Guide to Led Channel For Led Strip Lights

- Introduction: Navigating the Global Market for led channel for led strip lights

- Understanding led channel for led strip lights Types and Variations

- Key Industrial Applications of led channel for led strip lights

- Strategic Material Selection Guide for led channel for led strip lights

- In-depth Look: Manufacturing Processes and Quality Assurance for led channel for led strip lights

- Comprehensive Cost and Pricing Analysis for led channel for led strip lights Sourcing

- Spotlight on Potential led channel for led strip lights Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led channel for led strip lights

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led channel for led strip lights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led channel for led strip lights

- Strategic Sourcing Conclusion and Outlook for led channel for led strip lights

Introduction: Navigating the Global Market for led channel for led strip lights

In today’s rapidly evolving lighting industry, LED channels for LED strip lights have become indispensable components that enhance both the functionality and aesthetics of lighting installations. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the complexities of sourcing these specialized products is critical to ensuring competitive advantage and long-term success.

LED channels serve as protective housings and mounting solutions that not only safeguard LED strips from dust and moisture but also improve heat dissipation and create polished, professional finishes. Their role extends beyond mere accessories; they directly impact the durability, efficiency, and visual appeal of LED lighting projects. Given the variety of types, materials, and manufacturing standards, selecting the right LED channel requires thorough market insight and technical knowledge.

This guide offers a comprehensive roadmap for B2B buyers navigating the global supply landscape. It delves into the different types of LED channels—such as aluminum extrusions and polycarbonate options—explores material benefits, and highlights key manufacturing and quality control considerations. You will also gain actionable intelligence on evaluating suppliers, comparing cost structures, and understanding regional market trends, helping you optimize procurement strategies tailored to your geographic and project-specific needs.

Whether you represent a distributor in Mexico, a contractor in the UK, or a lighting integrator in the Middle East, this guide equips you with the expertise to make informed sourcing decisions, mitigate risks, and foster strong supplier partnerships. By leveraging this knowledge, international buyers can confidently navigate the complexities of the LED channel market and secure high-quality products that meet rigorous performance and compliance standards.

Understanding led channel for led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum LED Channels | Durable aluminum body, excellent heat dissipation | Architectural lighting, commercial displays | Pros: Long lifespan, good thermal management; Cons: Higher cost, heavier than plastic |

| Plastic LED Channels | Lightweight, cost-effective, often with frosted covers | Residential lighting, temporary setups | Pros: Affordable, easy to cut/install; Cons: Less durable, lower heat dissipation |

| Recessed LED Channels | Designed for flush installation within surfaces | Furniture, retail shelving, wall accents | Pros: Sleek look, space-saving; Cons: Requires precise installation, higher labor cost |

| Surface-Mounted Channels | Mounted on surface, easy retrofit and maintenance | Signage, exhibition stands, office lighting | Pros: Easy to install and replace; Cons: More visible, may be less aesthetic |

| Flexible LED Channels | Adaptable to curved or irregular surfaces | Automotive, creative architectural designs | Pros: Versatile shapes, unique applications; Cons: Limited load capacity, higher price |

Aluminum LED Channels

These channels are crafted from aluminum, providing superior durability and excellent heat dissipation, which extends the lifespan of LED strips. Ideal for commercial and architectural projects, aluminum channels support high-performance lighting needs where longevity and safety are critical. B2B buyers should consider the higher upfront cost balanced against the long-term savings from reduced maintenance and replacement. Their weight and rigidity make them less suitable for flexible applications.

Plastic LED Channels

Plastic channels offer an economical alternative, primarily used in residential or temporary lighting setups. They are lightweight and easy to customize, often coming with frosted diffusers to soften light output. While less durable and with poorer heat management than aluminum, they are favored by buyers prioritizing cost efficiency and ease of installation. However, plastic channels may not be ideal for high-heat or long-term commercial use.

Recessed LED Channels

Designed to be embedded into surfaces, recessed channels provide a clean, minimalist aesthetic favored in furniture manufacturing, retail displays, and upscale interior projects. This type demands precise cutting and installation, which can increase labor costs but delivers a premium finish. For B2B buyers, ensuring compatibility with the installation environment and planning for professional fitting are essential to maximize value.

Surface-Mounted Channels

These channels are attached directly onto surfaces, making them suitable for retrofit projects or applications where ease of maintenance is paramount. Common in signage, exhibition booths, and office lighting, surface-mounted channels are straightforward to install and replace. The trade-off is a more visible profile, which may not suit high-end design requirements. Buyers should weigh installation speed against aesthetic considerations.

Flexible LED Channels

Flexible channels accommodate curved or irregular surfaces, opening creative possibilities in automotive lighting and innovative architectural designs. They allow for unique lighting solutions that rigid channels cannot achieve. However, these channels often come at a premium price and have limitations on load capacity and protection. B2B buyers should assess the project’s design complexity and budget to determine if flexible channels are the best fit.

Related Video: How to Install LED Channel for LED Strip Lights – Smart Bright LEDs

Key Industrial Applications of led channel for led strip lights

| Industry/Sector | Specific Application of led channel for led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Display and accent lighting in storefronts and shelving units | Enhances product visibility, drives customer engagement | Durability, customizable sizes, ease of installation, IP rating |

| Hospitality & Leisure | Ambient and decorative lighting in hotels, restaurants, and bars | Creates inviting atmosphere, energy-efficient lighting | Aesthetic design options, heat dissipation, compliance with safety standards |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Improves worker productivity and safety | Robustness, impact resistance, compatibility with industrial controls |

| Architecture & Interior Design | Cove lighting and architectural highlights in offices and public buildings | Adds visual appeal and functional lighting | High-quality diffusers, color temperature options, and uniform light distribution |

| Transportation & Infrastructure | Lighting for tunnels, walkways, and vehicle interiors | Enhances visibility and safety, reduces maintenance costs | Weatherproofing, vibration resistance, long lifespan |

Retail & Commercial Applications

In retail environments across Africa, South America, and Europe, led channels for LED strip lights are extensively used to highlight products on shelves and in display cases. These channels provide clean, professional lighting that draws attention to merchandise while protecting the LED strips from dust and damage. International buyers must prioritize sourcing channels that offer flexible sizing and easy installation to adapt to varying store layouts and climate conditions, especially in humid or dusty regions.

Hospitality & Leisure Sector

Hotels, restaurants, and bars benefit from the ambient lighting capabilities of LED channels, which allow for subtle, customizable illumination that enhances guest experience. In markets like the Middle East and Europe, where design aesthetics are a priority, LED channels must accommodate different diffuser styles and heat management features to maintain lighting quality and safety. Buyers should seek products compliant with local electrical standards and fire safety regulations.

Manufacturing & Warehousing

LED channels are critical in industrial settings for protecting LED strips used in task lighting and safety indicators on production floors. They help prevent damage from dust, moisture, and mechanical impact, which is essential in harsh environments common in African and South American manufacturing hubs. Buyers should focus on sourcing channels made from durable materials with high impact resistance and compatibility with industrial-grade LED strips and control systems.

Architecture & Interior Design

Architectural projects in Europe and the Middle East often incorporate LED channels for cove and accent lighting to create sophisticated visual effects. These channels ensure uniform light diffusion and protect LED strips from environmental factors. For B2B buyers, selecting channels with customizable diffuser options and varying color temperature compatibility is key to meeting diverse design requirements and client expectations.

Transportation & Infrastructure

In transportation infrastructure such as tunnels, pedestrian walkways, and vehicle interiors, LED channels provide robust protection and enhance lighting longevity. This application demands channels that are weatherproof, vibration-resistant, and capable of operating in extreme temperature ranges. Buyers from regions with challenging climates, like parts of South America and the Middle East, should prioritize sourcing from manufacturers offering certifications for outdoor and industrial-grade use to ensure reliability and safety.

Strategic Material Selection Guide for led channel for led strip lights

When selecting materials for LED channels designed to house LED strip lights, B2B buyers must weigh various factors including thermal performance, durability, cost, and compliance with international standards. The choice of material directly impacts the longevity, safety, and aesthetic integration of the lighting solution, especially across diverse markets such as Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in LED channels, highlighting their key properties, advantages, drawbacks, and regional considerations.

Aluminum

Key Properties:

Aluminum is renowned for its excellent thermal conductivity, which helps dissipate heat generated by LED strips, thereby prolonging LED lifespan. It typically withstands temperatures up to 150°C and offers good corrosion resistance, especially when anodized. The material is lightweight yet strong, facilitating easy installation and handling.

Pros & Cons:

Aluminum channels are highly durable and resistant to UV degradation, making them suitable for both indoor and outdoor applications. The anodizing process enhances corrosion resistance but adds to manufacturing complexity and cost. While aluminum is more expensive than plastics, its thermal benefits often justify the investment. However, it requires precise extrusion tooling, which can increase lead times for custom profiles.

Impact on Application:

Ideal for architectural lighting, retail displays, and outdoor signage where heat management and longevity are critical. Aluminum channels are compatible with a wide range of LED strips and diffusers, enhancing light diffusion and aesthetics.

International B2B Considerations:

Buyers in Europe and the UK will benefit from aluminum channels complying with EN standards (e.g., EN 573 for aluminum alloys). In regions like the Middle East and Africa, anodized aluminum’s corrosion resistance is crucial due to harsh environmental conditions. South American buyers should verify compliance with ASTM standards and consider local supplier capabilities for anodizing.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It can tolerate temperatures up to approximately 120°C and offers good UV resistance when treated. It is lighter than aluminum and easier to mold into complex shapes.

Pros & Cons:

PC channels are cost-effective and allow for versatile designs, including integrated diffusers. However, they have lower thermal conductivity, which can lead to heat buildup if not properly ventilated. Over time, untreated PC may yellow under prolonged UV exposure, affecting light quality.

Impact on Application:

Best suited for indoor applications where impact resistance and design flexibility are priorities, such as residential or office lighting. Not recommended for high-heat or outdoor environments without UV stabilization.

International B2B Considerations:

Compliance with ISO 7823 for polycarbonate materials is important for buyers in Europe and South America. In regions with intense sunlight like the Middle East and Africa, UV-stabilized PC is essential to prevent degradation. Buyers should also consider local fire safety regulations, as PC is flammable unless treated.

PVC (Polyvinyl Chloride)

Key Properties:

PVC offers good chemical resistance and moderate thermal stability, typically up to 80-100°C. It is heavier than PC and less thermally conductive than aluminum but is highly resistant to moisture and many chemicals.

Pros & Cons:

PVC channels are among the most affordable options and are easy to manufacture in various shapes. However, they are less durable under mechanical stress and can become brittle over time, especially in cold climates. PVC also has limited UV resistance unless specially formulated.

Impact on Application:

Suitable for budget-conscious indoor lighting projects with low thermal demands. Not ideal for outdoor or high-temperature environments due to potential deformation and degradation.

International B2B Considerations:

Buyers in Europe and the UK should ensure PVC materials meet REACH and RoHS compliance due to environmental regulations. In Africa and South America, PVC’s chemical resistance is beneficial for industrial settings, but UV stabilization is recommended for outdoor use. Middle Eastern buyers should verify flame retardancy certifications.

Stainless Steel

Key Properties:

Stainless steel provides exceptional mechanical strength, corrosion resistance, and thermal stability (up to 500°C depending on grade). It is heavier and more expensive than aluminum but offers superior durability in harsh environments.

Pros & Cons:

While stainless steel channels are highly durable and resistant to corrosion, they are costly and more challenging to fabricate into complex profiles. Their weight can increase installation complexity and shipping costs.

Impact on Application:

Ideal for industrial, marine, or outdoor applications where maximum durability and corrosion resistance are required. Stainless steel channels are often used in environments exposed to chemicals, moisture, or extreme temperatures.

International B2B Considerations:

European and UK buyers often require compliance with DIN or EN standards for stainless steel grades (e.g., 304 or 316). In the Middle East and Africa, stainless steel is preferred for coastal or desert environments due to its resistance to salt and sand corrosion. South American buyers should consider local availability and cost implications.

| Material | Typical Use Case for led channel for led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Architectural lighting, outdoor signage, retail displays | Excellent thermal management | Higher cost and manufacturing complexity | High |

| Polycarbonate | Indoor residential and office lighting, impact-resistant applications | Lightweight, design flexibility | Lower heat resistance, potential UV degradation | Medium |

| PVC | Budget indoor lighting, industrial environments with low heat exposure | Cost-effective, chemical resistant | Limited thermal and UV resistance | Low |

| Stainless Steel | Industrial, marine, outdoor harsh environments | Superior durability and corrosion resistance | Heavy, costly, complex fabrication | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led channel for led strip lights

Manufacturing Processes for LED Channels for LED Strip Lights

The manufacturing of LED channels for LED strip lights involves a series of precise and controlled stages designed to ensure product durability, aesthetic quality, and functional performance. Understanding these steps is crucial for B2B buyers, especially those sourcing internationally from regions such as Africa, South America, the Middle East, and Europe, to evaluate potential suppliers effectively.

1. Material Preparation

- Raw Materials Selection: High-grade aluminum is the primary material used due to its excellent heat dissipation properties and lightweight nature. Buyers should ensure suppliers use certified aluminum alloys (e.g., 6063 T5) to guarantee strength and corrosion resistance.

- Polycarbonate or PMMA Diffusers: These materials are prepared for light diffusion components. Quality of these plastics affects light uniformity and UV resistance.

- Surface Treatment Chemicals: For anodizing or powder coating processes, chemical agents must meet environmental and safety standards.

2. Forming and Fabrication

- Extrusion Process: Aluminum profiles are shaped via extrusion, a critical step defining channel dimensions and cross-sectional accuracy. Precision dies ensure consistency across batches.

- Cutting and Machining: Post-extrusion, channels are cut to specified lengths using CNC machines or precision saws. Additional machining (e.g., drilling mounting holes) is performed as per design.

- Surface Finishing: Channels undergo anodizing, powder coating, or painting to enhance corrosion resistance and aesthetic appeal. Anodizing thickness and uniformity are key quality factors.

3. Assembly

- Diffuser Installation: Diffusers are fitted into the aluminum channels, often snapped or slid in place. Proper fit ensures optimal light diffusion and protection of LED strips.

- End Caps and Mounting Accessories: End caps (plastic or metal) and mounting brackets are assembled to complete the channel system. These components affect the ease of installation and product lifespan.

- Sealing and Waterproofing (if applicable): For outdoor or damp environments, sealing with silicone or rubber gaskets is performed to achieve IP65 or higher ratings.

4. Finishing and Packaging

- Quality Labeling: Each unit is labeled with batch numbers, certifications, and handling instructions to ensure traceability.

- Protective Packaging: Channels are wrapped or boxed with protective materials to prevent damage during shipping. Packaging should comply with international shipping standards to withstand handling and climatic variations.

Quality Assurance Framework in LED Channel Manufacturing

Quality assurance (QA) is a cornerstone of reliable LED channel production. International B2B buyers must rigorously assess suppliers’ QA systems to mitigate risks related to product defects, non-compliance, or shipment delays.

Key International and Industry Standards

- ISO 9001: This is the fundamental international quality management system standard. Suppliers certified under ISO 9001 demonstrate consistent manufacturing processes and continuous improvement practices.

- CE Marking: Mandatory for European markets, CE marking certifies compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restriction of hazardous substances ensures the LED channels are free from harmful materials like lead and mercury, critical for environmental and user safety.

- IP Rating Standards: For waterproof or dustproof LED channels, adherence to IP65, IP67, or higher is essential depending on intended use.

- Additional Certifications: Depending on region and application, certifications such as API (for industrial applications) or UL listings may be relevant.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components upon receipt to verify compliance with specifications. This includes material composition analysis and dimensional checks.

- In-Process Quality Control (IPQC): Continuous monitoring during extrusion, cutting, surface treatment, and assembly to identify defects early. This stage may involve dimensional inspections, surface finish evaluations, and assembly fit tests.

- Final Quality Control (FQC): Comprehensive testing of finished products before shipment. Typical tests include dimensional verification, surface finish inspection, waterproofing tests, and functional tests such as light diffusion uniformity and heat dissipation assessment.

Common Testing Methods

- Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMM) to ensure channels meet design tolerances.

- Surface Hardness and Finish Testing: Anodized layers are tested for thickness and adhesion; powder coatings are assessed for uniformity and resistance.

- Waterproof Testing: Immersion or spray tests per IP standards simulate environmental exposure.

- Mechanical Strength Testing: Impact and tensile tests validate the robustness of mounting brackets and end caps.

- Light Diffusion and Transmission Tests: Spectrophotometers measure the diffuser’s light transmission to ensure even illumination.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially those operating in Africa, South America, the Middle East, and Europe, verifying the supplier’s quality assurance capabilities is critical to ensuring product reliability and compliance.

Supplier Audits

- Factory Audits: On-site evaluations of manufacturing processes, equipment, worker skill levels, and QA protocols. Buyers or third-party inspection agencies can conduct these audits.

- Process Audits: Focus on critical manufacturing stages such as extrusion and surface treatment to verify consistency and adherence to standards.

- System Audits: Examination of the supplier’s quality management system, including document control, corrective action processes, and training records.

Documentation and Reporting

- Quality Control Reports: Request detailed IQC, IPQC, and FQC reports for each batch or shipment.

- Certification Verification: Confirm the validity and scope of ISO 9001, CE, RoHS, and other relevant certifications through official registries or certification bodies.

- Test Certificates: Obtain third-party laboratory test results for materials, coatings, and finished products, especially for compliance with regional standards.

Third-Party Inspection and Testing

- Engaging independent inspection firms to perform random sampling and testing before shipment reduces the risk of receiving substandard goods.

- Third-party labs can conduct specialized tests that may not be available at the supplier’s facility, such as advanced material composition or environmental aging tests.

QC and Certification Nuances for International B2B Buyers

- Regional Compliance Differences: European buyers (e.g., UK) prioritize CE marking and RoHS compliance, while buyers in Africa and South America may focus more on durability and IP ratings suited to local climate conditions.

- Import Regulations: Understanding local import regulations and required certifications helps avoid customs delays and ensures smooth market entry.

- Language and Documentation: Ensure all QC documentation is available in English or the buyer’s preferred language and includes clear product traceability.

- Supplier Responsiveness: Evaluate suppliers’ willingness to provide samples, documentation, and accommodate specific testing requests, as this reflects their commitment to quality and partnership.

- Sustainability and Environmental Standards: Increasingly important for European and Middle Eastern markets, environmental certifications and eco-friendly manufacturing processes can be a decisive factor.

Summary for B2B Buyers

For international buyers sourcing LED channels for LED strip lights, a deep understanding of the manufacturing process and rigorous quality assurance practices is essential. Prioritize suppliers with certified quality systems (ISO 9001), relevant product certifications (CE, RoHS), and robust QC checkpoints (IQC, IPQC, FQC). Conducting factory audits, reviewing comprehensive QC reports, and utilizing third-party inspections can significantly reduce risks. Tailor supplier selection criteria to regional compliance requirements and market expectations to ensure a reliable, high-quality supply chain.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led channel for led strip lights Sourcing

Breakdown of Cost Components in LED Channel for LED Strip Lights

Understanding the cost structure behind LED channels for LED strip lights is crucial for international B2B buyers to make informed purchasing decisions and negotiate effectively.

- Materials: The primary cost driver. Aluminum is the most common raw material due to its lightweight, corrosion resistance, and heat dissipation properties. The quality and grade of aluminum, as well as the type of diffuser (frosted, clear, or milky polycarbonate), directly influence cost.

- Labor: Skilled labor is required for extrusion, anodizing or powder coating, assembly of end caps and mounting brackets, and packaging. Labor costs vary significantly by country and factory efficiency.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and facility maintenance. Efficient plants with automated extrusion and finishing lines reduce overhead per unit.

- Tooling and Setup: Extrusion dies and molds represent upfront investments amortized over production volume. Custom profiles or complex shapes increase tooling costs.

- Quality Control (QC): Rigorous QC processes ensure dimensional accuracy, surface finish, and compatibility with LED strips. Higher QC standards may increase costs but reduce returns and warranty claims.

- Logistics and Shipping: International freight, customs duties, and inland transport affect landed cost. Bulk shipments reduce per-unit freight cost but increase inventory holding.

- Supplier Margin: Includes profit margin, often influenced by supplier reputation, exclusivity of design, and after-sales support.

Key Price Influencers for International B2B Buyers

Several factors shape the final price of LED channels in cross-border sourcing scenarios:

- Order Volume & Minimum Order Quantity (MOQ): Larger volumes typically unlock economies of scale, reducing per-unit cost. MOQ requirements vary; smaller buyers may face higher unit prices.

- Specifications and Customization: Custom lengths, colors, finishes, or integrated features (e.g., diffusers with UV protection) raise costs due to additional tooling, materials, and production complexity.

- Material Quality and Certifications: Buyers targeting premium markets or compliance-heavy regions (EU CE marking, RoHS, REACH) should expect higher prices linked to certified materials and processes.

- Supplier Factors: Established manufacturers with proven quality and service often command higher prices but reduce risk. New or lesser-known suppliers may offer aggressive pricing but require thorough vetting.

- Incoterms and Payment Terms: The choice between FOB, CIF, DDP, etc., affects who bears shipping risk and cost. Favorable payment terms (e.g., letter of credit, net 30/60 days) can improve cash flow but may impact pricing.

Practical Buyer Tips for Cost-Efficient Sourcing

- Negotiate Volume Discounts: Consolidate orders or collaborate with other buyers in your region (Africa, South America, Middle East, Europe) to meet MOQs and reduce unit costs.

- Prioritize Total Cost of Ownership (TCO): Evaluate not just unit price but also shipping, customs, potential import tariffs, and after-sales service costs.

- Request Detailed Cost Breakdown: Transparency helps identify which cost components can be optimized (e.g., opting for standard lengths over custom sizes).

- Assess Supplier Capabilities: Verify certifications and factory audits to avoid hidden costs from rejections or non-compliance penalties.

- Leverage Incoterms to Control Costs: For example, choosing FOB allows buyers to manage shipping logistics and potentially reduce freight expenses.

- Plan for Currency Fluctuations: In volatile markets, consider hedging or fixed exchange rate contracts to avoid unexpected price increases.

- Understand Regional Pricing Nuances: For instance, buyers in Europe or the UK may face higher compliance costs, while African and South American buyers should factor in longer shipping times and customs clearance challenges.

Indicative Pricing Disclaimer

Prices for LED channels can vary widely based on specifications, order size, and supplier location. As a general benchmark, extruded aluminum LED channels may range from USD 1.50 to USD 5.00 per meter for standard profiles, excluding shipping and taxes. Custom profiles and premium finishes will command higher prices. Buyers should obtain multiple quotes and factor in all associated costs before finalizing sourcing decisions.

By thoroughly analyzing cost drivers and pricing influencers, international B2B buyers can strategically source LED channels for LED strip lights that balance quality, compliance, and cost-effectiveness tailored to their regional market needs.

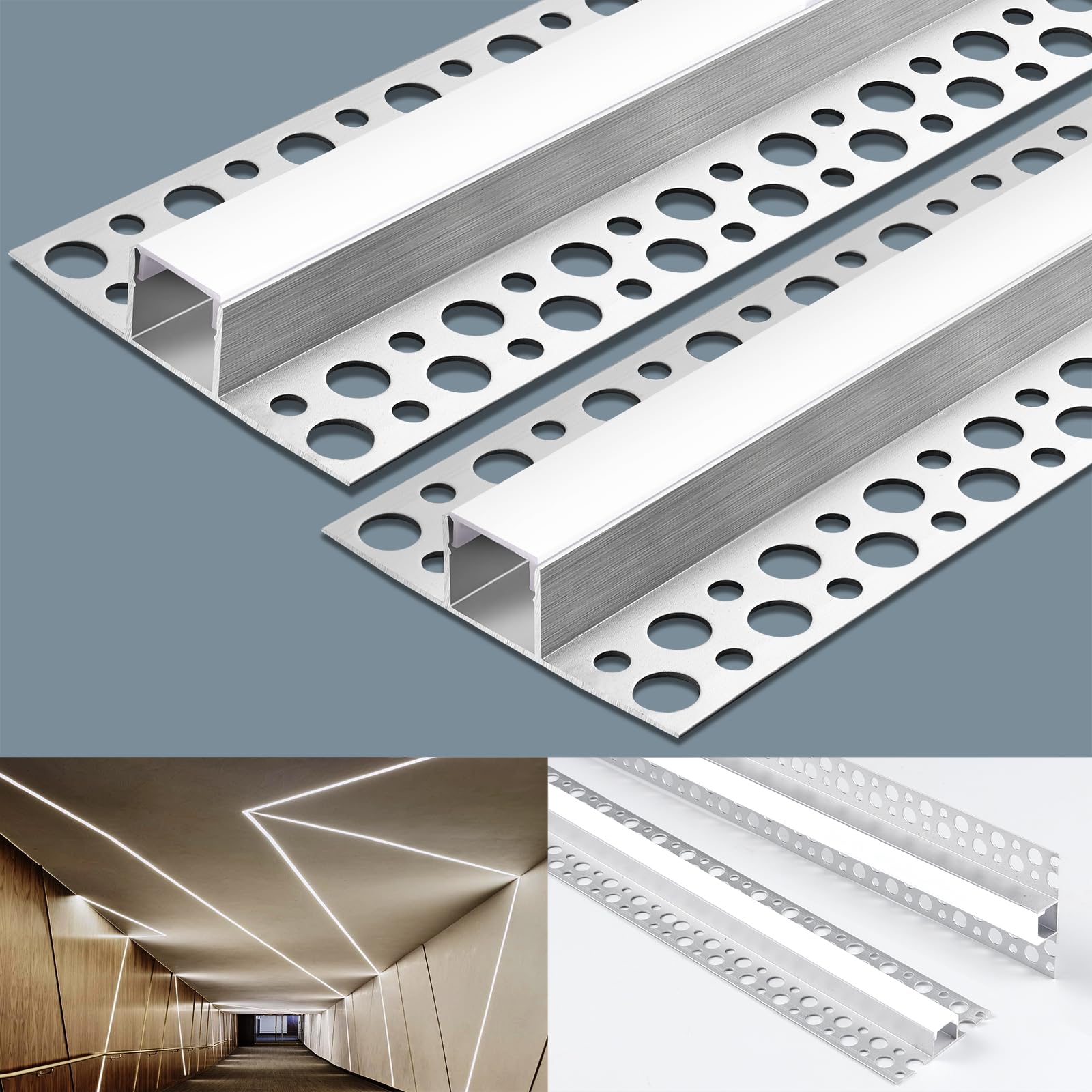

Illustrative Image (Source: Google Search)

Spotlight on Potential led channel for led strip lights Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led channel for led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led channel for led strip lights

Critical Technical Specifications for LED Channels

When sourcing LED channels for LED strip lights, understanding the key technical properties is essential for ensuring product quality, compatibility, and longevity. Here are the primary specifications to consider:

-

Material Grade

Most LED channels are made from aluminum or polycarbonate. Aluminum channels offer excellent heat dissipation, which extends the lifespan of LED strips, while polycarbonate diffusers provide impact resistance and light diffusion. For B2B buyers, specifying the exact alloy or polymer grade ensures durability and compliance with local regulations. -

Dimensional Tolerance

Precision in dimensions—length, width, height, and slot size—is critical to guarantee a snug fit for LED strips and diffusers. Tolerances usually range from ±0.1mm to ±0.3mm. Tight tolerances reduce installation issues and prevent light leakage, directly impacting customer satisfaction. -

IP Rating (Ingress Protection)

This rating indicates the channel’s resistance to dust and water. For indoor applications, IP20 may suffice, but for outdoor or humid environments, IP65 or higher is crucial. Choosing the right IP rating protects the LED strips and ensures longevity in diverse climates, a key consideration for international buyers. -

Surface Finish and Coating

Anodized or powder-coated finishes on aluminum channels enhance corrosion resistance and aesthetic appeal. For buyers targeting markets with harsh environmental conditions (e.g., coastal regions in the Middle East or humid areas in South America), specifying surface treatment is vital to prevent premature degradation. -

Heat Dissipation Efficiency

Effective thermal management is a must to prevent LED overheating. Channels designed with fins or increased surface area improve heat dissipation. This property directly influences LED performance and warranty claims, making it a crucial negotiation point with manufacturers. -

Compatibility with LED Strip Sizes

LED strips come in varying widths (commonly 8mm, 10mm, 12mm). Channels must match these sizes precisely to ensure proper installation and optimal light diffusion. Confirming compatibility avoids costly returns and project delays.

Key Trade Terminology for International LED Channel Transactions

Navigating international B2B sourcing requires familiarity with common industry terms. Below are essential terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing products based on a buyer’s design or specifications. For LED channels, many buyers opt for OEM services to customize dimensions, finishes, or branding. Understanding OEM capabilities helps in negotiating customization and pricing. -

MOQ (Minimum Order Quantity)

This is the smallest quantity a supplier is willing to produce or sell per order. MOQs vary widely depending on manufacturing complexity and materials. Buyers from emerging markets like Africa or South America should clarify MOQ early to align with budget and storage capacities. -

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, lead times, and terms for specific product requirements. A detailed RFQ including technical specs reduces misunderstandings and speeds up supplier evaluation. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms protects buyers from hidden costs and logistical risks. -

Lead Time

The period between order confirmation and product shipment. Longer lead times can affect project timelines. Buyers should negotiate lead times upfront, especially when sourcing from distant regions like Asia for delivery to Europe or the Middle East. -

Tolerance Stack-Up

A term referring to the cumulative effect of dimensional tolerances in assembled parts. For LED channels and strips, excessive tolerance stack-up can cause installation difficulties. Requesting detailed tolerance information helps maintain quality control.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, reduce procurement risks, and build stronger supplier partnerships in the LED channel market. This knowledge is particularly valuable for businesses in Africa, South America, the Middle East, and Europe, where sourcing challenges and market requirements can vary significantly.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led channel for led strip lights Sector

Market Overview & Key Trends

The global market for LED channels designed for LED strip lights is experiencing robust growth, driven by increasing demand for energy-efficient lighting solutions across commercial, residential, and industrial sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Mexico and the UK) are capitalizing on the shift toward smart lighting and architectural aesthetics, where LED channels play a crucial role in enhancing both functionality and design.

Key market drivers include the rising adoption of LED lighting for energy conservation, government incentives promoting sustainable infrastructure, and the growing trend of integrating LED strips with intelligent control systems. Buyers are increasingly seeking versatile LED channels that offer easy installation, superior heat dissipation, and compatibility with various LED strip types.

Emerging sourcing trends reflect a preference for manufacturers who provide customizable solutions, such as tailored channel lengths, diffusers with adjustable opacity, and innovative mounting options. Additionally, the rise of digital B2B platforms is streamlining international procurement, enabling buyers to compare specifications, certifications, and pricing more efficiently. For regions like Africa and South America, where infrastructure development is accelerating, demand is particularly strong for cost-effective yet high-quality LED channels that can withstand diverse environmental conditions.

Market dynamics emphasize the importance of supply chain resilience. The recent global disruptions have underscored the need for diversified sourcing strategies, including partnerships with manufacturers in multiple geographic locations. European buyers, for instance, are prioritizing suppliers with nearshoring capabilities to reduce lead times and logistics costs. Meanwhile, Middle Eastern buyers are focusing on products compliant with regional standards and certifications.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the procurement of LED channels for LED strip lights. Buyers globally are demanding products that minimize environmental impact throughout their lifecycle—from raw material extraction to end-of-life disposal. Aluminum, a common material for LED channels, is favored for its recyclability and lightweight properties, which contribute to reduced transportation emissions.

Ethical sourcing involves selecting suppliers who adhere to responsible labor practices and transparent supply chains. This is increasingly important for B2B buyers aiming to meet corporate social responsibility (CSR) goals and comply with international regulations such as the EU’s Conflict Minerals Regulation and similar frameworks in other regions.

Green certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management standards are essential benchmarks. Buyers should prioritize suppliers that provide documented proof of compliance to ensure product safety and environmental stewardship.

Furthermore, innovations in eco-friendly materials—such as channels made from recycled aluminum or bio-based plastics—are gaining traction. Incorporating such materials not only reduces carbon footprints but also aligns with the sustainability commitments of end-users.

Evolution and Industry Context

The LED channel industry has evolved significantly over the past decade, driven by advancements in LED technology and increasing demand for integrated lighting solutions. Initially, LED channels served primarily as protective housings; however, they have transformed into sophisticated components that enhance thermal management, light diffusion, and installation flexibility.

The shift from bulky, opaque channels to sleek, slim-profile designs reflects broader trends in architectural lighting, where aesthetics and performance are equally prioritized. Additionally, the integration of smart lighting controls has pushed manufacturers to innovate channels that accommodate sensors and wiring discreetly.

For international B2B buyers, understanding this evolution helps in selecting modern LED channels that not only meet technical specifications but also support long-term project goals related to efficiency, sustainability, and design excellence.

Related Video: Benefits of International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of led channel for led strip lights

-

How can I effectively vet LED channel suppliers for international B2B sourcing?

To vet suppliers, start by verifying their business licenses and certifications relevant to LED lighting products, such as ISO 9001 or RoHS compliance. Request product samples to assess quality and compatibility with your LED strips. Check references or customer reviews, especially from buyers in your region, to understand their reliability and communication. Use platforms like Alibaba or Global Sources cautiously, and consider visiting trade fairs or requesting virtual factory tours. Assess their production capacity and after-sales service to ensure they can meet your volume and support needs. -

What customization options are typically available for LED channels, and how should I approach these with suppliers?

LED channels can be customized in terms of length, shape (U, V, or corner profiles), materials (aluminum alloys), diffuser types (frosted, clear), and mounting accessories. When discussing customization, provide detailed technical drawings or samples to avoid misunderstandings. Clarify minimum order quantities (MOQs) for custom runs and confirm lead times. Negotiate design iterations upfront and ensure intellectual property agreements are in place if you provide proprietary designs. -

What are common MOQ and lead time expectations for LED channel orders, especially for buyers in Africa, South America, the Middle East, and Europe?

MOQ can vary widely, typically ranging from 500 to 2,000 units depending on customization and supplier capacity. Lead times generally span 3 to 8 weeks, factoring in production and international shipping. Buyers should communicate their volume forecasts early to negotiate better terms. Consolidating orders with other products or buyers can reduce MOQ pressure. For urgent needs, explore suppliers with local warehouses or faster production lines, but expect premium pricing. -

Which payment terms and methods are safest and most practical for international LED channel purchases?

Letter of Credit (L/C) is a secure option, especially for larger orders, as it protects both buyer and supplier by tying payment to shipment documents. For smaller transactions, 30% advance payment with balance on delivery via bank transfer or escrow services is common. Avoid full upfront payments without established trust. Use internationally recognized payment platforms like PayPal for samples or small orders. Always verify supplier bank details independently to prevent fraud. -

What quality assurance standards and certifications should I require to ensure product compliance and safety?

Demand certifications such as CE (for Europe), UL (for North America), RoHS (restriction of hazardous substances), and ISO 9001 quality management system. These indicate compliance with safety, environmental, and manufacturing standards. Request test reports from accredited labs and consider third-party inspections before shipment. For markets like the Middle East or Africa, check local certification requirements, as some countries have specific import standards. -

How can I optimize logistics and shipping for LED channel imports to diverse regions like Africa, South America, or Europe?

Choose suppliers experienced in international shipping and familiar with customs regulations in your target market. Opt for consolidated shipments to reduce freight costs and negotiate incoterms (e.g., FOB, CIF) that suit your logistics capabilities. Air freight offers speed but at higher cost, while sea freight is economical for bulk orders but slower. Partner with freight forwarders who offer door-to-door service and handle customs clearance efficiently to avoid delays.

Illustrative Image (Source: Google Search)

-

What strategies can help resolve disputes or quality issues with LED channel suppliers internationally?

Maintain clear, documented communication from the start, including contracts specifying product specs, delivery, and penalties for non-compliance. If quality issues arise, request photographic or video evidence and engage a third-party inspection agency for verification. Negotiate amicable solutions like partial refunds, replacements, or discounts before escalating. Use trade dispute resolution services or arbitration clauses in contracts to safeguard your interests, especially when dealing across different legal jurisdictions. -

Are there regional considerations I should be aware of when sourcing LED channels for markets in Mexico, the UK, or the Middle East?

Yes, regional market preferences and regulations vary significantly. For example, the UK requires CE marking and adherence to UKCA standards post-Brexit, while Mexico may require NOM certification. The Middle East often demands robust product durability for harsh climates and may have specific electrical safety standards. Understanding local installation practices and aesthetic preferences can help tailor product features. Engage local agents or consultants to navigate regulatory and cultural nuances effectively.

Strategic Sourcing Conclusion and Outlook for led channel for led strip lights

In summary, sourcing LED channels for LED strip lights demands a strategic approach that balances quality, cost-efficiency, and supplier reliability. International buyers from Africa, South America, the Middle East, and Europe should prioritize partners who demonstrate strong manufacturing capabilities, compliance with international standards, and adaptability to evolving design requirements. Leveraging regional insights and understanding the nuances of logistics and customs regulations can unlock competitive advantages in price and delivery timelines.

Key takeaways for B2B buyers include:

- Thorough supplier vetting to ensure consistent product quality and certification adherence.

- Negotiating flexible contract terms that accommodate volume fluctuations and customization needs.

- Integrating supply chain transparency tools for real-time monitoring and risk mitigation.

- Exploring local and regional manufacturers to optimize lead times and reduce shipping costs.

Looking ahead, the LED channel market is poised for innovation driven by sustainability demands and smart lighting integration. Buyers who adopt a proactive sourcing strategy—embracing technology, fostering supplier partnerships, and anticipating market trends—will secure a resilient supply chain and enhance their competitive positioning. International B2B buyers are encouraged to engage with trusted suppliers early, invest in collaborative development, and remain agile to capitalize on emerging opportunities in this dynamic sector.