Introduction: Navigating the Global Market for led backlight strip

The global demand for LED backlight strips is surging as industries worldwide embrace energy-efficient, high-performance lighting solutions. For international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, sourcing the right LED backlight strips is pivotal to gaining a competitive edge. These versatile lighting components are critical in applications ranging from consumer electronics and signage to automotive displays and architectural accents, making their quality and reliability non-negotiable.

Navigating this complex global market requires a strategic approach. Buyers must understand diverse product types, materials, and manufacturing processes that directly impact performance and longevity. Equally important is mastering quality control protocols and certifications that vary by region—such as CE and RoHS compliance in Europe or specific safety standards in emerging markets. Supplier evaluation, pricing structures, and logistics also play crucial roles in ensuring seamless procurement.

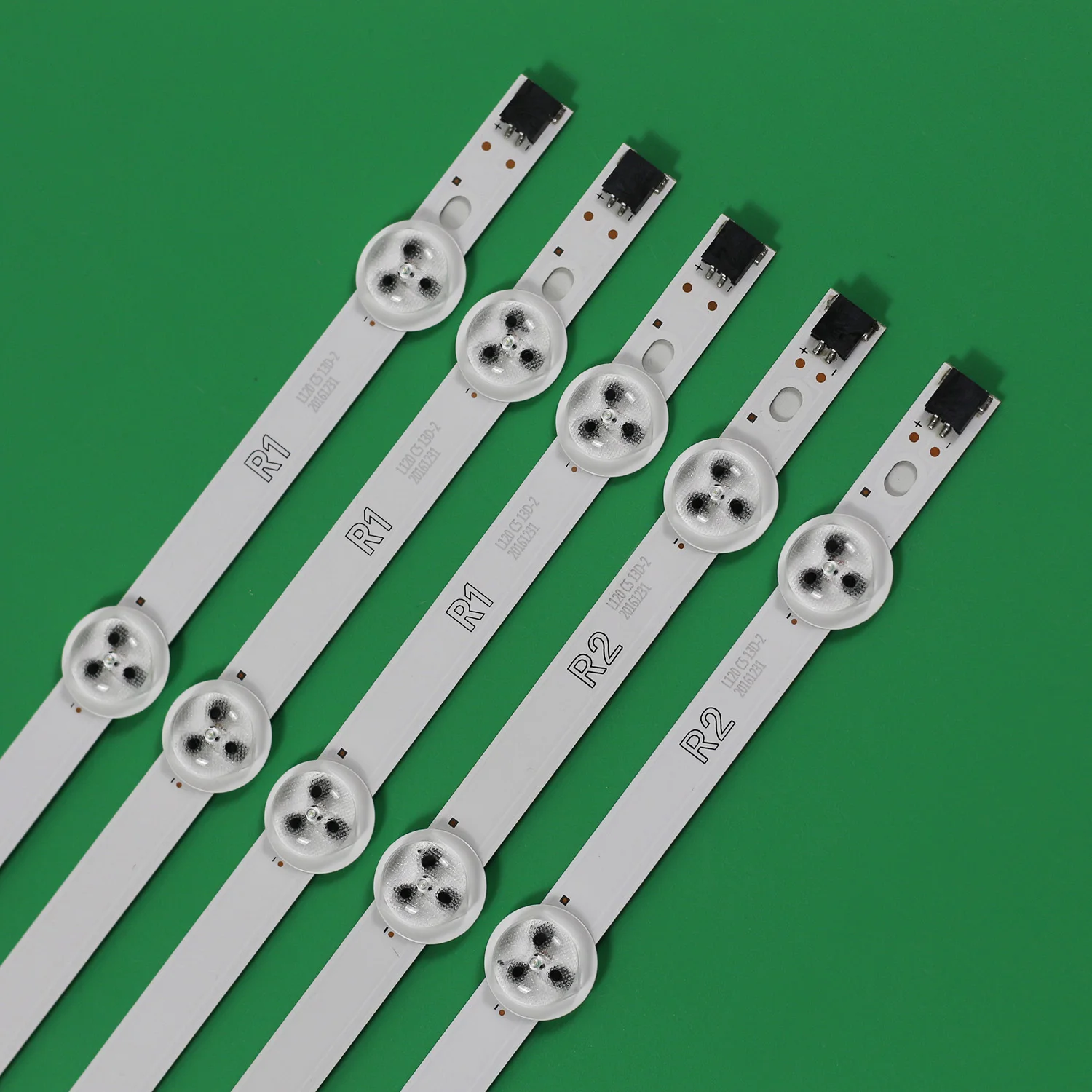

Illustrative Image (Source: Google Search)

This comprehensive guide equips B2B buyers with actionable insights on:

- Key LED backlight strip technologies and material innovations

- Manufacturing best practices and stringent quality assurance

- Evaluating and selecting reliable global suppliers

- Cost optimization strategies tailored to large-scale orders

- Navigating region-specific regulatory and certification requirements

- Frequently asked questions addressing common sourcing challenges

By leveraging this knowledge, businesses in Colombia, Brazil, the Middle East, Africa, and across Europe can confidently source LED backlight strips that meet stringent quality standards, optimize supply chain efficiency, and maximize long-term value. Empower your procurement strategy with expert guidance designed to transform complex sourcing into a streamlined, profitable process.

Understanding led backlight strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Edge-Lit LED Backlight Strip | Thin, flexible strips installed along edges; uses light guides for uniform distribution | LCD displays, signage, architectural lighting | Slim design, energy-efficient; requires precise installation for even lighting |

| Direct-Lit LED Backlight Strip | LED arrays placed directly behind the panel for high brightness | Large displays, industrial monitors, advertising | High brightness and uniformity; bulkier, higher power consumption |

| RGB LED Backlight Strip | Multi-color LEDs capable of dynamic color changes via control systems | Retail displays, event lighting, experiential marketing | Versatile and customizable; higher cost and complexity in control |

| Waterproof LED Backlight Strip | Encased in silicone or epoxy for moisture and dust resistance | Outdoor signage, marine applications, industrial environments | Durable in harsh conditions; may have reduced heat dissipation |

| High-Density LED Backlight Strip | Closely spaced LEDs for intense, uniform light output | Medical displays, precision instruments, premium screens | Superior uniformity and brightness; higher cost and heat management needed |

Edge-Lit LED Backlight Strip

Edge-lit LED backlight strips are characterized by their slim profile, mounted along the edges of a light guide panel to evenly distribute light across the surface. This type is ideal for thin LCD screens, signage, and architectural lighting where space-saving and sleek design are priorities. For B2B buyers, sourcing edge-lit strips requires attention to supplier expertise in light guide technology to ensure uniform illumination and minimal hotspots. Installation precision and quality control are critical to avoid uneven brightness, which can affect product reputation in competitive markets like Europe and South America.

Direct-Lit LED Backlight Strip

Direct-lit LED strips consist of arrays positioned directly behind the display panel, delivering high brightness and excellent uniformity. They are well-suited for large-format displays, industrial monitors, and outdoor advertising where intense illumination is necessary. Buyers should consider the increased power consumption and potential heat generation, necessitating robust thermal management solutions. Due to their bulkier design, direct-lit strips may not be suitable for ultra-thin applications but offer superior performance for demanding environments common in Middle Eastern and African commercial projects.

RGB LED Backlight Strip

RGB LED backlight strips integrate red, green, and blue LEDs, enabling dynamic color changes and customizable lighting effects. These strips are popular in retail displays, event venues, and experiential marketing where visual impact is key. For B2B procurement, buyers must evaluate supplier capabilities in providing compatible controllers and software for seamless color transitions. The complexity and higher unit cost are balanced by the ability to differentiate products and enhance customer engagement, particularly valuable in competitive markets such as Brazil and Colombia.

Waterproof LED Backlight Strip

Designed with protective silicone or epoxy coatings, waterproof LED backlight strips withstand moisture, dust, and harsh environmental conditions. They are essential for outdoor signage, marine applications, and industrial sites requiring reliable performance under adverse conditions. Buyers should verify the ingress protection (IP) ratings and certifications to ensure compliance with local standards. While the protective encasing can reduce heat dissipation slightly, the durability and extended lifespan make these strips a cost-effective choice for buyers targeting infrastructure projects in regions with challenging climates, including parts of Africa and the Middle East.

High-Density LED Backlight Strip

High-density LED backlight strips feature closely spaced LEDs to provide intense, uniform light output with minimal shadowing or color variance. These are critical for precision applications such as medical displays, premium screens, and instruments demanding exact color reproduction and brightness consistency. B2B buyers must focus on supplier quality assurance and thermal management capabilities, as higher LED density increases heat generation. Although costlier, these strips offer superior performance and are often required in regulated markets across Europe and high-end industrial sectors globally.

Related Video: How to Install LED Light Strips

Key Industrial Applications of led backlight strip

| Industry/Sector | Specific Application of led backlight strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Advertising | Illuminated signage and display backlighting | Enhances brand visibility, attracts customers, and improves product presentation | Consistent color temperature, long lifespan, ease of installation, and compliance with local safety standards (CE, RoHS) |

| Automotive Manufacturing | Dashboard and interior panel backlighting | Improves vehicle aesthetics and user experience with uniform illumination | High durability, heat resistance, and supplier ability to meet automotive certifications |

| Electronics & Consumer Devices | Screen backlighting for monitors, TVs, and portable devices | Delivers superior brightness and energy efficiency, supporting thinner device designs | Precision in LED density and brightness, low power consumption, and reliable supply chain |

| Hospitality & Interior Design | Ambient and accent lighting in hotels, restaurants, and offices | Creates mood lighting that enhances customer experience and reduces energy costs | Flexibility in length and color options, dimmable features, and warranty assurance |

| Industrial & Warehouse Facilities | Task and safety lighting in workstations and machinery panels | Increases operational safety and productivity through clear, consistent lighting | Robustness, IP rating for dust/water resistance, and compatibility with industrial control systems |

Retail & Advertising

In retail environments across Africa, South America, the Middle East, and Europe, LED backlight strips are critical for illuminated signage and display backlighting. These strips provide uniform, vibrant lighting that highlights products and brand logos, drawing customer attention and boosting sales. Businesses benefit from energy-efficient lighting that reduces operational costs and offers long service life. For B2B buyers, sourcing strips with consistent color temperature and robust certifications (e.g., CE in Europe) is essential to meet regional safety and quality standards.

Automotive Manufacturing

Automotive manufacturers rely on LED backlight strips for interior applications such as dashboard illumination and ambient lighting. These strips must withstand high temperatures and vibrations common in vehicles while delivering uniform brightness to enhance user experience. International buyers, especially from growing automotive hubs in South America and the Middle East, should prioritize suppliers who can provide automotive-grade LEDs with relevant certifications and proven durability. Customization options for color and intensity are also important for brand differentiation.

Electronics & Consumer Devices

For electronics manufacturers producing monitors, TVs, and portable devices, LED backlight strips enable slim, lightweight designs with superior brightness and energy efficiency. These strips must maintain strict tolerances in LED spacing and brightness uniformity to ensure high-quality screen performance. B2B buyers in regions like Europe and Brazil should focus on suppliers with advanced manufacturing capabilities and quality control processes to avoid defects that impact device reliability and customer satisfaction.

Hospitality & Interior Design

In hotels, restaurants, and corporate offices, LED backlight strips are used to create ambient and accent lighting that enhances the atmosphere while reducing energy consumption. Their flexibility allows designers to install them in ceilings, walls, or furniture, offering dynamic color options and dimming capabilities. Buyers from the Middle East and Europe must seek suppliers providing customizable solutions with reliable warranties to ensure long-term performance in diverse environmental conditions.

Industrial & Warehouse Facilities

Industrial sectors use LED backlight strips for task lighting on machinery panels and safety indicators in warehouses, improving visibility and operational safety. These strips need to be robust, often requiring IP-rated protection against dust and moisture. For buyers in Africa and South America, sourcing from manufacturers who offer ruggedized LED strips compatible with industrial controls and who comply with international safety standards is crucial to ensure durability and minimize maintenance costs.

Related Video: Install TV LED Backlighting the “Correct Way” – LIFX Z Strips

Strategic Material Selection Guide for led backlight strip

Polycarbonate (PC)

Polycarbonate is a widely used material in LED backlight strips due to its excellent transparency and high impact resistance. It offers good thermal stability, typically withstanding temperatures up to 120°C, which is critical for LED longevity and consistent light output. Its inherent resistance to UV radiation and corrosion makes it suitable for both indoor and outdoor applications.

Pros: Polycarbonate is durable, lightweight, and provides excellent optical clarity, enhancing light diffusion. It is relatively easy to mold and fabricate, allowing for complex designs and customization. The material complies with international standards such as ASTM D3935 and ISO 12086, which are commonly recognized in Europe and the Middle East.

Cons: Polycarbonate can be more expensive than other plastics and may yellow over time if not properly UV-stabilized. It also has moderate chemical resistance, which could be a limitation in harsh industrial environments.

Application Impact: Ideal for applications requiring high optical performance and durability, such as commercial displays and architectural lighting. Its UV resistance suits outdoor installations in regions with intense sunlight, like parts of Africa and South America.

B2B Considerations: Buyers in Europe and the Middle East should verify compliance with CE and RoHS directives, while African and South American buyers should ensure suppliers provide UV-stabilized grades to withstand local environmental conditions. Polycarbonate’s higher cost may be justified by its longevity and performance in premium projects.

Polyvinyl Chloride (PVC)

PVC is a cost-effective and versatile material commonly used for LED backlight strip housings and flexible substrates. It exhibits good chemical resistance and moderate thermal stability, generally tolerating temperatures up to 70°C. Its flame-retardant properties make it suitable for indoor commercial lighting applications.

Pros: PVC is inexpensive, widely available, and easy to process, enabling large-scale production at competitive prices. It offers good resistance to moisture and many chemicals, making it suitable for humid environments.

Cons: PVC has lower heat resistance compared to polycarbonate and can degrade under prolonged UV exposure unless specially treated. It also tends to be less environmentally friendly, which may pose challenges in markets with strict sustainability regulations like the EU.

Application Impact: Best suited for indoor lighting applications where cost constraints are significant, such as office retrofits or retail installations. Its flexibility allows for easy installation in tight or curved spaces.

B2B Considerations: Buyers in Europe must ensure PVC materials meet REACH and RoHS standards to avoid regulatory issues. In Africa and South America, sourcing flame-retardant and UV-resistant PVC variants is advisable to enhance product lifespan in diverse climates.

Aluminum

Aluminum is frequently used as a substrate or housing material in LED backlight strips due to its excellent thermal conductivity and mechanical strength. It effectively dissipates heat, extending LED lifespan and maintaining luminous efficiency. Aluminum alloys used typically comply with ASTM B209 or EN AW standards, ensuring consistent quality.

Pros: Aluminum is lightweight, corrosion-resistant (especially when anodized), and offers superior heat dissipation. It enhances structural integrity and is recyclable, aligning with sustainability goals.

Cons: Aluminum components can increase manufacturing complexity and cost due to machining and finishing requirements. It is less flexible than plastics, limiting use in highly curved installations.

Application Impact: Ideal for high-performance industrial or commercial lighting applications where heat management is critical, such as in warehouses or outdoor signage. Its corrosion resistance suits humid or coastal environments common in Middle Eastern and South American markets.

B2B Considerations: Buyers should confirm anodizing quality and corrosion resistance certifications, especially for installations in harsh climates like coastal Brazil or Gulf countries. Aluminum’s higher upfront cost is offset by reduced maintenance and longer product life.

Silicone

Silicone is increasingly adopted for LED backlight strips requiring flexibility, high temperature resistance, and environmental sealing. It can withstand temperatures up to 200°C and offers excellent resistance to UV, moisture, and chemicals, making it suitable for demanding applications.

Pros: Silicone is highly flexible, durable, and provides superior sealing against dust and water ingress (often IP67 or higher). It maintains optical clarity and softness over time without yellowing.

Cons: Silicone is more expensive than PVC and polycarbonate and can be challenging to process in high volumes. Its softness may reduce mechanical protection compared to rigid housings.

Application Impact: Perfect for outdoor, automotive, or industrial LED backlighting where flexibility and environmental protection are paramount. Its resilience to extreme temperatures and weather conditions suits markets in Africa and the Middle East.

B2B Considerations: International buyers should ensure suppliers provide silicone materials compliant with IEC 60529 for ingress protection and regional certifications. The higher cost is justified for applications demanding longevity and harsh environment resistance.

Summary Table

| Material | Typical Use Case for led backlight strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Commercial displays, architectural lighting | High impact resistance and optical clarity | Higher cost, potential yellowing over time | High |

| PVC | Indoor office, retail lighting, flexible substrates | Low cost, good chemical and moisture resistance | Lower heat and UV resistance, environmental concerns | Low |

| Aluminum | Industrial, outdoor signage, heat-critical applications | Excellent heat dissipation and corrosion resistance | Higher manufacturing complexity, less flexible | Medium |

| Silicone | Outdoor, automotive, industrial flexible backlighting | Superior flexibility, temperature and weather resistance | Higher cost, less mechanical protection | High |

In-depth Look: Manufacturing Processes and Quality Assurance for led backlight strip

Manufacturing Processes for LED Backlight Strips

The production of LED backlight strips involves a series of meticulously controlled stages designed to ensure performance, durability, and consistency. Understanding these stages helps international B2B buyers assess supplier capabilities and product quality before procurement.

1. Material Preparation

This initial phase focuses on sourcing and preparing the raw materials essential for the LED backlight strip:

- Substrate Fabrication: Common substrates include flexible printed circuit boards (FPCBs) made from polyimide or polyester materials. These provide mechanical support and electrical insulation.

- LED Chips and Components: High-quality LED chips, resistors, connectors, and adhesives are selected based on required brightness, color temperature, and durability.

- Surface Treatments: Substrates may undergo surface cleaning and coating to enhance solderability and adhesion.

Suppliers with rigorous incoming material inspection (IQC) protocols ensure raw materials meet specified standards, reducing defects downstream.

2. Forming and Circuit Patterning

At this stage, the physical and electrical layout of the strip is established:

- Circuit Printing: Using advanced screen printing or photolithography, copper traces and conductive pathways are precisely patterned onto the substrate.

- Etching and Plating: Excess copper is removed through chemical etching, and protective layers such as gold or tin plating are applied to improve conductivity and prevent oxidation.

- Cutting and Shaping: The strip is cut to standardized or custom lengths, with perforations or cut points enabling flexible installation.

Precision in circuit patterning directly affects electrical reliability and light uniformity, critical for backlighting applications.

3. Component Assembly and Soldering

This critical phase integrates the LEDs and electronic components onto the substrate:

- LED Placement: Automated pick-and-place machines position LED chips accurately on designated pads.

- Soldering: Techniques such as reflow soldering or wave soldering are used to secure components, ensuring strong electrical and mechanical bonds.

- Encapsulation: LEDs may be coated with silicone or epoxy to protect against moisture and mechanical damage.

Highly automated assembly lines paired with strict process controls minimize defects and improve throughput.

4. Finishing Processes

Final touches prepare the LED backlight strips for shipment and installation:

- Testing and Calibration: Initial electrical and optical testing verifies LED brightness, color consistency, and power consumption.

- Protective Coating: Application of waterproof or dustproof layers (e.g., silicone encapsulation or conformal coatings) enhances durability, especially for outdoor or harsh environment use.

- Packaging: Strips are carefully wound or boxed with anti-static materials to prevent damage during transit.

Robust finishing processes ensure product longevity and customer satisfaction.

Quality Assurance and Control for LED Backlight Strips

Quality assurance (QA) in LED backlight strip manufacturing is critical to guarantee product reliability and compliance with international standards. Buyers must understand the quality control (QC) framework suppliers follow to mitigate risks.

Key International and Industry Standards

- ISO 9001: The foundation of quality management systems, ensuring consistent production processes and continual improvement.

- CE Marking: Mandatory for products entering the European market, confirming conformity with health, safety, and environmental requirements.

- RoHS (Restriction of Hazardous Substances): Limits the use of hazardous materials, essential for compliance in Europe and increasingly adopted globally.

- UL and FCC: Relevant for electrical safety and electromagnetic compatibility, especially for North American and some Middle Eastern markets.

- Local Certifications: Markets such as Brazil (INMETRO) and Colombia may require additional certifications or compliance with national standards.

Buyers should request documentation proving adherence to these standards, especially when importing to regulated markets.

Quality Control Checkpoints

Effective QC is implemented at multiple stages during production:

- Incoming Quality Control (IQC): Inspection of raw materials and components for defects, correct specifications, and batch consistency.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly and soldering phases to detect issues such as misaligned LEDs, poor solder joints, or circuit defects.

- Final Quality Control (FQC): Comprehensive testing of finished strips, including electrical performance, light output, color temperature, and physical inspection for damage.

Suppliers with well-defined QC protocols reduce the risk of defective shipments and costly returns.

Common Testing Methods

- Electrical Testing: Verification of voltage, current, and resistance to ensure proper function.

- Optical Testing: Measurement of luminous intensity, color temperature, and uniformity using photometers and spectrometers.

- Environmental Testing: Exposure to temperature cycling, humidity, and vibration to assess durability under operational conditions.

- Mechanical Testing: Flexibility and adhesion tests to confirm the strip withstands bending and installation stress.

Buyers should request test reports or witness testing processes when possible.

How B2B Buyers Can Verify Supplier QC

- Factory Audits: Conduct or commission on-site supplier audits focusing on manufacturing processes, equipment calibration, and personnel training.

- Review of QC Documentation: Examine quality manuals, process flow charts, inspection records, and non-conformance reports.

- Third-Party Inspections: Employ independent inspection agencies to perform random sampling and testing pre-shipment.

- Sample Testing: Request product samples for in-house or third-party laboratory testing to verify performance claims.

These measures help buyers minimize risks and ensure consistent product quality.

QC and Certification Nuances for International Buyers

- Regional Regulatory Variations: Buyers from Africa, South America (e.g., Brazil, Colombia), the Middle East, and Europe must consider specific local requirements. For example, Brazilian INMETRO certification is mandatory for electrical products, while Middle Eastern buyers may require SASO certification for Saudi Arabia.

- Shipping and Handling Considerations: Long-distance shipments to these regions necessitate robust packaging and quality assurance to avoid damage and maintain warranty validity.

- Supplier Transparency: Buyers should prioritize suppliers offering traceability of production batches and transparent QC data to facilitate compliance audits and customs inspections.

- After-Sales Support: Strong technical support and warranty terms are vital, especially in regions where local repair facilities may be limited.

By aligning procurement strategies with these regional quality and certification factors, B2B buyers can secure reliable LED backlight strips that meet both functional and regulatory expectations.

Summary

For international B2B buyers targeting LED backlight strips, a deep understanding of the manufacturing process and quality assurance frameworks is essential. Evaluating suppliers based on their material preparation, assembly techniques, and finishing capabilities—alongside rigorous QC checkpoints and international certifications—ensures procurement of high-quality, durable products. Tailoring supplier selection and verification efforts to regional standards and market-specific requirements in Africa, South America, the Middle East, and Europe will empower buyers to achieve optimal value and minimize operational risks in their LED lighting projects.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led backlight strip Sourcing

Understanding Cost Components in LED Backlight Strip Sourcing

When sourcing LED backlight strips, it is crucial for international B2B buyers to grasp the multiple cost layers that contribute to the final price. These components include:

- Materials: The primary cost driver, encompassing high-quality LEDs (e.g., SMD or COB types), flexible PCBs, resistors, and encapsulating materials. The choice of LED chip quality and PCB substrate impacts both cost and performance.

- Labor: Skilled labor is required for assembly, soldering, and testing. Labor costs vary significantly by manufacturing location, affecting overall pricing.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with automation can reduce these costs.

- Tooling and Setup: Initial tooling for custom strip lengths, connectors, or specialized coatings can be a significant upfront expense, especially for small orders.

- Quality Control (QC): Rigorous testing for lumen output, color consistency, and durability adds to costs but ensures reliability—critical for maintaining brand reputation.

- Logistics and Freight: International shipping, customs clearance, and inland transport must be factored in, with costs fluctuating based on shipment size, Incoterms, and destination country infrastructure.

- Supplier Margin: Suppliers add a profit margin, which varies by supplier reputation, market demand, and order volume.

Key Price Influencers for LED Backlight Strips

Several factors influence the quoted price per unit, and understanding these will empower buyers to negotiate effectively:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock better unit pricing due to economies of scale. MOQ policies can affect pricing tiers, and buyers should aim to consolidate orders when possible.

- Product Specifications and Customization: Custom lengths, color temperatures, waterproofing, or special connectors increase complexity and cost. Standardized products are generally more cost-effective.

- Material Quality and Certifications: Certified LEDs (e.g., CE, RoHS, UL) and premium materials command higher prices but reduce risks related to compliance and product lifespan.

- Supplier Reliability and Location: Established suppliers with proven track records may price higher but offer value through consistent quality and timely delivery. Proximity to ports or buyers can reduce logistics costs.

- Incoterms: Terms like FOB, CIF, or DDP impact who bears shipping, insurance, and customs fees, influencing the total landed cost.

Actionable Tips for International B2B Buyers

- Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, consider durability, energy efficiency, warranty terms, and after-sales support. Lower upfront costs can lead to higher long-term expenses.

- Leverage Volume Discounts and Consolidate Shipments: Buyers from regions like Africa, South America (e.g., Colombia, Brazil), the Middle East, and Europe should plan orders strategically to meet or exceed MOQs, reducing per-unit costs and shipping fees.

- Request Samples and Certifications: Always validate product quality and compliance with local regulations before committing to large orders. This mitigates risks of costly returns or regulatory non-compliance.

- Factor in Currency Fluctuations and Payment Terms: International buyers should negotiate favorable payment terms (e.g., letters of credit, escrow) and consider currency exchange impacts on final costs.

- Choose Suppliers Offering Flexible Incoterms: Depending on local customs efficiency, buyers may prefer DDP to minimize logistical headaches or FOB to control freight arrangements.

- Understand Regional Import Duties and Taxes: For example, buyers in Brazil should be aware of import tariffs and VAT, which can add significantly to landed costs.

Pricing Nuances for Different Regions

- Africa: Logistics can be a major cost component due to port inefficiencies and inland transport challenges. Partnering with suppliers experienced in African markets can optimize costs.

- South America: High import duties in countries like Brazil require careful cost planning. Local distributors or nearshoring options may provide cost advantages.

- Middle East: Regulatory certifications and climate-resilient materials may increase costs but ensure product longevity in harsh environments.

- Europe: Strict compliance and high-quality expectations justify investing in certified products. Buyers should prioritize suppliers with EU certifications and robust warranties.

Disclaimer on Pricing

Prices for LED backlight strips vary widely based on specifications, volumes, and market conditions. The figures discussed should be considered indicative rather than definitive. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing aligned with their project requirements.

By understanding the intricate cost structure and influencing factors, international B2B buyers can negotiate smarter deals, optimize total procurement costs, and secure reliable, high-quality LED backlight strips tailored to their regional needs and applications.

Spotlight on Potential led backlight strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led backlight strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led backlight strip

Critical Technical Properties of LED Backlight Strips

Understanding the technical specifications of LED backlight strips is essential for B2B buyers aiming to procure products that meet performance, durability, and regulatory requirements. Below are key properties that influence product quality, compatibility, and long-term value.

-

Material Grade of PCB (Printed Circuit Board)

The PCB material, often FR4 or flexible polyimide, affects heat dissipation and flexibility. Higher-grade materials ensure better thermal management, reducing LED degradation over time. For buyers in hot climates or industrial applications, choosing a PCB with superior heat resistance is critical to maximize lifespan and reliability. -

Color Temperature and Color Rendering Index (CRI)

Color temperature (measured in Kelvin) defines the light’s warmth or coolness, ranging from warm white (~2700K) to daylight (~6500K). CRI indicates how accurately colors appear under the light source, with a higher CRI (above 80) preferred for retail or display environments. Selecting the right color temperature and CRI enhances product appeal and customer satisfaction. -

Luminous Intensity and Efficiency (Lumens per Watt)

This metric measures the brightness output relative to power consumption. High luminous efficiency means more light with less energy, critical for reducing operational costs in large-scale installations. Buyers should compare lumens per watt to ensure energy-efficient solutions that align with sustainability goals. -

Ingress Protection (IP) Rating

The IP rating indicates resistance to dust and water. For indoor backlighting, IP20 may suffice, while outdoor or humid environments require IP65 or higher. Understanding IP ratings helps buyers specify products suitable for local climate and installation conditions, reducing failure risks. -

Tolerance and Length Customization

Tolerance refers to allowable deviations in LED spacing and electrical parameters. Tight tolerance ensures uniform light distribution and consistent performance, essential for architectural or display lighting. Additionally, the ability to customize strip lengths or cut points facilitates seamless integration into varied designs, which is highly valued in bespoke projects. -

Voltage and Current Specifications

LED backlight strips typically operate at 12V or 24V DC, with current ratings impacting power supply choice and heat generation. Accurate voltage and current specifications ensure compatibility with drivers and prevent premature failure. Buyers should verify these specs to align with their existing infrastructure or planned installations.

Common Trade Terminology in LED Backlight Strip Procurement

Navigating the LED backlight strip market requires familiarity with industry jargon that impacts pricing, delivery, and contractual terms. Below are essential trade terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that other companies rebrand and sell. Choosing OEM suppliers can offer customization advantages and potentially lower costs but requires due diligence to ensure quality standards. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in a single order. MOQs affect inventory management and upfront investment. Buyers from emerging markets or smaller businesses should negotiate MOQs carefully to balance cost savings with stock risks. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specified products. A well-prepared RFQ accelerates supplier evaluation and helps secure competitive offers, particularly important when sourcing across continents. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms ensures clarity on who bears costs and risks during shipment, critical for managing import logistics in regions like Africa and South America. -

Bin Number / Binning

A classification system for LEDs based on brightness, color, and voltage consistency. Suppliers provide bin numbers to assure buyers of uniform quality. High bin consistency is vital for applications demanding color uniformity, such as retail displays or signage. -

Lead Time

The period from order placement to delivery. Lead times vary by supplier location, production capacity, and shipping method. Accurate lead time estimation is crucial for project planning and avoiding costly delays in markets with complex customs processes.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring procurement of LED backlight strips that deliver performance, compliance, and cost efficiency tailored to their regional market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led backlight strip Sector

Market Overview & Key Trends

The global LED backlight strip market is experiencing dynamic growth driven by increasing demand across diverse industries such as consumer electronics, automotive, advertising, and architectural lighting. For international B2B buyers, particularly in emerging and mature markets like Africa, South America (e.g., Colombia, Brazil), the Middle East, and Europe, understanding these market dynamics is crucial for strategic sourcing and procurement decisions.

Key Market Drivers:

– Energy Efficiency and Cost Reduction: LED backlight strips offer significant energy savings compared to traditional lighting solutions, aligning with global trends toward energy conservation and operational cost reduction. This is particularly relevant for industrial and commercial buyers aiming to lower electricity consumption.

– Technological Advancements: Innovations such as higher lumen efficiency, improved thermal management, and enhanced color rendering have expanded the applicability of LED backlight strips. Smart and tunable LED strips that integrate with IoT systems are gaining traction, especially in technologically advanced markets in Europe and the Middle East.

– Customization and Flexibility: The demand for customizable LED backlight strips — in terms of length, brightness, color temperature, and waterproofing — is rising. This trend supports diverse applications from retail display lighting in South America to automotive dashboard lighting in Africa.

– Supply Chain Localization and Risk Mitigation: Given recent global supply chain disruptions, buyers are increasingly seeking suppliers closer to their regions or with transparent, resilient supply chains to reduce lead times and logistical risks. For instance, Middle Eastern buyers prefer suppliers with certifications aligned to local standards (e.g., CE, RoHS), while South American buyers prioritize cost-effective bulk sourcing with reliable shipping solutions.

Emerging Sourcing Trends:

– Direct Manufacturer Partnerships: B2B buyers are moving towards direct engagement with manufacturers to negotiate better pricing and product customization, especially for large-scale projects.

– Digital Procurement Platforms: Online marketplaces and procurement platforms specializing in LED components enable buyers from remote regions to access wider supplier networks and compare technical specifications efficiently.

– Focus on Quality and Certification: International buyers are emphasizing compliance with global and regional certifications to ensure product safety, performance, and import clearance — a critical factor for African and European markets.

By understanding these evolving market trends and aligning procurement strategies accordingly, international buyers can secure competitive pricing, high-quality products, and reliable supply chains.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a decisive factor in the procurement of LED backlight strips, reflecting growing environmental awareness and regulatory pressures worldwide. For B2B buyers across Africa, South America, the Middle East, and Europe, integrating sustainability into sourcing decisions not only enhances corporate social responsibility but also mitigates risks associated with environmental compliance and brand reputation.

Environmental Impact Considerations:

LED backlight strips inherently consume less energy and have longer lifespans compared to traditional lighting, which reduces greenhouse gas emissions and electronic waste. However, the manufacturing process involves materials like rare earth elements and semiconductors that require responsible extraction and recycling practices.

Ethical Supply Chain Importance:

B2B buyers should prioritize suppliers who demonstrate transparency in their sourcing of raw materials, labor practices, and environmental management systems. Ethical sourcing helps prevent exposure to supply chain risks such as forced labor allegations or environmental violations, which can disrupt operations and damage reputations.

Green Certifications & Standards:

– RoHS (Restriction of Hazardous Substances): Ensures that LED strips are free from harmful materials like lead and mercury, critical for European and Middle Eastern markets.

– Energy Star & DLC (DesignLights Consortium): Certifications that validate energy efficiency and performance, increasingly demanded in commercial procurement.

– ISO 14001 Environmental Management: Indicates supplier commitment to minimizing environmental impact through systematic practices.

– REACH Compliance: Important for European buyers to ensure chemical safety in components.

Sustainable Materials & Design:

Buyers should seek LED backlight strips that use recyclable or biodegradable packaging and components designed for easy disassembly and recycling at end-of-life. Additionally, suppliers adopting low-impact manufacturing processes and renewable energy sources provide added sustainability value.

Incorporating sustainability criteria into supplier evaluation and contract terms can help businesses align with international environmental goals and meet the growing expectations of end clients and regulatory bodies.

Evolution of LED Backlight Strips in B2B Context

The LED backlight strip sector has evolved significantly over the past two decades, transitioning from niche applications to a mainstream lighting solution integral to many industries. Initially developed to replace fluorescent backlighting in LCD displays, LED backlight strips have expanded their footprint across signage, automotive interiors, architectural lighting, and consumer electronics.

Early LED strips were limited by low brightness and rigid designs, restricting their use to simple accent lighting. Advances in semiconductor technology, flexible circuit materials, and thermal management have enabled the production of highly efficient, durable, and customizable strips that meet complex industrial requirements.

For B2B buyers, this evolution means access to a broader range of products tailored to specific applications, supported by improved warranties and supplier capabilities. The shift towards smart, controllable LED backlight strips also opens new opportunities for integration with building management systems and IoT platforms, enhancing value through energy savings and user experience.

Understanding this historical context helps buyers appreciate the current product landscape and anticipate future innovations that could impact procurement strategies in their respective markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led backlight strip

-

How can I effectively vet LED backlight strip suppliers from different regions like Asia or Europe?

To ensure supplier reliability, conduct thorough due diligence including checking business licenses, factory audits, and customer reviews. Request detailed product specifications and certifications such as CE, RoHS, or CB relevant to your target markets (Europe, Middle East). Verify sample quality before bulk orders. Engage in direct communication to assess responsiveness and flexibility. Using third-party inspection services or sourcing platforms with verified supplier ratings can reduce risks. For buyers in Africa or South America, confirm supplier experience with international shipping and compliance with local import regulations. -

Are customization options like specific lengths, colors, or IP ratings commonly available, and how should I approach these requests?

Most reputable LED backlight strip manufacturers offer customization to meet project-specific needs, including tailored lengths, color temperatures, waterproof ratings (IP65, IP67), and packaging. Clearly communicate your technical requirements upfront and request prototype samples to validate custom specs. Factor in longer lead times and potentially higher MOQ for customized orders. Confirm that customization does not compromise product certifications or warranty. Collaborate closely with suppliers to align on design feasibility and cost implications, especially for large-scale or region-specific projects. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders?

MOQs vary widely but commonly range from 500 to 1,000 meters per SKU for LED backlight strips. Lead times typically span 3 to 6 weeks, depending on customization and order volume. For first-time buyers, suppliers may request 30%-50% upfront payment via secure methods like T/T or letter of credit, with balance paid upon shipment or delivery. Negotiate payment terms based on order history and volume; established buyers may secure more favorable terms. Account for additional time for customs clearance and inland logistics in your overall project timeline. -

Which quality assurance certifications should I verify to ensure compliance and safety in my region?

Key certifications include CE and RoHS for European markets, UL or DLC for North America, and CCC for Chinese products entering Asian markets. For the Middle East, look for SASO or G-Mark compliance. Certifications confirm electrical safety, hazardous substance limits, and electromagnetic compatibility. Request official test reports and verify their authenticity through issuing bodies. Ensure that product markings match certification claims. Proper certifications not only facilitate customs clearance but also reduce liability risks and enhance buyer confidence. -

How can I optimize logistics and shipping for bulk LED backlight strip orders to regions like Africa or South America?

Choose suppliers with experience in your target region and access to reliable freight forwarders familiar with local customs procedures. Consolidate shipments to reduce per-unit freight costs and consider sea freight for large volumes to balance cost and delivery time. Ensure packaging is robust to prevent damage during long transit. Plan shipments well in advance to accommodate customs clearance delays common in some African and South American ports. Utilize Incoterms like FOB or CIF to clarify responsibility and risk. Track shipments closely and maintain transparent communication with suppliers and logistics partners. -

What steps should I take if the LED backlight strips received do not meet quality or specification requirements?

Immediately document discrepancies with photos and detailed descriptions. Contact your supplier promptly to report issues and request corrective actions such as replacement, repair, or refund. Review your purchase agreement for warranty terms and dispute resolution clauses. Utilize third-party inspection reports if available to support your claim. Maintain professional communication to preserve supplier relationships while asserting your rights. If disputes escalate, consider involving trade mediation services or leveraging payment methods that offer buyer protection. -

How do regional electrical standards affect LED backlight strip procurement for international markets?

Electrical standards vary by region—for example, voltage ratings, wiring color codes, and plug types differ between Europe, the Middle East, and South America. Ensure that LED strips and their drivers are compatible with the local electrical infrastructure and safety codes. Suppliers should provide products tested for appropriate voltage (e.g., 220-240V for Europe, 110-127V for some South American countries) and frequency. Compliance reduces installation risks and warranty claims. When in doubt, consult local electrical engineers or certification bodies before finalizing orders. -

What are best practices for managing currency fluctuations and payment risks in international LED backlight strip procurement?

To mitigate currency risks, consider negotiating contracts and payments in stable currencies like USD or EUR. Use forward contracts or hedging instruments if possible. Opt for payment methods that balance security and cost, such as letters of credit or escrow services, especially for new suppliers. Establish clear payment schedules aligned with delivery milestones. Maintain open communication with suppliers to manage expectations during market volatility. Regularly monitor exchange rates and factor potential fluctuations into pricing and budgeting to avoid unexpected cost overruns.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led backlight strip

The procurement of LED backlight strips presents a unique opportunity for international B2B buyers to enhance energy efficiency, reduce operational costs, and meet evolving regulatory standards across diverse markets. Strategic sourcing in this sector demands a comprehensive evaluation of supplier capabilities, product certifications, and customization options to ensure compatibility with local requirements and long-term reliability. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate consistent quality control, scalable production capacity, and transparent logistics to mitigate risks associated with global supply chains.

Key takeaways for successful sourcing include:

– Thorough supplier vetting to verify compliance with international standards such as CE, RoHS, and region-specific certifications.

– Demanding product customization to accommodate specific application needs and branding preferences, especially for large-scale or specialized projects.

– Leveraging bulk purchasing to capitalize on cost efficiencies and maintain uniformity across installations.

Looking ahead, the LED backlight strip market is poised for continued innovation with smart lighting integration and enhanced durability features becoming standard. International buyers are encouraged to build resilient partnerships with forward-thinking manufacturers who invest in R&D and sustainable practices. By adopting a strategic, informed approach, businesses can secure competitive advantages, future-proof their lighting solutions, and contribute meaningfully to global sustainability goals.