marking accuracy

Common Testing Methods and Their Importance

- Electrical Testing: Using precision ohmmeters and automated testers to verify low contact resistance and proper insulation resistance, ensuring minimal power loss and safety.

- Environmental Testing: Accelerated aging, UV exposure, and thermal cycling tests simulate harsh conditions encountered in markets like the Middle East or parts of South America.

- Mechanical Testing: Repeated mating cycles test connector durability, vital for installations requiring maintenance or upgrades.

- Waterproof Verification: Submersion or spray tests confirm IP ratings, critical for outdoor lighting projects in African or European climates.

How B2B Buyers Can Verify Supplier Quality Control

For buyers in Africa, South America, the Middle East, and Europe, confirming a supplier’s QC capability is essential to mitigate risks and avoid costly project delays.

- Factory Audits: Conduct on-site or third-party audits assessing production processes, equipment, workforce skills, and QC systems. Remote audits are increasingly feasible for international buyers.

- Quality Reports: Request detailed IQC, IPQC, and FQC reports with batch traceability. These reports should include test data, inspection methods, and non-conformance handling procedures.

- Third-Party Inspections: Engage independent inspection agencies to perform random batch sampling and testing before shipment, adding an extra layer of assurance.

- Sample Validation: Obtain product samples for in-house testing or pilot installations to verify performance under local conditions.

- Certification Verification: Confirm authenticity of certifications (ISO 9001, CE, RoHS) via official registries or certification bodies’ databases.

QC and Certification Nuances for International Buyers

- Africa & Middle East: Prioritize connectors with high IP ratings and corrosion-resistant materials due to humid, salty, or desert environments. Certifications like CE and RoHS are becoming more recognized as these markets align with global standards.

- South America: Focus on suppliers compliant with RoHS and with robust packaging to withstand long shipping routes and tropical climates. Local certification requirements may vary; buyers should verify harmonization with international standards.

- Europe (France and Beyond): The strictest adherence to CE marking, RoHS, and sometimes REACH regulations is mandatory. Buyers benefit from suppliers with ISO 9001 and UL certifications, ensuring seamless integration with EU regulations.

- Documentation and Traceability: International buyers should insist on comprehensive documentation to facilitate customs clearance and compliance audits, avoiding shipment delays.

Summary for B2B Buyers

- Engage suppliers with transparent, documented manufacturing processes and strict QC checkpoints.

- Verify compliance with international and regional standards relevant to your market and application.

- Utilize third-party audits and inspections to independently confirm quality claims.

- Consider environmental and operational conditions of your region when evaluating connector specifications.

- Demand traceability and batch-specific quality reports for accountability and future reference.

By thoroughly understanding manufacturing and quality assurance practices for 2-pin LED strip connectors, international B2B buyers can secure reliable products that meet their project demands, regulatory requirements, and market expectations. This strategic due diligence ultimately supports successful procurement and long-term supplier partnerships.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led light strip connectors 2 pin Sourcing

Understanding the Cost Structure of 2 Pin LED Light Strip Connectors

When sourcing 2 pin LED light strip connectors, international B2B buyers must first grasp the comprehensive cost components that define the final pricing. These connectors, essential for seamless LED strip installations, have costs shaped by several key factors:

- Materials: The primary raw materials include high-quality plastics (often flame-retardant and UV-resistant) and copper or copper alloy contacts, sometimes plated with nickel or tin for corrosion resistance and conductivity. Material quality directly impacts durability and performance, influencing cost.

- Labor: Labor costs vary significantly by manufacturing region. For instance, Asian manufacturers may offer lower labor costs compared to European counterparts, but this can affect lead times and communication.

- Manufacturing Overhead: This includes factory utilities, machinery depreciation, and indirect labor. High-precision molding and plating equipment contribute to overhead costs.

- Tooling: Injection molding tools for plastic housings and stamping dies for metal contacts represent upfront investments amortized over production volumes. Custom tooling for specialized connector designs elevates initial costs.

- Quality Control (QC): Rigorous QC processes—such as electrical conductivity testing, waterproofing validation, and mechanical durability checks—add to the cost but ensure reliability and certification compliance.

- Logistics: International shipping, customs duties, and local distribution costs are significant, especially for buyers in Africa, South America, and the Middle East, where freight infrastructure and customs processes vary.

- Profit Margin: Supplier margins depend on brand positioning, market competition, and service levels, including after-sales support.

Key Pricing Influencers for 2 Pin LED Strip Connectors

Several factors influence the quoted prices from suppliers and should be carefully evaluated by buyers:

- Order Volume and Minimum Order Quantities (MOQ): Bulk orders dramatically reduce per-unit costs due to economies of scale. Small orders often carry premium pricing and higher shipping costs.

- Specifications and Customization: Standard connectors are more affordable, but customization—such as waterproofing (IP65/IP67 ratings), cable length variations, or specialized locking mechanisms—adds complexity and cost.

- Material Grade and Certification: Certified connectors compliant with CE, RoHS, UL, or other regional standards command higher prices but reduce risks related to safety and regulatory compliance.

- Supplier Location and Reputation: Established suppliers with proven quality control and export experience may offer premium pricing but reduce risks of delays and defects.

- Incoterms and Shipping Terms: Pricing can vary widely depending on whether terms are FOB, CIF, DDP, etc. Buyers should clarify who bears freight, insurance, and customs clearance costs.

Practical Buyer Tips for International B2B Procurement

For buyers in Africa, South America, the Middle East, and Europe, strategic sourcing can optimize cost-efficiency and total cost of ownership:

- Negotiate Based on Volume and Long-Term Partnership: Suppliers often provide tiered discounts. Establishing ongoing relationships can unlock better pricing, priority production slots, and flexible MOQs.

- Evaluate Total Cost of Ownership (TCO): Don’t focus solely on unit price. Consider warranty terms, expected lifespan, compatibility with LED strips, and after-sales service. A slightly higher upfront cost may yield savings by reducing replacement and downtime expenses.

- Request Samples and Certifications: Before large purchases, verify product quality with samples and request certification documents to ensure compliance with local electrical and safety standards.

- Leverage Regional Trade Agreements: Buyers in Europe or the Middle East should explore sourcing from regions with favorable trade agreements to minimize tariffs and customs delays.

- Clarify Incoterms and Shipping Logistics: Insist on transparent shipping terms to avoid unexpected import fees. For African and South American buyers, DDP (Delivered Duty Paid) terms might simplify import processes despite higher initial costs.

- Consider Lead Times and Inventory Buffering: Longer shipping times may require inventory buffers. Factor these into cost calculations to avoid project delays.

Indicative Pricing Range and Disclaimer

As a general guideline, standard 2 pin LED light strip connectors typically range from $0.10 to $0.50 per unit depending on volume, quality, and customization. Waterproof or certified variants command prices at the higher end or beyond. Prices fluctuate due to raw material costs, currency exchange rates, and global logistics dynamics.

Note: All prices are indicative and should be confirmed with suppliers. Buyers are advised to conduct due diligence and obtain multiple quotations to ensure competitive sourcing.

By understanding these cost components and pricing influencers, international B2B buyers can make informed sourcing decisions that balance quality, cost-efficiency, and reliability in their LED lighting projects.

Spotlight on Potential led light strip connectors 2 pin Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led light strip connectors 2 pin’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led light strip connectors 2 pin

Critical Technical Properties of 2-Pin LED Light Strip Connectors

When sourcing 2-pin LED light strip connectors for international projects, understanding their key technical specifications is essential to ensure compatibility, durability, and performance. Here are the most critical properties that impact procurement and application:

-

Material Grade and Conductivity

Connectors typically use copper alloys or phosphor bronze for their conductive parts, often plated with tin or nickel to resist corrosion. High-grade materials ensure low electrical resistance, reliable current flow, and longer connector lifespan—especially vital in humid or outdoor environments common in Africa and the Middle East. -

Waterproof Rating (IP Code)

Many 2-pin connectors come with IP65 to IP68 ratings, indicating protection against dust and water ingress. For buyers targeting outdoor or industrial applications, waterproof connectors prevent short circuits and extend operational life, reducing costly replacements and maintenance. -

Voltage and Current Ratings

Standard 2-pin LED connectors usually support 12V or 24V DC systems with current ratings ranging from 2A to 10A depending on design. Accurate matching of voltage and current ratings with the LED strip specifications is critical to avoid overheating, voltage drop, or connector failure in large installations typical in commercial projects across Europe and South America. -

Tolerance and Mechanical Fit

Tolerance refers to the allowable dimensional variation ensuring connectors fit LED strips precisely without loose contacts. Tight mechanical fit reduces signal loss and enhances installation reliability, which is crucial for high-volume B2B orders where consistent quality is expected. -

Operating Temperature Range

Connectors should withstand temperatures from -20°C up to +60°C or higher, depending on the environment. This range supports installations in diverse climates, from cold European winters to hot Middle Eastern summers, ensuring stable electrical performance without material degradation. -

Solderless vs. Soldered Design

Solderless connectors provide quick, tool-free assembly, ideal for fast installation and maintenance, while soldered connectors offer stronger electrical and mechanical bonds for permanent setups. Understanding this distinction helps buyers specify connectors aligned with their workforce skills and project timelines.

Key Trade Terminology for B2B Buyers of 2-Pin LED Strip Connectors

Navigating international LED component procurement requires familiarity with common trade terms that influence pricing, delivery, and contract negotiations:

-

OEM (Original Equipment Manufacturer)

Refers to connectors produced by a manufacturer for rebranding by another company. Buyers should clarify if they require OEM products for customization or prefer standard branded items to meet certification and warranty expectations. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. Understanding MOQ helps buyers from emerging markets like Africa and Colombia plan budgets and inventory, balancing cost-efficiency with storage capabilities. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers detailing product specifications and quantities to obtain pricing and terms. Preparing a precise RFQ with technical specs like connector dimensions, IP rating, and certifications expedites supplier responses and avoids misunderstandings. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyer and seller during shipment. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Buyers should select Incoterms aligned with their logistics capabilities to control delivery and import costs effectively. -

Lead Time

The duration from order placement to product shipment. In high-demand LED markets, lead time impacts project scheduling and cash flow, so buyers must negotiate realistic timelines, especially when sourcing from overseas manufacturers. -

Certification Standards

Certifications such as CE (Europe), RoHS (restriction of hazardous substances), and UL (safety standards) confirm product compliance with regional regulations. Ensuring connectors have relevant certifications safeguards buyers from customs delays and liability issues.

By focusing on these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that 2-pin LED strip connectors meet their project requirements while optimizing cost, quality, and supply chain efficiency. This knowledge is especially valuable for buyers operating in diverse markets with varying environmental and regulatory conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led light strip connectors 2 pin Sector

Market Overview & Key Trends

The global market for 2-pin LED light strip connectors is experiencing robust growth driven by the expanding adoption of LED lighting solutions across commercial, residential, and industrial sectors. Key regions such as Africa, South America, the Middle East, and Europe are witnessing increased demand due to urbanization, infrastructure development, and rising energy efficiency standards. Countries like France and Colombia are actively integrating LED technologies in smart building projects and energy-saving initiatives, boosting the need for reliable and easy-to-install connectors.

Technological advancements are shaping the sourcing landscape, with waterproof and solderless 2-pin connectors gaining traction for their durability and ease of installation. These connectors are increasingly preferred in outdoor and harsh environment applications, common in regions with extreme weather conditions such as the Middle East and parts of Africa. Additionally, the trend toward modular and plug-and-play lighting systems is driving demand for connectors that enable quick assembly and maintenance, reducing downtime and labor costs.

From a sourcing perspective, international buyers are prioritizing suppliers who offer consistent quality certifications, transparent supply chains, and competitive lead times. The shift toward digital procurement platforms and direct factory partnerships is improving access to diverse product ranges and customization options. Buyers in emerging markets benefit from suppliers offering flexible MOQ (Minimum Order Quantity) and localized support to navigate import regulations and logistics complexities.

Market dynamics also reflect increasing price sensitivity balanced with quality demands. While cost competitiveness remains crucial, buyers are investing in connectors with enhanced electrical performance and longer lifespans to minimize total cost of ownership. This is especially pertinent for large-scale commercial projects in Europe and South America where regulatory compliance and warranty standards are stringent.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are becoming integral to procurement decisions for 2-pin LED strip connectors. The environmental impact of manufacturing processes, material sourcing, and product lifecycle management is under scrutiny, particularly in Europe where regulations such as RoHS and REACH impose strict limits on hazardous substances. International buyers are increasingly demanding connectors made from recyclable and non-toxic materials to align with corporate social responsibility goals and green building certifications like LEED and BREEAM.

Ethical sourcing is equally important, with buyers emphasizing supply chain transparency to avoid components linked to conflict minerals or exploitative labor practices. Certifications such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) serve as valuable benchmarks for evaluating supplier commitments to ethical manufacturing.

Innovations in connector design are also contributing to sustainability. For instance, the use of halogen-free plastics and lead-free soldering techniques reduces environmental footprint and enhances safety. Additionally, durable waterproof connectors extend product lifespan and reduce electronic waste by minimizing replacement frequency in demanding environments.

B2B buyers from Africa, South America, and the Middle East, where environmental regulations may be evolving, benefit from partnering with suppliers who proactively adopt sustainability standards. This approach not only future-proofs their projects but also appeals to end customers increasingly conscious of eco-friendly solutions.

Evolution and Historical Context

The evolution of 2-pin LED light strip connectors reflects the broader development of LED lighting technology over the past two decades. Initially, LED strips were connected using basic soldered joints, limiting flexibility and installation speed. The introduction of solderless connectors revolutionized the sector by enabling quick, tool-free assembly, which significantly reduced labor costs and installation errors.

As LED strips became ubiquitous in both indoor and outdoor applications, the demand for waterproof and weather-resistant connectors grew. This led to innovations such as silicone sealing and robust plastic housings, making 2-pin connectors suitable for harsh environments and outdoor lighting projects.

Today’s connectors are the result of continuous refinement focused on ease of use, electrical reliability, and environmental compliance, making them indispensable components in modern LED lighting systems worldwide. For international buyers, understanding this evolution helps in selecting connectors that meet both technical and regulatory requirements across diverse markets.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led light strip connectors 2 pin

-

How can I effectively vet suppliers of 2-pin LED light strip connectors for international B2B purchases?

When sourcing 2-pin LED light strip connectors internationally, prioritize suppliers with verifiable certifications such as CE, RoHS, and ISO 9001 to ensure compliance with quality and safety standards. Request detailed product datasheets and samples to test compatibility and durability. Check their track record through trade references, customer reviews, and third-party audits. For buyers in Africa, South America, the Middle East, and Europe, verify the supplier’s export experience and ability to meet regional regulatory requirements to minimize customs or compliance issues. -

Is customization of 2-pin LED strip connectors feasible for bulk orders, and what should I consider?

Many manufacturers offer customization options including waterproofing levels, connector length, and pin material. For international B2B buyers, it’s critical to discuss minimum order quantities (MOQs), lead times, and tooling fees upfront. Ensure your specifications align with your LED strip system’s voltage and current requirements to avoid compatibility issues. Custom packaging and private labeling can enhance your brand presence but may add to production time. Early engagement with suppliers on customization ensures smoother production and shipment schedules, especially for markets with unique environmental conditions like high humidity or dust. -

What are typical MOQ and lead times for 2-pin LED strip connectors in international trade?

MOQs for 2-pin LED strip connectors vary widely but typically start from 1,000 units for standard models, with customized orders requiring higher minimums. Lead times can range from 2 to 6 weeks depending on order size, customization, and supplier location. Buyers from Europe, South America, or Africa should factor in additional time for international shipping and customs clearance. Negotiating partial shipments or stockpiling inventory with your supplier can mitigate risks associated with long lead times and fluctuating demand. -

Which payment terms are commonly accepted for international B2B transactions involving LED strip connectors?

Common payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), and increasingly, secure online escrow services. New buyers typically pay a deposit (30-50%) upfront with the balance due upon shipment or delivery. Established partnerships often negotiate net payment terms (e.g., net 30 or net 60). For buyers in emerging markets, working with suppliers who accept flexible payment terms or escrow reduces financial risk. Always verify supplier banking details through secure channels to avoid fraud. -

What quality assurance measures should I expect from reputable 2-pin LED strip connector manufacturers?

Top manufacturers implement rigorous quality control including automated optical inspection (AOI), continuity testing, and waterproof testing for IP-rated connectors. Request quality certificates such as IPC standards compliance or factory inspection reports. Pre-shipment inspections by third-party agencies are advisable to verify order accuracy and product integrity. For sensitive markets like the EU or Middle East, ensure connectors meet environmental directives (RoHS, REACH) to avoid regulatory penalties and returns. -

How can I optimize logistics and shipping for 2-pin LED strip connectors to Africa, South America, or Europe?

Choose suppliers experienced with your target region’s import regulations and preferred shipping methods (air freight for speed, sea freight for cost efficiency). Consolidate shipments to reduce freight costs and ensure proper packaging to prevent damage during transit. Utilize Incoterms like FOB or CIF clearly to define responsibilities. Collaborate with freight forwarders familiar with customs clearance in countries like France or Colombia to expedite delivery and avoid delays. -

What steps should I take if there is a dispute or product quality issue with my 2-pin LED strip connector order?

First, document all communications, product defects, and shipment details. Engage your supplier promptly to resolve issues via replacement, refund, or credit note. If unresolved, escalate using trade dispute resolution mechanisms such as mediation through chambers of commerce or arbitration under international trade agreements. For large orders, consider contracts with clear warranty clauses and dispute resolution terms. Using payment methods with buyer protection can also safeguard your investment. -

Are there region-specific considerations when importing 2-pin LED strip connectors to markets like Africa or the Middle East?

Yes, regional factors such as voltage standards, climate conditions, and import regulations significantly impact connector selection and logistics. For example, connectors with higher IP ratings are recommended in humid or dusty environments common in Africa and the Middle East. Customs documentation must comply with local standards and often requires product certifications. Understanding tariff classifications and potential import duties helps budget accurately. Partnering with local distributors or agents can facilitate smoother market entry and after-sales support.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led light strip connectors 2 pin

Strategic sourcing of 2-pin LED light strip connectors is pivotal for international B2B buyers aiming to optimize product quality, installation efficiency, and long-term system reliability. Key considerations include selecting connectors with robust waterproofing and compatibility with standard 12V or 24V LED strips, ensuring compliance with regional electrical standards, and prioritizing suppliers who offer flexible MOQ and reliable supply chains. For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of wire gauge selection, power distribution methods, and connector durability can significantly reduce installation complexities and maintenance costs.

Illustrative Image (Source: Google Search)

Strategic sourcing empowers buyers to:

- Secure cost-effective, high-performance connectors tailored to diverse climate and application requirements

- Leverage supplier expertise for technical support and customized solutions

- Mitigate risks related to voltage drops, connection failures, and environmental exposure

Looking ahead, the LED lighting market is rapidly evolving with increasing demand for smart, energy-efficient solutions. Buyers are encouraged to engage with manufacturers who invest in innovation, quality assurance, and sustainable practices. Proactively establishing partnerships with reputable suppliers will enable businesses in France, Colombia, and beyond to stay competitive, deliver superior lighting projects, and capitalize on emerging market opportunities. Take decisive action now to align your procurement strategy with future-ready LED connector technologies.