Introduction: Navigating the Global Market for led diffuser strip

The global demand for LED diffuser strips is surging as businesses worldwide recognize their vital role in enhancing LED lighting performance and aesthetics. These components not only soften and evenly distribute light to reduce glare and hotspots but also protect delicate LED elements, thereby extending fixture lifespan and improving user experience. For international B2B buyers—especially those operating in diverse and fast-evolving markets across Africa, South America, the Middle East, and Europe—securing high-quality LED diffuser strips is essential for delivering reliable, energy-efficient lighting solutions that meet local regulatory standards and customer expectations.

Navigating this complex global market requires a deep understanding of product variations, materials, manufacturing processes, and quality control measures. Buyers must also evaluate supplier credibility, assess cost structures, and stay informed about region-specific compliance requirements such as CE marking in Europe or relevant certifications in the Middle East and Africa. Furthermore, customization capabilities and logistical reliability can significantly influence procurement success and operational efficiency.

This comprehensive guide equips international B2B buyers with actionable insights on:

– Types and materials of LED diffuser strips suited for various applications

– Advanced manufacturing and quality assurance protocols ensuring durability and performance

– Strategic supplier selection criteria tailored to different regional markets

– Transparent pricing models and cost optimization tactics

– Key regulatory frameworks impacting import and installation

– Frequently asked questions addressing common sourcing challenges

By leveraging this knowledge, buyers will confidently optimize their procurement strategies, minimize risks, and build resilient partnerships that drive sustainable growth in the dynamic global LED lighting industry.

Understanding led diffuser strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frosted Diffuser Strip | Translucent finish that softens light, reducing glare | Retail displays, office lighting, hospitality | + Enhances visual comfort – Slight reduction in brightness |

| Clear Diffuser Strip | Transparent cover allowing maximum light output | Architectural lighting, signage, exhibitions | + Maximizes brightness – Less glare control |

| Milky/Opal Diffuser | Semi-opaque with balanced light diffusion and brightness | Residential, commercial ambient lighting | + Balanced diffusion and brightness – May alter color tones |

| Micro-Textured Diffuser | Surface with micro-patterns to evenly spread light | High-end retail, museums, galleries | + Superior uniformity – Higher cost and specialized sourcing |

| UV-Resistant Diffuser | Enhanced material to withstand UV exposure without yellowing | Outdoor installations, façades, landscaping | + Longevity in harsh environments – Premium price |

Frosted Diffuser Strip

Frosted diffusers are characterized by their matte, translucent surfaces that soften and scatter LED light, minimizing harsh glare and hotspots. This makes them ideal for environments where visual comfort is paramount, such as retail spaces and office interiors. B2B buyers should consider the slight trade-off in brightness for improved ambiance. Evaluating supplier consistency in diffusion quality and material durability is crucial, especially for large-scale projects targeting markets in Africa and South America where lighting comfort enhances customer experience.

Clear Diffuser Strip

Clear diffuser strips offer minimal light obstruction, allowing LEDs to emit near-maximum brightness. They are preferred in applications demanding high visibility and crisp illumination, such as architectural highlights and exhibition lighting in Europe and the Middle East. Buyers must balance the advantage of brightness with potential glare issues. Sourcing from manufacturers who provide UV-stable materials and precise dimensions ensures longevity and compatibility with LED strips, reducing maintenance costs over time.

Milky/Opal Diffuser

Milky or opal diffusers strike a balance between light diffusion and brightness retention, producing a soft, uniform glow without heavily diminishing output. This type is widely used in residential and commercial ambient lighting, offering aesthetic appeal with functional illumination. B2B buyers should verify color consistency and material quality to prevent color shifting and yellowing, especially when sourcing for markets with strict quality standards like Germany and the Middle East.

Micro-Textured Diffuser

Featuring subtle micro-patterns on the surface, micro-textured diffusers excel at dispersing light evenly, eliminating hotspots and enhancing visual uniformity. They are favored in premium retail environments, museums, and galleries where light quality directly impacts product presentation and visitor experience. For B2B procurement, these diffusers command higher prices and may require specialized supply chains. Buyers should assess supplier capabilities in customization and certification to meet high-end project demands.

UV-Resistant Diffuser

UV-resistant diffusers are engineered with materials that resist degradation and yellowing from prolonged sun exposure, making them essential for outdoor LED lighting applications such as façades, landscaping, and signage in regions with intense sunlight like parts of Africa and the Middle East. While commanding a premium price, these diffusers ensure longevity and consistent performance. Buyers must prioritize certifications for UV stability and confirm supplier adherence to regional environmental standards to maximize return on investment.

Related Video: BRILLIANT Design – Govee’s Complete LED + Diffuser System

Key Industrial Applications of led diffuser strip

| Industry/Sector | Specific Application of led diffuser strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Architecture & Interior Design | Ambient and accent lighting in office buildings, hotels, and retail stores | Enhances visual comfort and aesthetic appeal while reducing glare and hotspots | Requires customizable lengths, consistent light diffusion, and compliance with regional safety standards such as CE (Europe) and SASO (Middle East) |

| Manufacturing & Industrial Facilities | Machine area illumination and safety pathway lighting | Improves worker safety and operational efficiency by providing uniform lighting | Must withstand harsh environments; sourcing should focus on durability, IP ratings, and certifications for hazardous locations |

| Hospitality & Leisure | Decorative lighting in restaurants, lounges, and exhibition spaces | Creates inviting atmospheres and highlights architectural features | Needs high color rendering index (CRI) and options for dimming; suppliers should offer flexible profiles for easy installation |

| Retail & Display | Product showcase lighting and shelving illumination | Increases product visibility and enhances customer experience | Buyers must ensure UV resistance and even light distribution to prevent product damage and shadows |

| Transportation Infrastructure | Lighting in airports, train stations, and tunnels | Provides safe, energy-efficient illumination with minimal maintenance | Focus on long lifespan, energy efficiency, and compliance with local electrical codes |

Commercial Architecture & Interior Design

In commercial architecture, led diffuser strips are widely used to create smooth, uniform ambient lighting in offices, hotels, and retail environments. They solve common issues such as harsh glare and uneven lighting, contributing to a comfortable and visually appealing workspace or customer area. For international buyers, particularly in Europe and the Middle East, it is crucial to source diffuser strips that meet stringent safety certifications (like CE or SASO) and offer customization in length and diffusion properties to fit varied architectural designs.

Manufacturing & Industrial Facilities

Industrial settings benefit from led diffuser strips by achieving consistent illumination on factory floors and along safety pathways, reducing accidents and enhancing productivity. These strips must be robust, resistant to dust and moisture, and compliant with industrial safety standards, especially in regions like South America and Africa where environmental conditions can be challenging. Buyers should prioritize IP-rated products and verify certifications for use in potentially hazardous environments to ensure durability and worker safety.

Hospitality & Leisure

In hospitality venues such as restaurants, lounges, and exhibition halls, led diffuser strips serve as decorative lighting elements that enhance ambiance and highlight design features. Their ability to provide high CRI lighting and support dimming functions makes them indispensable for creating mood lighting. B2B buyers should seek suppliers offering flexible and easy-to-install profiles, ensuring the lighting solutions can adapt to diverse interior styles and meet energy efficiency regulations prevalent in European and Middle Eastern markets.

Retail & Display

Led diffuser strips are essential in retail environments for illuminating product displays and shelving uniformly, which helps attract customer attention and improve product appeal. They prevent hotspots and shadows, ensuring that merchandise is presented in the best light possible. Buyers in Africa, South America, and Europe should focus on UV-resistant materials to prevent product degradation and confirm that diffuser strips maintain consistent light diffusion over time to protect merchandise integrity.

Illustrative Image (Source: Google Search)

Transportation Infrastructure

Transportation hubs such as airports, train stations, and tunnels utilize led diffuser strips for safe, efficient lighting that requires minimal maintenance. These strips contribute to energy savings and provide uniform illumination critical for traveler safety. International buyers must consider long lifespan, energy efficiency ratings, and adherence to local electrical codes. For regions like Europe and the Middle East, compliance with environmental and electrical standards is particularly important to ensure seamless integration and operational reliability.

Strategic Material Selection Guide for led diffuser strip

When selecting materials for LED diffuser strips, international B2B buyers must carefully evaluate options based on performance, durability, cost, and regional compliance requirements. The choice of material directly influences light diffusion quality, thermal management, and the overall lifespan of LED installations. Here is an in-depth analysis of four common materials used for LED diffuser strips:

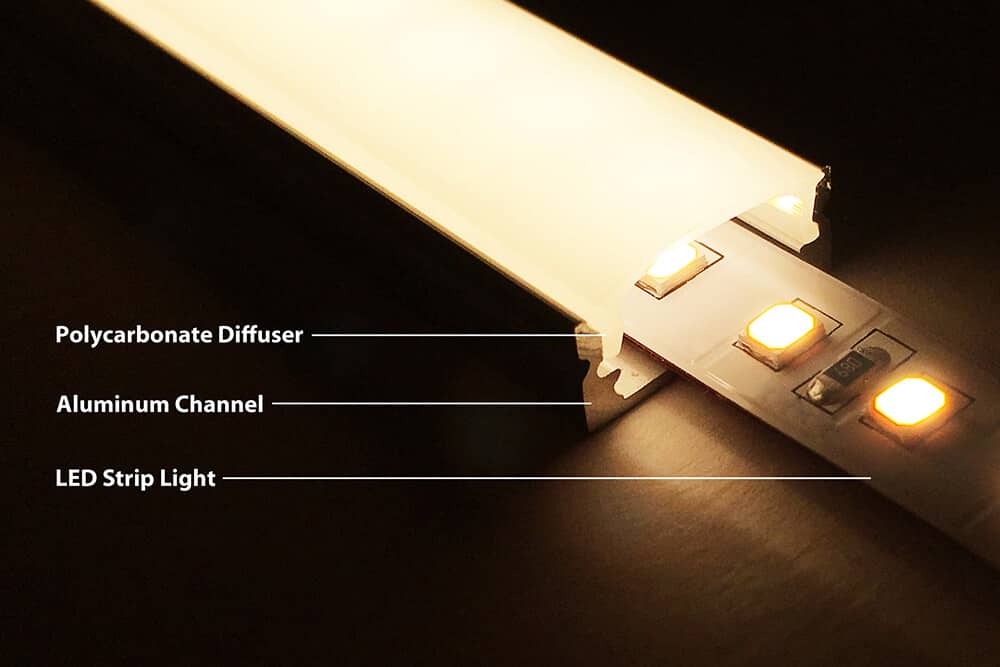

Polycarbonate (PC)

Key Properties:

Polycarbonate is a highly durable thermoplastic known for excellent impact resistance, high temperature tolerance (typically up to 120°C), and good optical clarity. It offers moderate UV resistance and is resistant to many chemicals, making it suitable for various indoor and outdoor applications.

Pros & Cons:

PC’s durability and toughness make it ideal for environments where mechanical stress or impact is a concern. It provides good light diffusion while maintaining high light transmission. However, polycarbonate is generally more expensive than other plastics and may yellow over time if not UV stabilized. Manufacturing complexity is moderate, requiring precise extrusion or injection molding.

Impact on Application:

Polycarbonate diffusers are well-suited for commercial and industrial lighting where robustness and longevity are critical. Its resistance to heat and impact makes it a preferred choice for outdoor or high-traffic installations.

Considerations for International Buyers:

Buyers in regions with intense sunlight, such as the Middle East and parts of Africa, should ensure UV-stabilized PC to prevent discoloration and brittleness. Compliance with ASTM D3935 (UV resistance) and ISO 9001 manufacturing standards is common in Europe and Germany. PC’s higher cost may be a consideration for budget-sensitive markets in South America, but its durability can offset replacement costs.

Acrylic (PMMA)

Key Properties:

Acrylic offers excellent optical clarity and light transmission (up to 92%), with a lower temperature resistance (up to ~80°C) compared to polycarbonate. It is less impact-resistant but provides superior resistance to yellowing and weathering.

Pros & Cons:

Acrylic is lightweight and easier to fabricate, often resulting in lower manufacturing costs. It provides a smooth, high-quality finish with excellent light diffusion properties. The main drawback is its brittleness and lower impact resistance, which can lead to cracking under stress.

Impact on Application:

Ideal for indoor LED diffuser strips in controlled environments such as offices, retail, and residential lighting. Acrylic is less suitable for harsh outdoor conditions or industrial settings where mechanical durability is paramount.

Considerations for International Buyers:

European buyers, especially in Germany, often prefer acrylic for its premium optical qualities and compliance with DIN 5036 (light transmission standards). Buyers in South America and Africa should assess environmental conditions carefully, as acrylic may degrade faster under high UV exposure unless treated. Acrylic’s moderate cost and ease of customization make it attractive for mid-range projects.

Silicone

Key Properties:

Silicone diffusers are flexible, highly resistant to extreme temperatures (from -60°C to 230°C), and exhibit excellent UV and weather resistance. They are also chemically inert and have good electrical insulation properties.

Pros & Cons:

Silicone’s flexibility allows for innovative diffuser designs and installation in curved or irregular surfaces. It withstands harsh environmental conditions without yellowing or cracking. However, silicone is more expensive and less rigid, which may complicate handling and mounting.

Impact on Application:

Best suited for premium or specialized LED lighting applications requiring durability in extreme climates or flexible form factors. Common in outdoor signage, architectural lighting, and harsh industrial environments.

Considerations for International Buyers:

Buyers in the Middle East and Africa benefit from silicone’s heat and UV resistance, ensuring longevity under intense sun and temperature swings. European markets value silicone for its compliance with RoHS and REACH regulations. The higher cost and specialized manufacturing processes require buyers to partner with experienced suppliers to ensure quality and certification.

Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight, chemically resistant plastic with moderate temperature tolerance (up to 70°C) and good dimensional stability. It offers decent optical diffusion but lower impact resistance than PC or acrylic.

Pros & Cons:

PET is cost-effective and recyclable, making it attractive for environmentally conscious projects. It is easy to process but less durable in high-temperature or high-impact applications. PET diffusers may yellow over time if exposed to UV without protective coatings.

Impact on Application:

Commonly used in budget-sensitive LED strip lighting projects, especially indoor applications with limited mechanical stress. PET’s recyclability aligns well with sustainability initiatives.

Considerations for International Buyers:

In South America and Africa, PET’s low cost and recyclability are appealing for large-scale, cost-driven projects. Buyers in Europe must verify compliance with strict environmental standards such as EU’s Ecodesign Directive and ISO 14001. PET’s lower thermal resistance limits its use in high-heat environments common in the Middle East unless combined with UV stabilizers or coatings.

| Material | Typical Use Case for led diffuser strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Outdoor and industrial LED lighting requiring durability | High impact resistance and heat tolerance | Higher cost and potential yellowing without UV stabilization | High |

| Acrylic (PMMA) | Indoor commercial and residential lighting | Superior optical clarity and weather resistance | Brittle, lower impact resistance | Medium |

| Silicone | Specialized outdoor, architectural, and flexible applications | Extreme temperature and UV resistance, flexibility | Higher cost and less rigidity | High |

| PET | Budget indoor LED strip lighting and eco-friendly projects | Cost-effective and recyclable | Lower thermal resistance and durability | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for led diffuser strip

Manufacturing and quality assurance of LED diffuser strips are critical factors that directly impact product performance, durability, and compliance with international standards. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding these processes and quality controls ensures informed procurement decisions, mitigates risk, and supports long-term supplier partnerships.

Typical Manufacturing Process of LED Diffuser Strips

The production of LED diffuser strips involves several precise stages designed to optimize light diffusion, durability, and compatibility with LED channels or fixtures.

1. Material Preparation

- Raw Material Selection: High-quality optical-grade polycarbonate (PC) or acrylic (PMMA) plastics are commonly used for diffusers due to their excellent light transmission, impact resistance, and UV stability.

- Additive Mixing: Materials may be compounded with UV stabilizers, anti-yellowing agents, or fire retardants tailored to regional regulatory requirements or specific end-use environments.

- Pelletizing: Raw polymers are often pelletized to ensure uniform melting and extrusion consistency.

2. Extrusion and Forming

- Extrusion Process: The polymer pellets are melted and extruded through precision dies to form continuous diffuser strips with the desired cross-sectional profile.

- Profile Accuracy: Die design and temperature control are critical for maintaining consistent thickness, width, and surface texture, which affect diffusion quality and fit within LED channels.

- Surface Treatment: Some diffusers undergo surface texturing or micro-etching during extrusion to enhance light scattering and reduce glare.

3. Assembly and Integration

- Cutting and Sizing: Extruded strips are cut to specified lengths based on customer requirements or standard module sizes.

- Fitting and Sealing: For integrated diffuser-strip assemblies, sealing against LED channels is performed to ensure dust and moisture resistance.

- Customization: Additional coatings or color tinting can be applied to meet design or functional specifications.

4. Finishing and Packaging

- Edge Polishing: Edges may be polished or chamfered to prevent damage and facilitate installation.

- Quality Inspection: Visual and dimensional inspections are conducted to detect surface defects, warping, or inconsistencies.

- Protective Packaging: Diffuser strips are packed in clean, moisture-resistant packaging to maintain integrity during international shipping.

Quality Assurance and Control Measures

Robust quality assurance (QA) and quality control (QC) frameworks are essential to guarantee that LED diffuser strips meet performance, safety, and regulatory standards, which vary across regions.

Key International and Industry Standards

- ISO 9001: The foundational quality management system standard ensuring consistent production processes and continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, certifying compliance with EU directives on safety, health, and environmental protection.

- RoHS (Restriction of Hazardous Substances): Ensures materials are free from hazardous substances like lead and mercury, critical for European and Middle Eastern markets.

- UL or ETL Certifications: Often required in Middle Eastern and North African markets to validate electrical safety.

- Regional Certifications: Examples include INMETRO in South America or SASO in the Gulf region, which B2B buyers should verify depending on destination markets.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Raw materials and components undergo stringent testing for purity, mechanical properties, and compliance with specification sheets before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during extrusion and forming phases includes dimensional checks, surface quality inspection, and optical performance assessment.

- Final Quality Control (FQC): Finished diffuser strips are tested for light diffusion uniformity, color consistency, mechanical strength, and environmental resistance.

Common Testing Methods

- Light Transmission and Diffusion Testing: Spectrophotometers measure the percentage of light transmitted and the degree of diffusion to ensure even illumination.

- Mechanical Strength Tests: Tensile, impact, and bend tests confirm durability under installation and operational stresses.

- UV and Weather Resistance: Accelerated aging tests simulate exposure to sunlight and environmental factors to assess yellowing and degradation.

- Dimensional Accuracy: Precision calipers and optical gauges verify adherence to specified dimensions critical for fitting in LED channels.

- Chemical Resistance: Tests ensure diffusers withstand cleaning agents or atmospheric pollutants common in target markets.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers especially in regions with evolving regulatory frameworks or logistical complexities, thorough supplier evaluation and verification is vital.

- Supplier Audits: Conduct on-site audits or remote video inspections to assess manufacturing facilities, equipment condition, and quality management systems. Focus on process controls and employee training programs.

- Review of Quality Documentation: Request ISO 9001 certificates, test reports, and batch traceability records. Confirm that certifications are current and issued by accredited bodies.

- Third-Party Inspections: Engage independent inspection agencies to perform pre-shipment inspections or random sampling to validate product conformity.

- Sample Testing: Procure samples and conduct independent lab testing for optical performance, material composition, and mechanical properties.

- References and Case Studies: Verify supplier track records with other international buyers, particularly in similar climates or regulatory environments.

QC and Certification Nuances for Global Markets

Understanding regional nuances in quality and certification requirements can help buyers avoid costly compliance issues and product rejections.

- Europe (e.g., Germany): Emphasis on CE marking, RoHS compliance, and strict environmental standards. Buyers should insist on full documentation, including Declaration of Conformity and test reports from accredited European labs.

- Middle East (e.g., Egypt, GCC): UL or ETL certifications alongside regional SASO compliance are often mandatory. Environmental conditions such as high temperatures and dust require diffusers with enhanced UV and chemical resistance.

- Africa: Regulatory frameworks vary widely. Buyers should prioritize suppliers with flexible quality systems and certifications recognized internationally. Durability under harsh environmental conditions is crucial.

- South America: INMETRO certification is essential for many countries. Buyers should verify local testing requirements and ensure suppliers can provide compliant documentation.

Final Recommendations for B2B Buyers

- Prioritize Suppliers with Transparent Quality Systems: Clear communication on manufacturing and QC processes builds trust and reduces risk.

- Invest in Third-Party Testing and Inspection: Independent verification complements supplier documentation, especially when entering new markets.

- Consider Environmental and Regulatory Contexts: Tailor diffuser specifications (material additives, coatings) to match local climate and compliance mandates.

- Negotiate for Quality Guarantees and After-Sales Support: Long-term warranties and responsive technical support help mitigate risks in international supply chains.

By comprehensively understanding the manufacturing stages and quality assurance protocols of LED diffuser strips, international B2B buyers can ensure procurement of reliable, high-performance products that meet their operational and regulatory needs across diverse global markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led diffuser strip Sourcing

Key Cost Components in LED Diffuser Strip Sourcing

Understanding the detailed cost structure behind LED diffuser strips enables international B2B buyers to make informed procurement decisions that optimize both budget and product quality. The main cost components include:

-

Materials: The choice of diffuser material (typically polycarbonate or acrylic) significantly impacts cost. High-quality, UV-stabilized, or flame-retardant materials command premium prices but enhance durability and compliance with safety standards, which is critical for markets like Europe and the Middle East.

-

Labor: Skilled labor for extrusion, cutting, and finishing contributes to unit cost. Labor costs vary widely by manufacturing location, influencing price competitiveness. For buyers sourcing from Asia or Eastern Europe, labor cost advantages may translate into lower prices.

-

Manufacturing Overhead: This includes factory utilities, maintenance, and indirect labor. Efficient production lines with automation can reduce overhead per unit, benefiting buyers with larger volume orders.

-

Tooling and Setup Costs: Custom diffuser profiles or colors require specific extrusion dies and tooling, often involving upfront investment. These costs are amortized over the order volume, so smaller orders typically carry higher per-unit tooling costs.

-

Quality Control (QC): Rigorous QC processes ensure consistent light diffusion and dimensional accuracy. QC costs include inspection, testing, and certification efforts, essential for buyers prioritizing compliance with certifications like CE (Europe) or SASO (Middle East).

-

Logistics and Shipping: Freight charges, customs duties, and import taxes vary by region and shipping method. Buyers from Africa and South America should factor in longer transit times and potential port handling fees, which can add 10–20% to landed costs.

-

Supplier Margin: This varies depending on supplier reputation, exclusivity of product, and market demand. Established suppliers with certifications and proven reliability tend to price at a premium but reduce procurement risks.

Critical Price Influencers for LED Diffuser Strips

Several factors influence the final pricing, offering negotiation levers and decision criteria for international buyers:

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders reduce per-unit cost by spreading fixed costs like tooling and shipping. Buyers should negotiate MOQs aligned with their inventory capacity and sales forecasts to optimize cash flow.

-

Product Specifications and Customization: Custom lengths, colors, or finishes increase complexity and cost. Standard profiles and diffuser opacities are more cost-effective. Buyers should balance customization needs against price sensitivity.

-

Material Grade and Certification: Premium materials with certifications (e.g., UL94 flame retardant, RoHS compliance) cost more but are often mandatory in regulated markets like Germany or UAE. Non-certified products may be cheaper but carry risk of non-compliance penalties.

-

Supplier Location and Capabilities: Suppliers closer to buyer regions reduce logistics costs and lead times. However, suppliers from established manufacturing hubs may offer better quality assurance and post-sale support.

-

Incoterms: Terms such as FOB, CIF, or DDP affect who bears shipping and customs costs. Buyers should clarify responsibilities upfront to avoid unexpected charges, particularly when importing into countries with complex customs regimes.

Actionable Buyer Tips for International B2B Procurement

-

Negotiate Beyond Price: Engage suppliers on payment terms, lead times, warranty, and after-sales support. These factors often have greater long-term value than marginal price reductions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the unit price but also installation ease, durability, replacement frequency, and energy efficiency. High-quality diffuser strips can reduce maintenance and replacement costs, especially in harsh climates common in Africa and the Middle East.

-

Leverage Volume for Discounts: Consolidate orders across subsidiaries or projects to reach higher volume tiers and access better pricing.

-

Verify Certifications Early: Ensure suppliers provide up-to-date compliance documents to avoid costly delays or rejections in regulated markets like the EU.

-

Factor in Logistics Complexity: For buyers in South America and Africa, plan for longer transit times and potential customs delays. Using freight forwarders familiar with local regulations can minimize disruptions.

-

Request Samples and Conduct Testing: Validate diffuser performance and material quality before committing to large orders, particularly for custom designs.

Pricing Disclaimer

Due to rapidly changing raw material prices, labor rates, and shipping costs, the prices for LED diffuser strips vary widely across suppliers and regions. The pricing insights provided here are indicative and should be validated through direct supplier quotations and market research tailored to the buyer’s specific requirements and location.

By dissecting cost components and price drivers, international B2B buyers—from Germany to Egypt and beyond—can strategically source LED diffuser strips that meet both budgetary and technical demands, while mitigating risks associated with cross-border procurement.

Spotlight on Potential led diffuser strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led diffuser strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led diffuser strip

Critical Technical Properties of LED Diffuser Strips

Understanding the technical specifications of LED diffuser strips is essential for international B2B buyers to ensure product performance, compatibility, and durability in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Material Grade (Polycarbonate vs. Acrylic):

LED diffuser strips are primarily made from polycarbonate (PC) or acrylic (PMMA). Polycarbonate offers higher impact resistance and better heat tolerance, making it suitable for industrial or outdoor applications common in harsh environments like the Middle East. Acrylic provides superior light transmission and scratch resistance, preferred for indoor architectural lighting in Europe. Selecting the right material affects longevity, safety compliance, and visual quality. -

Light Transmission Rate (%):

This indicates how much light passes through the diffuser. Typical rates range from 70% to 95%. Higher transmission yields brighter illumination but may reduce diffusion quality, causing hotspots. Buyers targeting retail or display lighting should balance transmission with uniformity, while industrial buyers may prioritize durability over maximum brightness. -

Diffusion Uniformity (Haze Level):

Measured as haze percentage, this defines how evenly the light is spread to eliminate glare and hotspots. Higher haze (up to 60%) results in softer, more uniform light—ideal for office or hospitality sectors in Europe and South America. Lower haze levels maintain sharper light but can cause uneven illumination. Understanding haze helps buyers specify the right diffuser for their application. -

Dimensional Tolerance (mm):

Precision in length, width, and thickness is critical for seamless integration with LED channels and fixtures. Typical tolerance ranges are ±0.2 mm to ±0.5 mm. Tighter tolerances reduce installation errors and improve aesthetic appeal, essential for large-scale architectural projects and standardized manufacturing in Germany or Egypt. -

UV Resistance and Color Stability:

For outdoor or high-exposure environments, UV-resistant coatings or materials prevent yellowing and degradation over time. This property is especially important for buyers in sunny regions like Africa and the Middle East, ensuring consistent color and performance throughout the product lifespan. -

Fire Retardant Rating:

Compliance with fire safety standards (e.g., UL94 V-0) is mandatory in many markets to minimize fire hazards. Buyers must verify certifications aligned with local regulations, such as CE marking in Europe, to avoid legal and safety risks.

Key Trade Terminology for LED Diffuser Strip Procurement

Navigating international procurement requires familiarity with essential trade terms. Clear understanding facilitates smoother negotiations, compliance, and logistics.

-

OEM (Original Equipment Manufacturer):

Refers to suppliers who produce LED diffuser strips based on the buyer’s specifications and branding. OEM partnerships allow customization in dimensions, materials, and finish, enabling buyers to differentiate their products in competitive markets. -

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to sell in one order. MOQs vary widely; understanding this helps buyers plan inventory and budget, especially important for emerging markets in Africa or South America where demand volumes may fluctuate. -

RFQ (Request for Quotation):

A formal inquiry sent by buyers to suppliers asking for price, lead time, and terms based on specific product requirements. A well-prepared RFQ accelerates supplier evaluation and ensures accurate cost comparisons across regions. -

Incoterms (International Commercial Terms):

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities for shipping, insurance, and customs clearance. Knowledge of Incoterms empowers buyers to negotiate favorable delivery terms, control costs, and mitigate risks in cross-border transactions. -

Lead Time:

The total time from order placement to delivery. Lead times affect project schedules and inventory management, critical for markets with variable shipping infrastructure like parts of South America or Africa. -

Certification Compliance:

Refers to adherence to mandatory standards such as CE (Europe), RoHS (Europe, Middle East), or local certifications (e.g., SASO in Saudi Arabia). Ensuring compliance avoids customs delays and legal penalties, safeguarding brand reputation.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, tailor procurement strategies to regional needs, and establish resilient supply chains for LED diffuser strips across diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led diffuser strip Sector

Market Overview & Key Trends

The global LED diffuser strip market is experiencing robust growth driven by rapid adoption of energy-efficient lighting solutions across commercial, industrial, and architectural sectors. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, this growth is fueled by increasing urbanization, infrastructure development, and government incentives promoting sustainable energy use. In Europe, particularly Germany, stringent regulations around energy efficiency and product safety (e.g., CE and RoHS certifications) shape procurement strategies, emphasizing compliance and quality assurance. Meanwhile, emerging markets in Africa and South America prioritize affordability and scalability, seeking suppliers that can deliver cost-effective, customizable LED diffuser solutions without compromising basic performance and durability.

Key sourcing trends include a shift towards modular and customizable LED diffuser strips, allowing buyers to tailor lighting profiles to specific architectural or industrial applications. Advances in extrusion materials and diffuser designs enhance light uniformity and reduce glare, which is increasingly demanded in retail, hospitality, and office environments globally. Additionally, the integration of smart lighting controls and IoT compatibility is gaining momentum, enabling energy management and remote monitoring—features particularly appealing to technologically progressive buyers in the Middle East and Europe.

Supply chain dynamics reflect a growing preference for suppliers offering end-to-end solutions, including custom extrusion, diffuser lens options, and reliable logistics support. Regional buyers are increasingly vetting suppliers for certifications, production transparency, and after-sales service to mitigate risks associated with cross-border procurement. Given the diverse market requirements, international buyers benefit from partnering with manufacturers who can provide tailored solutions that align with local regulatory frameworks and installation conditions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor in LED diffuser strip procurement, with B2B buyers demanding products that minimize environmental impact throughout their lifecycle. The choice of materials plays a pivotal role—many suppliers are transitioning from traditional polycarbonate and acrylic diffusers to recyclable or bio-based polymers that reduce carbon footprint and facilitate circular economy practices. Moreover, energy-efficient manufacturing processes and reduced waste generation during extrusion and assembly are key differentiators for suppliers targeting eco-conscious buyers.

Ethical sourcing extends beyond materials to encompass labor practices, supply chain transparency, and compliance with international standards such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability). Buyers from Europe and the Middle East, in particular, are scrutinizing supplier certifications and audit reports to ensure adherence to ethical labor conditions and sustainable sourcing policies. This diligence mitigates reputational risks and aligns procurement with corporate social responsibility (CSR) goals.

Green certifications such as UL Environment’s GREENGUARD, TÜV Rheinland’s eco-labels, and Energy Star compatibility increasingly influence purchasing decisions. These certifications provide assurance that LED diffuser strips meet stringent environmental and health safety criteria, including low chemical emissions and energy efficiency. For B2B buyers in Africa and South America, leveraging such certifications can enhance product credibility and facilitate market acceptance in regulated markets.

Evolution of LED Diffuser Strips

Originally, LED diffuser strips were simple plastic covers designed primarily to protect LED light sources and soften emitted light. Over time, innovation in materials and extrusion techniques transformed these components into sophisticated lighting elements that enhance light distribution, reduce glare, and improve aesthetic appeal. The integration of advanced diffusion patterns and multi-layered optics allows for consistent light output and customizable color temperatures, meeting diverse application needs from retail displays to architectural accents.

This evolution parallels broader LED technology advancements, where the focus has shifted from basic illumination to smart, energy-efficient, and sustainable lighting solutions. For B2B buyers, understanding this progression underscores the importance of selecting suppliers that offer the latest diffuser technologies combined with reliable performance and compliance with evolving market standards.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led diffuser strip

-

How can I effectively vet LED diffuser strip suppliers in different international markets?

To vet suppliers, start by verifying their business licenses and certifications relevant to your region (e.g., CE for Europe, SASO for the Middle East). Request samples to assess product quality and consistency. Check references or case studies of previous B2B clients, especially those in similar industries or regions. Evaluate their communication responsiveness and transparency about manufacturing processes. Using third-party inspection services or factory audits can further reduce risks. Prioritize suppliers with proven export experience and compliance with international standards to ensure smooth cross-border transactions. -

What customization options are typically available for LED diffuser strips, and how should I approach them?

Most manufacturers offer customization in length, diffuser material (e.g., frosted, clear, opal), and profile shape to suit specific lighting designs. Color temperature compatibility and mounting options can also be tailored. Clearly communicate your technical requirements and intended application early in discussions. For markets like Germany or Egypt, specifying compliance with local electrical and safety standards is crucial. Negotiate minimum order quantities (MOQs) and lead times upfront, as custom orders often require longer production cycles. Collaborate closely with suppliers to finalize prototypes before mass production. -

What are common MOQ and lead time expectations for international B2B orders of LED diffuser strips?

MOQ varies widely depending on the supplier’s scale and customization level, typically ranging from 500 to 2,000 meters or equivalent units. Standard lead times for ready-made diffuser strips are around 2 to 4 weeks, but custom profiles or colors can extend production to 6-8 weeks. For buyers in Africa or South America, factor in additional shipping time and potential customs clearance delays. Discuss flexible MOQ options if your market testing requires smaller batches. Clear payment terms and upfront deposits often influence production scheduling and delivery reliability.

Illustrative Image (Source: Google Search)

-

Which quality assurance certifications should I insist on when sourcing LED diffuser strips for Europe and the Middle East?

For Europe, CE marking, RoHS compliance, and REACH certification are critical to meet environmental and safety regulations. The Middle East market often requires SASO certification (Saudi Arabia) or ESMA compliance (UAE). Additionally, ISO 9001 certification from the supplier demonstrates robust quality management systems. Request test reports for impact resistance, UV stability, and flame retardancy, especially for outdoor or industrial applications. Insisting on these certifications helps ensure product safety, reduces liability risks, and facilitates smooth import clearance. -

What logistics considerations should B2B buyers from Africa and South America be aware of when importing LED diffuser strips?

Shipping LED diffuser strips requires careful packaging to prevent damage during transit, typically using reinforced cartons or pallets. Sea freight is cost-effective for large volumes but slower, while air freight suits urgent or smaller shipments. Anticipate customs documentation needs such as commercial invoices, certificates of origin, and compliance certificates. Partnering with freight forwarders experienced in your region can streamline clearance and reduce delays. Also, verify Incoterms clearly to understand who assumes responsibility for shipping risks and costs at each stage. -

How can I manage payment terms and reduce financial risks when dealing with new LED diffuser strip suppliers internationally?

Negotiate payment terms that balance trust and cash flow, such as 30% upfront deposit and 70% upon delivery or inspection. Letters of credit (LC) offer strong protection but may be costly. Consider escrow services or trade finance options that secure funds until contract conditions are met. Always confirm supplier banking details independently to avoid fraud. For first-time suppliers, smaller initial orders can limit exposure. Maintain clear contracts specifying product specifications, delivery schedules, and penalties for non-compliance. -

What steps should I take if I encounter product quality disputes after receiving LED diffuser strip shipments?

Immediately document discrepancies with photos and detailed descriptions. Review purchase agreements and quality standards agreed upon. Contact the supplier promptly to negotiate remedies such as replacements, refunds, or discounts. Engage third-party inspection or testing labs to provide objective evidence if disputes escalate. Maintain professional communication and consider mediation or arbitration clauses in contracts to resolve conflicts efficiently. Building strong supplier relationships and clear quality checkpoints can prevent most disputes. -

Are there specific considerations for LED diffuser strip procurement in regions with fluctuating regulations like Africa and the Middle East?

Yes, regulatory environments in these regions can change rapidly. Stay updated on import duties, safety standards, and environmental regulations by consulting local trade authorities or chambers of commerce. Establish partnerships with local agents or distributors who understand regulatory nuances. Suppliers offering flexible certification support and adapting product specs accordingly provide a competitive edge. Additionally, be prepared for variable customs clearance times and ensure all documentation is accurate and complete to avoid costly delays or fines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led diffuser strip

Strategic sourcing of LED diffuser strips is a critical lever for international B2B buyers aiming to optimize product performance, cost efficiency, and supply chain resilience. Key takeaways include the importance of verifying supplier certifications aligned with regional standards (such as CE in Europe and local compliance in Africa and the Middle East), prioritizing customization capabilities to meet diverse installation requirements, and ensuring rigorous quality control to guarantee consistent light diffusion and durability. Additionally, understanding the nuances of material types and diffuser profiles enables buyers to select solutions that enhance LED lifespan and aesthetic appeal, crucial for competitive differentiation.

For buyers in Africa, South America, the Middle East, and Europe, embracing a strategic sourcing approach means forging partnerships with manufacturers who demonstrate transparency, logistical reliability, and adaptability to local market conditions. Leveraging global supply options while mitigating risks related to tariffs, shipping delays, and evolving regulations will be essential to maintaining uninterrupted project timelines and budget control.

Looking ahead, the LED diffuser strip market is poised for innovation driven by sustainability demands and smart lighting integration. International buyers are encouraged to proactively engage with suppliers offering eco-friendly materials and advanced diffuser technologies, positioning their businesses at the forefront of energy-efficient lighting solutions. By adopting a forward-thinking sourcing strategy, B2B purchasers can secure long-term value and capitalize on emerging market opportunities worldwide.